Vanadium-raising cooling agent, method for preparing same and use method

A technology for coolant and ferrovanadium, which is applied in the field of metallurgy, can solve the problems of complicated use of coolant and difficult operation of the vanadium extraction process, and achieves the effects of the vanadium extraction process being in the right direction, the method being simple, and the preparation method being simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

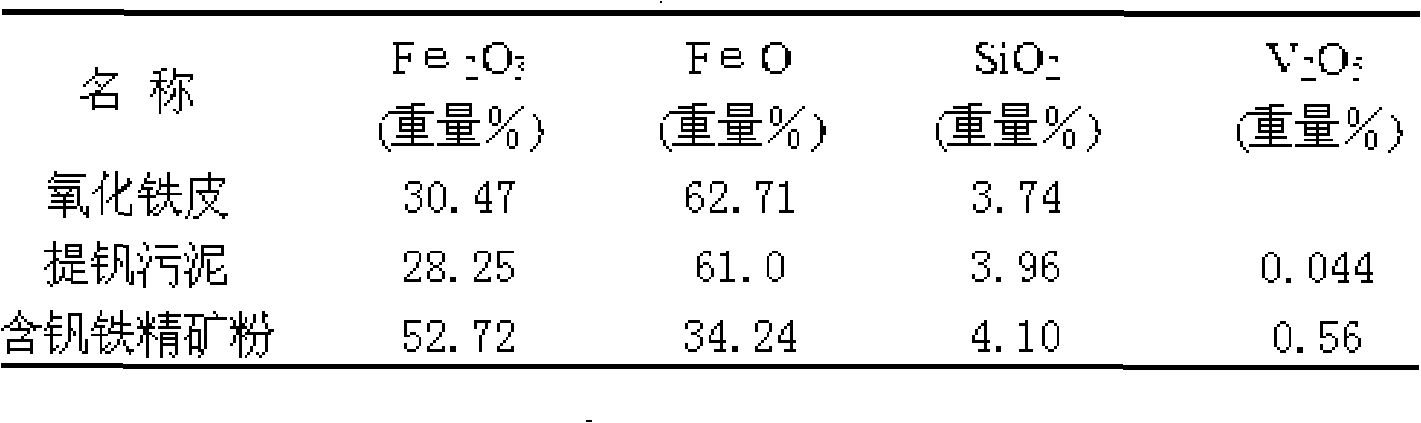

[0032] Put the vanadium-containing iron ore concentrate powder, iron oxide scale, and binder in the above Table 1 into the roller sand mixer with a mass ratio of 20:75:5 for mixing and stirring, and then add them to the symmetrical ball briquetting machine after stirring evenly, and adjust the symmetric briquetting machine. The pressure of the ball machine is 15Mpa, and the spherical particles with a diameter of 8-12mm are extruded, and the spherical particles are naturally dried for 72 hours to obtain the coolant for extracting vanadium from the pellets.

[0033] After testing, the composition of the obtained pellet vanadium extraction coolant is: Fe 2 o 3 36.03%, FeO 55.6%, V 2 o 5 0.15%, SiO 2 4.83%, MgCl 2 2.74%. The prepared pellet vanadium extraction coolant is used for furnace temperature control under the condition of vanadium-containing molten iron converter in Panzhihua Iron and Steel Corporation. The main components of vanadium-containing molten iron are: 4...

Embodiment 2

[0035]Put the vanadium-containing iron ore concentrate powder, iron oxide scale, and binder in the above Table 1 into the roller sand mixer in a mass ratio of 40:55:5 for mixing and stirring, and then add them to the symmetrical ball briquetting machine after stirring evenly, and adjust the symmetric briquetting machine. The pressure of the ball machine is 15Mpa, and the spherical particles with a diameter of 8-12mm are extruded, and the spherical particles are naturally dried for 56 hours to obtain the coolant for extracting vanadium from the pellets.

[0036] After testing, the composition of the obtained pellet vanadium extraction coolant is: Fe 2 o 3 37.85%, FeO 48.19%, V 2 o 5 0.22%, SiO 2 5.70%, MgCl 2 1.28%. The balance is the content of impurity elements, such as TiO 2 、Cr 2 o 3 , P, S, etc. The obtained pellet vanadium extraction coolant is used for furnace temperature control under the condition of vanadium-containing molten iron converter in Panzhihua I...

Embodiment 3

[0038] Put the vanadium-containing iron ore concentrate powder, vanadium-extracting sludge, and binder in the above Table 1 into the roller sand mixer in a mass ratio of 35:60:5 for mixing and stirring, and then add them to the symmetrical ball press after stirring evenly, and adjust The pressure of the symmetrical briquetting machine is 15Mpa, and the spherical particles with a diameter of 8-12mm are extruded, and the spherical particles are naturally dried for 72 hours to obtain the coolant for extracting vanadium from the pellets.

[0039] After testing, the composition of the obtained pellet vanadium extraction coolant is: Fe 2 o 3 35.4%, FeO48.58%, V 2 o 5 0.23%, SiO 2 5.36%, MgCl 2 2.05%, the balance is the content of impurity elements, such as TiO 2 、Cr 2 o 3 , P, S, etc. The obtained pellet vanadium extraction coolant is used for furnace temperature control under the condition of vanadium-containing molten iron converter in Panzhihua Iron and Steel Co., Ltd....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com