Copper-clad ceramic substrate with high bonding strength and preparation process thereof

A copper-clad ceramic substrate and preparation process technology, which is applied in the processing of insulating substrates/layers, printed circuit manufacturing, printed circuits, etc. Uniformity, affecting the activity of reagents, etc., to avoid the production of copper sulfate, reduce the depth of brush marks, and shorten the time of micro-etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

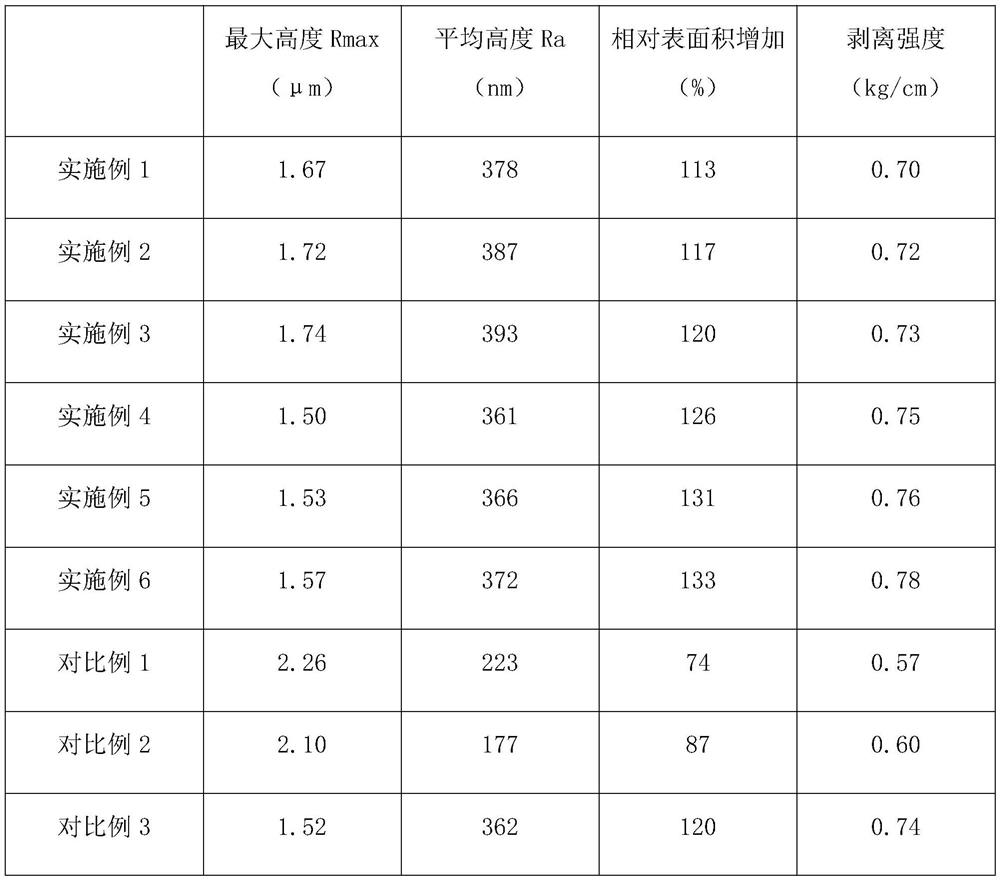

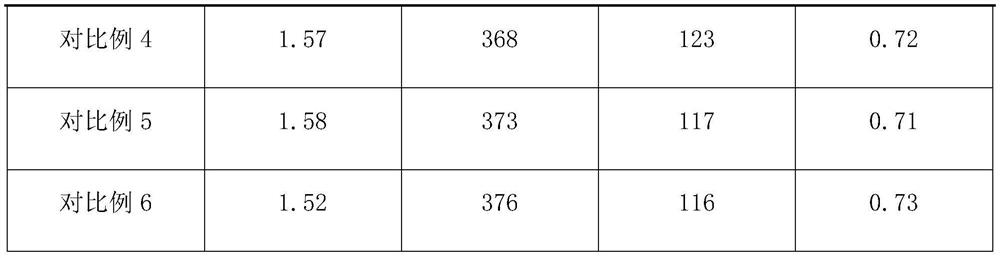

Examples

Embodiment 1

[0037] (1) Grinding plate: Use ceramic brush and cloth brush to polish the copper-clad ceramic substrate in turn; the mesh number of the ceramic brush is 600 mesh, the thickness of the ceramic sheet is 8mm, the speed selection is 2.5m / min, and the brushing current is 2.7 A; The weaving brush is 400 mesh, the speed is 2.5m / min, and the brushing current is 2.9A;

[0038] Spray washing: clean the copper powder produced by the grinding plate, and recycle the copper powder;

[0039] Pickling: Use 98% concentrated sulfuric acid, 5-aminotetrazole, nickel sulfate, and 30% hydrogen peroxide to prepare a pickling agent, and clean the copper base at a temperature of 32°C to remove surface oxides;

[0040]Alkaline cleaning: Use sodium hydroxide aqueous solution to clean the copper base at 37°C to remove surface grease, fingerprints, slight oxidation and other organic pollutants, and at the same time form an oxide film, which is beneficial to accelerate the copper base surface to the organ...

Embodiment 2

[0043] (1) Grinding plate: Use ceramic brush and cloth brush to polish the copper-clad ceramic substrate in turn; the mesh number of the ceramic brush is 500 mesh, the thickness of the ceramic sheet is 8mm, the speed selection is 2.5m / min, and the brushing current is 2.7 A; The weaving brush is 50 mesh, the speed is 2.5m / min, and the brushing current is 2.9A;

[0044] Spray washing: clean the copper powder produced by the grinding plate, and recycle the copper powder;

[0045] Pickling: Use 98% concentrated sulfuric acid, 5-aminotetrazole, nickel sulfate, and 30% hydrogen peroxide to prepare a pickling agent, and clean the copper base at a temperature of 35°C to remove surface oxides;

[0046] Alkaline cleaning: Use sodium hydroxide aqueous solution to clean the copper base at 40°C to remove surface grease, fingerprints, slight oxidation and other organic pollutants, and at the same time form an oxide film, which is beneficial to accelerate the reaction of organic matter on th...

Embodiment 3

[0049] (1) Grinding plate: Use ceramic brush and cloth brush to polish the copper-clad ceramic substrate in turn; the mesh number of the ceramic brush is 400 mesh, the thickness of the ceramic sheet is 8mm, the speed selection is 2.5m / min, and the brushing current is 2.7 A; The weaving brush is 400 mesh, the speed is 2.5m / min, and the brushing current is 2.9A;

[0050] Spray washing: clean the copper powder produced by the grinding plate, and recycle the copper powder;

[0051] Pickling: Use 98% concentrated sulfuric acid, 5-aminotetrazole, nickel sulfate, and 30% hydrogen peroxide to prepare a pickling agent, and clean the copper base at a temperature of 38°C to remove surface oxides;

[0052] Alkaline cleaning: Use sodium hydroxide aqueous solution to clean the copper base at 43°C to remove surface grease, fingerprints, slight oxidation and other organic pollutants, and form an oxide film at the same time, which is beneficial to accelerate the copper base surface to the orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com