Organic silicon damping additive and preparation method thereof

An organosilicon and additive technology, applied in the field of organosilicon damping materials, can solve the problems of low chemical activity of EPDM rubber, decline in damping performance, decline in mechanical properties, etc., to solve the migration problem, reduce the influence of mechanics, reduce internal The effect of high frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

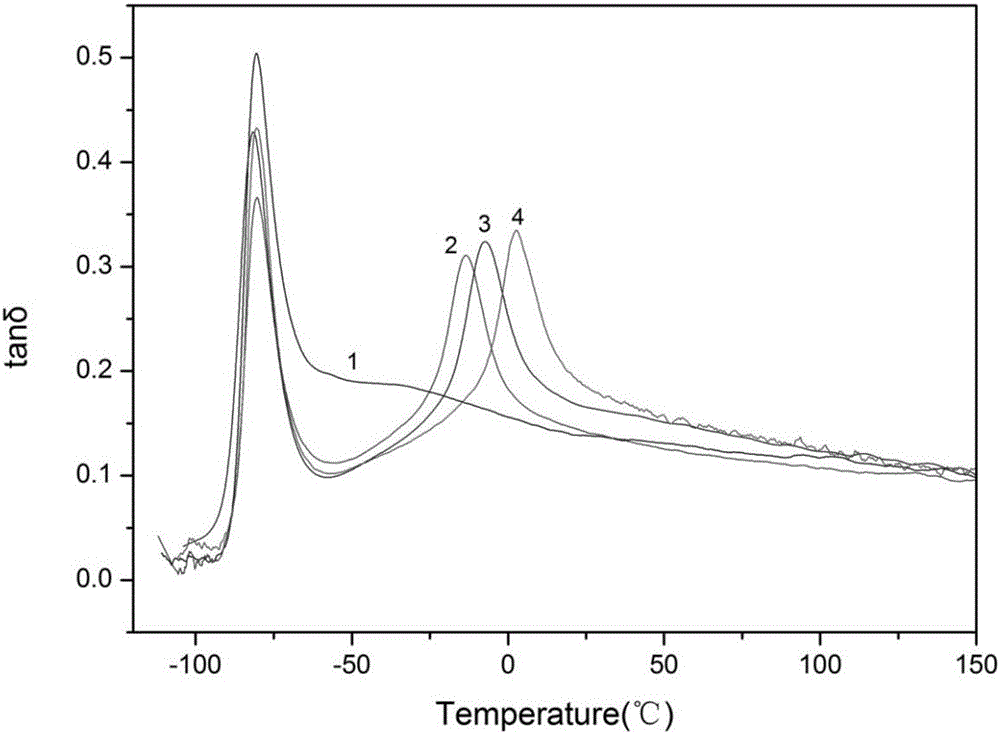

Problems solved by technology

Method used

Image

Examples

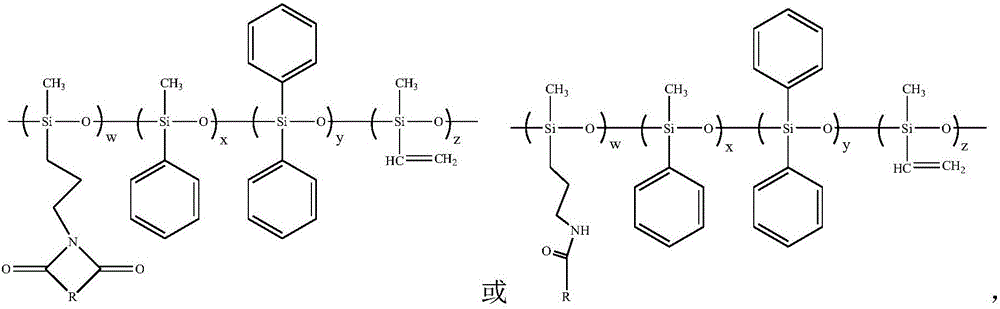

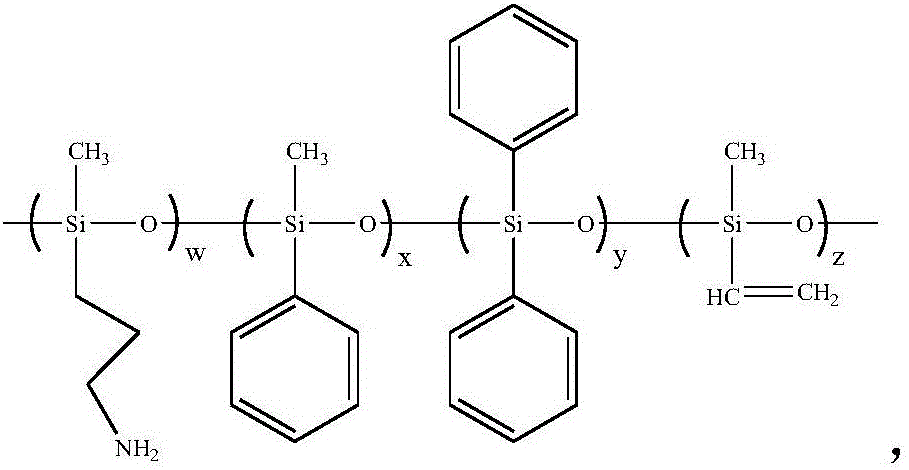

Embodiment 1

[0035] Example 1: Preparation of aminopropylphenyl silicone oil (i.e. the modified silicone oil in the summary of the invention): 13.6g methylphenylcyclosiloxane, 0.88g aminopropylmethyl dimethyl Oxysilane, 0.09g Tetramethyltetravinylcyclotetrasiloxane (D 4 Vi ), 0.1gKOH powder, 30gH 2 O, 20mL DMSO and 0.90g decamethyltetrasiloxane (MD 2 M), heat up to 90-110°C in a nitrogen atmosphere, stir for 3 hours, vacuumize to remove the water and ethanol generated in the system, keep the vacuum and heating state for 30 minutes, remove the vacuum, keep warm and continue to balance for 5-6 hours, and then cool down the system to 50°C, then add metered ratio of glacial acetic acid to neutralize KOH. After neutralization for 5 minutes, the temperature was raised to 200°C, and the small molecules in the system were removed under vacuum conditions to obtain a compound with a molecular weight of 5000, a molar content of aminopropylsiloxane chains of 5%, and a methylphenyl chain of 94%. , ...

Embodiment 2

[0037] Example 2: 10 g of aminopropylphenyl with a molecular weight of 5000, aminopropylsiloxane chains with a molar content of 5%, methylphenyl chains with 94%, and vinyl chains with a content of 1% Silicone oil was dissolved in 100g of xylene, under nitrogen atmosphere, the temperature was raised to 150°C, 0.55g of phthalic anhydride was added, and the reflux was maintained, and the water produced in the reaction was continuously removed with a water separator until the reaction was complete. Lower the temperature, fully shake with hot sodium bicarbonate solution, wash off the unreacted anhydride, filter, dry, and remove the solvent in a vacuum to obtain 5% phthalimide imide propyl siloxane chain unit damping additives.

Embodiment 3

[0038] Embodiment 3: Referring to Example 2. The silicone oil is replaced with a molecular weight of 50,000, an aminopropylsiloxane chain unit content of 10%, a methylphenyl chain unit of 89%, and a vinyl chain unit content of 1%. Add 1.32 g of phthalic anhydride to aminopropylphenyl silicone oil, and keep other conditions constant, to prepare a damping additive with a phthalimide propylsiloxane chain segment content of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com