Scrap iron compression equipment for machining workshop

A compression equipment and machining technology, which is applied in the field of iron filings compression equipment in machining workshops, can solve the problems of large machining allowance, large iron filing volume, inconvenient handling and transportation of iron filings, etc., and achieves low production cost and reasonable structure. Simple, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

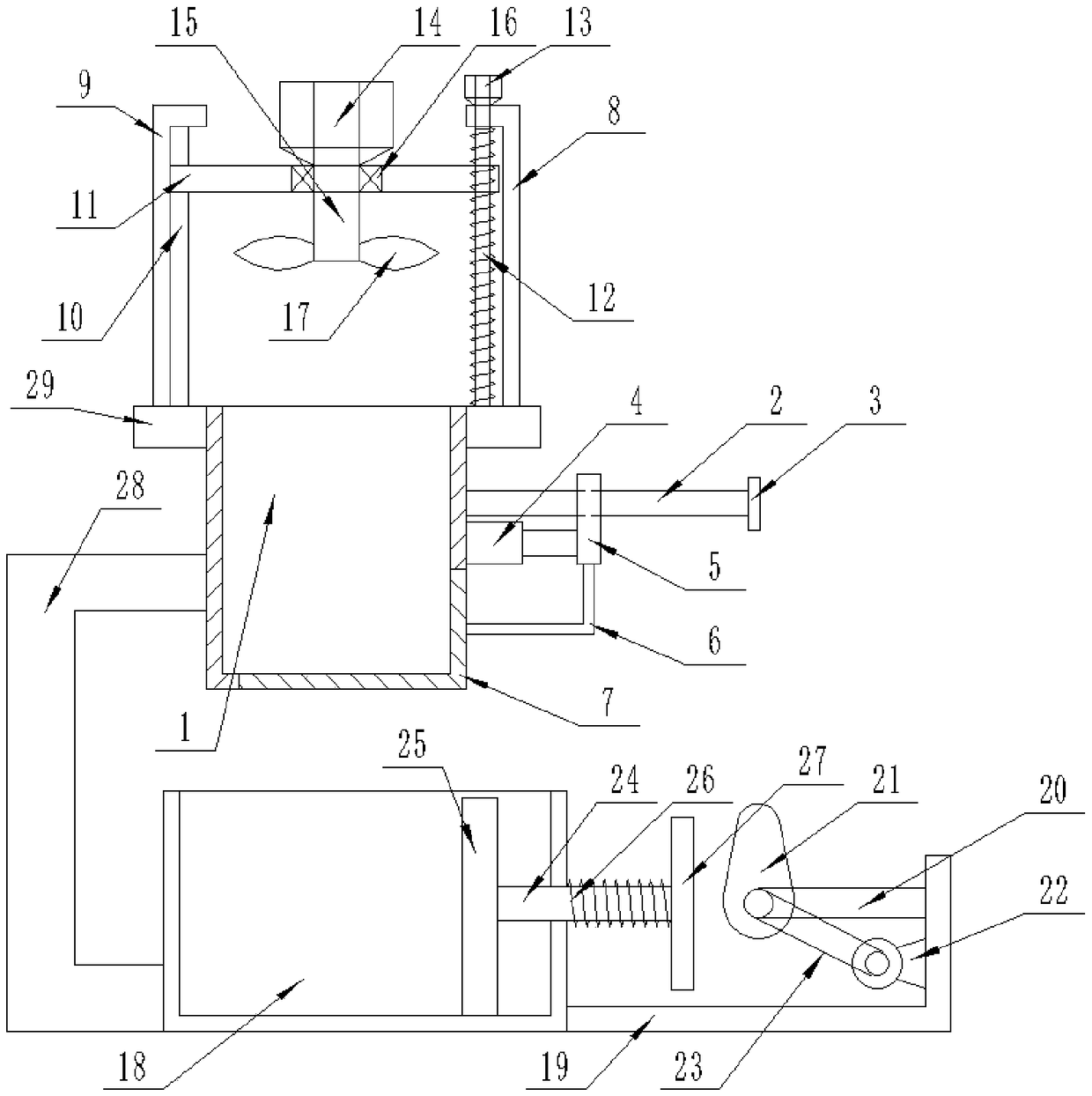

[0012] Such as figure 1 As shown, this specific embodiment adopts the following technical solutions: a kind of iron chip compression equipment for machining workshops, including a crushing chamber 1, a pin shaft 2, a limit block 3, a hydraulic cylinder 4, a shaft sleeve 5, and an L-shaped connecting rod 6 , bottom cover 7, right cover 8, left cover 9, slide rail 10, lifting platform 11, lead screw 12, first motor 13, second motor 14, rotating shaft 15, bearing 16, crushing blade 17, compression chamber 18 , side chamber 19, cam lever 20, cam 21, third motor 22, belt 23, push rod 24, briquetting block 25, spring 26, contact plate 27, concave word connecting rod 28 and platform 29; the right side of the crushing chamber 1 A pin shaft 2 and a hydraulic cylinder 4 are fixedly connected to the middle end of the side, a limit block 3 is fixedly connected to the other end of the pin shaft 2, and a bushing 5 is slidably connected to the pin shaft 2, so The bushing 5 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com