High-strength and high-toughness corrosion-resistant steel capable of being used in low-temperature environment of -60 DEG C, and production method thereof

A low-temperature environment, corrosion-resistant steel technology, used in high-strength, high-toughness corrosion-resistant steel and its production field, can solve the problems of high Ni and Cu content and high production costs, improve low-temperature impact toughness, and reduce ductile-brittle transition temperature. , the effect of reducing the source of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific embodiment, but this embodiment should not be construed as limiting the present invention:

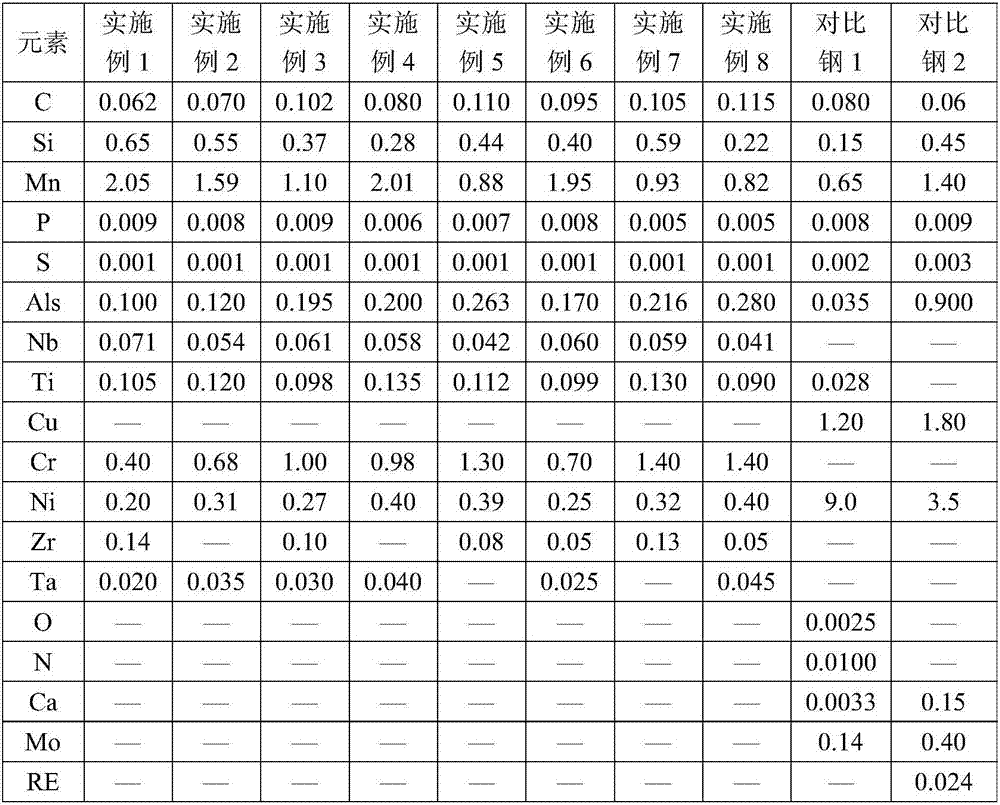

[0031] Table 1 shows the chemical components and weight percentages of the various examples and comparative steels of the present invention.

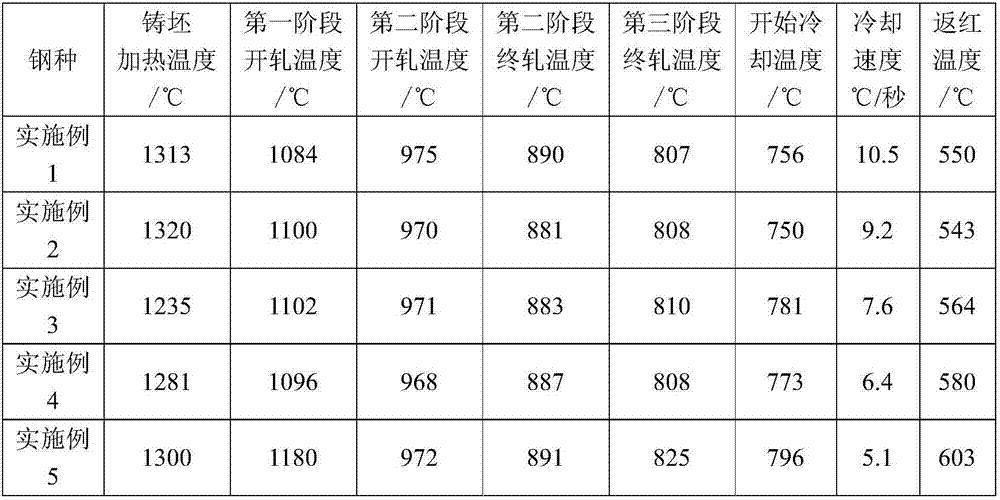

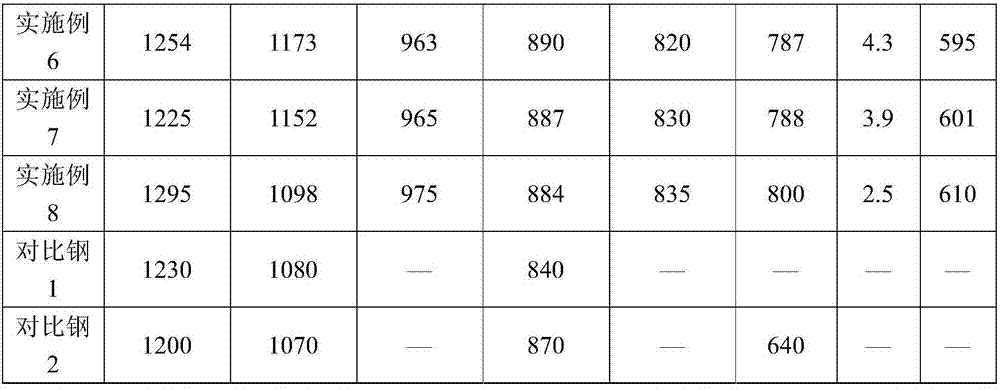

[0032] The values of main process parameters of each embodiment of the present invention and comparative steel are shown in Table 2.

[0033] The mechanical and corrosion resistance test results of the various embodiments of the present invention and comparative steels are shown in Table 3, wherein the corrosion resistance of the steels is comprehensively evaluated by simulating the mass loss after the corrosion of seawater solution by the cycle immersion corrosion test, and the test period is 240h.

[0034] Various embodiments of the present invention are carried out according to the following process steps:

[0035] 1) Carry out desulfurizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com