Water cooling system of machining workshop

A water cooling and machining technology, which is applied in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of poor cooling effect and waste of water resources, so as to reduce production costs, improve economic benefits, improve The effect on overall utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

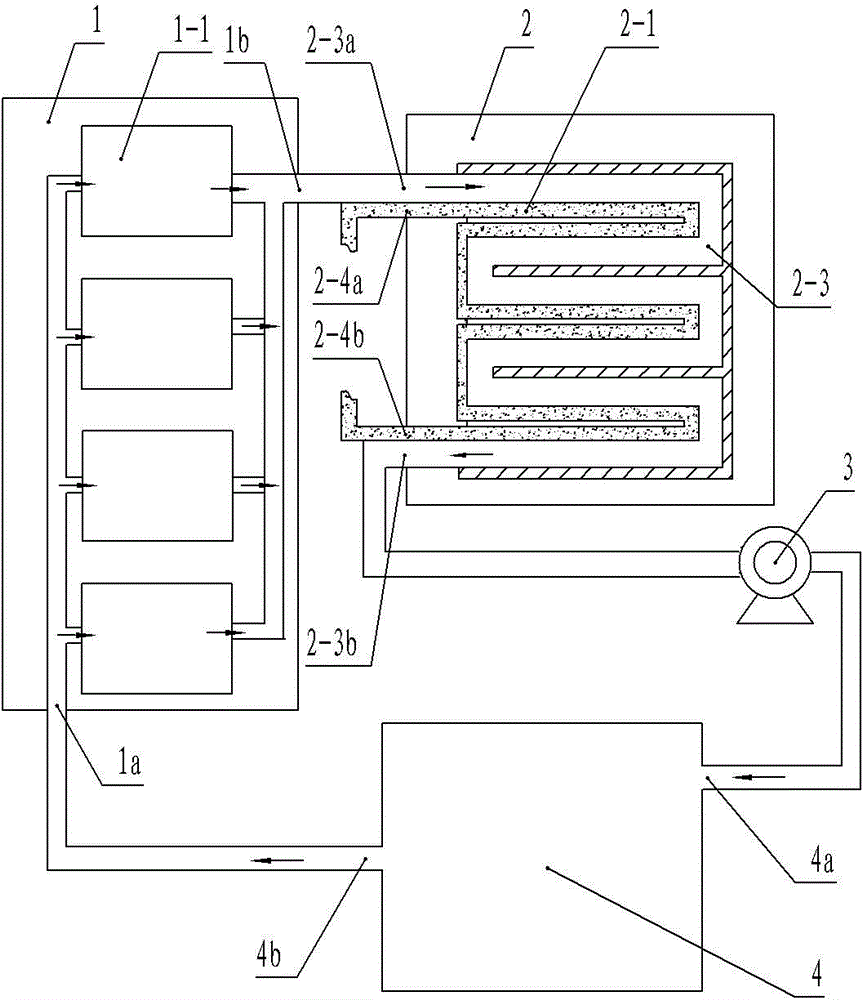

[0013] figure 1 The water cooling system for a machining workshop shown includes a water tank 4 and a circulation pipeline for supplying water to the workshop 1, and a water cooling tank 2 is connected to the pipeline between the water outlet 1b of the workshop 1 and the water return port 4a of the water tank 4. The water cooling box 2 includes a U-shaped passage 2-3 communicated with the circulation pipeline, and a cold medium passage 2-1 is embedded between the U-shaped passages 2-3, and the cold medium passage 2-1 is connected to the cold medium outside the water cooling box 2. The medium conveying pipes are connected, and the cold medium is oil; the water tank 4 has a water inlet 4a and a water outlet 4b, and the workshop 1 has a water inlet 1a and a water outlet 1b, and the water outlet 4b of the water tank 4 is connected with the water inlet 1a of the workshop 1, and the workshop The water outlet 1b of 1 is connected with the water inlet 2-3a of the water cooling tank 2,...

Embodiment 2

[0016] The cooling medium is water; the rest are the same as in Example 1.

Embodiment 3

[0018] The cold medium is gas; the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com