Organic-inorganic hybrid silica modified acrylic resin and coating thereof

A technology of acrylic resin and silicon dioxide, applied in anti-corrosion coatings, coatings, etc., can solve the problems of easy carcinogenicity, high environmental pollution, and high toxicity, and achieve good corrosion resistance, improved shielding performance, and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

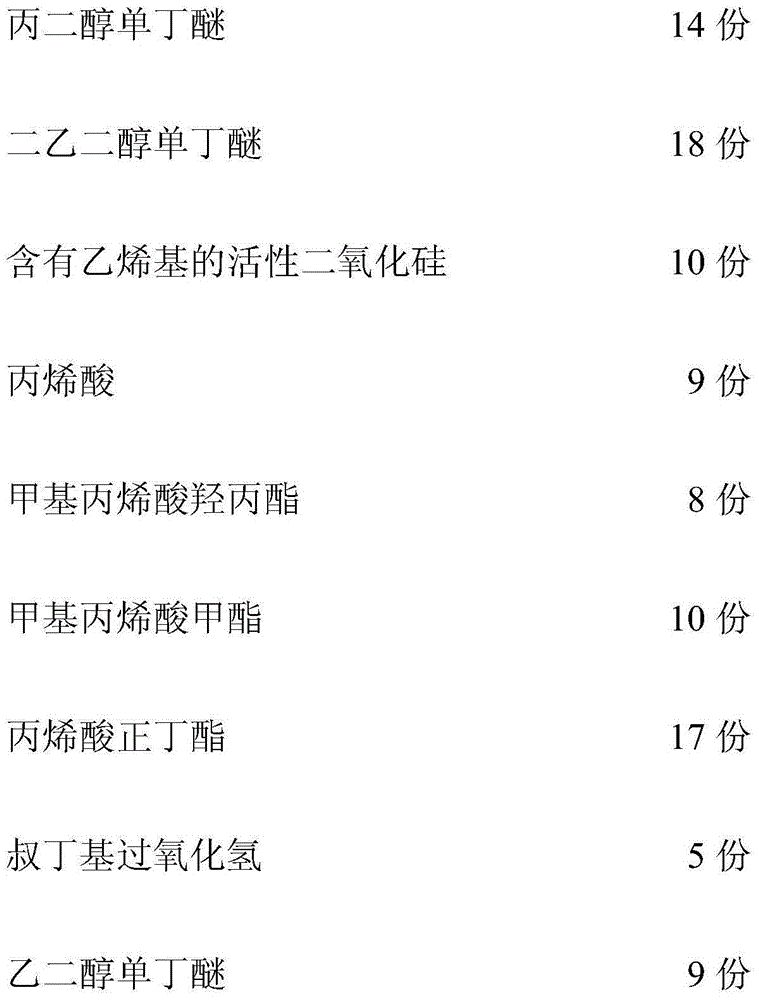

[0021] 1) The formula of the machine-inorganic hybrid silica-modified acrylic resin:

[0022]

[0023] Mix active silicon dioxide containing vinyl, acrylic acid, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, and part of tert-butyl hydroperoxide evenly according to the formula amount, and it is called mixed solution a ; Mix part of tert-butyl hydroperoxide and ethylene glycol monobutyl ether evenly according to the formula quantity, which is called mixed solution b. Add propylene glycol monobutyl ether and diethylene glycol monobutyl ether into a reaction vessel with a stirrer and a condenser according to the formula, blow nitrogen gas, raise the temperature to 115°C, start adding the mixed solution a dropwise, and keep it warm after 3 hours Half an hour, then drop the mixed solution b, drop it for half an hour, then keep it warm for 2 hours, then cool down to below 45°C and discharge to obtain the organic-inorganic hybrid silica-modified acrylic resin; ...

