Cylinder cover with double sparking plugs

A technology of double spark plugs and spark plug holes, which is applied in the directions of cylinder heads, cylinders, and engine components, can solve the problems of unreasonable gas distribution, unreasonable spark plug arrangement, and unsatisfactory combustion characteristics, so as to reduce the flame propagation distance and improve the Combustion stability, effect of large compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

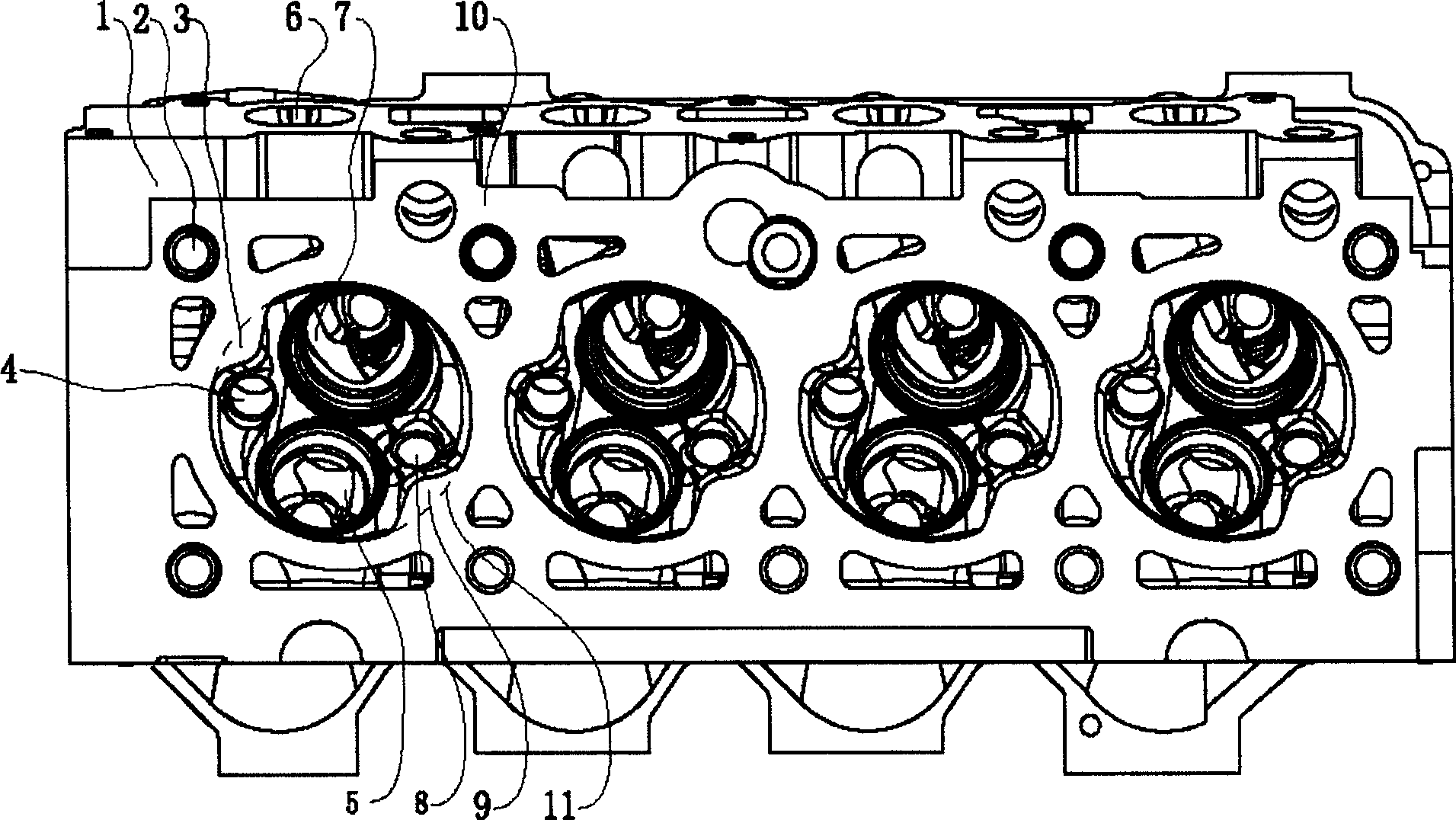

