Ceramic polished tile and manufacturing method thereof

A technology for ceramic polished tiles and ceramic tiles, which is applied in the field of ceramic industry, can solve the problems of not having high requirements for appearance, not being ceramic polished tiles, etc., and achieve the effects of saving cost, improving efficiency and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

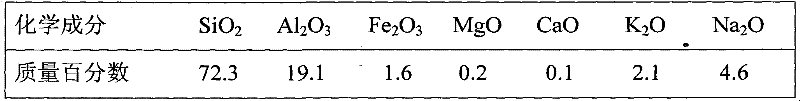

[0021] The chemical composition of the raw materials at the bottom of the polished tiles in the first step is:

[0022]

[0023] In the second step, the chemical composition determined in the first step is converted into the raw material formula to be used, and the powder used for the bottom layer of the polished tile is obtained through batching-ball milling-slurry aging-spray drying-homogenization.

[0024] In the third step, the prepared powder for the surface layer of polished tiles and the powder for the bottom layer obtained in the second step are distributed through a computer-controlled secondary distribution system, and are dry-pressed under a pressure of 30 MPa to make a surface. A square green body with a layer thickness of 3 mm, a base layer thickness of 9 mm, and a side length of 680 mm.

[0025] In the fourth step, after drying the green body obtained in the third step, it is fired in a roller kiln at a firing temperature of 1200° C. and a firing cycle of 70 m...

Embodiment 2

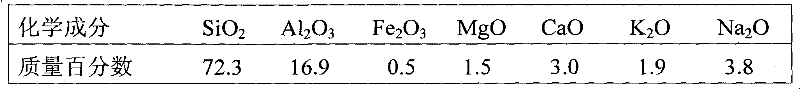

[0029] The chemical composition of the bottom layer of the polished tile in the first step is:

[0030]

[0031] In the second step, the chemical composition determined in the first step is converted into the raw material formula to be used, and the powder used for the bottom layer of the polished tile is obtained through batching-ball milling-slurry aging-spray drying-homogenization.

[0032] In the third step, the prepared powder for the surface layer of polished tiles and the powder for the bottom layer obtained in the second step are distributed through a computer-controlled secondary distribution system, and are dry-pressed under a pressure of 30 MPa to form a The thickness of the surface layer is 3mm, the thickness of the bottom layer is 9mm, and the square green body with a side length of 680mm.

[0033] In the fourth step, after drying the green body obtained in the third step, it is fired in a roller kiln at a firing temperature of 1180° C. and a firing cycle of 60...

Embodiment 3

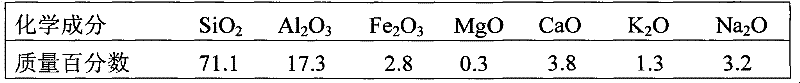

[0037] The chemical composition of the raw materials at the bottom of the polished tiles in the first step is:

[0038]

[0039] In the second step, the chemical composition determined in the first step is converted into the raw material formula to be used, and the powder used for the bottom layer of the polished tile is obtained through batching-ball milling-slurry aging-spray drying-homogenization.

[0040] In the third step, the prepared powder for the surface layer of polished tiles and the powder for the bottom layer obtained in the second step are distributed through a computer-controlled secondary distribution system, and are dry-pressed under a pressure of 30 MPa to form a The thickness of the surface layer is 3mm, the thickness of the bottom layer is 9mm, and the square green body with a side length of 680mm.

[0041] In the fourth step, after drying the green body obtained in the third step, it is fired in a roller kiln at a firing temperature of 1170° C. and a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com