Switch and capacitor integrated quick discharge unit

A discharge unit and capacitor technology, applied in the field of fast discharge, can solve the problem of increasing branch inductance, etc., to achieve the effect of increasing output current, reducing module size and branch inductance, and reducing rise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

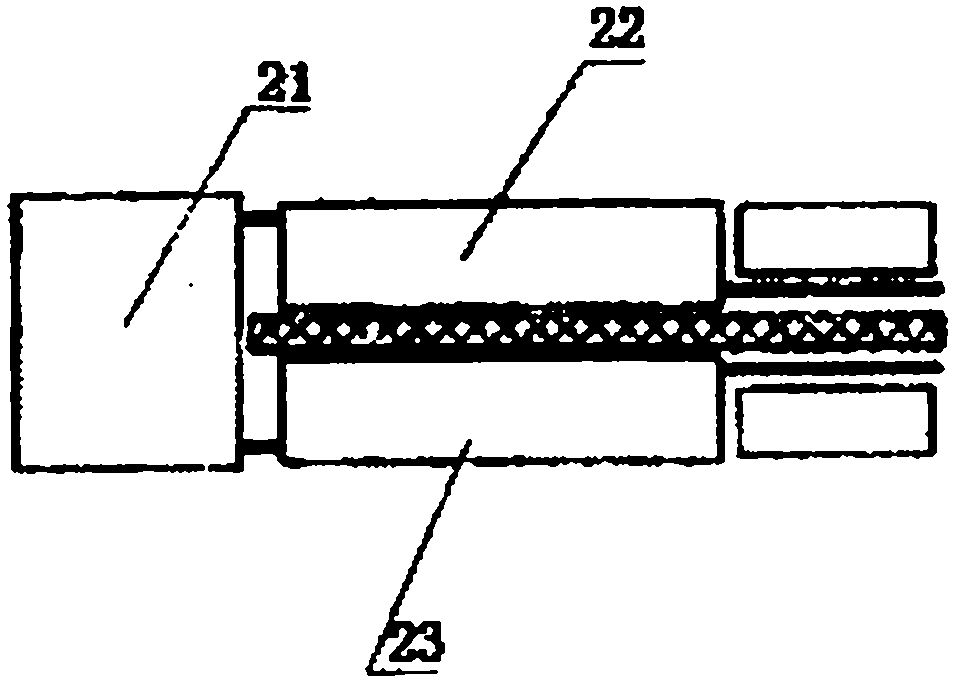

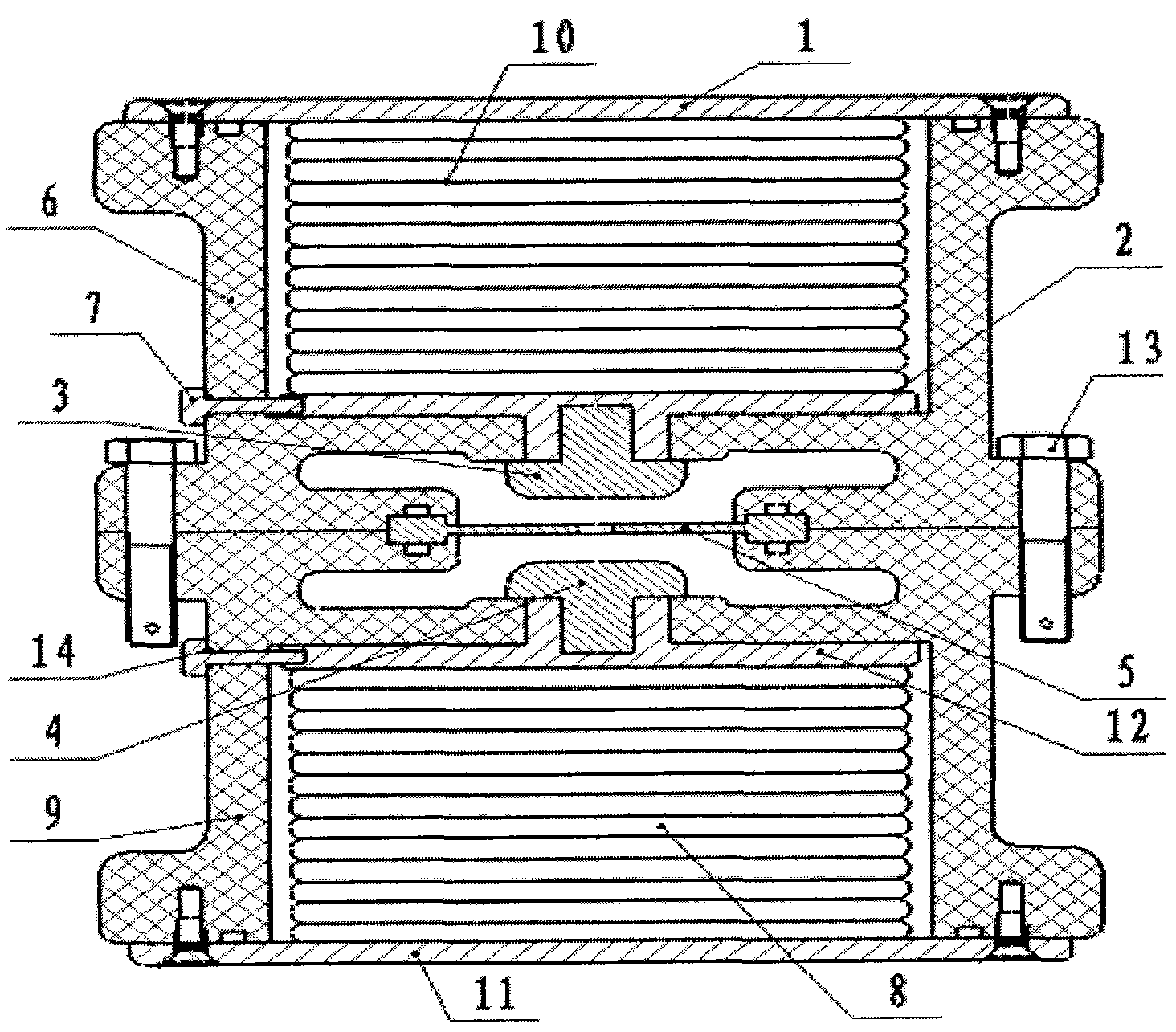

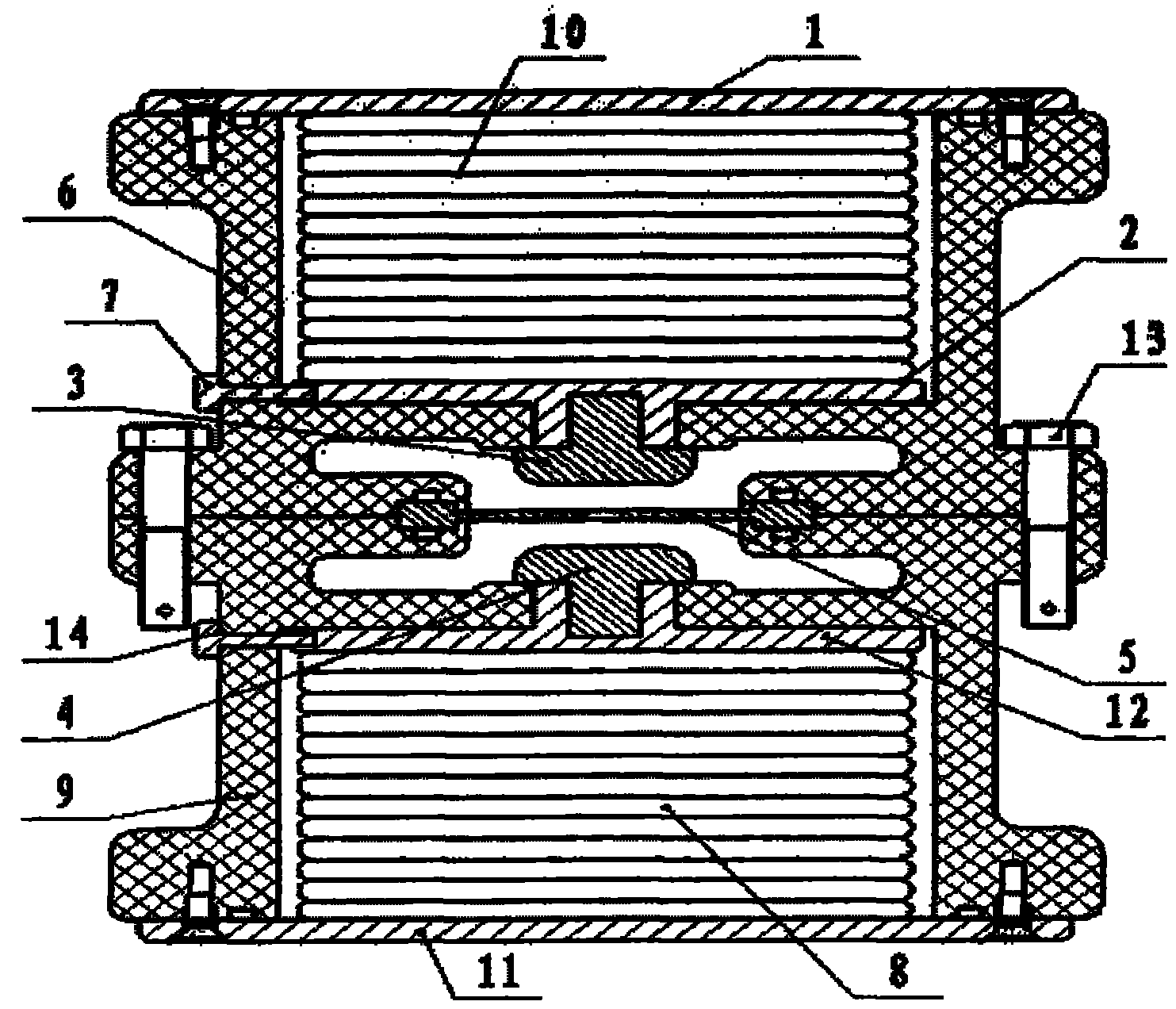

[0018] combine figure 2 Describe the implementation technical scheme of the capacitor and switch integrated single-stage discharge unit, the double-terminal lead-out electrode insert of the capacitor element (10) connected in series, the high-voltage electrode 2 of the upper capacitor, the low-voltage lead-out electrode 1 of the upper capacitor, the insulating shell 6, and the charging lead-in electrode 7 forms a capacitor, the capacitor element 8 is connected in series with the double-terminal lead-out electrode insert, the lower capacitor low-voltage lead-out electrode 11, the lower capacitor high-voltage electrode 12, the insulating case 9, and the charging lead-in electrode 14 forms another capacitor, the capacitor insulating case 6 The lower end face and the upper end face of the capacitor insulating shell 9 form a gas switch sealed chamber through insulating fastening screws 13. The upper and lower high-voltage electrodes 3, 4 of the gas switch and the trigger electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com