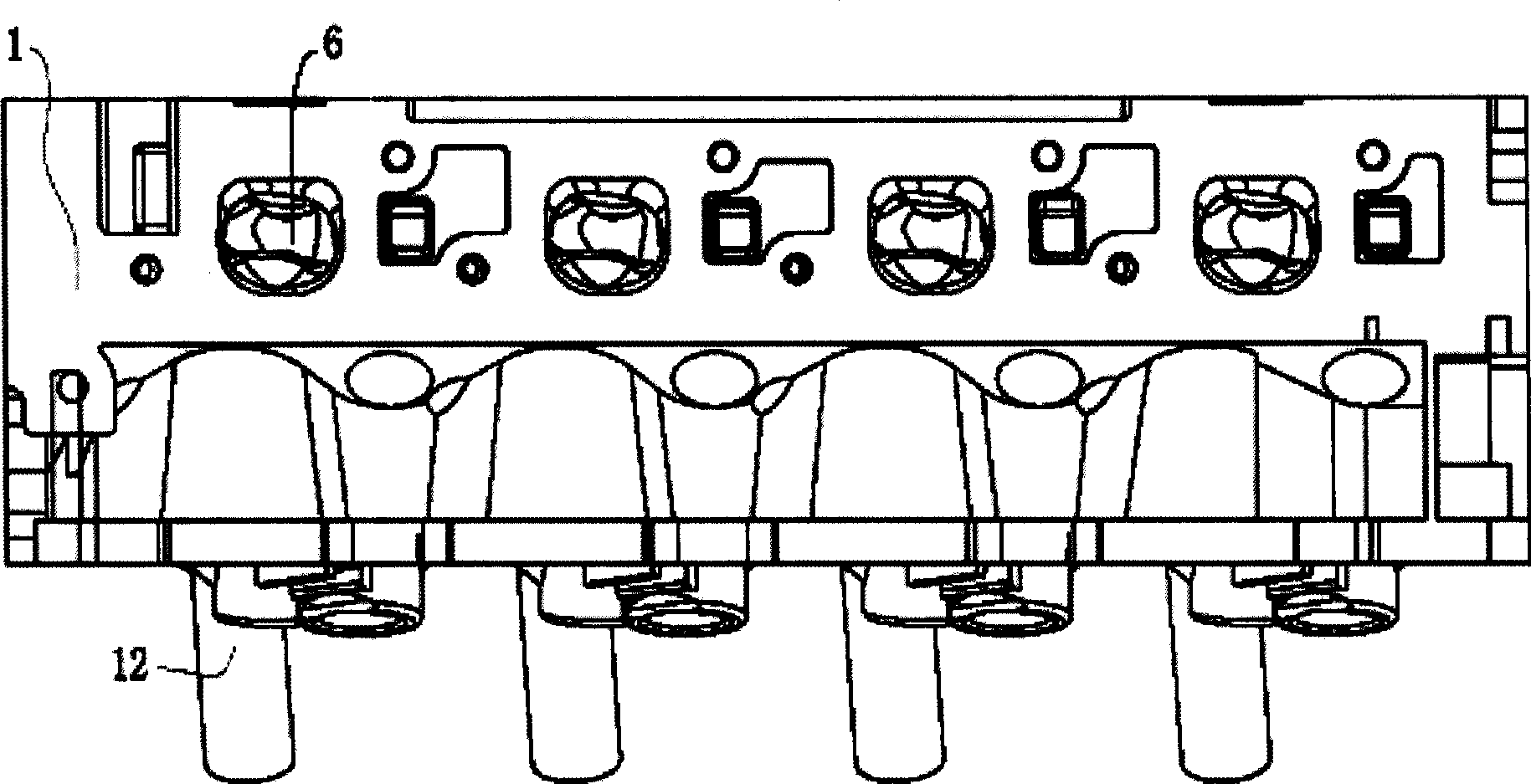

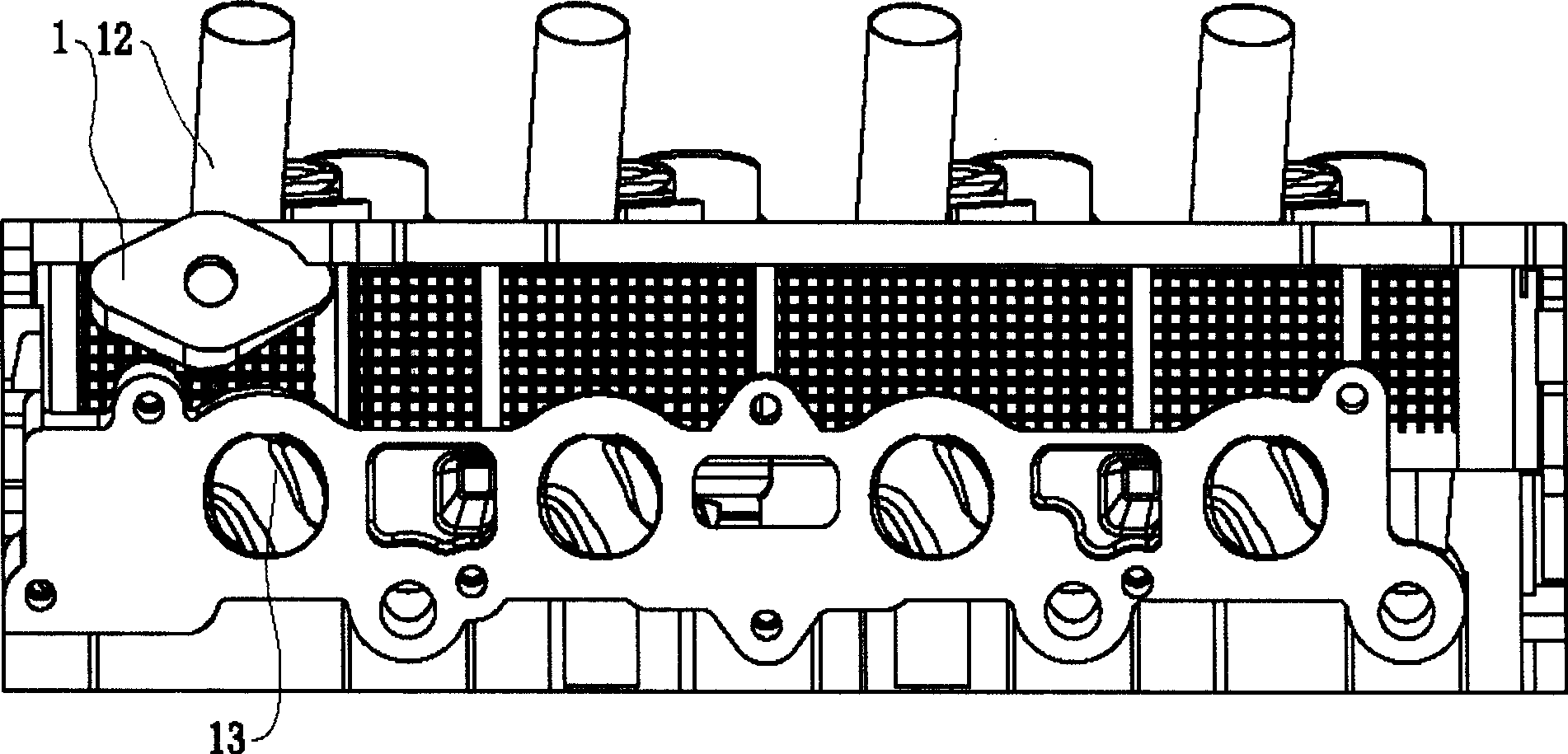

[0018] exist figure 1 , 2 , 3, 4, 5, 6, a double spark plug cylinder head, including at least one spherical combustion chamber 11, the spherical combustion chamber 11 is provided with an air inlet 7, an exhaust port 5, the first spark plug hole 4 and the second Spark plug hole 8; air inlet 7 communicates with intake channel 6, and exhaust port 5 communicates with exhaust channel 13; There are first squeezer 3 and second squeezer at the bottom plane circumference of described combustion chamber 11 near spark plug hole position flow piece9. The first squeeze piece 3 and the second squeeze piece 9 are provided with a squeeze surface on the bottom plane of the combustion chamber 11, and the line connecting the projected sides of the bottom plane is an obtuse triangle; the distance from the spark plug hole is 5-20mm; Its area is 30-150mm 2 . The first spark plug hole 4 is located in the middle of the area on one side of the intake port 7 and the exhaust port 5, and is inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com