High iron aluminate-belite-sulfoaluminate cement clinker and preparation method thereof

A technology of sulfoaluminate cement and aluminate, applied in cement production and other directions, can solve the problem of low mechanical properties, and achieve the effects of improving service performance, facilitating resource treatment, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

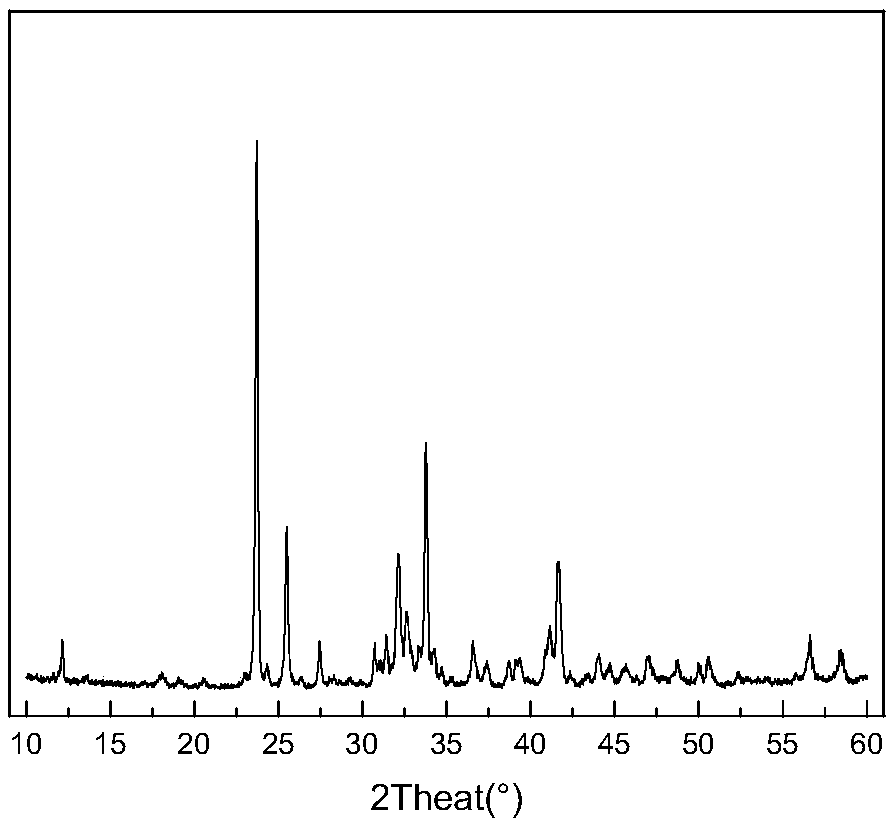

Embodiment 1

[0056] The clinker mineral composition design and raw material ratio of this embodiment are shown in Table 2, wherein the percentages are mass percentages.

[0057] Table 2: Mineral composition design and raw material ratio table of embodiment 1

[0058]

[0059] The specific steps are:

[0060] (1) Dry limestone, steel slag, desulfurized gypsum, and bauxite at 105°C for 2 hours, crush and grind them separately to below 200 mesh, and continue grinding if the fineness does not meet the requirements;

[0061] (2) The raw materials obtained in step (1) are weighed and proportioned according to the proportioning in Table 2, put into a mixing tank, and mix in a mixer for 20 minutes to obtain raw meal; add 10% water of raw meal quality and mix Mix evenly, and use a press to press the sample;

[0062] (3) Dry the pressed test block in step (2) at 105°C for 6 hours; then place the dried test block in a 950°C muffle furnace for calcination for 30 minutes, and then immediately tran...

Embodiment 2

[0068] The clinker mineral composition design and raw material ratio of this embodiment are shown in Table 4, wherein the percentages are mass percentages.

