Self-possessed type production monitoring and supervision system facing bearing ring grinding and machining shop

A technology of grinding and bearing rings, which is applied in the field of autonomous production supervision system, can solve the problems of complex encryption of process parameters and machine tool accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

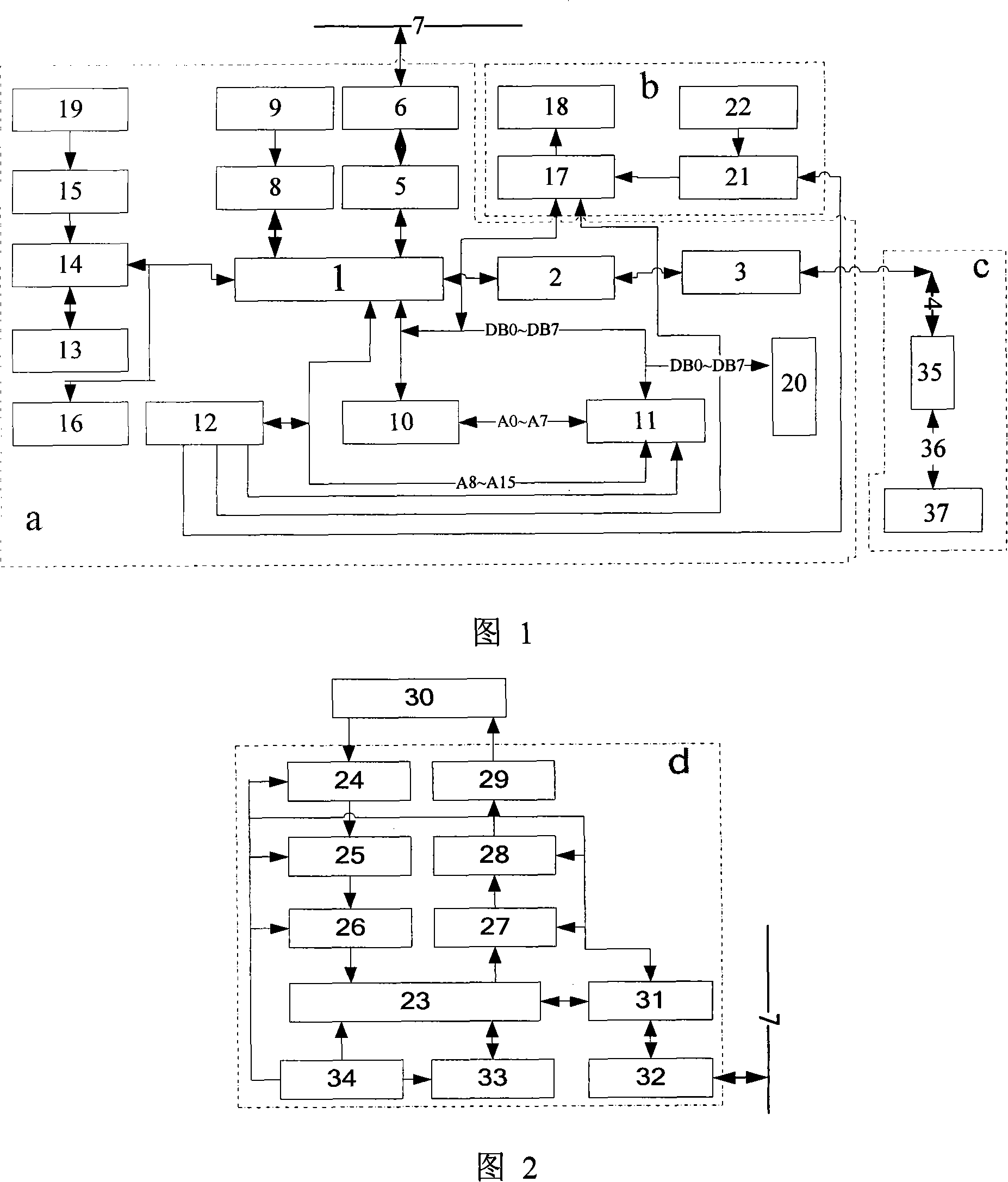

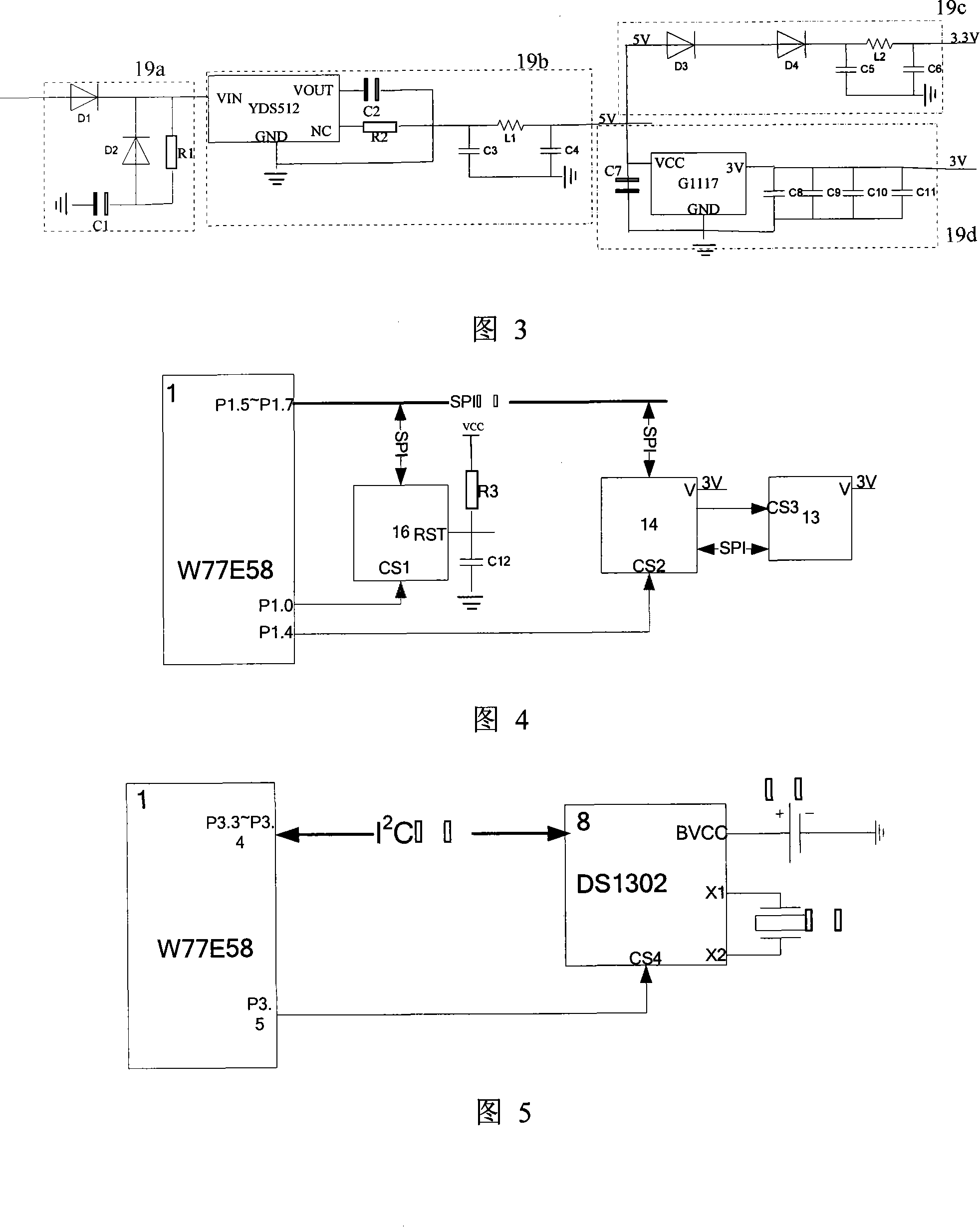

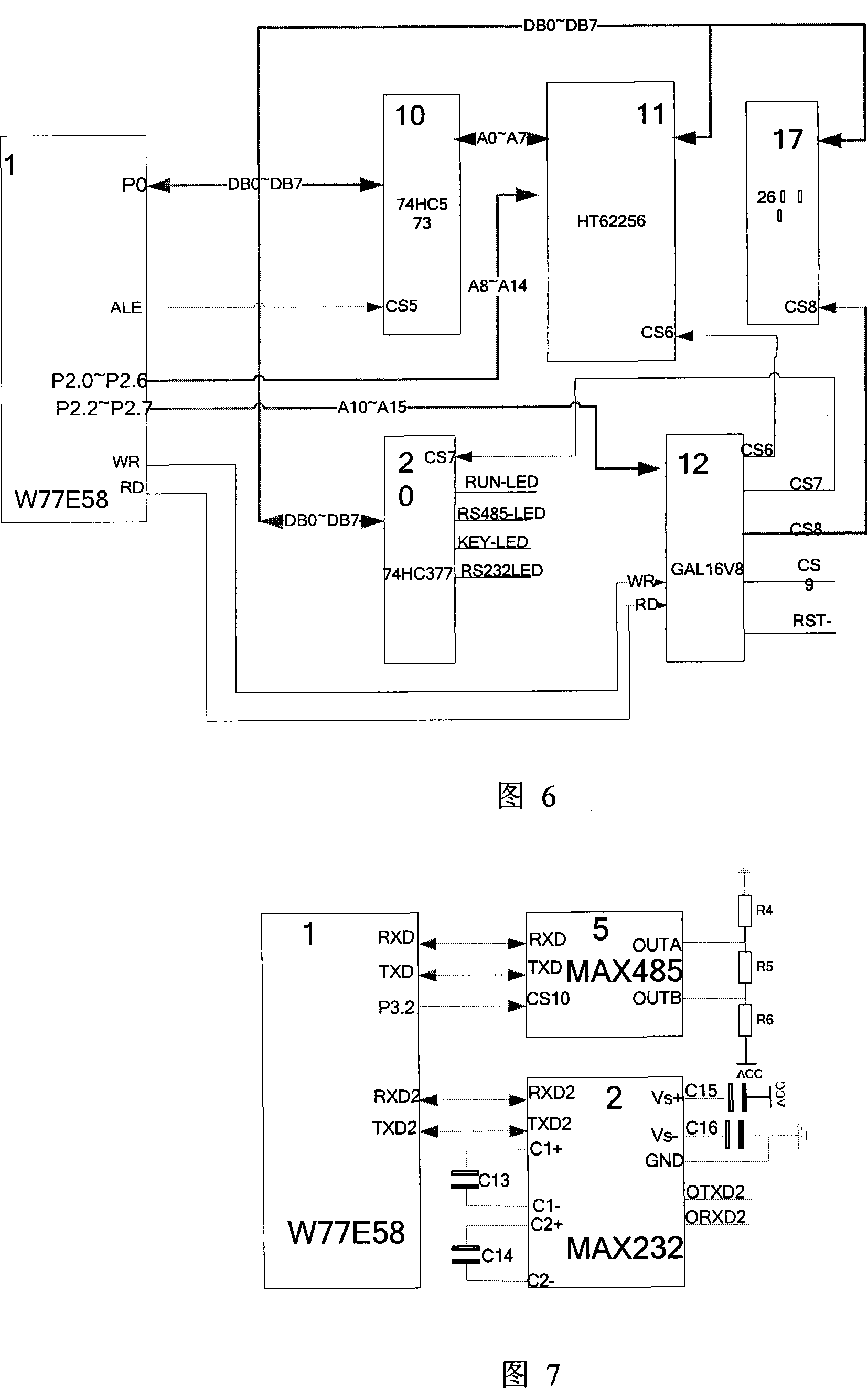

[0026]The present invention includes a machine tool supervision master station module a, a display and keyboard processing module b, an Ethernet protocol converter and an enterprise information server module c, and N machine tool work supervision substation modules d with identical structures, wherein:

[0027] As shown in Figure 1, machine tool supervision master station module a: the first port including the RS232 bus driver chip MAX2322 is connected to the first serial port of the master station data processing single-chip microcomputer W77E581, and its second port is connected to the RS232 bus 4 through the DB9 interface 3; The first port of the RS485 bus driver chip MAX4855 is connected to the second serial port of the data processing MCU W77E581 of the machine tool supervision master station, and its second port is connected to the RS485 bus 7 through the RS485 bus interface 6; the data processing MCU of the machine tool supervision master station is connected through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com