Machining workshop part manufacturing management method

A management method and technology for parts, applied in manufacturing computing systems, database management systems, data processing applications, etc., and can solve the problems of damage, splitting, and loss of transfer cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

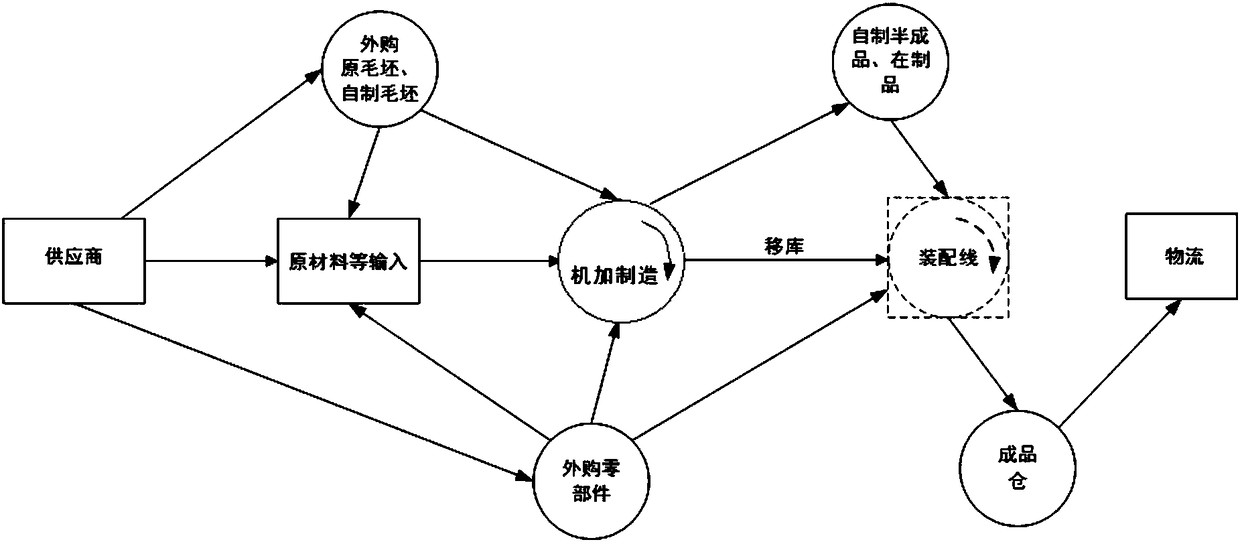

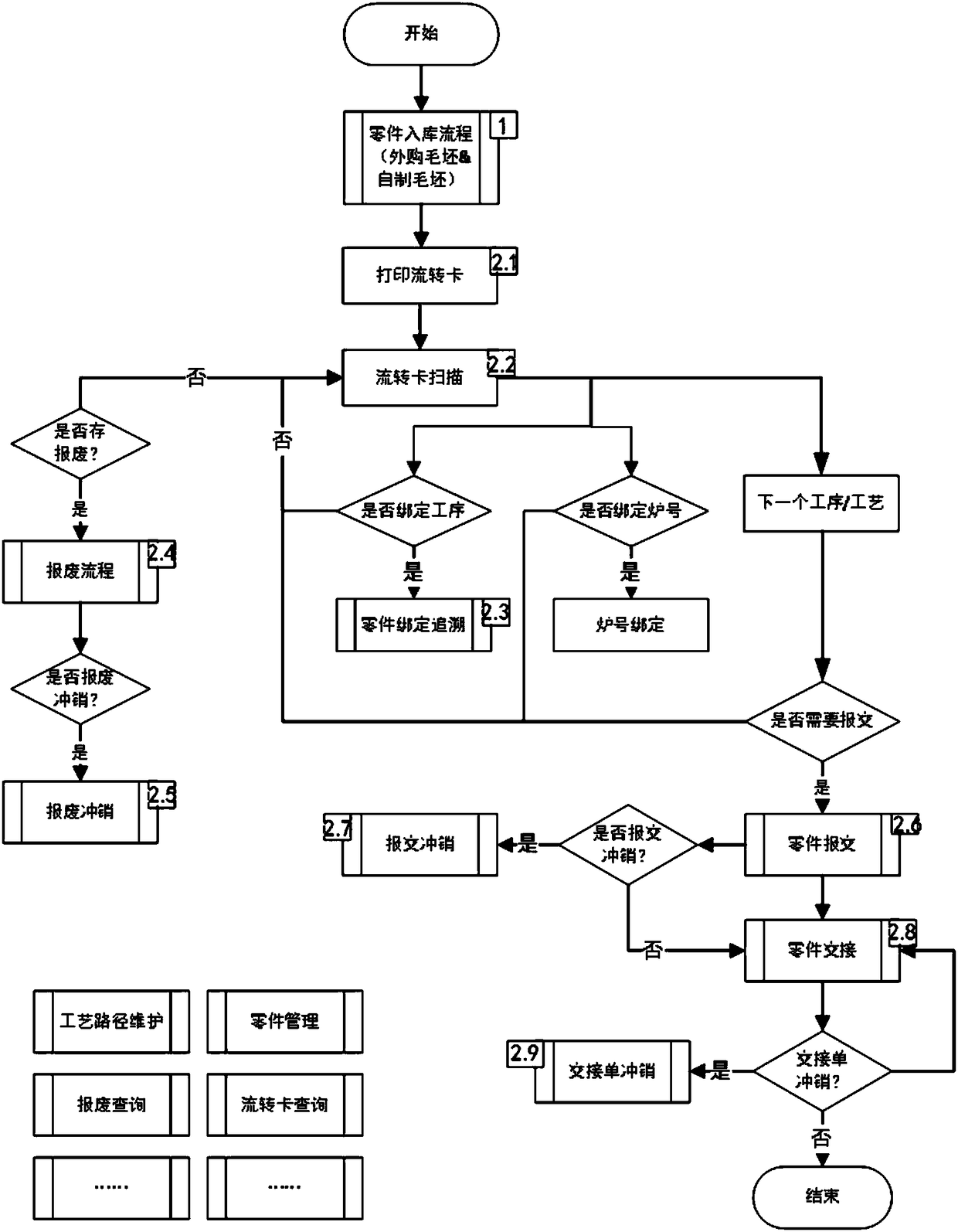

[0046] In order to achieve the object of the present invention, in some embodiments of the method for managing parts manufacturing in a machine shop, such as figure 1 As shown, the method for managing parts manufacturing in a machine shop includes the following steps:

