High-solid content high-build water-based damping coating and preparation method thereof

A high-solid content, damping coating technology, applied in coatings and other directions, can solve the problems of not wide damping temperature range, inability to coat a thick enough paint film, poor low-temperature damping performance, etc., to achieve good mechanical properties and coating performance, Good application prospects and wide damping temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

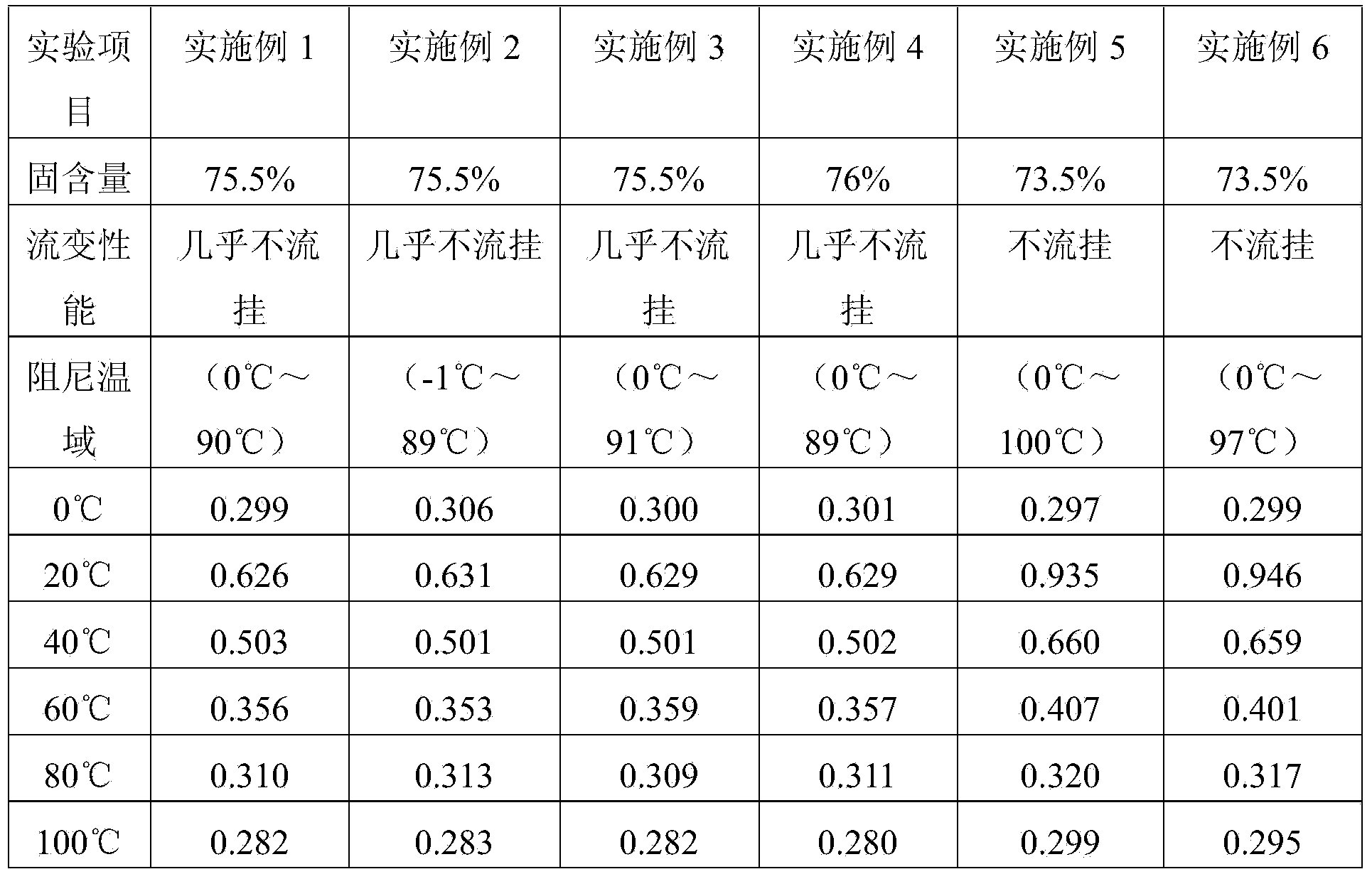

Examples

Embodiment 1

[0023] (1) Preparation of water-based styrene-acrylic emulsion

[0024] First mix 27.75g styrene, 45g butyl acrylate, 0.75g methacrylic acid, 1.5 methacrylamide, 4.076g DSB, 1.875gPE6100, 5.357gEF810, 0.75gNaHCO3, 300g water and add them into the reaction kettle, turn on the speed of the stirring device It is 330r / min and the heating device is up to 82°C, and the whole process is protected by nitrogen gas. 1.125g of ammonium persulfate and 1.125g of sodium bisulfite were respectively dissolved in 25g of water and then added dropwise for 35 minutes to react, and the seed emulsion was obtained after aging for 30 minutes.

[0025] Then mix 249.75g styrene, 405g butyl acrylate, 6.75g methacrylic acid, 13.5g methacrylamide, 4.076g DSB, 1.875gPE6100, 5.357gEF810, 0.75gNaHCO3, 300g water and mix well, then pre-emulsify by stirring for 0.5h and drop together Add it to the reaction kettle, and at the same time, add the initiator dropwise. The initiator is 1.125g ammonium persulfate an...

Embodiment 2

[0032] (1) Preparation of water-based styrene-acrylic emulsion

[0033] Same as Example 1.

[0034] (2) Dispersion of fillers

[0035] Same as Example 1

[0036] (3) Preparation of paint

[0037] With a high-speed mixer at 1600r / min, add 19.25g of methyl etherified melamine (CYEML385) to 100g of emulsion, then add 3g of aminomethylpropanol to adjust the pH to 8.8-9.0, stir for 10min, then add 1.93g of byk-333 and 1.93g of byk-190 and 1.93g byk-011 and 1.93g byk-024, adjust the speed to 3000r / min, stir for 15min. Then in another beaker, add heavy calcium slurry in 214g step (2), 32.6g step (2) medium slip, cloud slurry, 3.85g vermiculite powder (325 order) and 11.55g mica powder (1000 order), as far as possible After stirring evenly, add it into the emulsion at a speed of 1000r / min. After adding, adjust the speed to 2000r / min and stir evenly. After 15 minutes, when the liquid level is stable, add 3.85g of fumed silica and 3.85g of bentonite, and stir for 5 minutes after add...

Embodiment 3

[0039] (1) Preparation of water-based styrene-acrylic emulsion

[0040] Same as Example 1.

[0041] (2) Dispersion of fillers

[0042] Add 20g of 190 to 100g of water, stir evenly with a high-speed mixer at 1600r / min, then add 1.5g of byk-011 and 3.5g of byk-024, disperse at 3000r / min for 10min, add 900g of heavy calcium (of which 1250 mesh The mass ratio of calcium to 800 mesh heavy calcium and 400 mesh heavy calcium is 1:2:2). After adding, adjust the speed to 2000r / min to disperse evenly. After the slurry is smooth and stable, add 10g byk-333, 3.5g For byk-425 and 3.5gbyk-428, keep stirring at the rotating speed for 10 minutes to obtain heavy calcium slurry.

[0043] Add 30g190 to 150g water, stir well at 1600r / min with a high-speed mixer, add 1.5g byk-011 and 3.5g byk-024, disperse at 3000r / min for 10min, add 375g talcum powder (1250 mesh) and 75g mica powder (1000 mesh), after adding, adjust the speed to 2000r / min to disperse evenly, add 5g byk-333, 2g byk-425 and 2g b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com