Supported composite photocatalytic coating and preparation method thereof

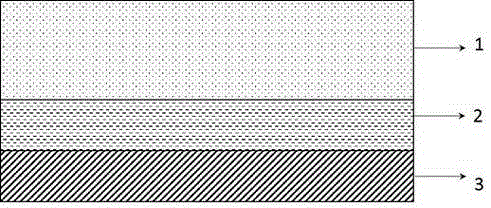

A technology of composite photocatalysis and photocatalytic layer, which is applied in the fields of wall decoration, building roof and building curtain wall, can solve the problems of limited application and low quantum efficiency, and achieves the effect of realizing building environmental protection, simple preparation method and preventing carbonization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) After removing the dust, dirt and impurities on the surface of the substrate, let it dry naturally for 3 hours to ensure that the surface of the substrate is clean and dry;

[0026] 2) Mix 5% 30-mesh glass powder and 15% nano-SiO 2 Add it to 80% silicone resin, stir evenly, apply it on the surface of the substrate, and form a waterproof adhesive layer after curing;

[0027] 3) 40% mica, 20% nano TiO 2 , 40%g-C 3 N 4 The supported photocatalyst was prepared after high-energy ball milling for 45 minutes, and the rotation speed was 400 r / min;

[0028] 4) Mix 4% loaded photocatalyst, 1% styrene-acrylic emulsion and 95% water evenly, spray on the waterproof adhesive layer, and dry for 30 minutes after spraying to make a loaded composite photocatalytic coating.

Embodiment 2

[0030] 1) After removing the dust, dirt and impurities on the surface of the substrate, let it dry naturally for 2 hours to ensure that the surface of the substrate is clean and dry;

[0031] 2) Mix 15% 40-mesh glass powder and 5% nano-SiO 2 Add it to 80% silicone resin, stir evenly, apply it on the surface of the substrate, and form a waterproof adhesive layer after curing;

[0032] 3) 40% bentonite, 25% nano TiO 2 , 35%g-C 3 N 4 The loaded photocatalyst was prepared after high-energy ball milling and mixing for 50 minutes, and the rotation speed was 500r / min;

[0033] 4) Take 6% loaded photocatalyst, 3% silicone acrylic emulsion and 91% water and mix evenly, spray on the waterproof adhesive layer, and dry for 10 minutes after spraying to make a loaded composite photocatalytic coating.

Embodiment 3

[0035] 1) After removing the dust, dirt and impurities on the surface of the substrate, let it dry naturally for 5 hours to ensure that the surface of the substrate is clean and dry;

[0036] 2) Mix 15% 50-mesh glass powder and 35% nano-SiO 2 Add it to 60% silicone resin, stir evenly, apply it on the surface of the substrate, and form a waterproof adhesive layer after curing;

[0037] 3) 50% zeolite, 35% nano TiO 2 , 15%g-C 3 N 4 High-energy ball milling and mixing for 30 minutes to make a supported photocatalyst, the rotation speed is 600r / min;

[0038] 4) Take 7% loaded photocatalyst, 4% polypropylene emulsion and 89% water to mix and spray evenly on the waterproof adhesive layer, and dry for 60 minutes after spraying to make a loaded composite photocatalytic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com