Aqueous damping paint and preparation method thereof

A damping coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of inconvenient processing and use, and achieve the effects of high elastic modulus, simple production method and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

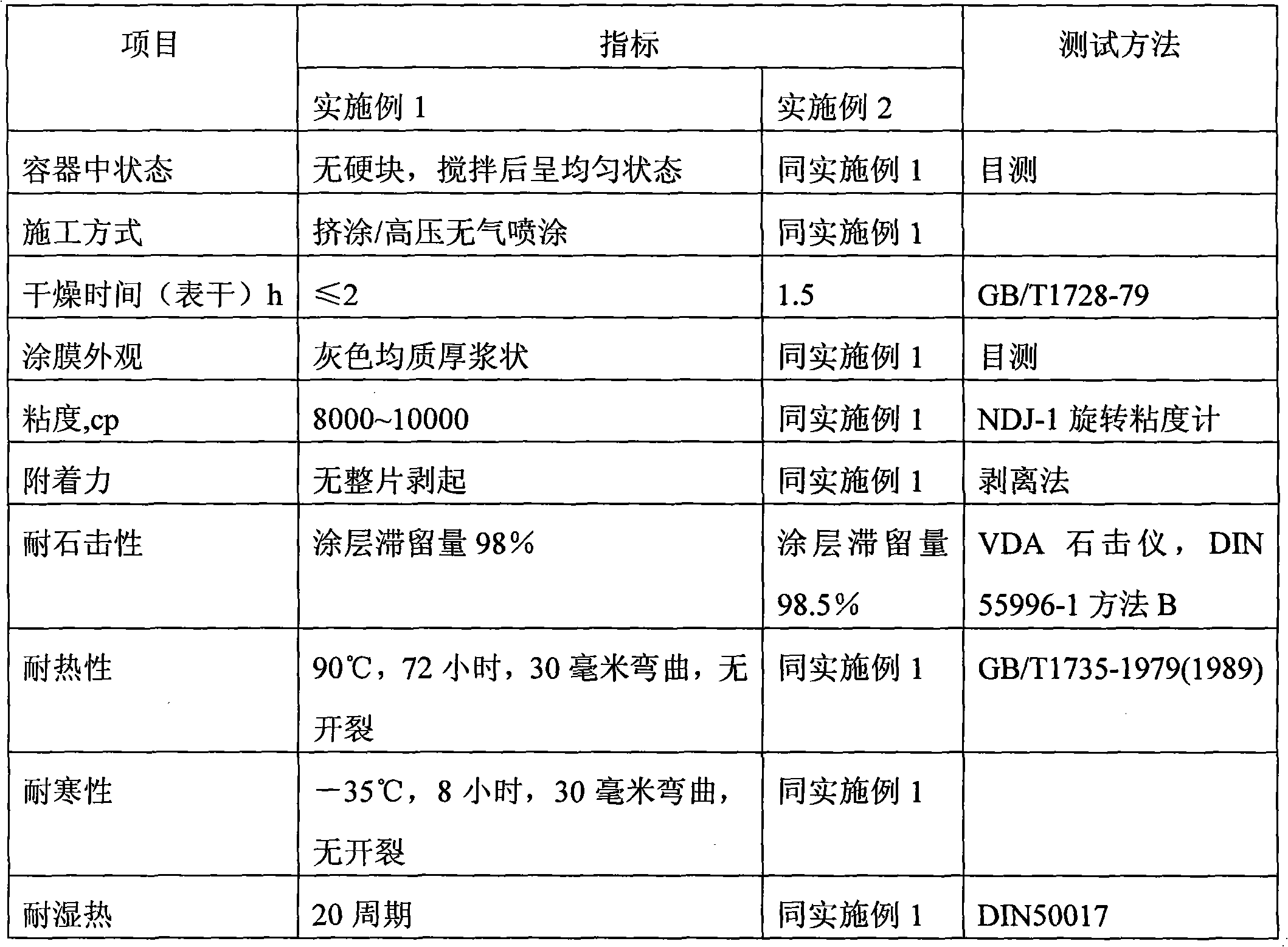

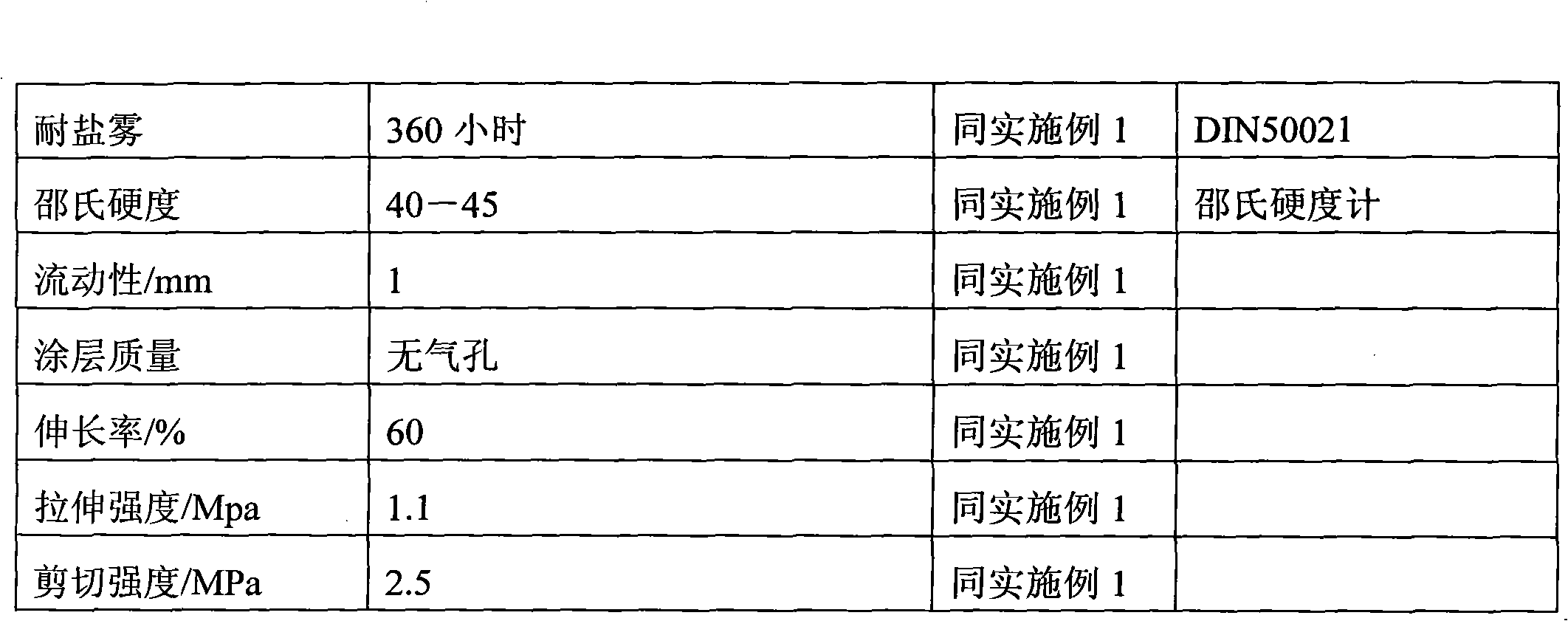

Examples

Embodiment 1

[0023] A water-based damping paint comprises the following components by weight percentage: 30% of acrylic emulsion, 10% of PUD, 5% of protective colloid, 46% of filler, and 9% of deionized water.

[0024] The filler includes 3% of precipitated barium sulfate, 6% of talcum powder, 5% of mica powder, 11% of light calcium carbonate, 12% of wollastonite powder, 4% of expansive soil, 4% of titanium dioxide and 1% of carbon black. The protective colloid is a mixture of hydroxyethyl cellulose and sodium poly(meth)acrylate. The PUD is an aqueous polyurethane dispersion.

[0025] Preparation method: According to the production volume, select equipment and tools such as dispersing cylinder and dispersing machine, and select the power of the machine. In principle, the higher the power, the easier it is to disperse the material, and make sure it is clean and trouble-free.

[0026] At room temperature, add half of the formula amount of water into the disperser, start the disperser, and s...

Embodiment 2

[0029] A water-based damping paint comprises the following components by weight percentage: 31% of acrylic emulsion, 11% of PUD, 6% of protective colloid, 43% of filler, and 9% of deionized water.

