Electroluminescent devices with electrode protection

a technology of electroluminescent devices and electrode protection, which is applied in the direction of discharge tube/lamp details, discharge tube luminescnet screens, other domestic objects, etc., can solve the problems of exciton confinement, high photoluminescence and electroluminescence efficiency, and observe detrimental effects, so as to facilitate the removal of any interaction with the electrode during conversion. , the effect of reducing the effect of the interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment i

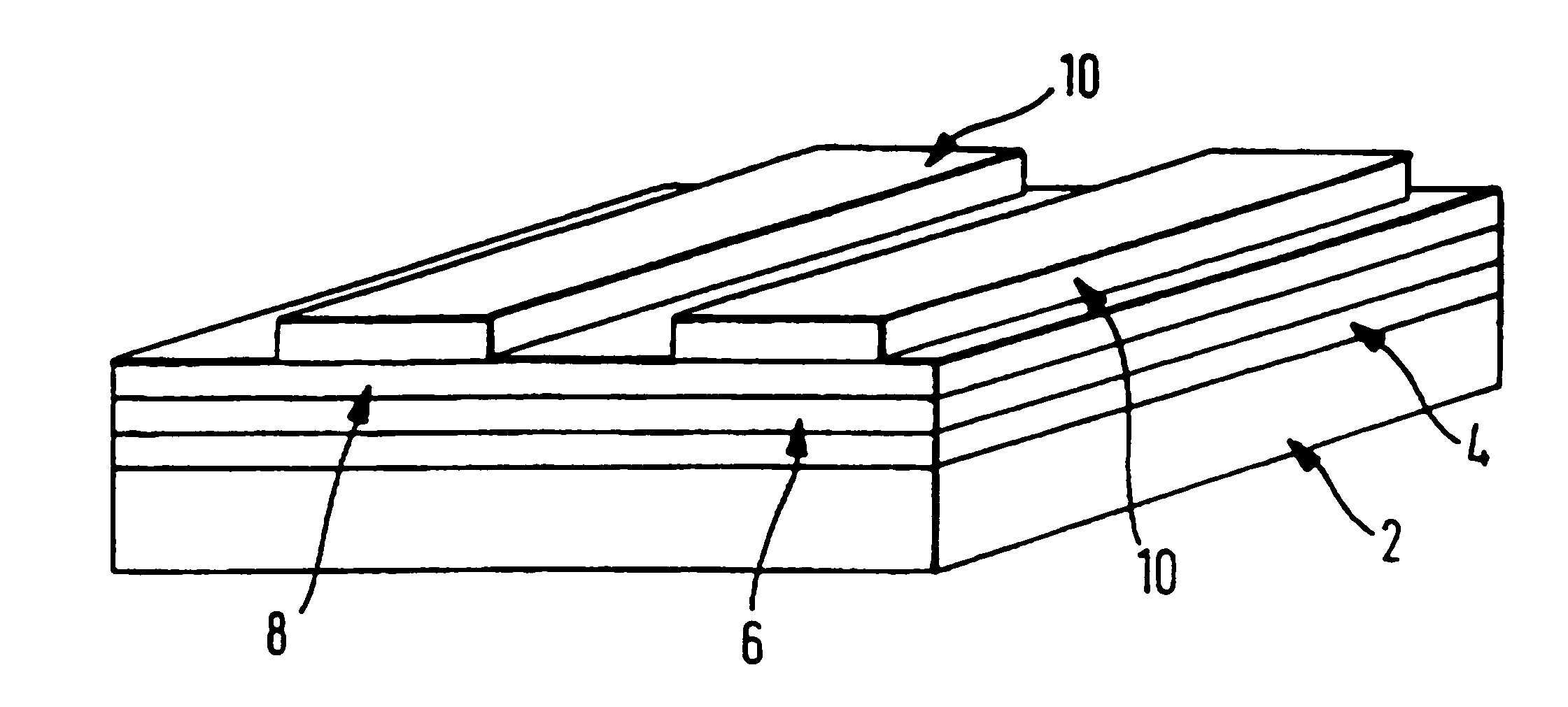

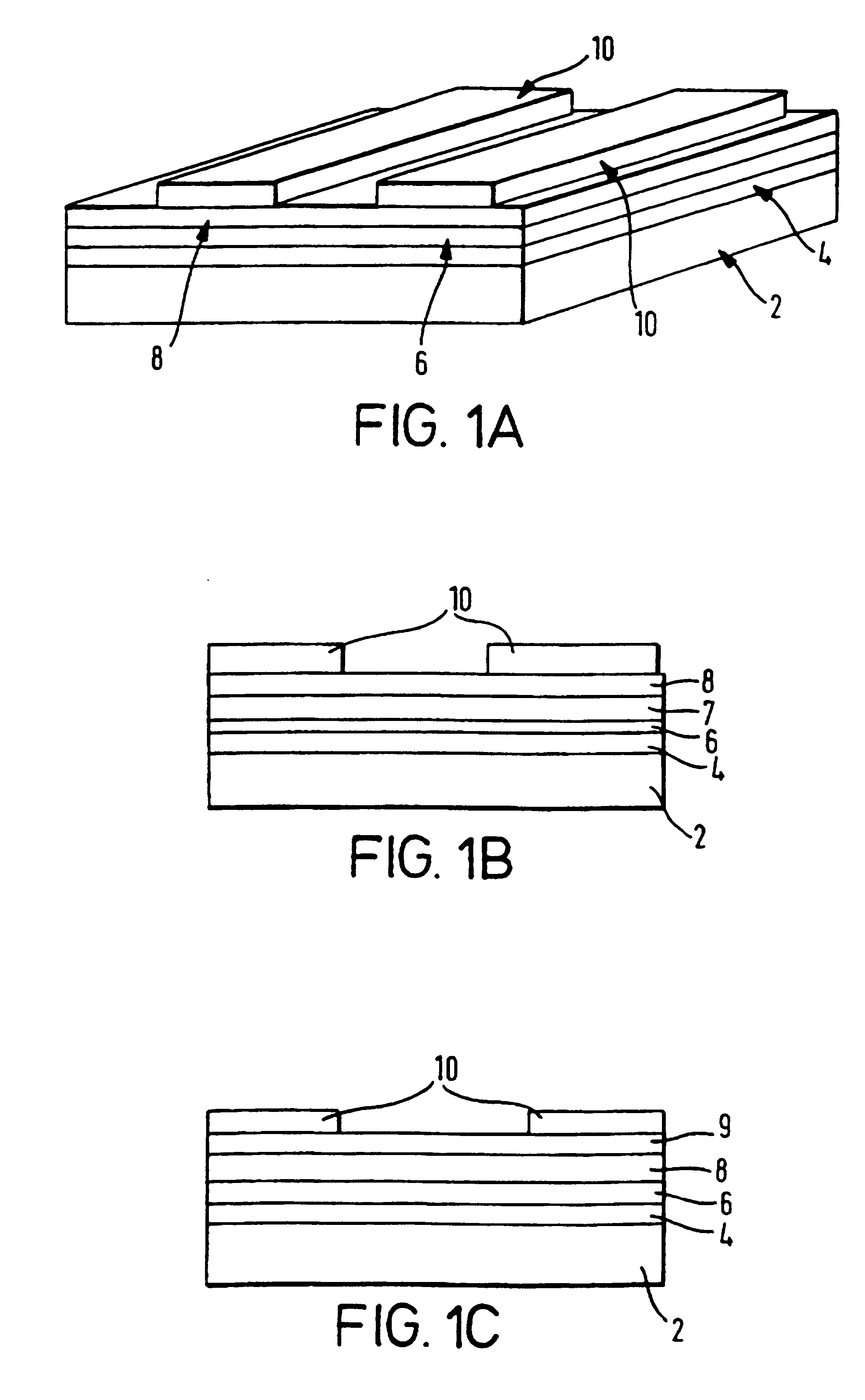

[0049] A first embodiment is now described. Indium tin oxide constituting the anode 4 is deposited using either dc or rf sputtering techniques onto the polished glass substrate 2. Such substrates are available commercially. Soda lime glass with a thin silica barrier and an indium tin oxide layer of resistivity of 30 Ohm / square and transparency of about 85%, with a thickness of order 1500 Å, can be used. A polythiophene based conducting polymer system is used as the anode protection layer 6. Polyethylene dioxythiophene / polystyrene sulphonate (PEDT / PSS @ 1:1.2 molar ratio)—which is available from Bayer AG, Leverkusen, Germany as Trial Product AI 4071. A 100 Å film of the conducting polymer is spin-coated on the substrate. The EL layer 8 is formed by spin-coating a precursor polymer such as a homopolymer PPV. With this precursor polymer the solubilising group that is removed during conversion at 150° C. in nitrogen for 4 hours is tetrahydrothiophene, and the counter-ion to the thiophen...