Embodiment 2

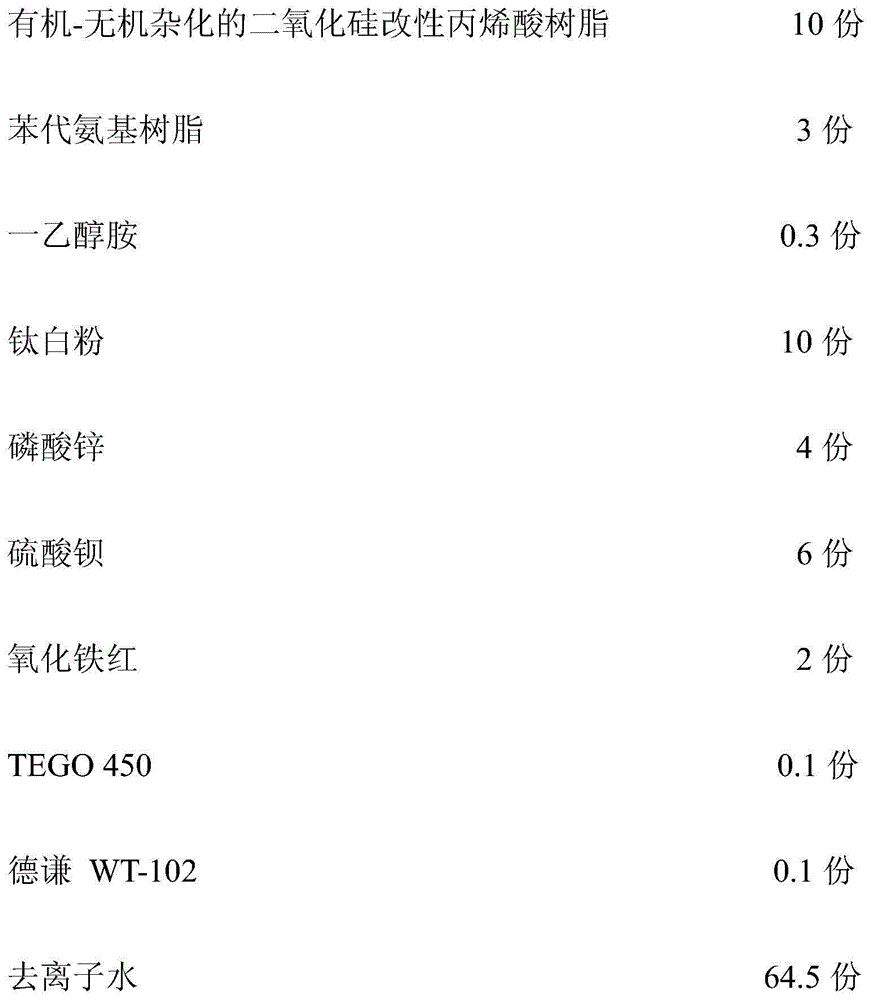

[0028] 1) The formula of the machine-inorganic hybrid silica-modified acrylic resin:

[0029]

[0030] Mix active silicon dioxide containing vinyl, acrylic acid, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, and part of tert-butyl hydroperoxide evenly according to the formula amount, and it is called mixed solution a ; Mix part of tert-butyl hydroperoxide and ethylene glycol monobutyl ether evenly according to the formula quantity, which is called mixed solution b. Add propylene glycol monobutyl ether and diethylene glycol monobutyl ether into a reaction vessel with a stirrer and a condenser according to the formula, blow nitrogen gas, raise the temperature to 115°C, start adding the mixed solution a dropwise, and keep it warm after 3 hours Half an hour, then drop the mixed solution b, drop it for half an hour, then keep it warm for 2 hours, then cool down to below 45°C and discharge to obtain the organic-inorganic hybrid silica-modified acrylic resin; ...

Embodiment 3

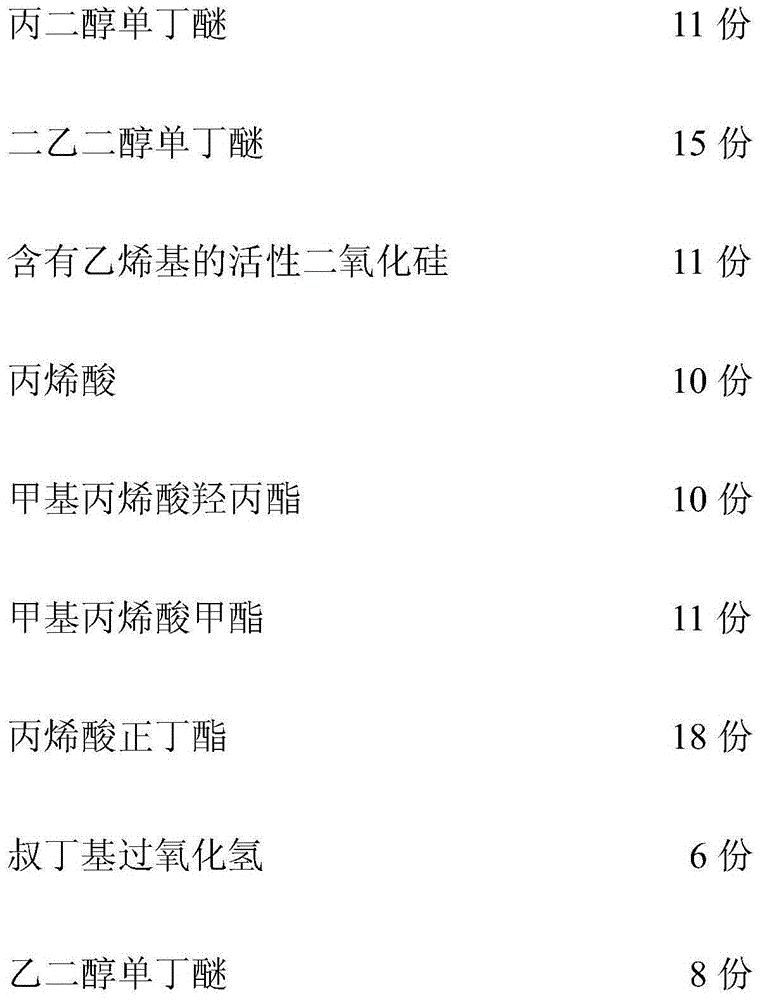

[0035] 1) The formula of the machine-inorganic hybrid silica-modified acrylic resin:

[0036]

[0037] Mix active silicon dioxide containing vinyl, acrylic acid, hydroxypropyl methacrylate, methyl methacrylate, n-butyl acrylate, and part of tert-butyl hydroperoxide evenly according to the formula, and it is called mixed solution a ; Mix part of tert-butyl hydroperoxide and ethylene glycol monobutyl ether evenly according to the formula quantity, which is called mixed solution b. Add propylene glycol monobutyl ether and diethylene glycol monobutyl ether into the reaction vessel with agitator and condenser according to the formula, blow nitrogen gas, heat up to 115°C, start adding the mixed solution a dropwise, keep it warm after 3 hours Half an hour, then drop the mixed solution b, drop it for half an hour, then keep it warm for 2 hours, then cool down to below 45°C and discharge to obtain the organic-inorganic hybrid silica-modified acrylic resin;

[0038] 2) the organic-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com