Cold-resistant and water-proof damping coating

A damping coating and polymer technology, applied in the coating field, can solve the problems that damping coating damping performance, cold resistance and water resistance cannot meet the requirements of society, and achieve good chemical compatibility and stability, wide damping temperature range, The effect of great adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

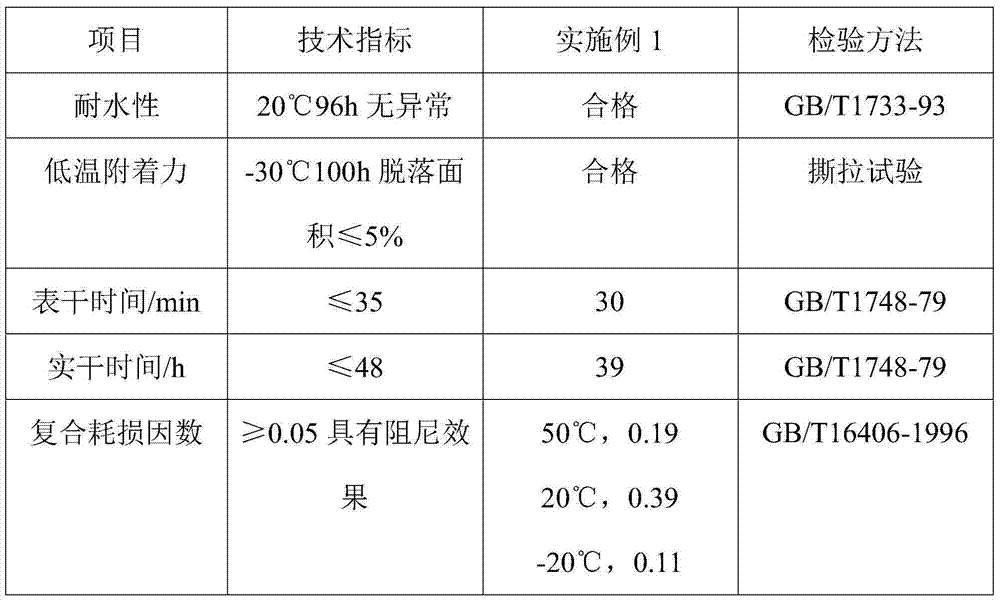

Embodiment 1

[0019]The cold-resistant and water-resistant polymer damping coating of the present invention, its raw material comprises the following components by weight: 40 parts of water-based polyurethane / polyacrylate emulsion, 16 parts of coupling agent modified sericite, 5 parts of talcum powder, hollow glass microspheres 10 parts, 3 parts of mica powder, 12 parts of perlite, 5 parts of diatomaceous earth, 10 parts of nanometer acrylate rubber powder, 0.3 parts of phosphate modified amine compound, 6 parts of magnesium hydroxide, 5 parts of aluminum hydroxide, glass 10 parts of fiber, 1 part of boron phenolic resin, 5 parts of organic solvent, 2 parts of film-forming aid, 5 parts of auxiliary agent, 20 parts of deionized water;

[0020] Wherein, the phosphate-modified amine complex is prepared according to the following process: 20 parts by weight of phosphoric acid and 20 parts of ethylenediamine are added to the flask, stirred for 20 minutes, heated to 55° C., reacted for 20 minutes,...