embodiment ii

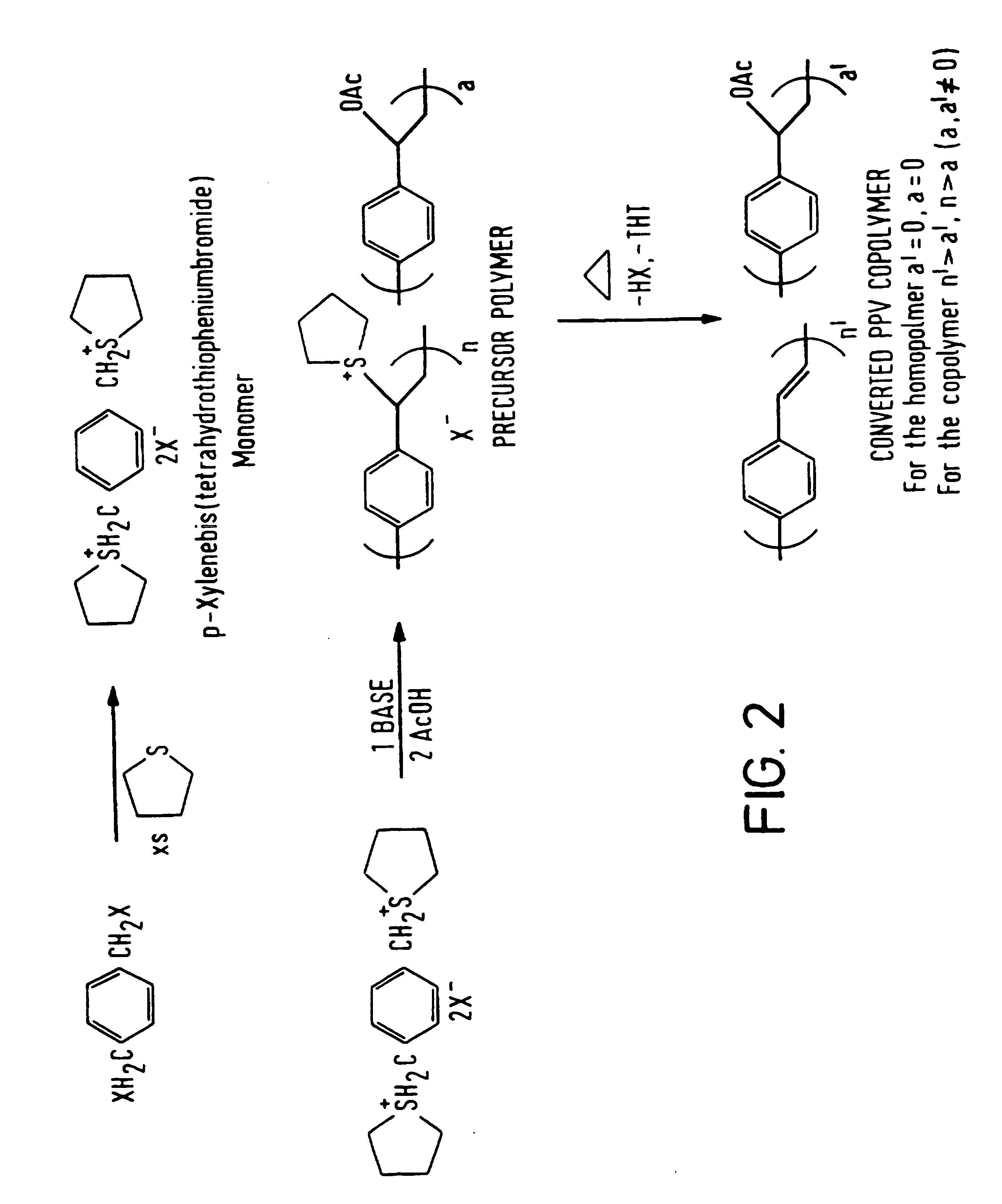

[0051] Another specific embodiment is now described. The initial steps are the same as embodiment I up to formation of the EL layer. In this embodiment, a precursor to an acetate-based PPV copolymer is deposited. This material has a very high photoluminescence (PL) efficiency, where the solubilising group that is removed during conversion is tetrahydrothiophene, and the counter-ion to the thiophene salt is bromide. Another by-product is therefore hydrogen bromide which readily attacks ITO and can cause the release of detrimental products into the film which quenches the photoluminescence and causes enhanced conversion. Without the anode protection layer 6, the PL efficiency of the PPV material is dramatically reduced from about 50-60% to, at best about 7% following the thermal conversion process (150° C. in nitrogen for 4 hours as before). However, with the protector layer a PL efficiency of ˜22% is obtained following conversion. FIG. 2 shows the conversion system, where a≠0, a≠0. A...

embodiment iii

[0055] Another specific embodiment is now described. In this embodiment, the production steps are the same for Embodiment II except that the polyethylene dioxythiophene / polystyrene sulphonate material which is used as the anode protection layer has been optimised to give beneficial lifetime performance by increasing the PSS content. Thus, the material now has a 1:5 molar ratio PEDT / PSS. The device performance of these system may be summarised as 100 cd / m2 starting brightness, efficiency of 0.3-1.2 lm / W, and up to 2 lm / W with a half-life of ˜500 hours and up to 2000 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sheet resistances | aaaaa | aaaaa |

| sheet resistances | aaaaa | aaaaa |

| sheet resistances | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com