Energy-saving type low-temperature-difference ultra-wide ultra-long tunnel sintering kiln

An energy-saving, firing kiln technology, used in the field of ceramic firing kilns, can solve the problems of high unit cost, unstable quality control of fired products, and high unit energy consumption of fired products, reducing unit costs and improving kiln internals. Temperature and quality guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

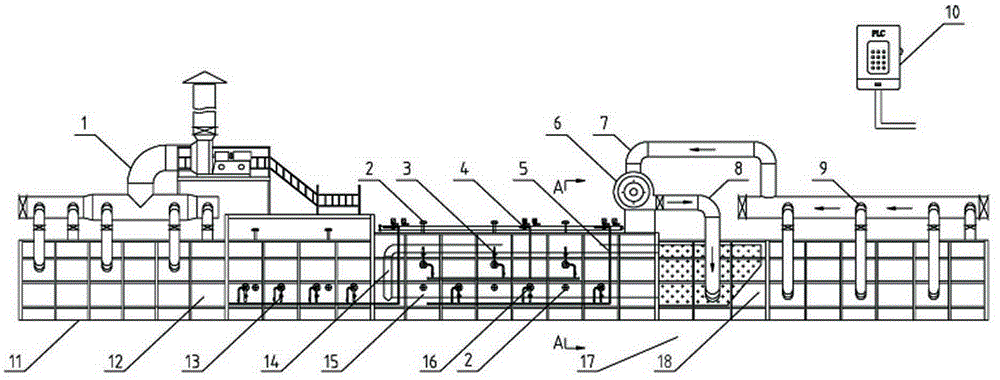

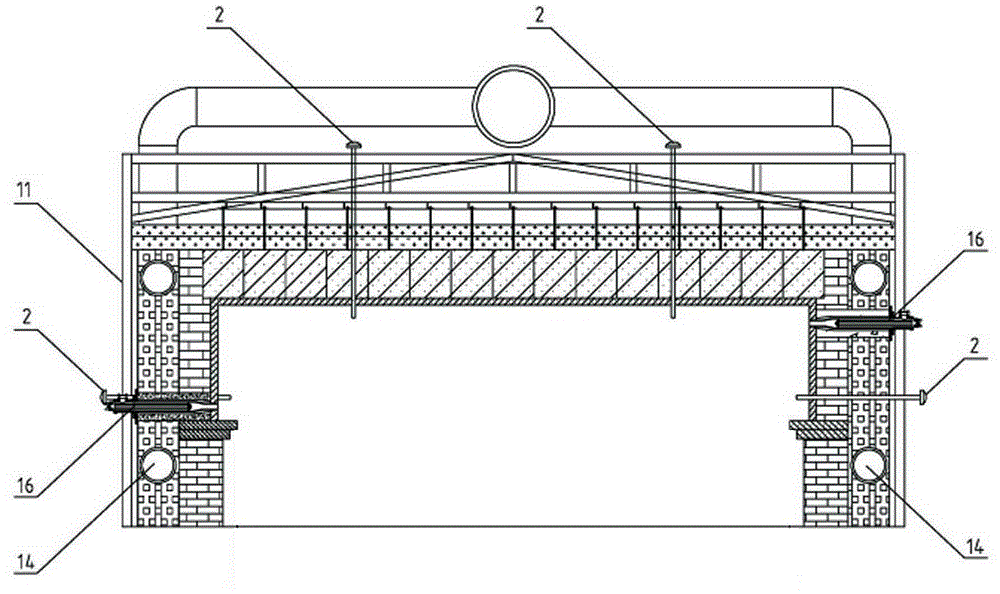

[0020] see figure 1 , figure 2 , a kind of energy-saving low-temperature differential ultra-wide ultra-long tunnel firing kiln of the present invention, it has kiln body 11 and control system 10, described kiln body 11 is divided into preheating section 12, firing section 15 and cooling section 18; A combustion-supporting air device 7 is arranged on the kiln body 11. The combustion-supporting air device 7 is provided with an air inlet pipe 9, an air outlet pipe 8 and a hot air pipe 14. The air inlet pipe 9 is arranged on the front and rear side walls of the cooling section 18 of the kiln body. Above, the hot air pipe 14 is located in the wall of the kiln body preheating section 12 and the front and rear side walls of the firing section 15, the preheating section 12 of the kiln body 11 is arranged with a smoke exhaust device 1, the preheating section 12 of the kiln body The hot section 12 and the firing section 15 are arranged with a combustion system 3, and the combustion sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com