[0030] The filler includes 3% of precipitated barium sulfate, 5% of talc powder, 5% of mica powder, 10% of light calcium carbonate, 11% of wollastonite powder, 4% of expansive soil, 4% of titanium dioxide and 1% of carbon black. The protective colloid is a mixture of hydroxyethyl cellulose and sodium poly(meth)acrylate. The PUD is an aqueous polyurethane dispersion.

[0031] Preparation method: According to the production volume, select equipment and tools such as dispersing cylinder and dispersing machine, and select the power of the machine. In principle, the higher the power, the easier it is to disperse the material, and make sure it is clean and trouble-free.

[0032] At room temperature, add half of the formula amount of water into the disperser, start the disperser, and sti...

Embodiment 3

[0035] A water-based damping paint comprises the following components by weight percentage: 35% of acrylic emulsion, 8% of PUD, 6% of protective colloid, 43% of filler, and 8% of deionized water.

[0036] The filler includes 3% of precipitated barium sulfate, 5% of talc powder, 5% of mica powder, 10% of light calcium carbonate, 11% of wollastonite powder, 4% of expansive soil, 4% of titanium dioxide and 1% of carbon black. The protective colloid is a mixture of hydroxyethyl cellulose and sodium poly(meth)acrylate. The PUD is an aqueous polyurethane dispersion.

[0037] Preparation method: According to the production volume, select equipment and tools such as dispersing cylinder and dispersing machine, and select the power of the machine. In principle, the higher the power, the easier it is to disperse the material, and make sure it is clean and trouble-free.

[0038] At room temperature, add half of the formula amount of water into the disperser, start the disperser, and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com