Air filtering device for machining workshop

An air filtration device and machining technology, applied in the field of machining, can solve the problems of convulsions, coma, damage to the liver, kidneys, brain and nervous system, memory loss, etc., and achieve the effects of reasonable and simple structure, low production cost and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

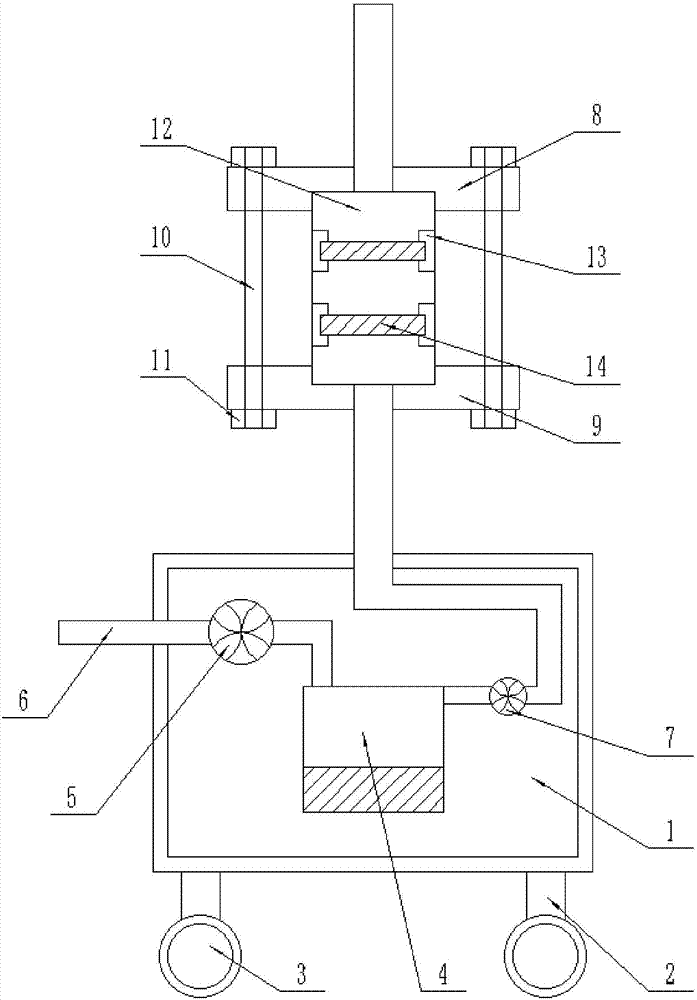

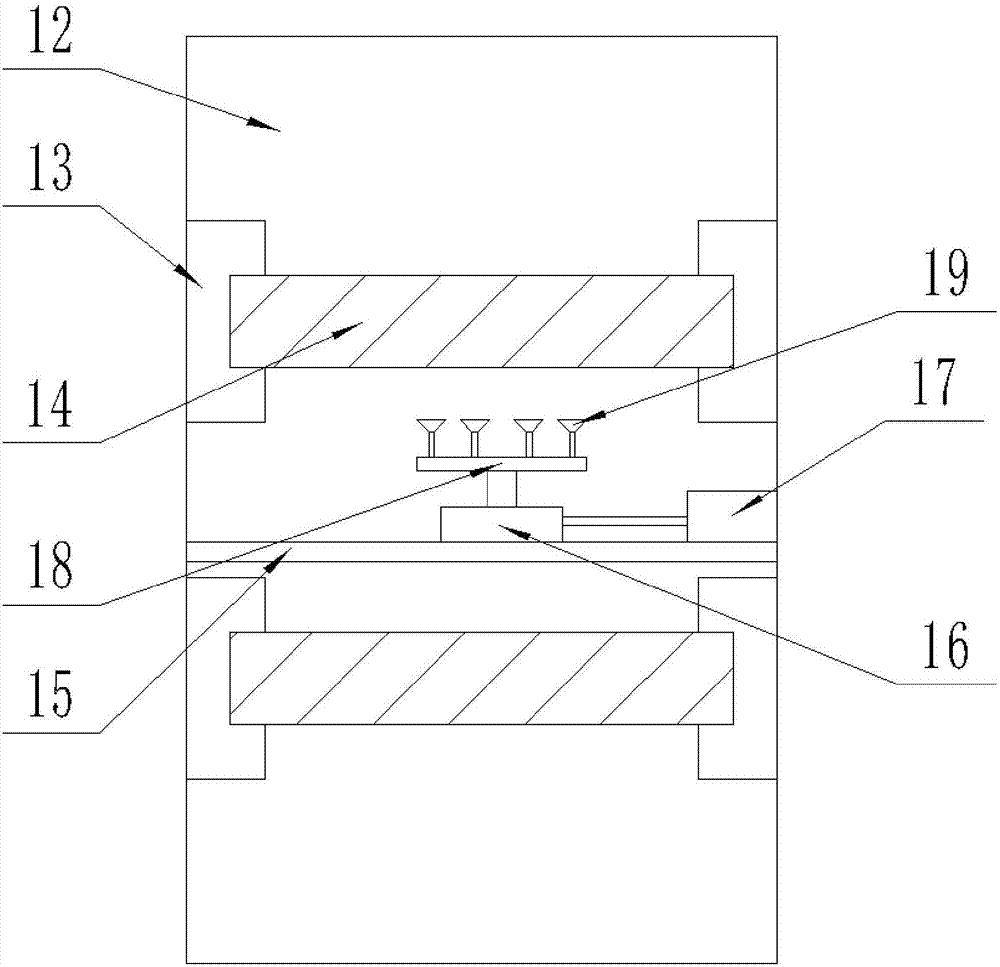

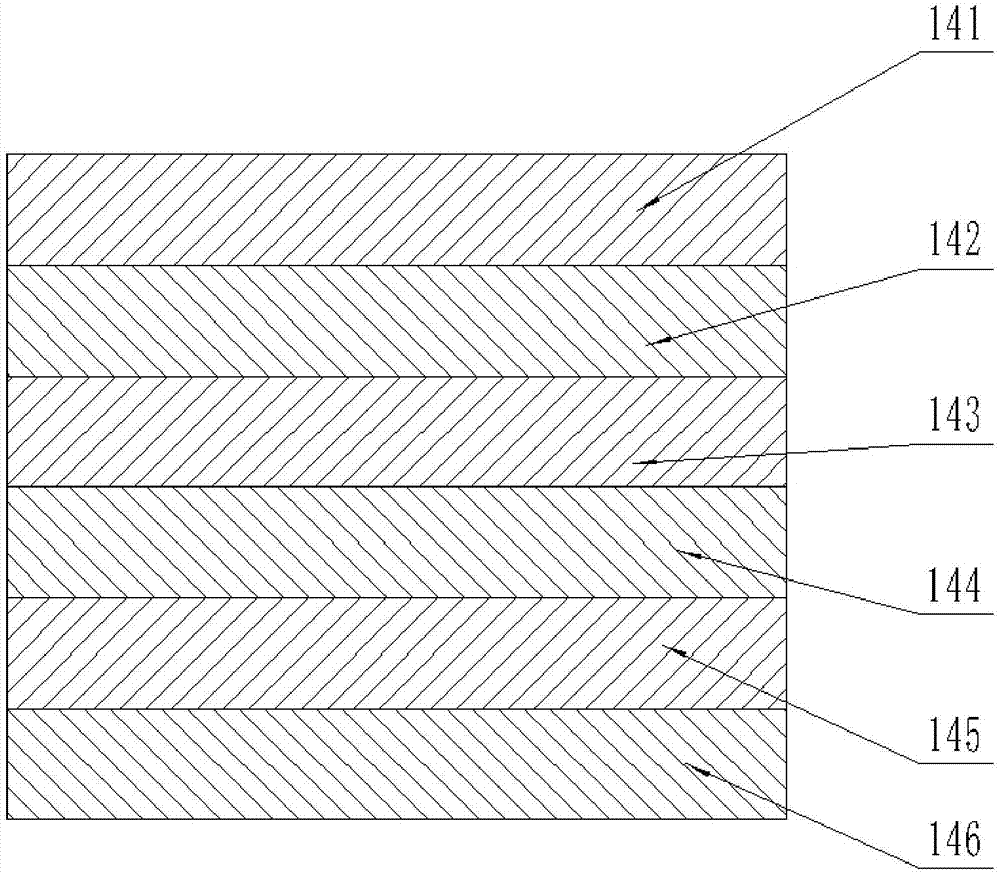

[0017] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: an air filter device for a machining workshop, including an adsorption chamber 1, a column 2, a universal wheel 3, a clean water chamber 4, a first exhaust fan 5, an air duct 6, a second Two exhaust fans 7, upper support 8, lower support 9, bolt 10, nut 11, filter chamber 12, deck 13 and filter core 14; The lower surface of described adsorption chamber 1 is fixedly connected with several columns 2; The column 2 A universal wheel 3 is connected to the end of each; the chamber of the adsorption chamber 1 is provided with a clean water chamber 4, a first exhaust fan 5 and a second exhaust fan 7; the first exhaust fan 5 passes through the air duct 6 It is connected with the clean water chamber 4, the second exhaust fan 7 and the filter chamber 12 in sequence; an upper bracket 8 is fixedly connected to the top of the filter chamber 12; a lower support 8 is fixedly connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com