Insulation environment friendly paint for non-oriented electrical steel

A technology of oriented electrical steel and insulating coating, applied in the direction of coating, etc., to achieve the effect of bright and uniform surface, good insulation and good wettability

Active Publication Date: 2009-02-04

SHOUGANG CORPORATION

View PDF3 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, compared with the traditional chromate coating, there is still a certain gap between the new chromium-free environmental protection coating in terms of wettability, heat resistance, adhesion, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

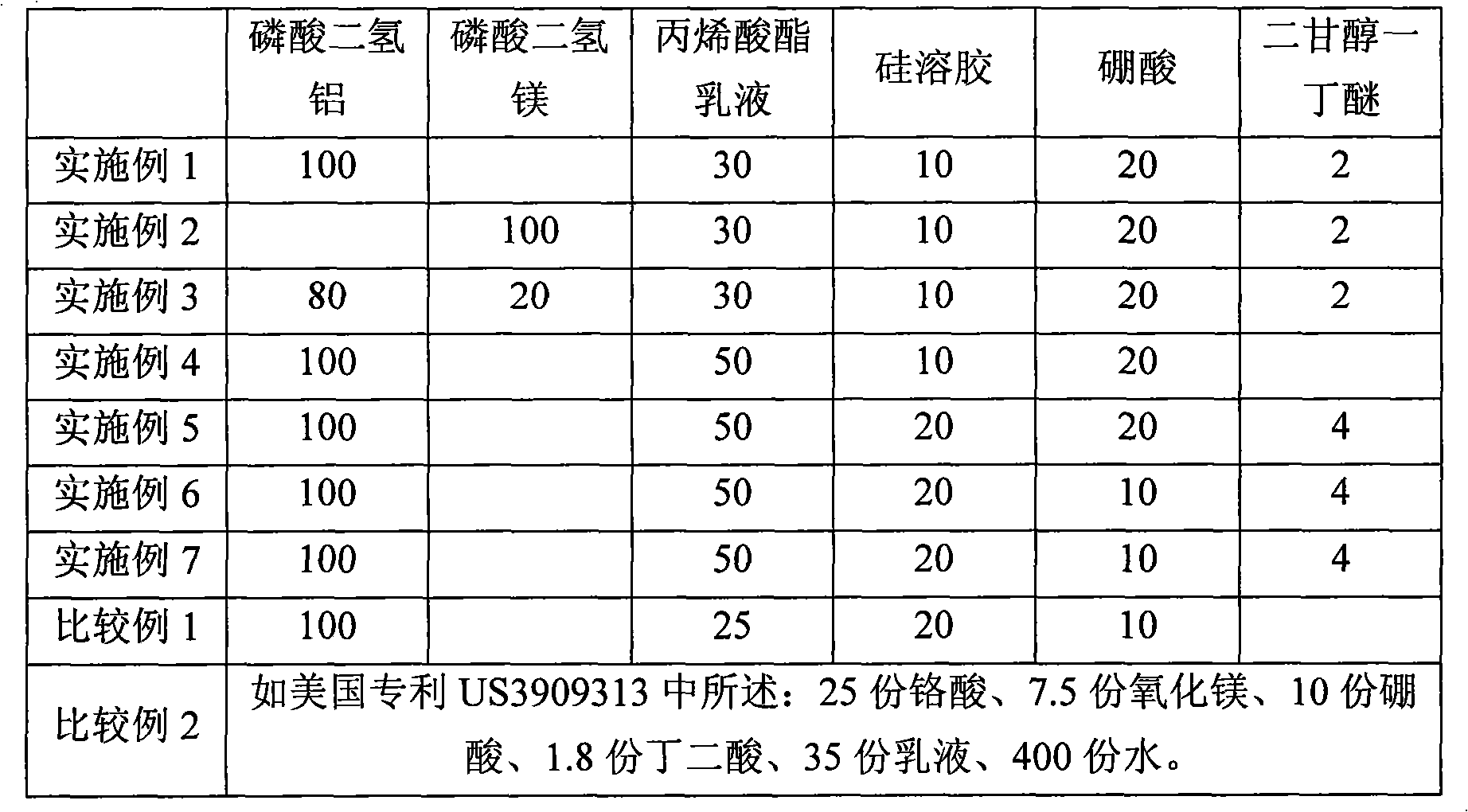

[0027] Each component and its content of the embodiment of the present invention and the corresponding comparative example are shown in Table 1, and the coating of the present invention is prepared according to Table 1.

[0028] Table 1: Coating composition (the contents of all components are calculated according to the dry weight of the substance)

[0029]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an insulating, environment-friendly coating for non-oriented electrical steel, which belongs to the technical field of electrical steel coatings. The coating contains the following ingredients calculated according to the dry weights of the substances: 20 percent to 60 percent of dihydric phosphate; 20 percent to 40 percent of acrylate emulsion; 2 percent to 20 percent of boracic acid; 0.5 percent to 15 percent of silicasol; 0 percent to 5 percent of diethylene glycol monobutyl ether; all are weight percentages. The coating of the present invention is an environment-friendly coating which does not contain chrome; the coating, the surface of which is shiny and uniform, has good insulating property, adhesive property, rust-resisting property and heat-resisting property; moreover, the coating has good wetting property and is characterized by convenient coating and little foam amount.

Description

technical field [0001] The invention belongs to the technical field of electrical steel coatings, in particular to an insulating and environmentally friendly coating for non-oriented electrical steels. Background technique [0002] Electrical steel sheet is an important magnetic material, and non-oriented electrical steel is widely used in the iron core of motors such as electric motors, generators, and small transformers. When manufacturing iron cores, it is necessary to continuously punch and cut electrical steel sheets into iron core-shaped blanks, and fix the edges of a certain number of stacked chips by welding. In order to reduce eddy current loss, an insulating coating is applied to the surface of the steel plate to insulate the layers from each other. [0003] Coating is the last process of electrical steel production. The type, process and quality of coating will have a significant impact on the mutual insulation, adhesion, punching, weldability and corrosion resis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D133/04C09D5/25

Inventor 耿立王崇学王全礼罗文彬周谊军

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com