Temperature sensing cable material with CRT characteristics and preparation method thereof

A temperature-sensing cable and characteristic technology, applied in the direction of organic insulators, plastic/resin/wax insulators, rubber insulators, etc., can solve the problems of lower resistivity and rigid characteristics that cannot be realized in flexible cable manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The embodiment of the present invention also provides a method for preparing a temperature-sensitive cable material with CRT characteristics. The specific steps are: use a high-speed mixer to add each material according to the proportion and then mix it at a low speed for 3-10 minutes;

[0047] Then mix at a high speed for 5-10 minutes to obtain a mixed powder, extrude the mixed powder through an extruder at 120-200° C., and shape it to obtain a temperature-sensitive cable material with CTR characteristics.

Embodiment 1

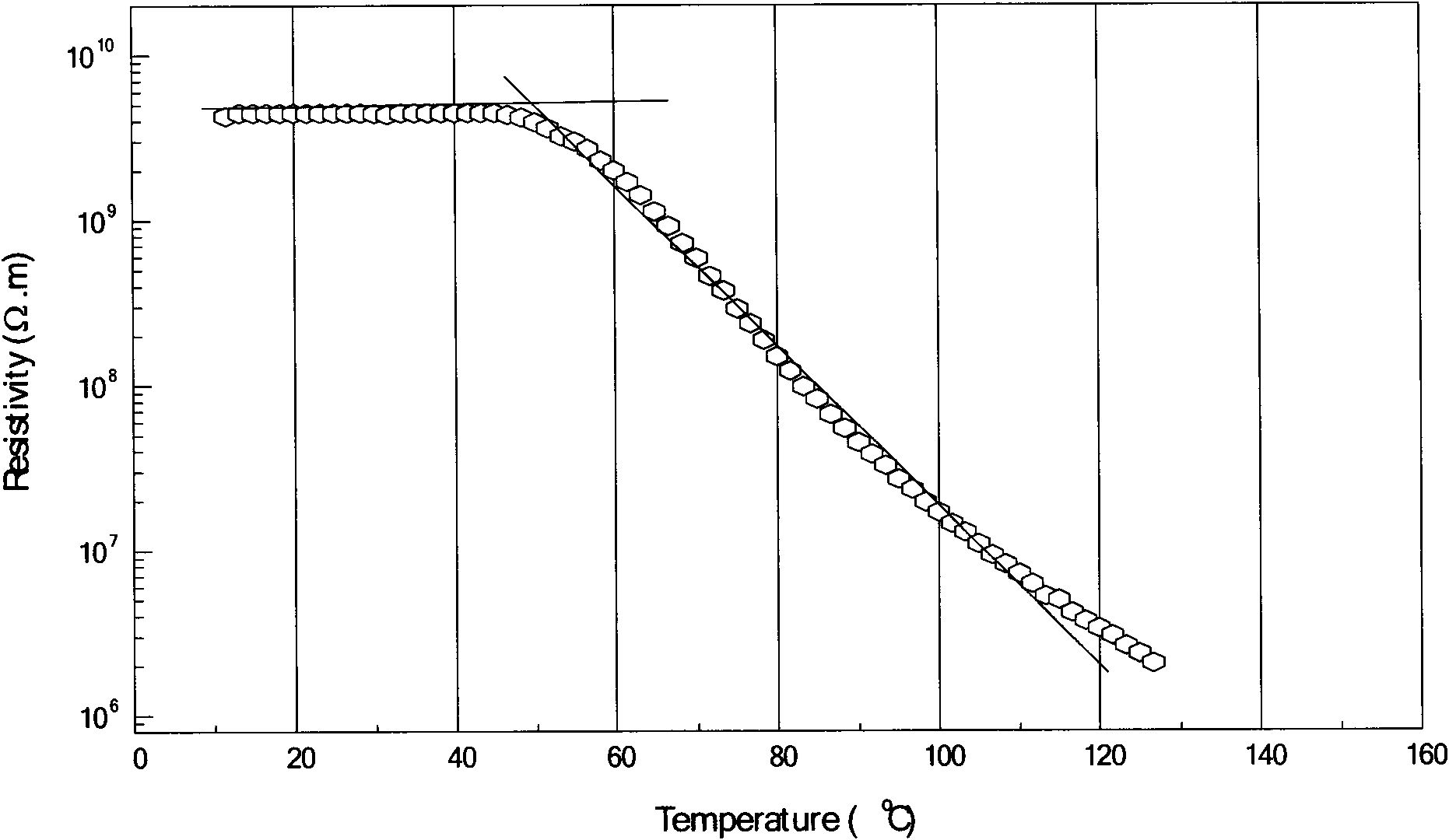

[0049]Take 100 parts of polyvinyl chloride, 10 parts of fumed white carbon black, 20 parts of dibutyl phthalate, 10 parts of organic-inorganic composite functional additives mainly based on zinc oxide, 2 parts of dibutyltin dilaurate, dibutyltin trioxide Add 1 part of antimony and 1 part of antioxidant 1010 into a high-speed mixer, mix at a low speed of 200rpm for 3 minutes, and then mix at a high speed of 1000rpm for 5 minutes to obtain a mixed powder, which is extruded at 160°C by a single-screw extruder Cable granules are obtained by granulation. The pellet sample was hot-pressed at 160°C into a sample sheet with a thickness of 1mm, and the resistivity-temperature change was measured on a megger to obtain a cable material with CTR characteristics with a critical temperature of 50°C. Resistivity-temperature change curve such as figure 1 .

