Flexible armor structure for protecting cable and assembly method

A cable protection and cable structure technology, applied in the direction of electrical components, etc., can solve the problems that the machining workshop is difficult to meet, the structure of the corrugated pipe is complex, and the interface is easy to disengage, etc., to increase safety and reliability, good twistability, and production. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

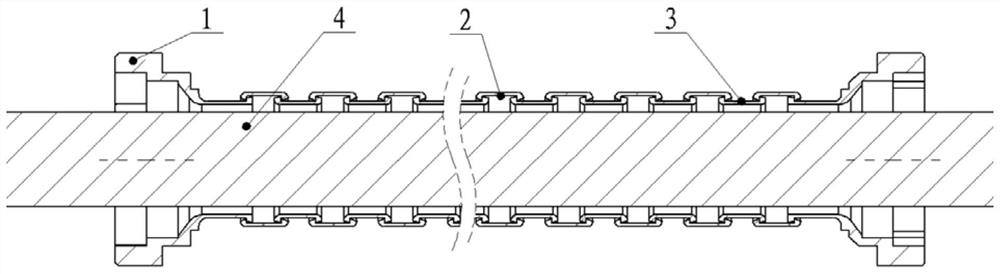

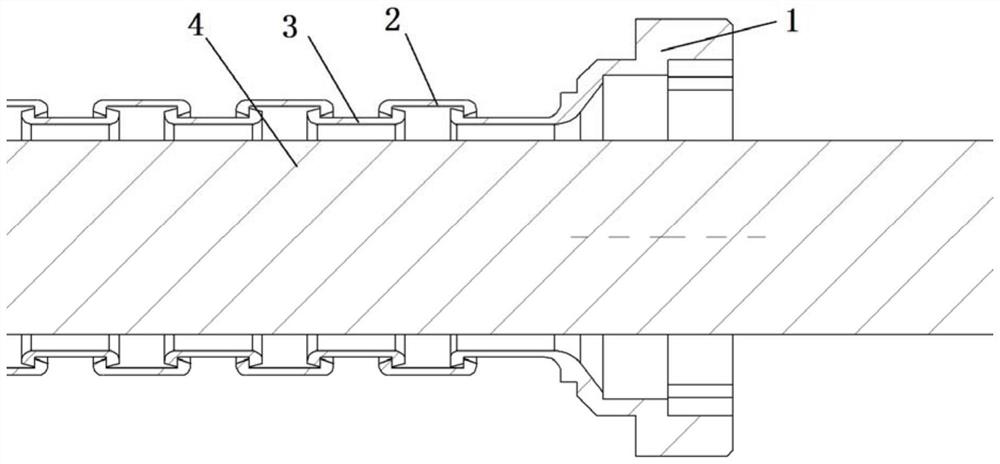

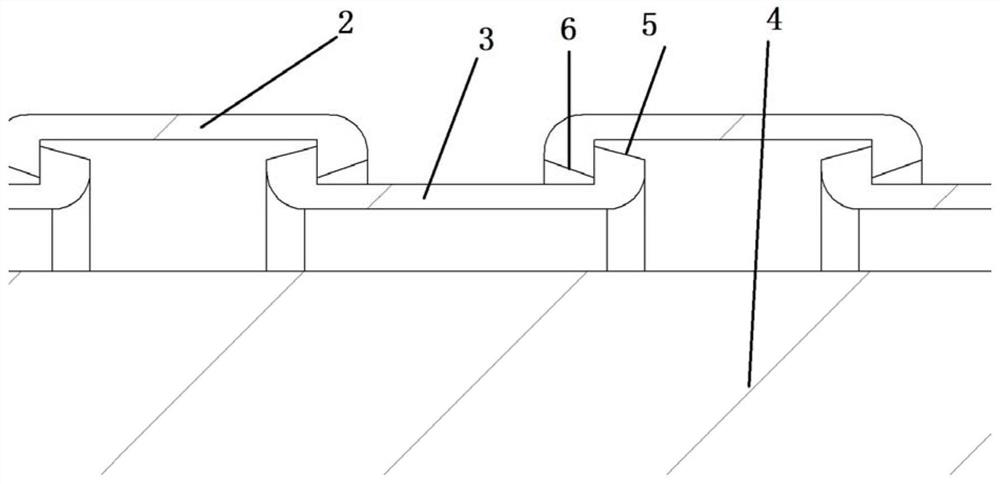

[0023] The present invention will be described in detail below in conjunction with accompanying drawing:

[0024] As shown in the accompanying drawings, this flexible armor structure for cable protection mainly includes a flexible armor interface 1, a flexible armor outer ring 2, a flexible armor inner tube 3, and a cable structural member 4, and the outer casing of the cable structural member 4 is hooked head to tail. The flexible armor inner tube 3 and the flexible armor outer ring 2, and the flexible armor outer ring 2 and the flexible armor inner tube 3 are fastened by hooks A5 and B6 to realize the flexible armor outer ring 2 and the flexible armor inner tube 3 360 degree twist between. The overall bending radius of the multi-section connection is controllable. The flexible armor outer ring 2 and the flexible armor inner tube 3 can adopt different sizes and materials according to requirements. The hooks A5 and B6 are machined with groove angles θ or rounded corners to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com