Ceramic tile cement slurry laying machine with stirring device

A mixing device and cement technology, which is applied in the direction of cement mixing device, unloading device, clay preparation device, etc., can solve the problems of high construction technology requirements, affecting the construction progress, hollowing, etc., and achieve easy disassembly of the mixing device, convenient flow, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

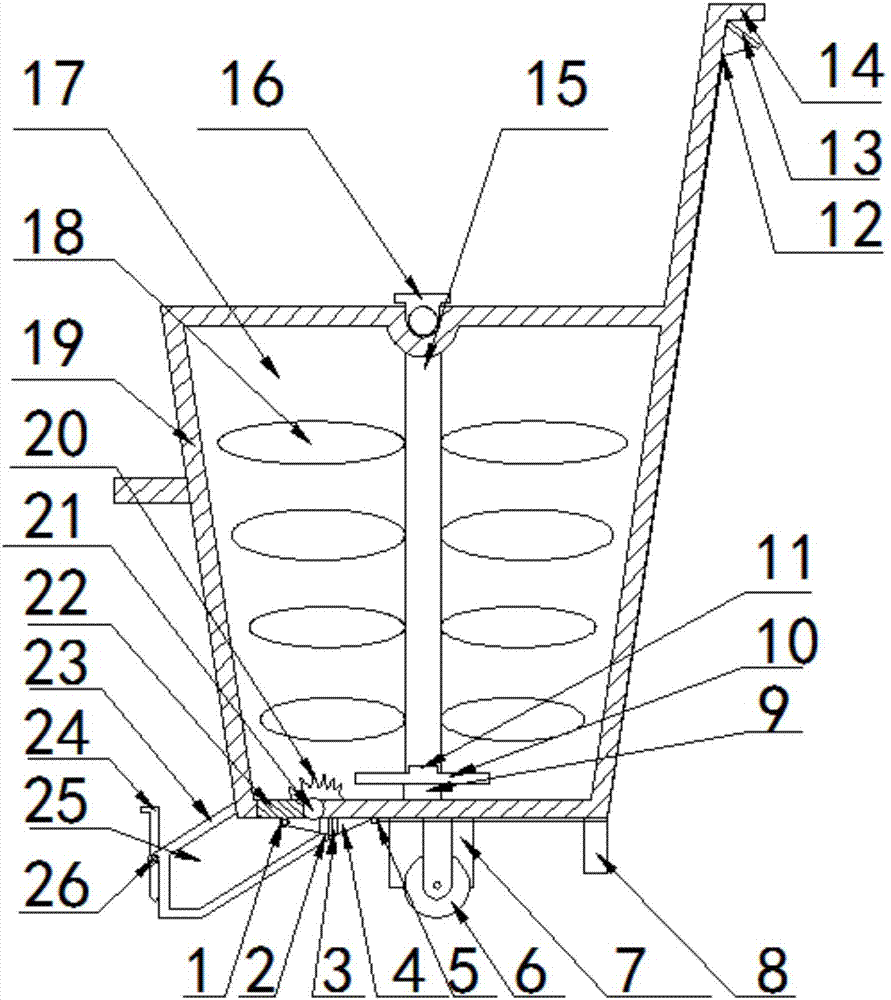

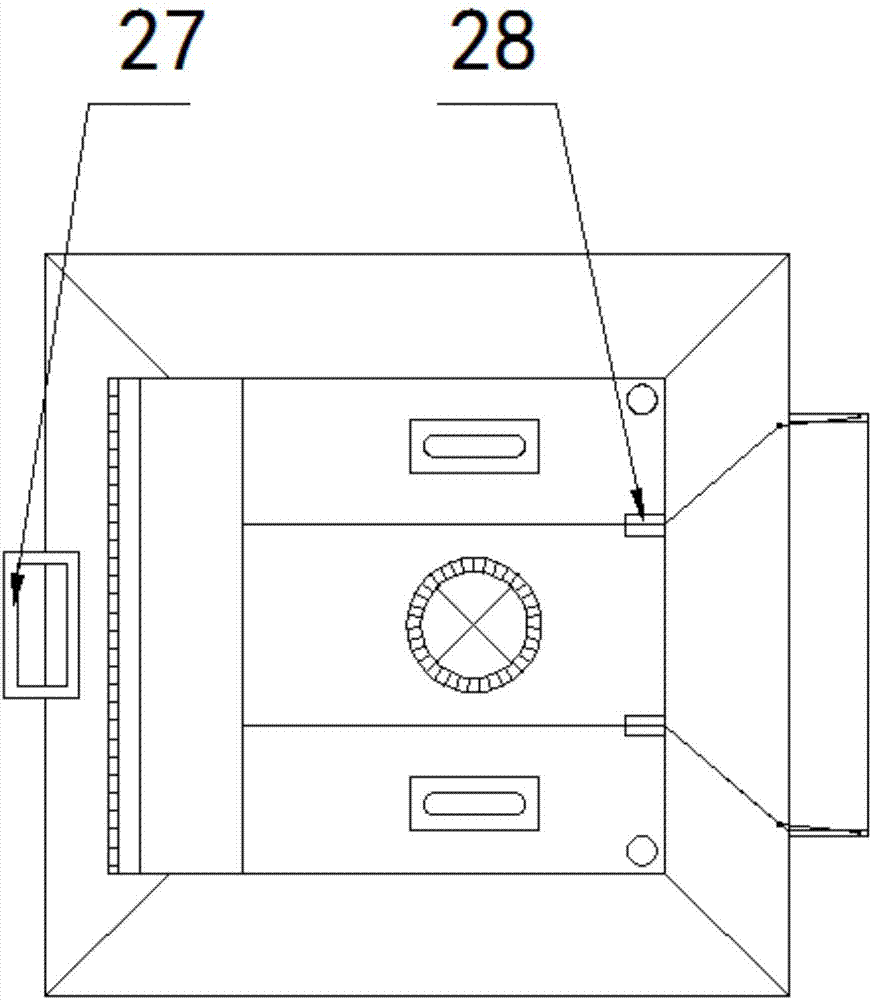

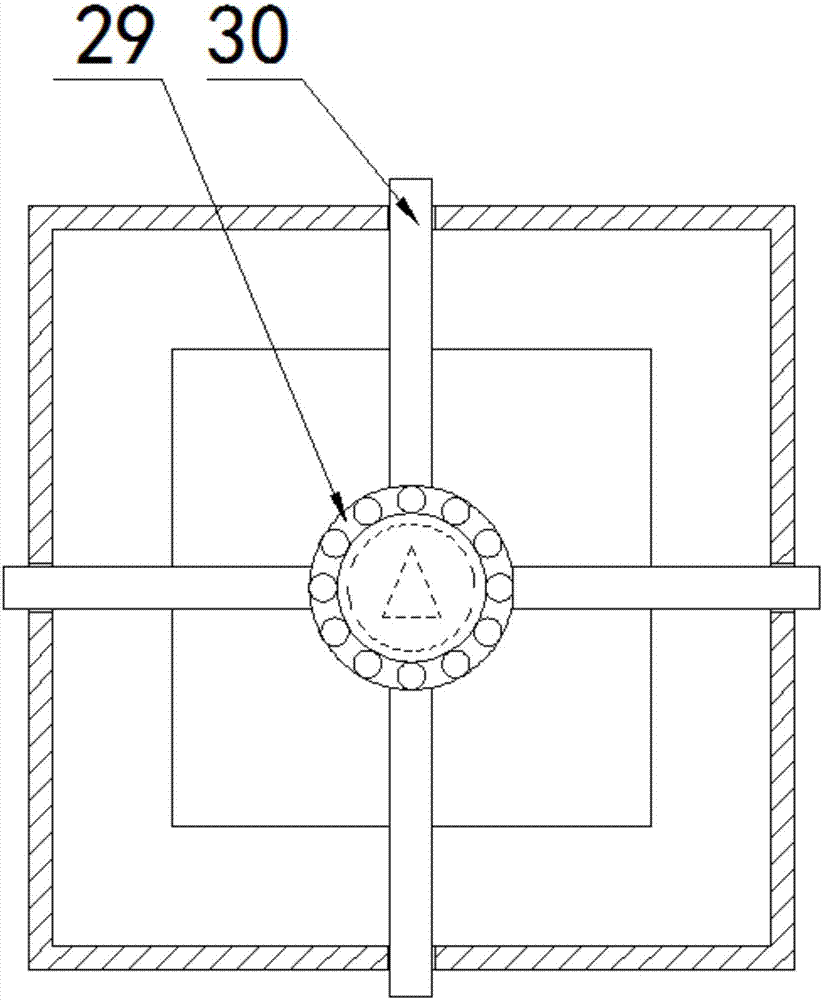

[0018] see Figure 1-3 , a tile cement grouting machine with a stirring device, including a housing 19, a traction device 4, a detachable stirring device 17, a cement scraping device 25, a spring movable door 22, a hand push rod 14 and a first pulley 6; The detachable stirring device 17 is arranged inside the casing 19 for stirring cement and reducing labor intensity; the bottom of the detachable stirring device 17 is fixed with the triangular fixing bump 11 on the top of the turntable 10 for fixing the detachable The stirring device 17 drives the rotation of the detachable stirring device 17 by the rotation of the turntable 10; the detachable stirring device 17 is provided with a rotating shaft 15, a top projection 16, a stirring blade 18, a bearing 29 and a fixed rod 30; the rotating The top of shaft 15 is connected together with fixed rod 30 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com