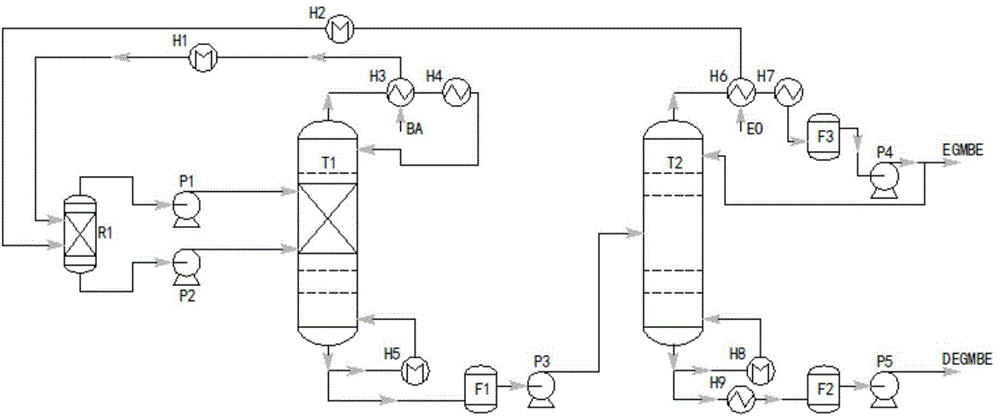

Device and processing method for synthesis of ethylene glycol monobutyl ether through reactive distillation

A technology of ethylene glycol monobutyl ether and reactive distillation, which is applied in the fields of ether preparation, chemical industry, and alkylene oxide preparation ether, etc., which can solve the problems of easy side reactions, difficulty in improving production efficiency, and difficulty in large-scale continuous production and other problems to achieve the effect of solving unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The reaction section of the reactive distillation column is 20 trays (reactive distillation trays); the first stripping section is 15 trays, the upper feed port of the reaction section corresponds to the third tray, and the lower feed port of the reaction section corresponds to The 18th tray; the rectification section of the ethylene glycol monobutyl ether refining tower has 12 trays, and the second stripping section has 5 trays.

[0040] N-butanol and ethylene oxide enter the reactor through preheating, and after preheating, the temperature of n-butanol and ethylene oxide reaches 45°C when entering the reactor. The feed molar ratio of ethylene oxide and n-butanol was 1:2. The reaction temperature in the reactor is 120° C., and the reaction pressure is 0.5 MPa (gauge pressure). In the reactive distillation tower, the reaction temperature is 100°C, the operating pressure is 0.1 MPa (gauge pressure), and the top of the tower is total reflux. When the reactor of the reac...

Embodiment 2

[0043] The reaction section of the reactive distillation tower is a 22-layer tray (reactive distillation tray); the first stripping section is a 12-layer tray, the upper feed port of the reaction section corresponds to the 4th tray, and the lower feed port of the reaction section corresponds to The 18th tray; the rectification section of the ethylene glycol monobutyl ether refining tower has 10 trays, and the second stripping section has 6 trays.

[0044] N-butanol and ethylene oxide enter the reactor through preheating, and after preheating, the temperature of n-butanol and ethylene oxide reaches 45°C when entering the reactor. The feed molar ratio of ethylene oxide and n-butanol was 3:1. The reaction temperature in the reactor is 100° C., and the reaction pressure is 0.1 MPa (gauge pressure). In the reactive distillation tower, the reaction temperature is 120° C., the operating pressure is 0.01 MPa (gauge pressure), and the top of the tower is total reflux. When the reacto...

Embodiment 3

[0047] The reaction section of the reactive distillation column is 25 trays (reactive distillation trays); the first stripping section is 14 trays, the upper feed port of the reaction section corresponds to the 4th tray, and the lower feed port of the reaction section corresponds to The 18th tray; the rectification section of the ethylene glycol monobutyl ether refining tower has 10 trays, and the second stripping section has 7 trays.

[0048] The n-butanol and ethylene oxide enter the reactor through preheating, and after preheating, the temperature of n-butanol and ethylene oxide reaches 100°C when entering the reactor. The feed molar ratio of ethylene oxide and n-butanol was 8:1. The reaction temperature in the reactor is 30° C., and the reaction pressure is 0.01 MPa (gauge pressure). In the reactive distillation tower, the reaction temperature is 40° C., the operating pressure is 0.5 MPa (gauge pressure), and the top of the tower is total reflux. When the reactor of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com