Water-based viscoelastic damping soundproof sealant

A technology of sound insulation, sealing and viscoelasticity, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of inability to achieve sound insulation effect, poor sound insulation effect, low bonding strength, etc. Sound insulation effect, damping effect of wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

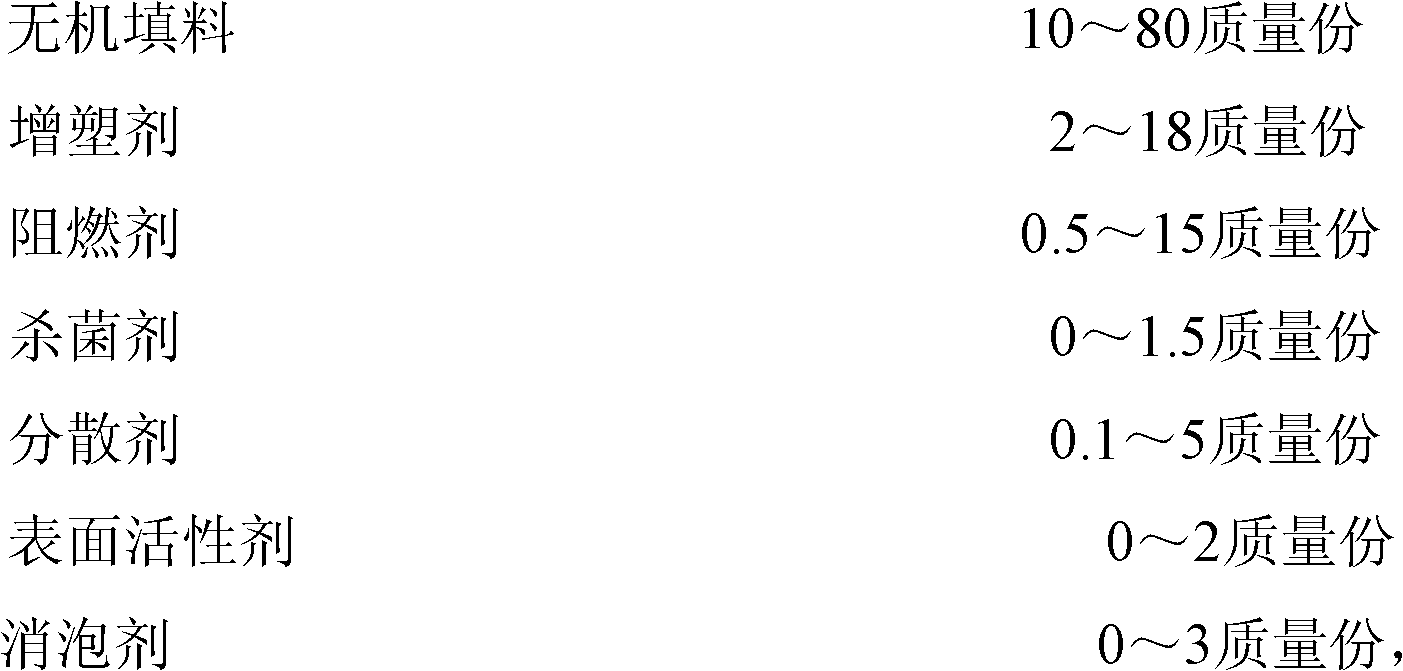

[0021] Weigh each component raw material according to the following composition formula:

[0022]

[0023] The preparation process is as follows: first, add plasticizer, dispersant and flame retardant into the water-based acrylic emulsion, stir to make the mixture uniform, then uniformly add inorganic filler, and stir at high speed for 0.3 to 1.5 hours to obtain the product.

[0024] The water-based viscoelastic damping and sound-insulating sealant is in the form of a paste when it is not dry, and it is in a soft state after being surface-dried at room temperature for 1 hour.

[0025] The temperature range where the damping value of the water-based viscoelastic damping and sound-insulating sealant described in this embodiment is above 0.7 is -15 to 65°C as measured by the US ASTME756-83 vibration damping material testing system.

[0026] The bond strength of the water-based viscoelastic damping and sound-insulating sealant described in this embodiment was measured by a bond...

