Modular flexible torsion joint based on air bag inflation and deflation actuation

A modular, inflatable and deflated technology, applied in the field of flexible robots, which can solve the problems of mechanism pollution, high cost of micro servo control motors, and inability to resist vibration phenomenon well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

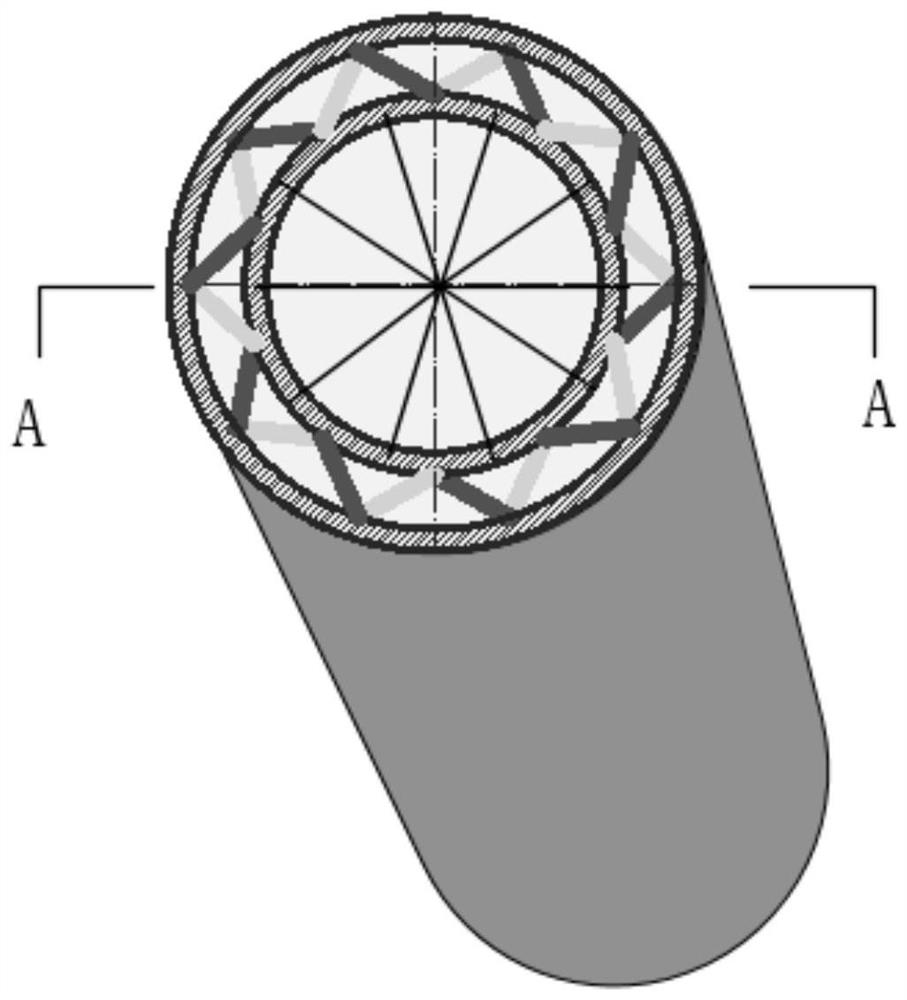

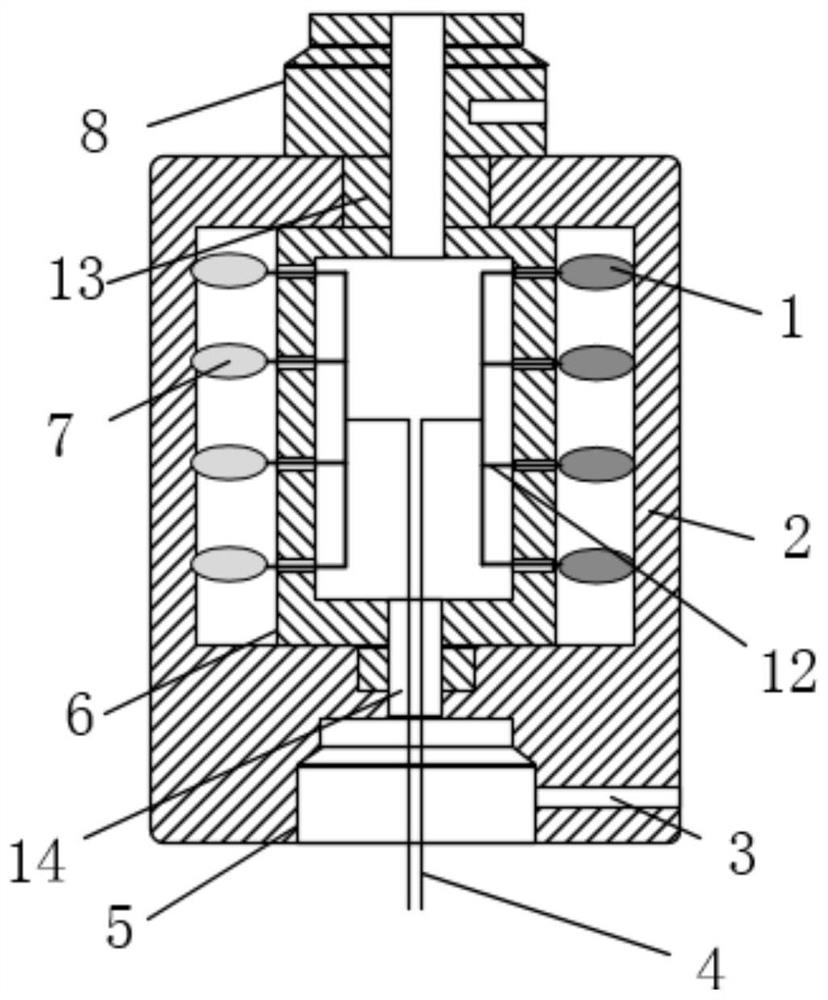

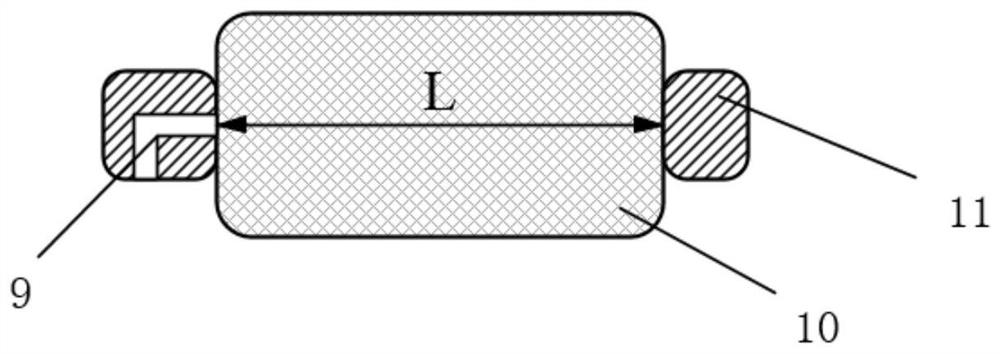

[0033] Such as Figure 1-Figure 6 As shown, the modular flexible torsion joint based on air bag inflation and deflation actuation includes several groups of reversely distributed air bag groups, a torsion joint shell 2, several groups of forwardly distributed air bag groups, a torsion joint inner shell 6 and a built-in air circuit 4 , the torsional joint outer shell 2 and the torsional joint inner shell 6 are cylindrical structures, the torsional joint outer shell 2 and the torsional joint inner shell 6 are coaxially installed, and the torsional joint outer shell 2 and the torsional joint inner shell 6 Relative rotation setting;

[0034] Between the torsion joint shell 2 and the torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com