H-shaped vertical axis wind turbine blade static force structure test device and method

A wind turbine blade and static test technology, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., can solve problems such as complex force conditions on blades and difficult analysis of blade structural performance, and achieve strong Adaptability, accurate and reliable results, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

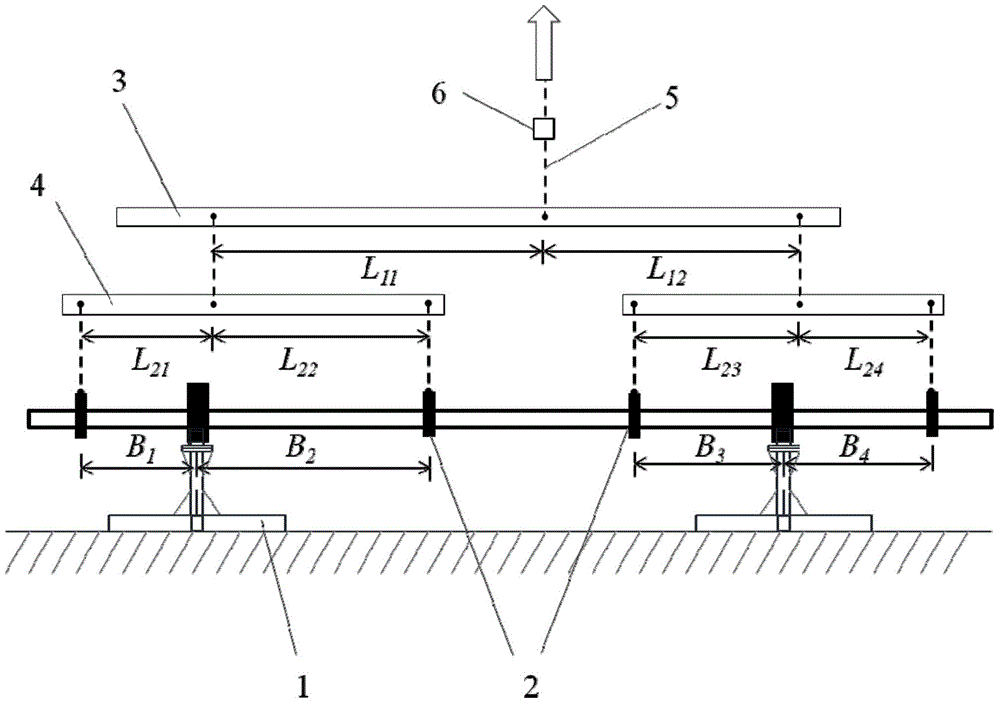

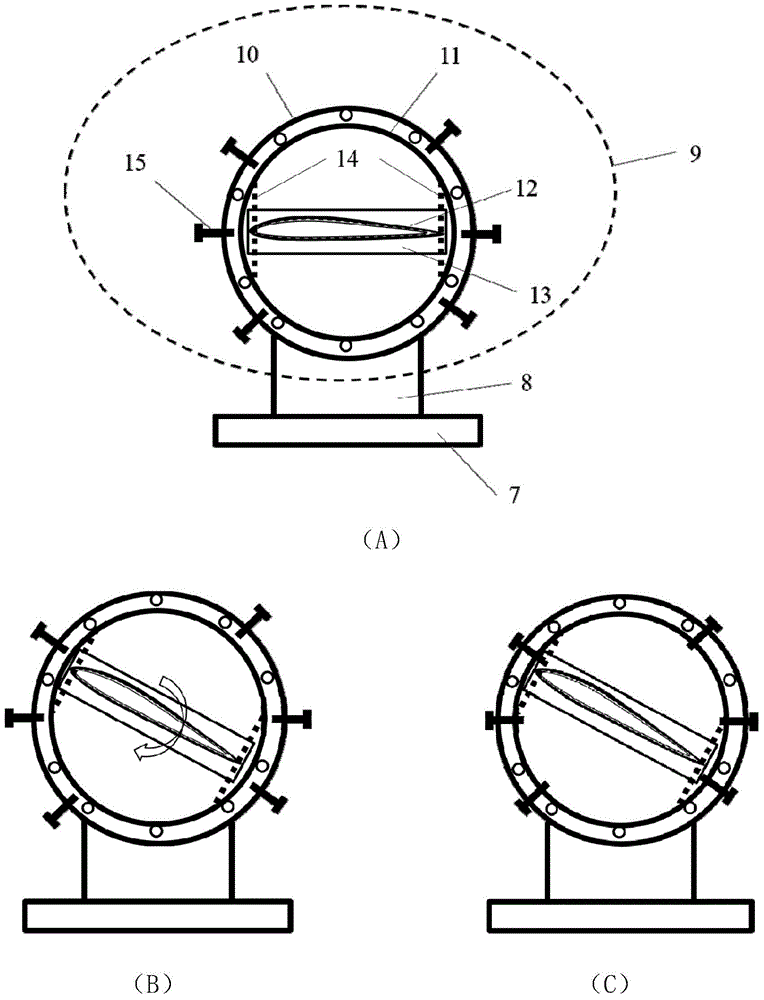

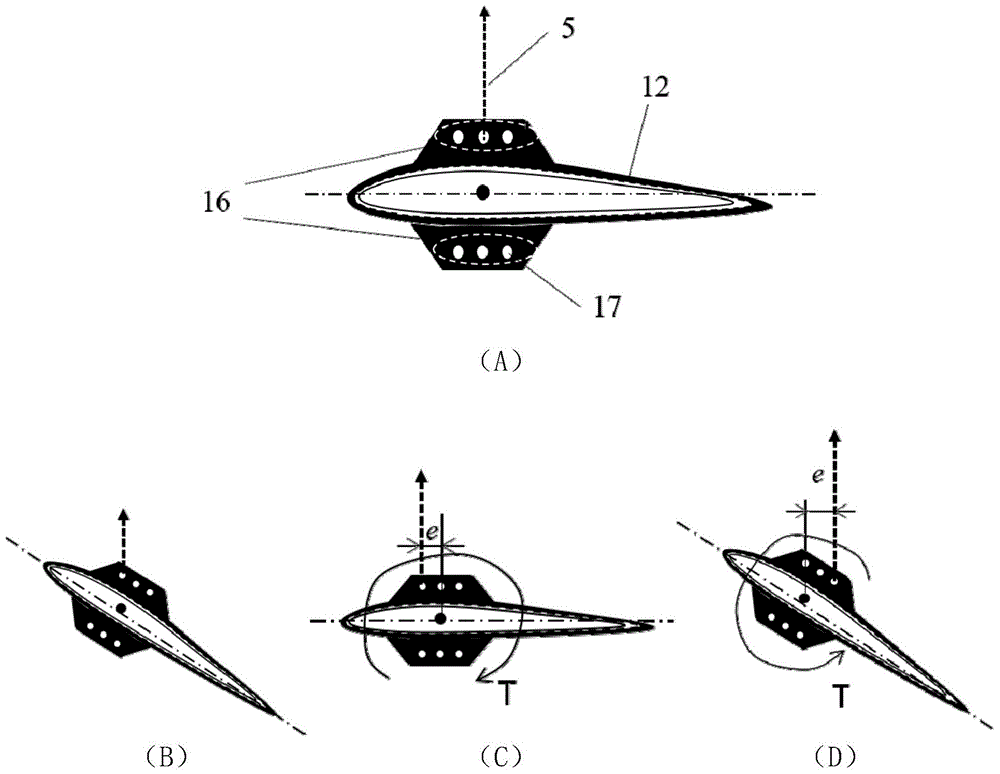

[0023] Taking double-supported blades as an example, such as figure 1 As shown, the H-type vertical axis wind turbine blade structure static test device of the present invention includes a bearing part 1, a loading hoop 2, a primary distribution beam 3, two secondary distribution beams 4, a connecting part 5 (preferably For suspension rope or hinge), force sensor 6, displacement sensor and strain gauge. According to the bending moment distribution required to load the blade, determine the position of the support part 1, the position of the loading hoop 2 and the lengths of the first-level distribution beam 3 and the second-level distribution beam 4, specifically including: the connection between the loading hoop 2 and the support part 1 distance B 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com