Rubber base damping material and preparation method thereof

A damping material and rubber-based technology, applied in the field of damping materials, can solve problems such as the increase of damping value, achieve the effect of widening the damping temperature range and improving the bubble phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

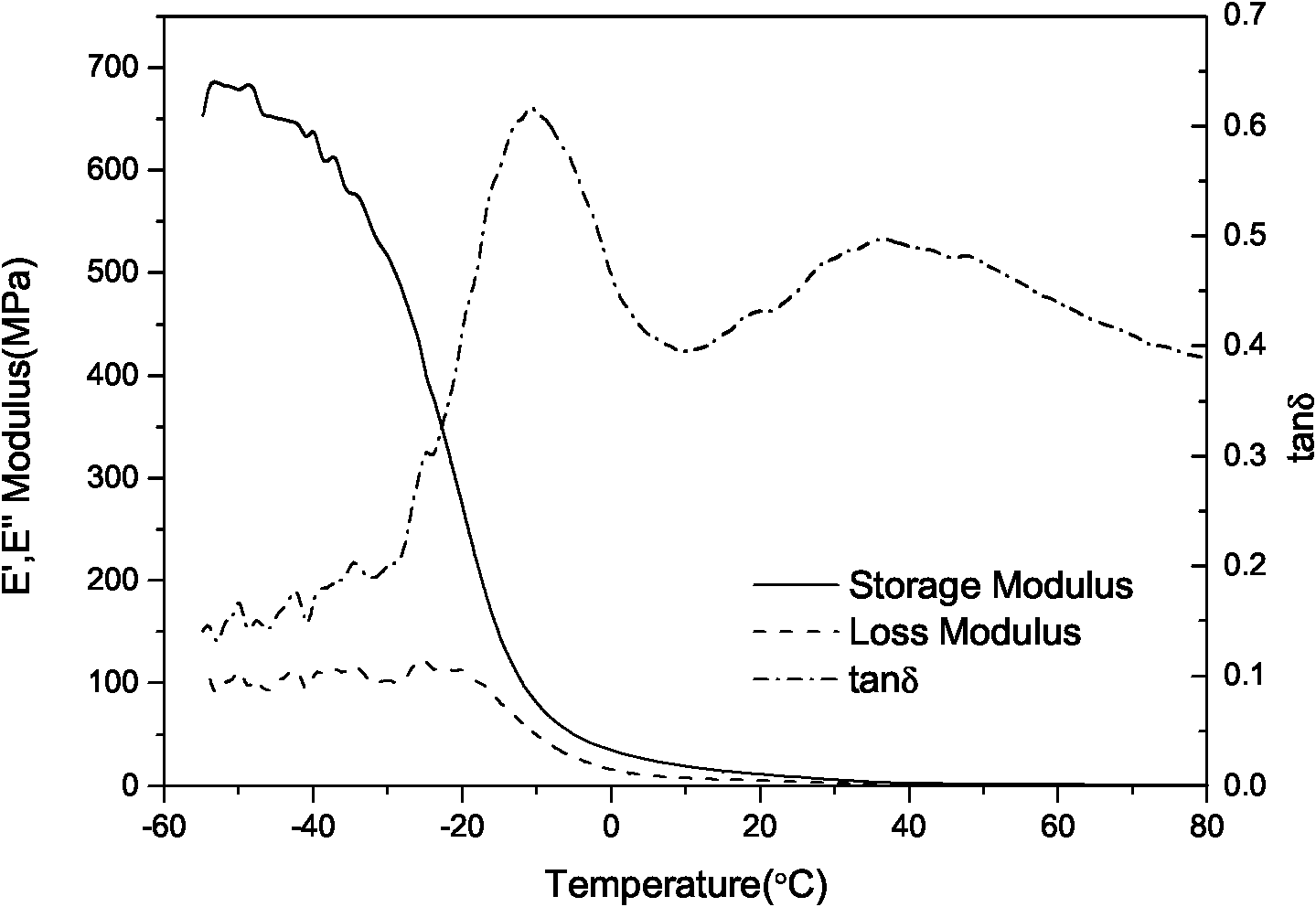

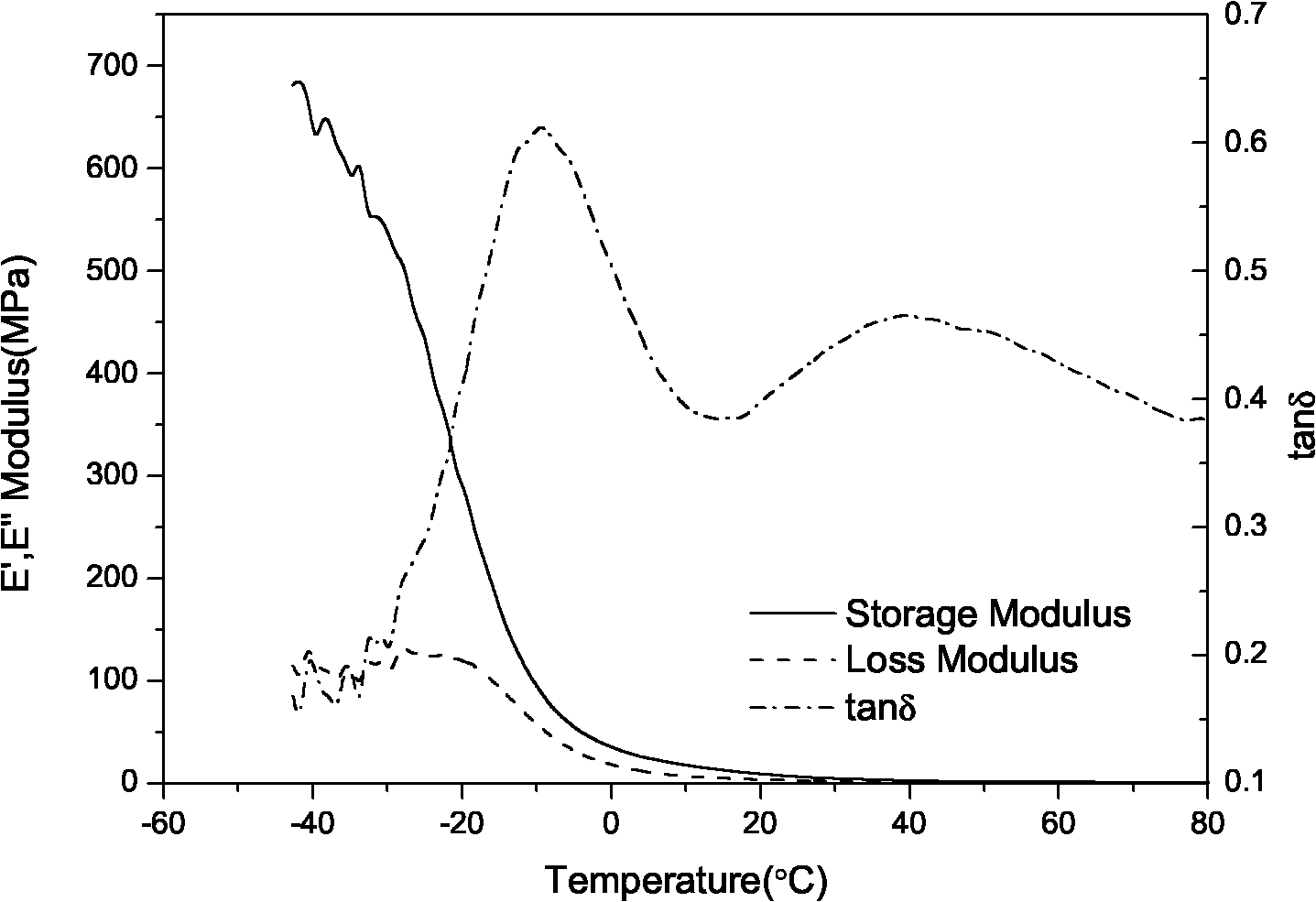

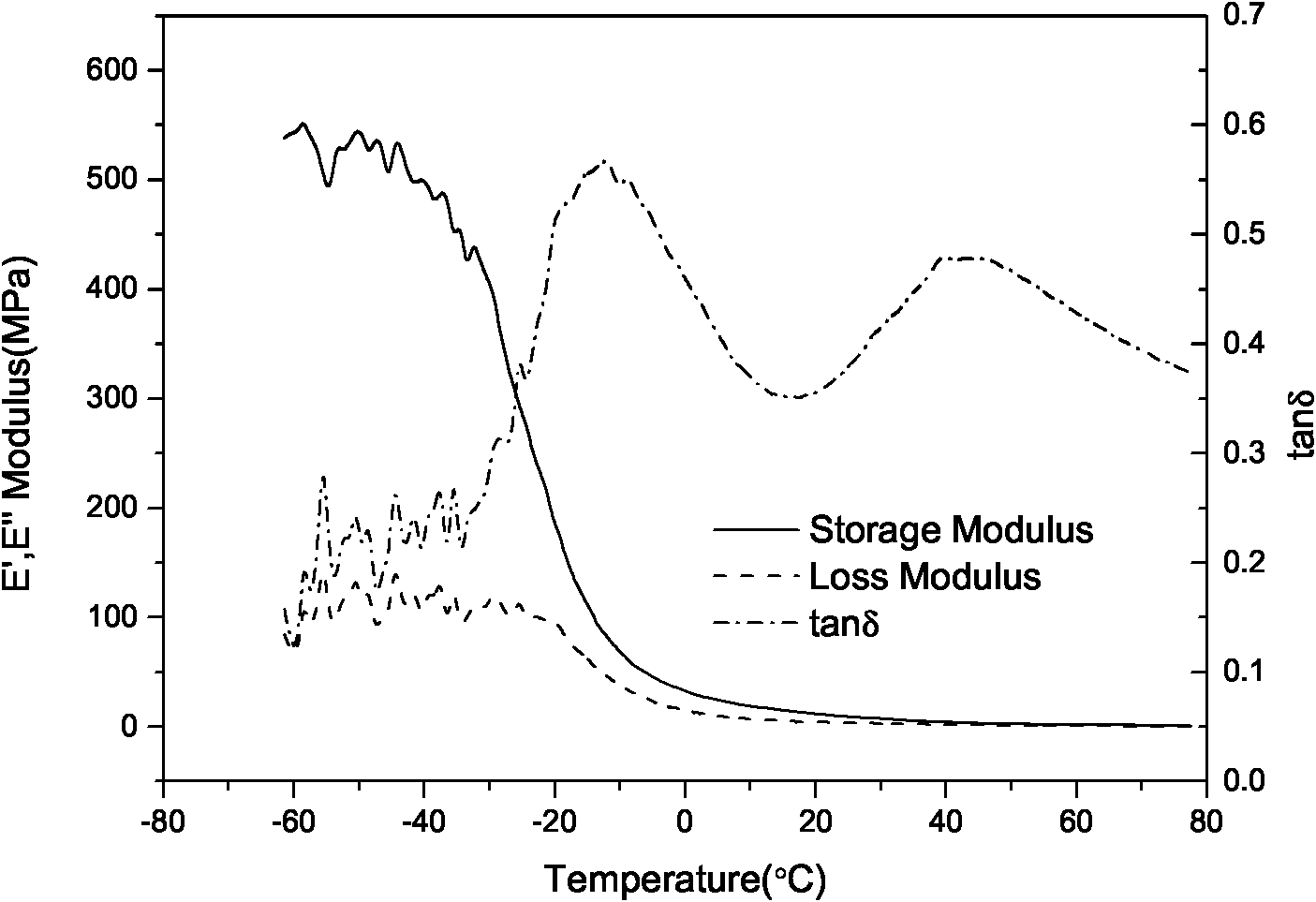

Image

Examples

Embodiment 1

[0028] At room temperature, mix 50 parts of EPDM rubber and 50 parts of petroleum resin on the open mill evenly, add 3 parts of stearic acid and 3 parts of dicumyl peroxide, thin pass and make triangular bags 8 times, and then put The roller distance is adjusted to 2mm, and the film is released, and it is parked for 24 hours for use. And at room temperature, mix 50 parts of nitrile rubber and 50 parts of phenolic resin on the open mill evenly, add 3 parts of paraffin, thin pass and make a triangular bag 8 times, adjust the roller distance to 2mm, and leave the sheet for 24 hours . Afterwards, the above-mentioned EPDM rubber / petroleum resin compound rubber and the above-mentioned nitrile rubber / phenolic resin compound rubber were thinly passed on the open mill and made a triangular bag for 10 times, and the roll distance was adjusted to 2mm to produce the sheet, and quickly Place it on a flat vulcanizing machine, mold it at a temperature of 170°C and a pressure of 10MPa for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com