Energy consumption simulating method orienting machining task of machine shop

A technology of mechanical workshop and simulation method, which is applied in computer simulation and energy consumption field of machinery manufacturing industry to achieve broad application prospects, reduce energy consumption cost, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The method of the invention is used to simulate the energy consumption of three groups of processing tasks in a flexible machine workshop. The three groups of processing tasks are respectively recorded as workpiece A, workpiece B and workpiece C; the batch size of workpiece A is 20 pieces, the batch size of workpiece B is 40 pieces, and the batch size of workpiece C is 30 pieces. There are 7 machine tools in the workshop that can be used to perform the processing tasks, numbered as: Machine Tool 1 (M1), Machine Tool 2 (M2), Machine Tool 3 (M3), Machine Tool 4 (M4), Machine Tool 5 (M5), Machine Tool 6 (M6) and machine tool 7 (M7).

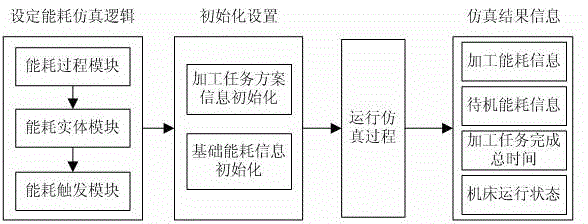

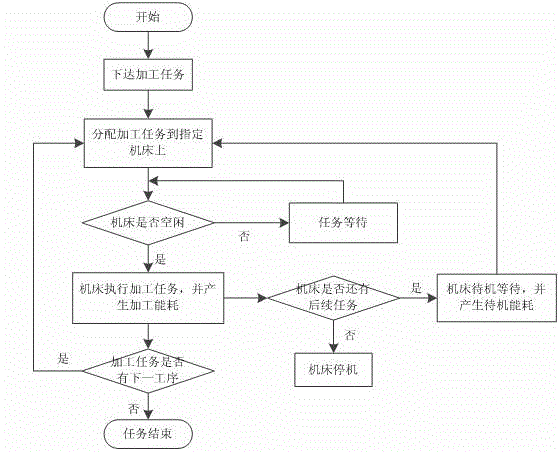

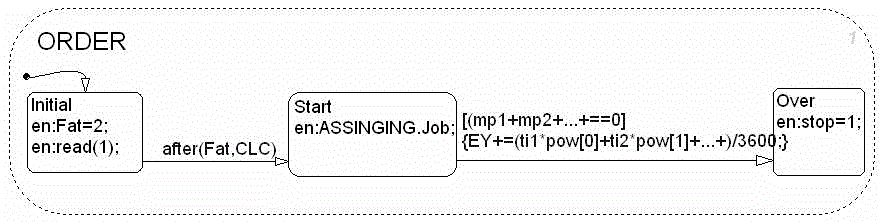

[0067] Referring to the specific implementation steps of the method, at first the simulation logic of the processing task energy consumption process is implemented on the Simulink platform in the Matlab simulation tool, as Image 6 shown.

[0068] Then, initialize and set the processing task plan information in the energy consumption proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com