[0069] Table 4: Mineral composition design and raw material ratio table of embodiment 2

[0070]

[0071] The specific steps are:

[0072] (1) Dry limestone, steel slag, desulfurized gypsum, and bauxite at 105°C for 2 hours, crush and grind them separately to below 200 mesh, and continue grinding if the fineness does not meet the requirements;

[0073] (2) The raw materials obtained in step (1) are weighed and batched according to the proportioning in Table 4, put into a mixing tank, and mix in a mixer for 20 minutes to obtain raw meal; add 10% water of raw meal quality and mix Mix evenly, and use a press to press the sample;

[0074] (3) Dry the pressed test block in step (2) at 105°C for 4 hours; then place the dried test block in a 950°C muffle furnace for calcination for 30 minutes, and then immediately transfer ...

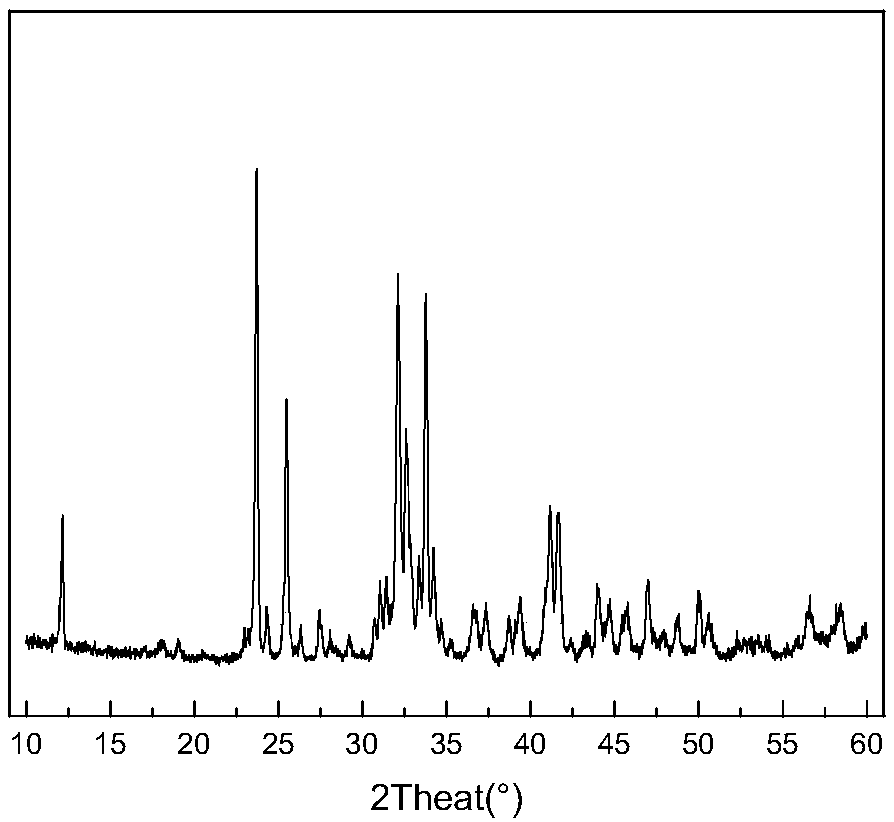

Embodiment 3

[0080] In this embodiment, the clinker mineral composition design and raw material ratio are shown in Table 6, wherein the percentages are mass percentages.

[0081] Table 6: Mineral composition design and raw material ratio table of embodiment 3

[0082]

[0083] The specific steps are:

[0084] (1) Dry limestone, fly ash, desulfurized gypsum, and steel slag at 105°C for 2 hours, crush and grind them separately to below 200 mesh, and continue grinding if the fineness does not meet the requirements;

[0085] (2) The raw materials obtained in step (1) are weighed and proportioned according to the proportioning in Table 6, put into a mixing tank, and mixed in a mixer for 20 minutes to obtain raw meal; add 10% water of raw meal quality and mix Mix evenly, and use a press to press the sample;

[0086] (3) Dry the compressed test block in step (2) at 105°C for 6 hours; then place the dried test block in a muffle furnace at 950°C for 30 minutes, and then immediately transfer it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com