Airblast fuel atomization system

a fuel atomization and air blast technology, which is applied in the ignition of turbine/propulsion engines, engine starters, lighting and heating apparatus, etc., can solve the problems of limiting the service life of the fuel injector, the inability to atomize fuel, and the difficulty of initiating the fuel ignition during engine startup cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

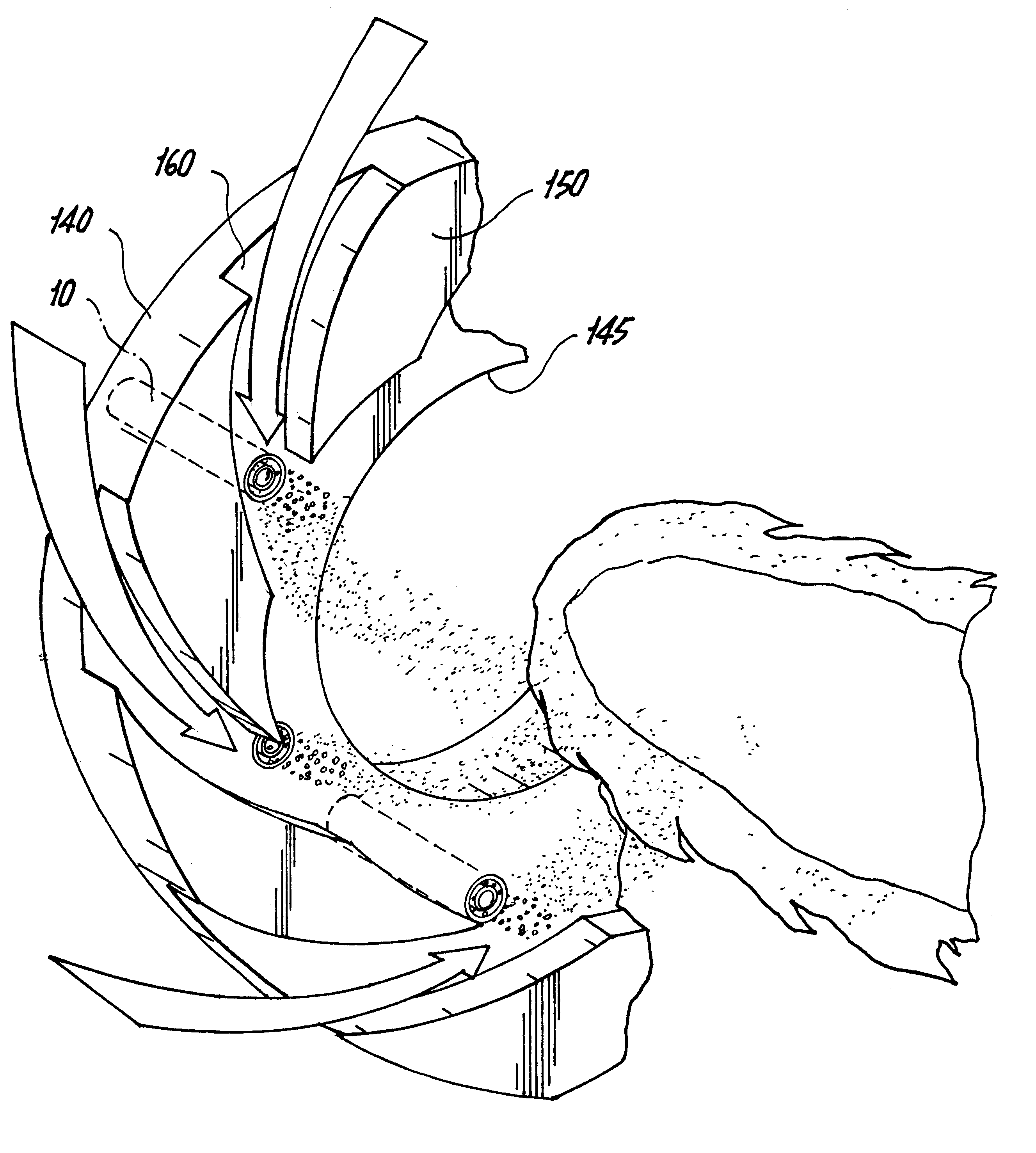

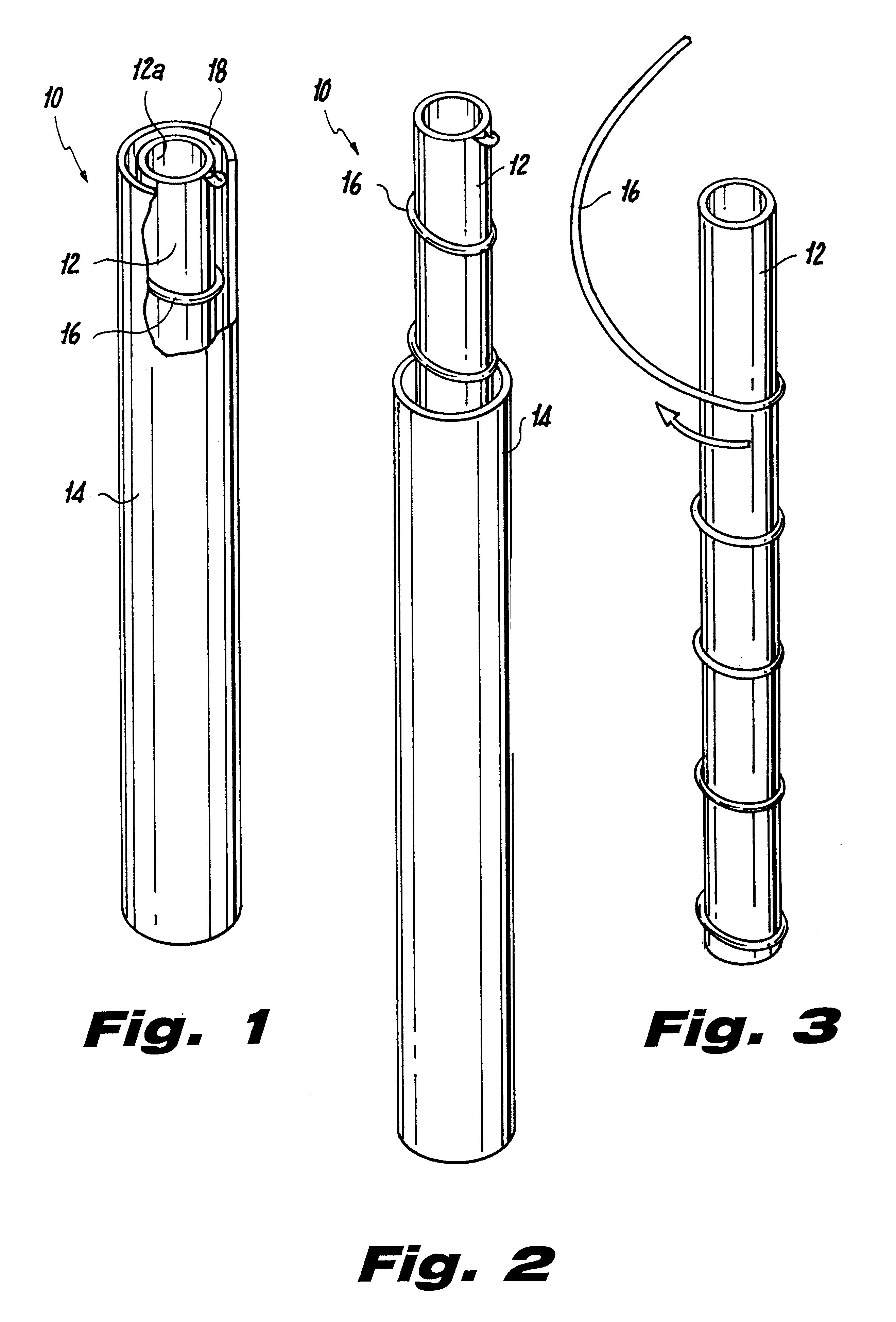

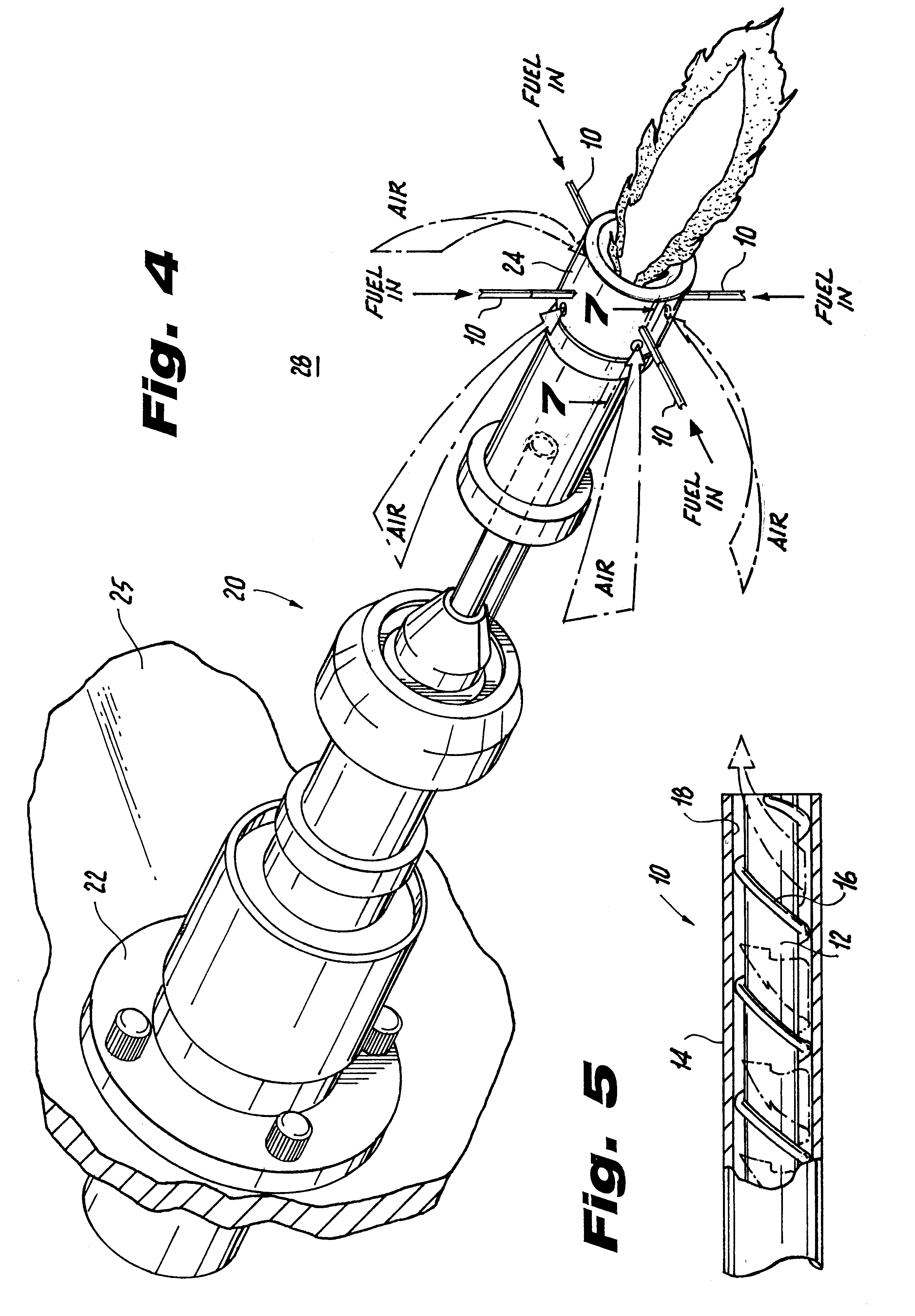

Referring now to the drawings wherein like reference numerals identify similar structural features of the apparatus disclosed herein, there is illustrated in FIG. 1 an airblast fuel injection device constructed in accordance with a preferred embodiment of the subject invention and designated generally by reference numeral 10. Fuel injection device 10 preferably includes concentric inner and outer tubular members 12 and 14. The tubular members are maintained in a coaxially spaced apart relationship by a helical spacer wire 16 wrapped around the inner tubular member 12, as illustrated in FIG. 3. Spacer wire 16 is preferably brazed onto the exterior surface of inner tubular member 12 and defines an annular fuel passage 18 between the inner and outer tubular members, which is best seen in FIG. 5.

The inner and outer tubular member 12 and 14 are not fastened together. This allows the outer tubular member 14 to move axially with respect to the inner tubular member 12, as shown for example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com