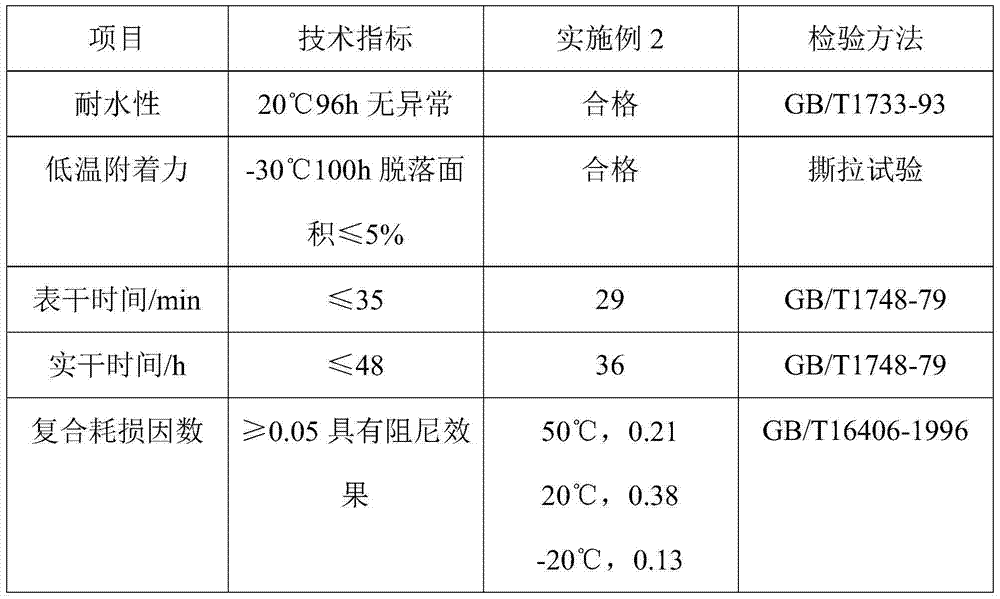

Embodiment 2

[0025] The cold-resistant and water-resistant polymer damping coating of the present invention, its raw material comprises the following components by weight: 60 parts of water-based polyurethane / polyacrylate emulsion, 5 parts of coupling agent modified sericite, 15 parts of talcum powder, hollow glass microspheres 3 parts, 8 parts of mica powder, 5 parts of perlite, 17 parts of diatomaceous earth, 4 parts of nanometer acrylate rubber powder, 0.9 parts of phosphate modified amine compound, 3 parts of magnesium hydroxide, 12 parts of aluminum hydroxide, glass 3 parts of fiber, 3 parts of boron phenolic resin, 2 parts of dipropylene glycol, 3 parts of propylene glycol phenyl ether, 4 parts of alcohol ester twelve, 2 parts of additives, 35 parts of deionized water;

[0026] Wherein, the auxiliary agent is a combination of defoamer, thickener, leveling agent, dispersant, and wetting agent in any ratio by weight;

[0027] The phosphate-modified amine complex is prepared according t...

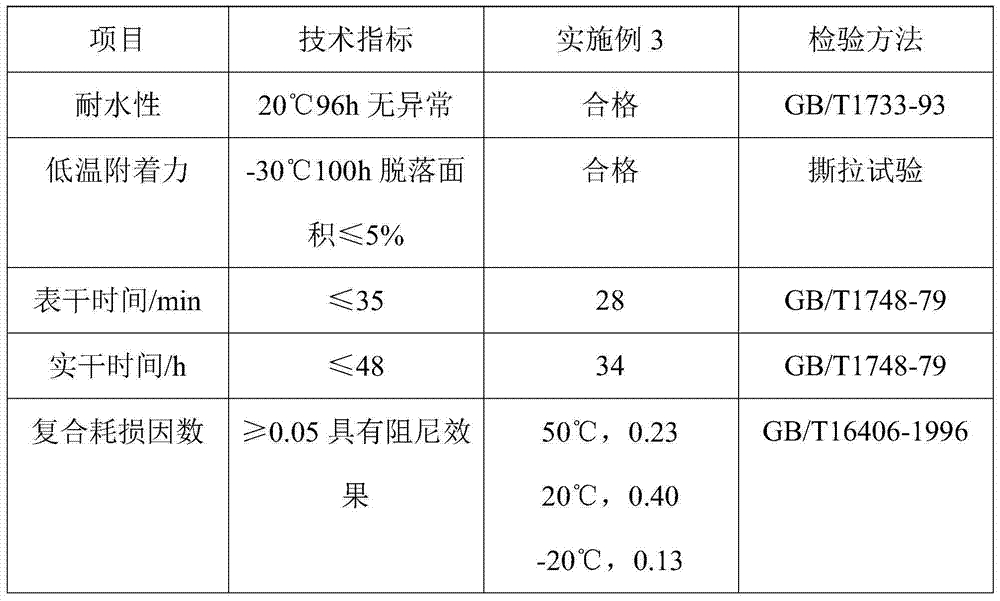

Embodiment 3

[0032] The cold-resistant and water-resistant polymer damping coating of the present invention, its raw material comprises the following components by weight: 51.2 parts of water-based polyurethane / polyacrylate emulsion, 10 parts of coupling agent modified sericite, 13.5 parts of talcum powder, hollow glass microspheres 6.4 parts, 7.8 parts of mica powder, 11.2 parts of perlite, 11.5 parts of diatomaceous earth, 8.7 parts of nanometer acrylate rubber powder, 0.83 parts of phosphate modified amine compound, 5.8 parts of magnesium hydroxide, 10.8 parts of aluminum hydroxide, glass 7 parts of fiber, 2.6 parts of boron phenolic resin, 1.5 parts of 1,4-butanediol, 2.3 parts of pentylene glycol, 5.8 parts of film-forming aid, 3.8 parts of thickener, 30 parts of deionized water;

[0033] Wherein, the film-forming aid is a combination of polyethylene glycol, propylene glycol phenyl ether, alcohol ester dodecane, and ethylene glycol butyl ether in any ratio by weight; the thickener is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com