Embodiment 2

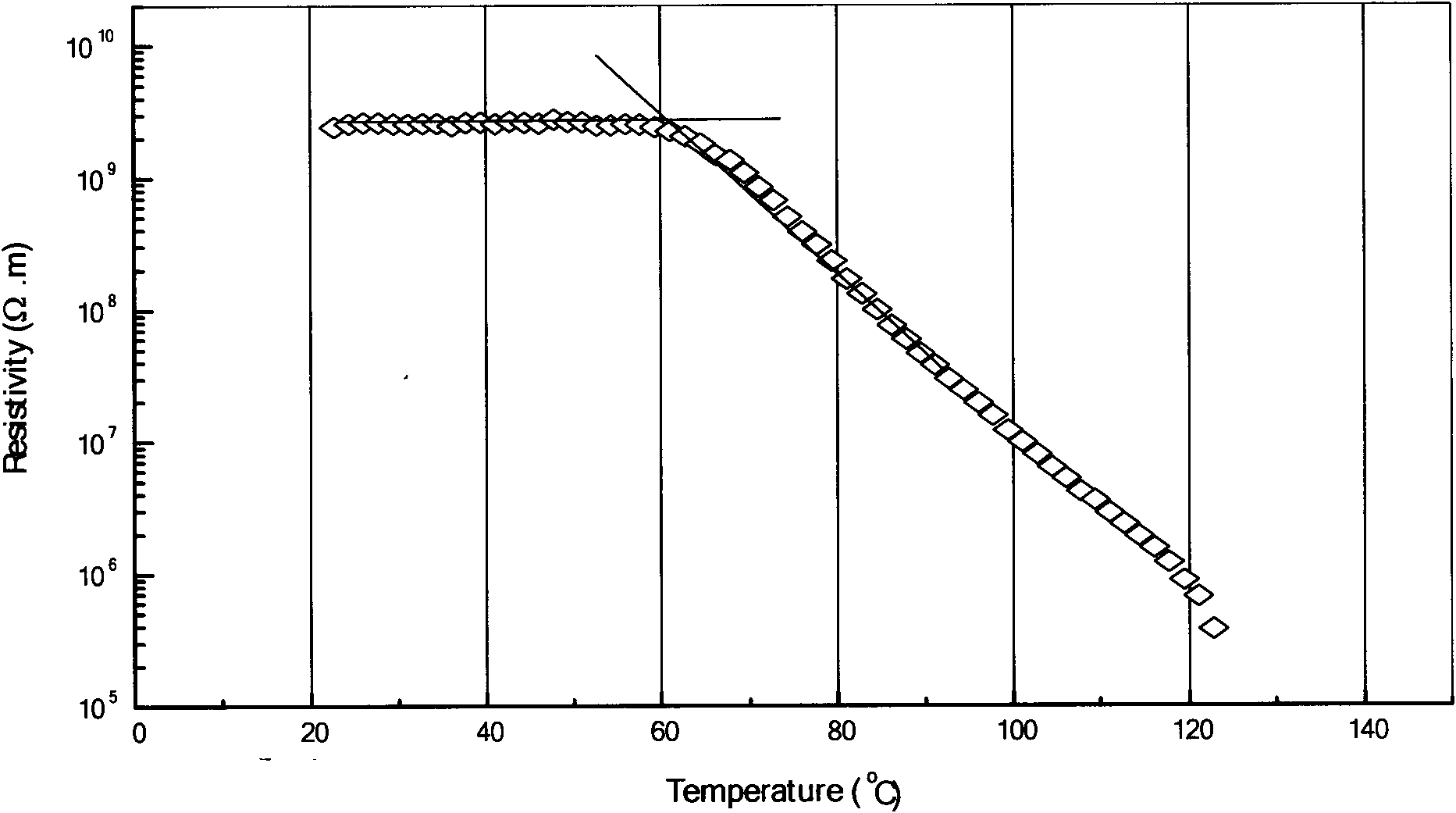

[0051] Take 50 parts of polyvinyl chloride, 50 parts of chlorinated polyethylene, 10 parts of fumed silica, 10 parts of triphenyl phosphite, 10 parts of dioctyl phthalate, organic and inorganic compounds mainly composed of chromium oxide and vanadium oxide Add 5 parts of composite functional additives, 2 parts of dibutyltin maleate, 2 parts of microcrystalline paraffin, 5 parts of magnesium hydroxide, and 1 part of antioxidant 264 into a high-speed mixer, first mix at a low speed of 200rpm for 3 minutes, and then Mix at a high speed of 1000 rpm for 5 minutes to obtain a mixed powder, which is extruded and pelletized at 160° C. by a single-screw extruder to obtain cable pellets. The pellet sample was hot-pressed at 160°C into a sample sheet with a thickness of 1mm, and the resistivity-temperature change was measured on a megger to obtain a cable material with CTR characteristics with a critical temperature of 60°C. Resistivity-temperature change curve such as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com