Embodiment 2

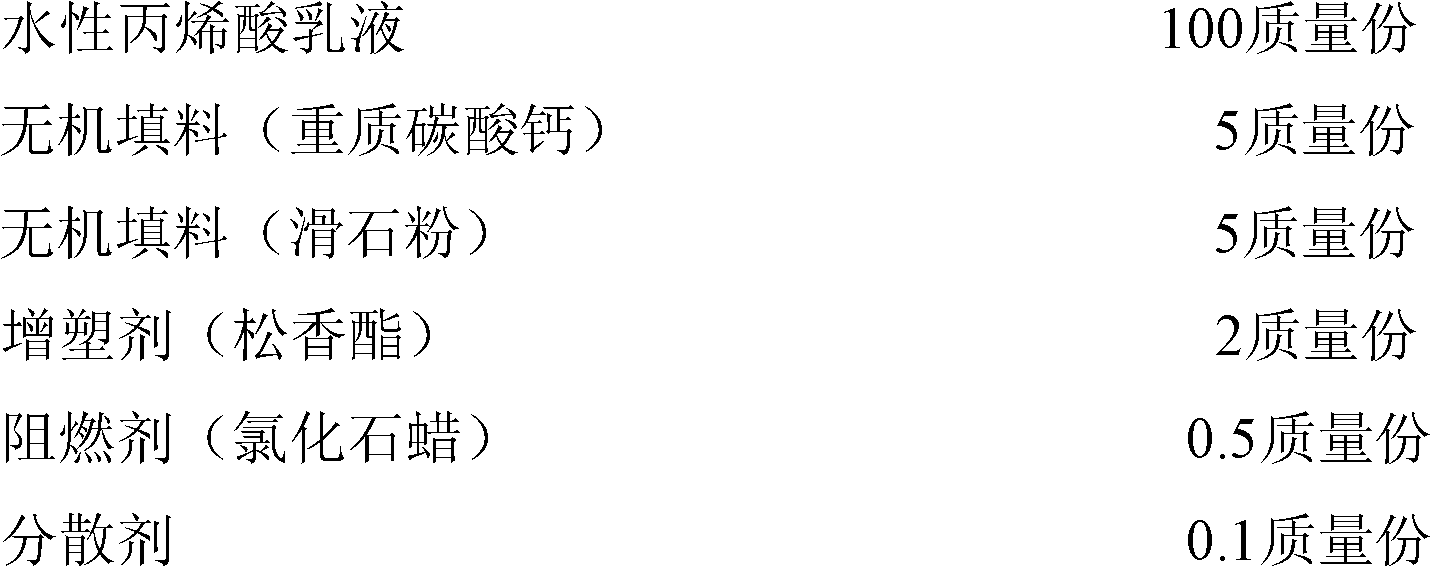

[0028] Weigh each component raw material according to the following composition formula:

[0029]

[0030]

[0031] The preparation process is as follows: First, add plasticizer, dispersant, flame retardant, bactericide, surfactant, and defoamer into the water-based acrylic emulsion, stir to mix evenly, then add inorganic filler evenly, and stir for 0.3 to 1.5 hours. Instantly.

[0032] The water-based viscoelastic damping and sound-insulating sealant is in the form of a paste when it is not dry, and it is in a soft state after being surface-dried at room temperature for 1 hour.

[0033] The temperature range where the damping value of the water-based viscoelastic damping and sound-insulating sealant described in this embodiment is above 0.7 is -17 to 78° C. as measured by the American ASTME756-83 vibration damping material testing system.

[0034] The bond strength of the water-based viscoelastic damping and sound-insulating sealant described in this embodiment was mea...

Embodiment 3

[0036] Weigh each component raw material according to the following composition formula:

[0037]

[0038] The preparation process is the same as described in Example 2.

[0039] The water-based viscoelastic damping and sound-insulating sealant is in the form of a paste when it is not dry, and it is in a soft state after being surface-dried at room temperature for 1 hour.

[0040] The temperature range where the damping value of the water-based viscoelastic damping sound-insulating sealant described in this embodiment is above 0.7 is -7 to 70° C. measured by the US ASTME756-83 vibration damping material testing system.

[0041] The bond strength of the water-based viscoelastic damping and sound-insulating sealant described in this embodiment was measured by a bond strength tester (tensile testing machine) to be 0.75 MPa.

[0042] The use method of the water-based viscoelastic damping and soundproof sealant of the present invention needs to be continuously filled inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com