Waste heat recovery type hot-water boiler device in bathroom

A hot water boiler and waste heat recovery technology, applied in the energy field, can solve the problem of low efficiency, and achieve the effects of reducing usage, reducing fuel usage, and being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

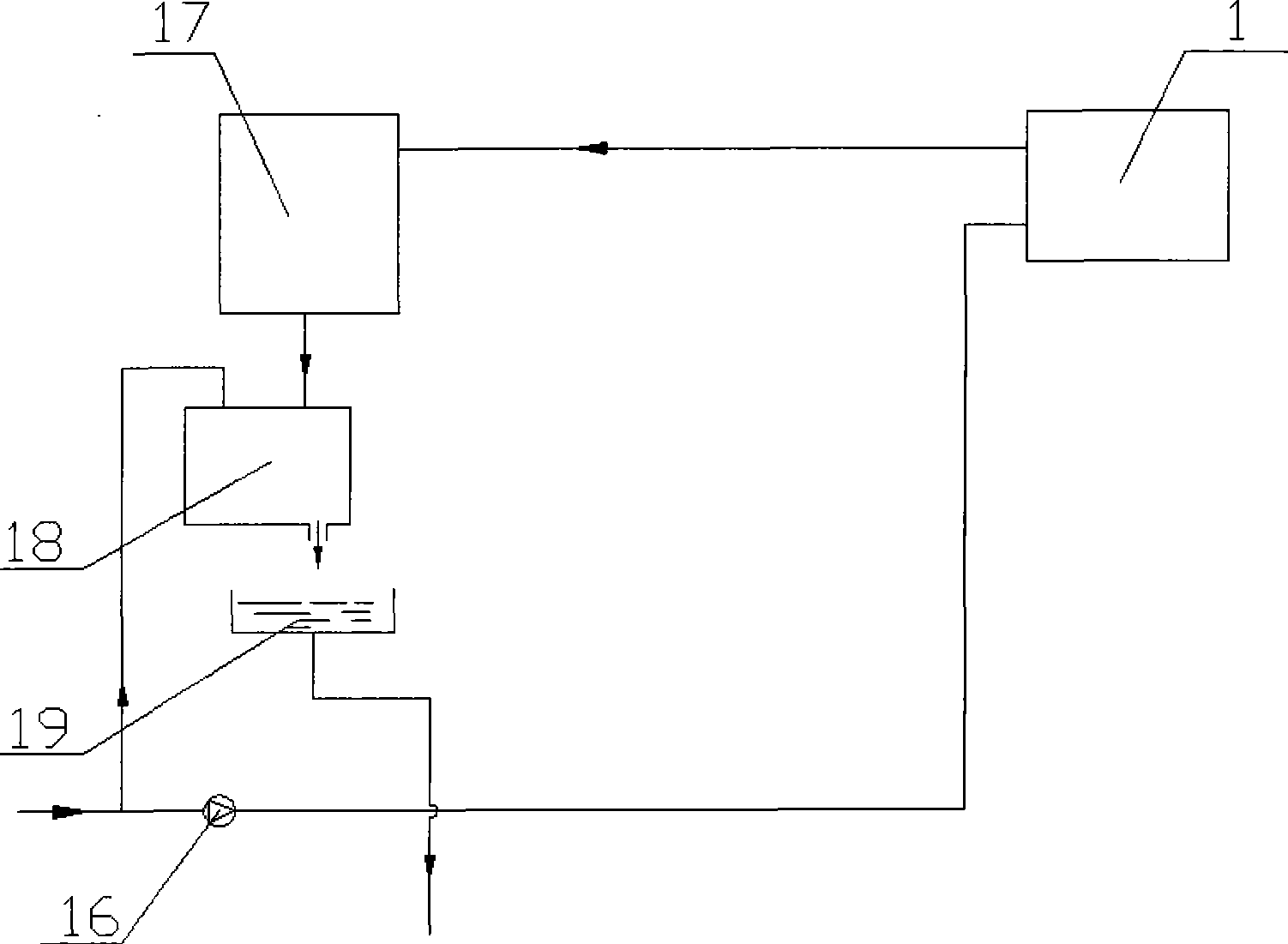

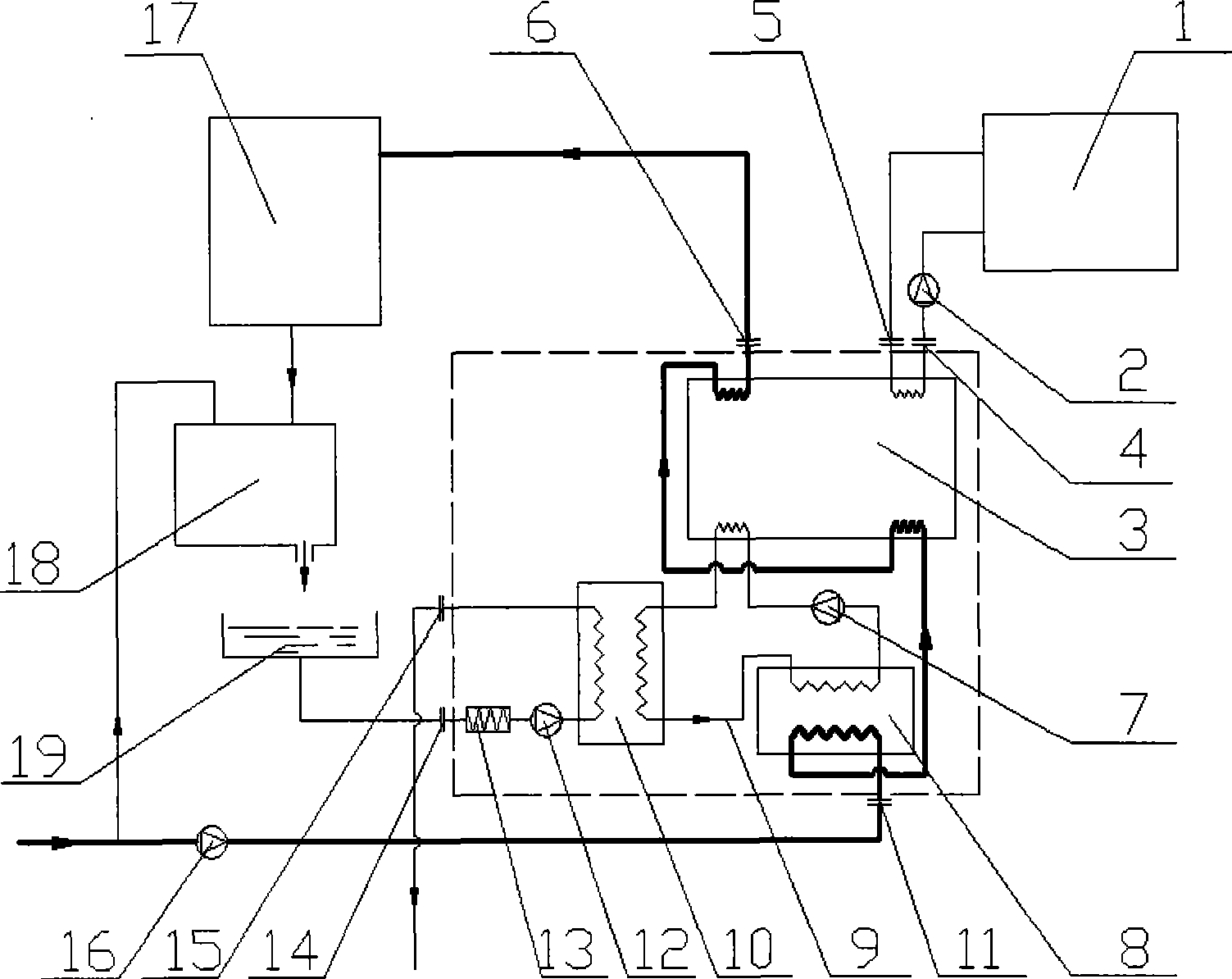

[0019] figure 2 A waste heat recovery type bathroom hot water boiler device disclosed in the present invention is given, which includes a boiler 1, an absorption heat pump unit 3, a sewage heat exchanger 10, a tap water preheater 8, a circulation loop 9, and a hot water storage tank 17. Sewage pool 19, sewage filter 13, feed water pump 16, sewage pump 12, circulating water pump 7, boiler return water pump 2; the present invention mainly figure 1 A set of devices is added on the basis of figure 2 The part framed by the dotted line in the middle, the device has six ports that can be connected to external pipelines, which are respectively the outlet connection port 4 of the absorption heat pump unit generator, the inlet connection port 5 of the absorption heat pump unit generator, and the condensing port of the absorption heat pump unit. Device outlet connection port 6, tap water preheater inlet connection port 11, sewage heat exchanger inlet connection port 14, sewage heat ex...