[0047] 1) The system receives materials, WMS synchronizes the basic data of parts to the intermediate database, and the system automatically synchronizes the data from the intermediate database to the MES database and saves the parts inventory information;

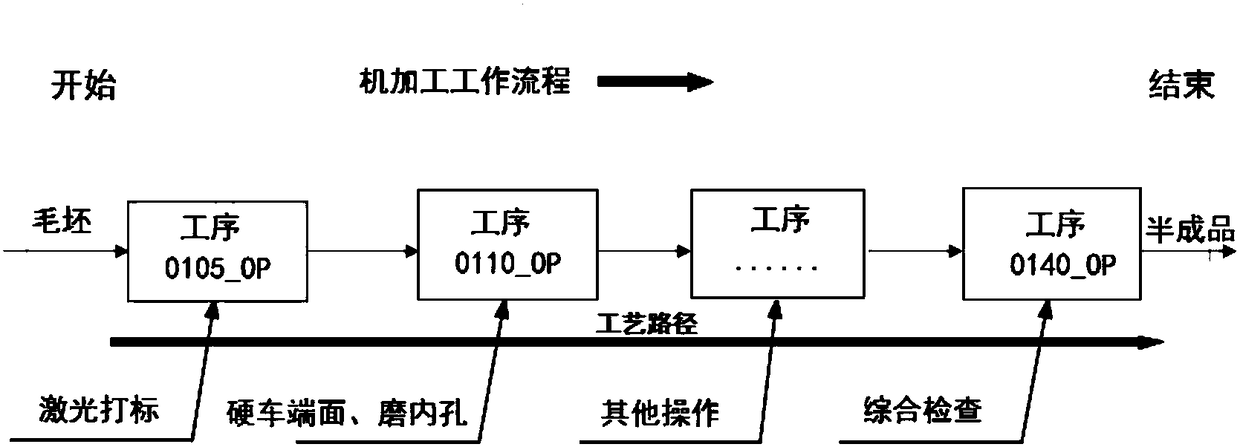

[0048] 2) Machining and manufacturing. The machine-added manufacturing process is executed according to the corresponding process path information. The machine-added manufacturing process is a relatively complicated production process, and it is also a process of production consumption and new value creation. Its operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com