Machining workshop air supply device

An air supply device and machining technology, applied in the field of mechanical processing plants, can solve problems such as single function and incomplete removal of metal dust, and achieve the effects of avoiding environmental pollution, reducing production costs and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

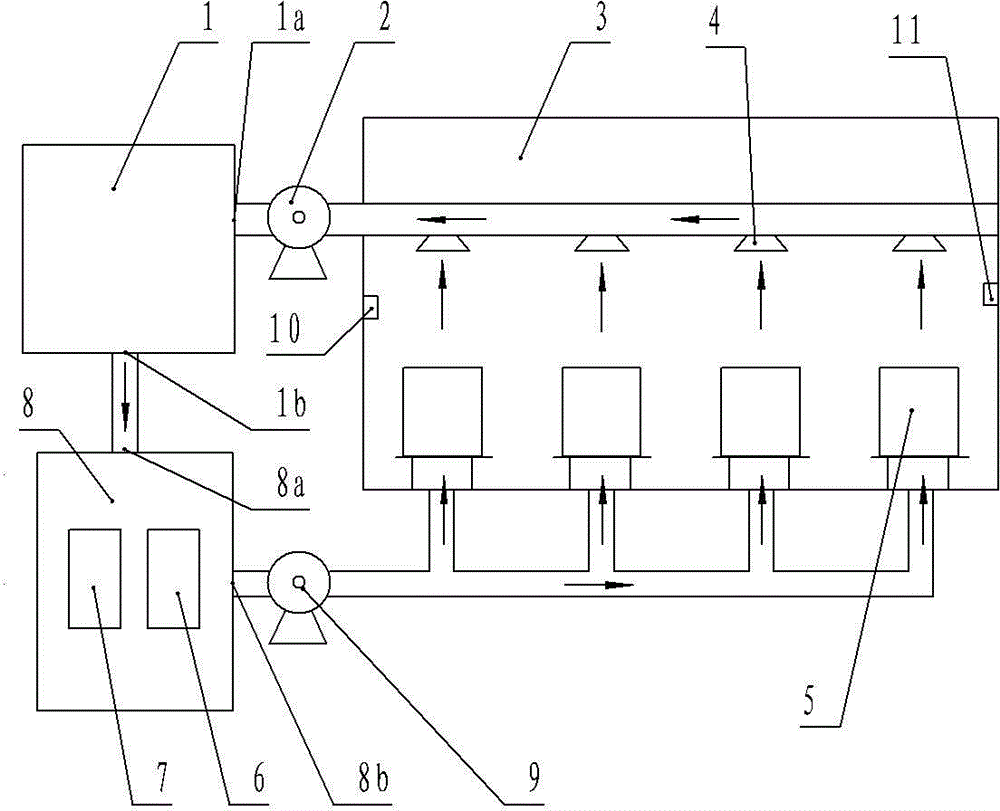

[0013] figure 1 The shown air supply device in the machining workshop includes a plurality of suction heads 4 corresponding to each station 5 arranged on the upper part of the workshop 3, and the suction heads 4 communicate with the air inlet of the first suction fan 2 through a pipeline, The air outlet of the first suction fan 2 is connected with the air inlet 1a of the bag vacuum cleaner 1, the air outlet 1b of the bag vacuum cleaner 1 is connected with the air inlet 8a of the first regulating room 8, and the air outlet 8b of the regulating room 8 is connected with the second suction port. The air inlets of the fan 9 are connected, and the air outlet of the second suction fan 9 corresponds to the air outlet of each station; a temperature sensor 10 and a humidity sensor 11 are respectively arranged in the machining workshop 3, and an air conditioner is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com