Embodiment 2

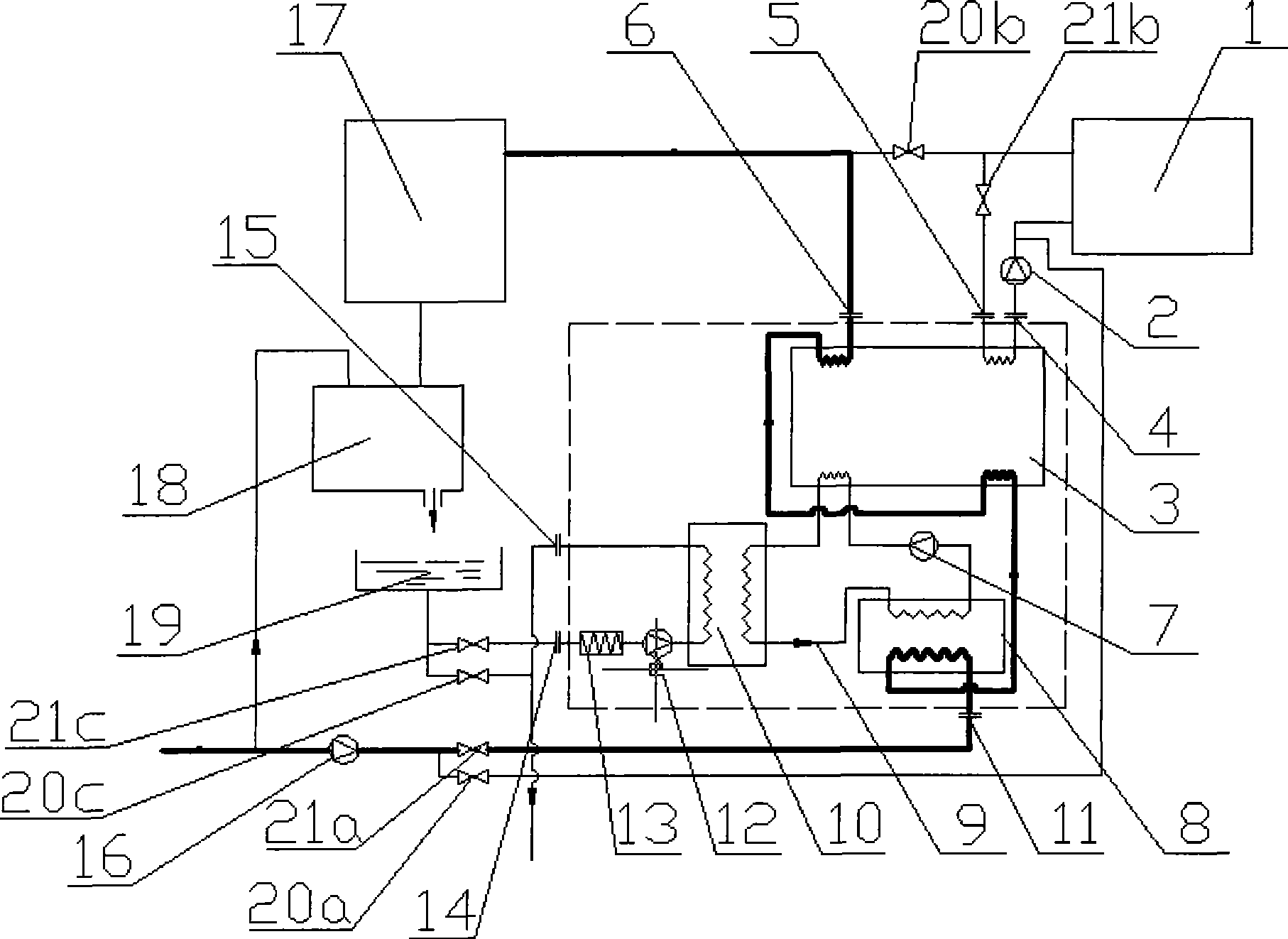

[0021] image 3 It is a working principle diagram of using a waste heat recovery type bathroom hot water boiler device to transform the traditional boiler hot water supply system for bathing. in the right figure 1When the traditional boiler hot water supply system shown in the bath is transformed, a bypass pipeline is set between the outlet of the feed pump 16 and the boiler water inlet, and a first switching valve-20a is arranged on the bypass pipeline, and at the same time A pipeline is set between the outlet of the boiler and the inlet of the hot water storage tank 17, and a second switching valve-20b linked with the first switching valve-20a is arranged on the pipeline; A first switching valve 21a is provided on the pipeline between the inlet connection ports 11, and a second switching valve linked with the first switching valve 21a is set between the boiler outlet and the generator inlet connection port 5 in the absorption heat pump unit. Valve two 21b; a third switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com