Distributed remote monitoring system and monitoring method for machining workshop

A technology of remote monitoring system and monitoring system, applied in general control system, control/regulation system, program control, etc., can solve the state that cannot be centrally managed, cannot trace the history of workshop equipment, equipment production utilization rate, low degree of visualization, etc. problem, to achieve the effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

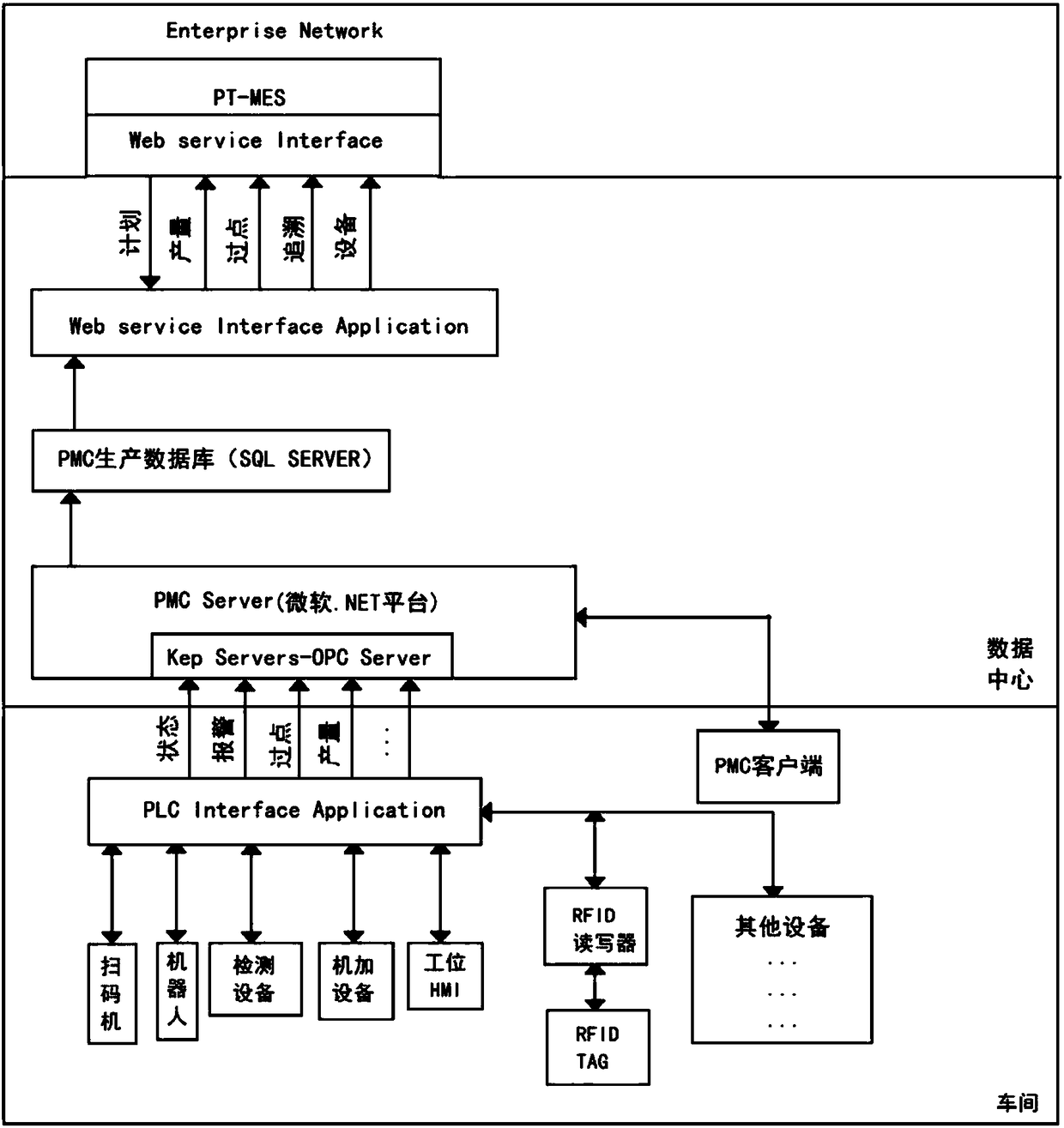

[0058]In order to achieve the purpose of the present invention, in some embodiments of a distributed remote monitoring system and monitoring method for machining workshops,

[0059] A distributed remote monitoring system for machining workshops, the monitoring system is connected and communicated with the equipment to be monitored, which includes:

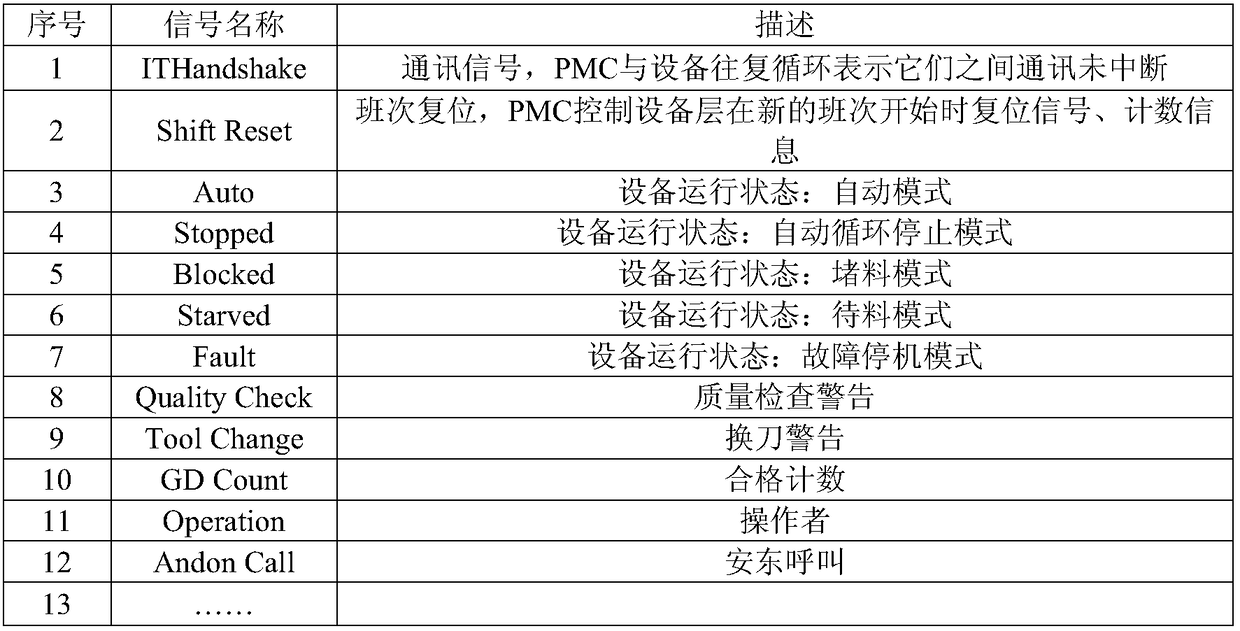

[0060] The real-time monitoring module of operating status is used to monitor the operating status of the equipment, and send the status of the equipment to the monitoring terminal in real time, so that managers can understand the production situation;

[0061] The production data real-time collection module is used to collect the time and frequency of each state change of the equipment, collect the running time composition of the current cycle of the equipment and the completion of the equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com