Display module and its full bonding method

A display module, full lamination technology, applied in identification devices, instruments, calculations, etc., can solve the problems of easy generation of air bubbles, entering the interior of the display module, etc., to achieve the effect of improving the bubble phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

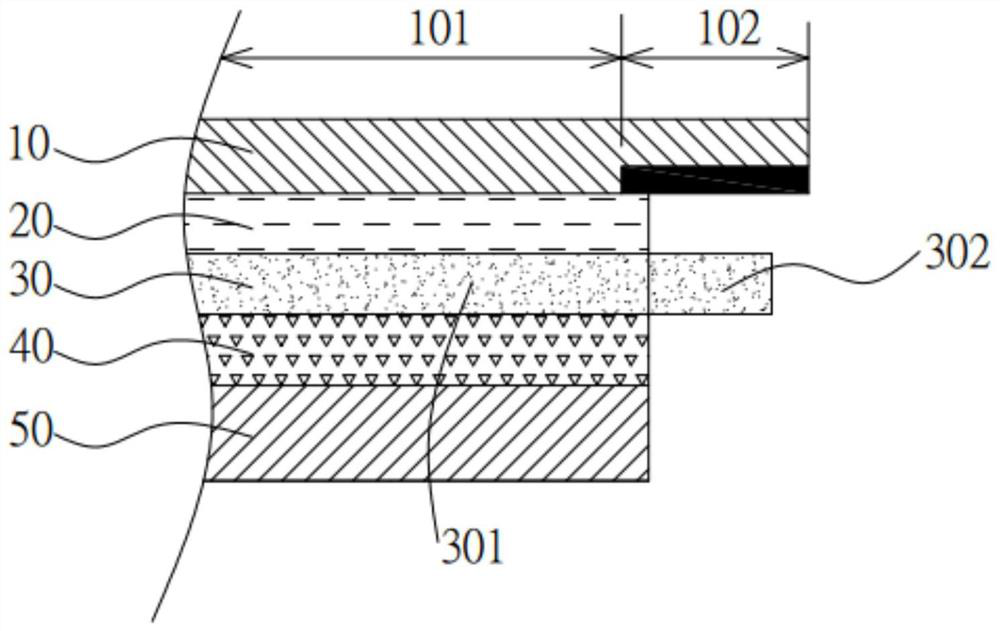

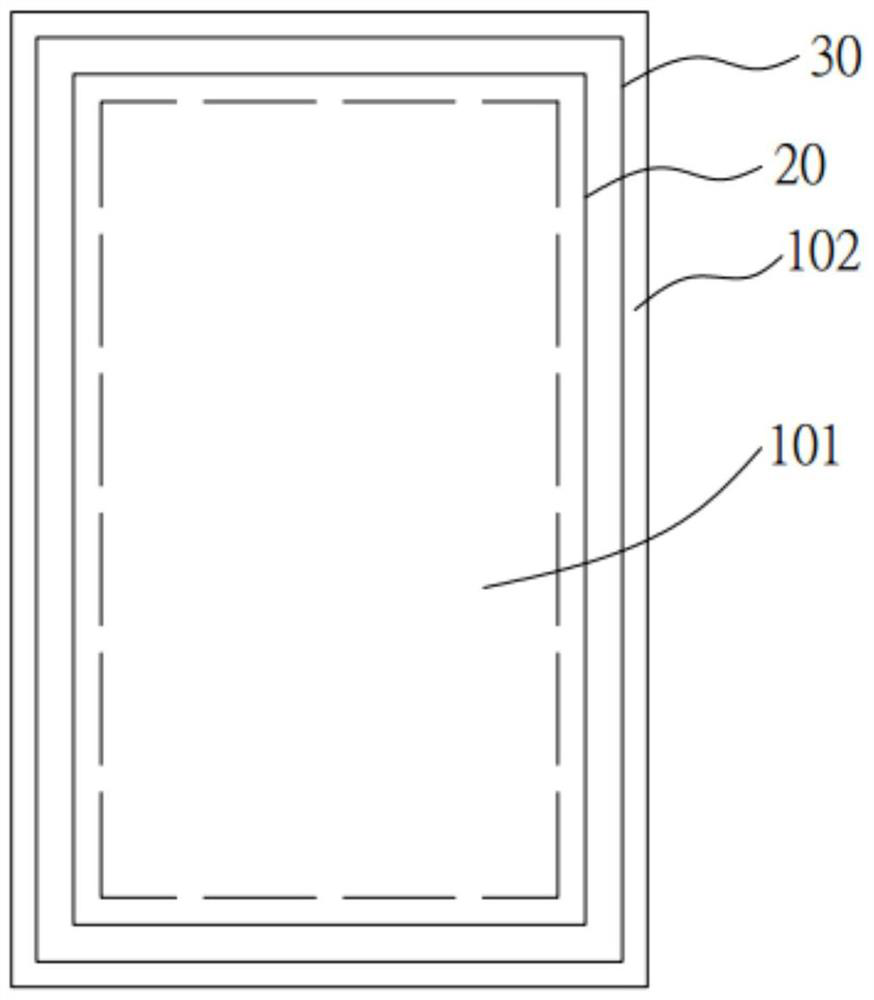

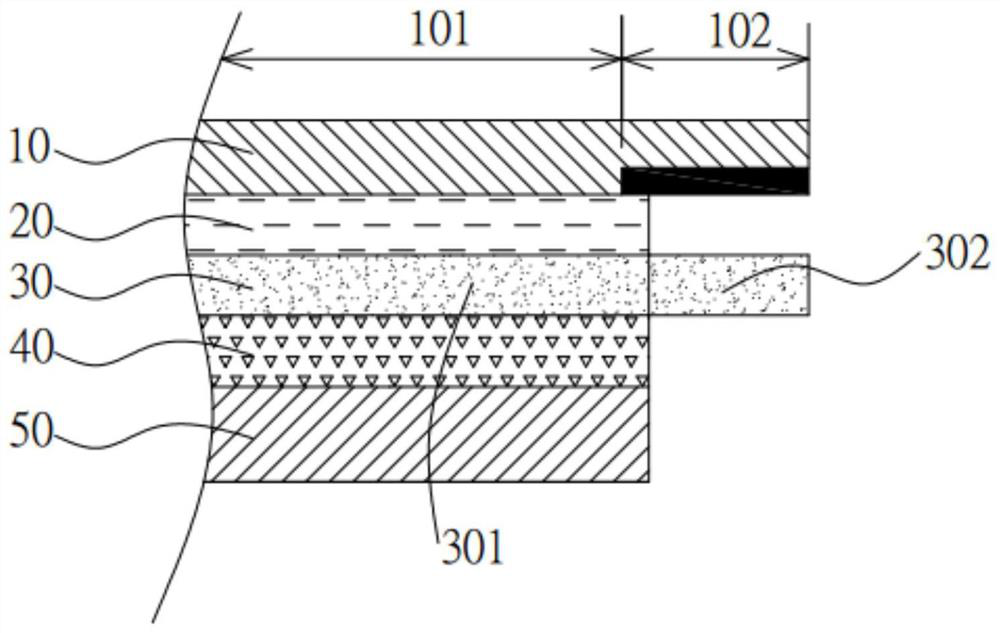

[0037] Such as figure 1 Shown is a schematic cross-sectional structure diagram of a display module provided by an embodiment of the present disclosure. The display module includes a cover plate 10 , a glass substrate 20 , a display panel 50 and an adhesive layer 30 .

[0038] Wherein, the cover plate 10 includes a visible area 101 and an ink area 102 surrounding the visible area, the visible area 101 is used to display images, and the ink area 102 is an opaque area.

[0039] The glass substrate 20 is combined with the cover plate 10, and its periphery is superposed to the ink area 102, that is to say, the outer edge of the glass substrate 20 corresponds to the ink area 102. It should be noted that , the outer edges are defined for the inner and outer sides of the display module.

[0040] The display panel 50 is located on the side of the glass substrate 20 away from the cover plate 10, and the display panel 50 can be a liquid crystal display panel, or an organic light-emittin...

Embodiment 2

[0050] Such as Figure 5 As shown, the full lamination method of the display module provided by the embodiment of the present disclosure includes the following steps:

[0051] Step S10: Under a vacuum environment, attach the adhesive layer 30 to the cover plate 10 combined with the glass substrate 20 in position;

[0052] Specifically, the cover plate 10 includes a visualization area 101 and an ink area 102, the glass substrate 20 is bonded to the cover plate 10, and its periphery is superimposed to the ink area 102 of the cover plate 10; The adhesive layer is UV-OCA optical glue.

[0053] Step S20: Under a vacuum environment, align and attach the cover plate 10 and the display panel 50 together;

[0054] Step S30: performing a defoaming treatment on the adhesive layer 30;

[0055] Specifically, the in-plane degassing is carried out under low temperature and low pressure conditions, wherein the conditions of one degassing treatment are: the temperature is controlled within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com