Inorganic whisker-modified adhesive sheet for damping and noise reducing

An inorganic whisker, modified technology, applied in the direction of adhesive, epoxy resin glue, film/flake adhesive, etc., to achieve the effect of good damping performance, simple and convenient construction operation, excellent strength and damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the shock-absorbing and noise-reducing film modified by inorganic whiskers, the steps are as follows:

[0022] (1), butyl rubber is plasticized with an open mill;

[0023] (2), the plasticized butyl rubber and the remaining inorganic whiskers, solid tackifying resin, liquid polyisobutylene, liquid epoxy resin, white carbon black, carbon black are mixed with a three-roll mixer or internal mixer Mix evenly and discharge;

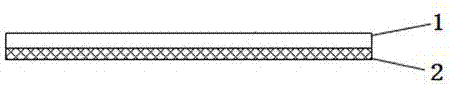

[0024] (3) The uniform material is extruded by a calender to form a damping rubber layer 1, and a layer of isolation reflection layer 2 is bonded on the damping rubber layer (1) to obtain a shock-absorbing and noise-reducing material modified by inorganic whiskers. film.

[0025] Furthermore, butyl rubber, as the main material of the film of the present invention, can provide a higher basic damping performance for the damping system.

[0026] Furthermore, inorganic whiskers are a transition state between fibers and particles...

Embodiment 1

[0035] Embodiment 1: A kind of inorganic whisker-modified shock-absorbing and noise-reducing film, the damping rubber layer 1 comprises the raw material composition of following parts by weight: 100 parts of butyl rubber, 200 parts of calcium sulfate whiskers, 40 parts of rosin resin, 100 parts of liquid epoxy resin, 60 parts of liquid polyisobutylene, 40 parts of white carbon black;

[0036] Preparation process: ① Masticate butyl rubber with an open mill; ② Use a three-roller to knead butyl rubber and the remaining calcium sulfate whiskers, rosin resin, liquid epoxy resin, liquid polyisobutylene, and white carbon Mix black evenly; ③ Extrude the mixture with a calender to form a damping rubber layer 1, and glue a layer of 0.1mm thick glass fiber cloth on the damping rubber layer 1; ④ Cut it according to the required size.

[0037] Preparation process: ①Multify the butyl rubber with an open mill; ②Use a three-roll machine to mix the plasticized butyl rubber and the remaining ma...

Embodiment 2

[0038] Embodiment 2: A kind of shock-absorbing and noise-reducing film modified by inorganic whiskers, the damping rubber layer 1 comprises the raw material composition of following parts by weight: 100 parts of butyl rubber, 350 parts of zinc oxide whiskers, 40 parts of petroleum resin, 20 parts of terpene resin, 240 parts of liquid epoxy resin, 60 parts of carbon black;

[0039] Preparation process: ① Masticating butyl rubber with an open mill; ② Using an internal mixer to knead butyl rubber and the remaining zinc oxide whiskers, petroleum resin, terpene resin, liquid epoxy resin, and carbon black Mix evenly; ③ Extrude the mixture with a calender to form the damping rubber layer 1, and bond a layer of non-woven fabric with a thickness of 0.3mm on the damping rubber layer 1; ④ Cut it according to the required size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com