Remote monitoring, early warning and fault-diagnosing system and method for anodic protection device

A fault diagnosis system and anode protection technology, which are used in early warning and fault diagnosis systems, early warning and fault diagnosis, remote monitoring of anode protection equipment, and remote monitoring of anode protection equipment based on Internet of Things technology, which can solve the maintenance and management level of anode protection equipment. Low and other problems, to ensure high-quality operation and safety "zero" failure, accurate early warning of equipment abnormalities, and eliminate equipment hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

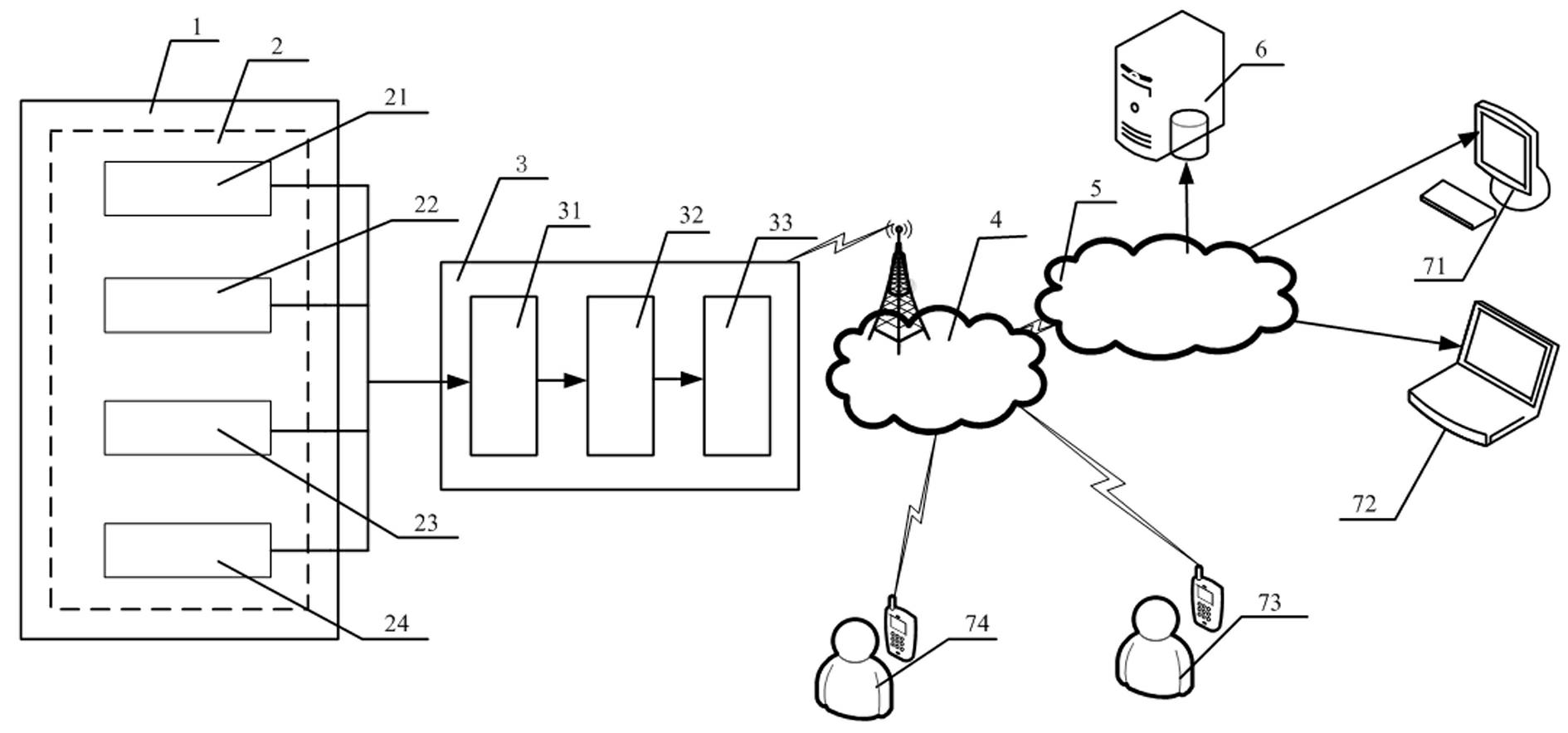

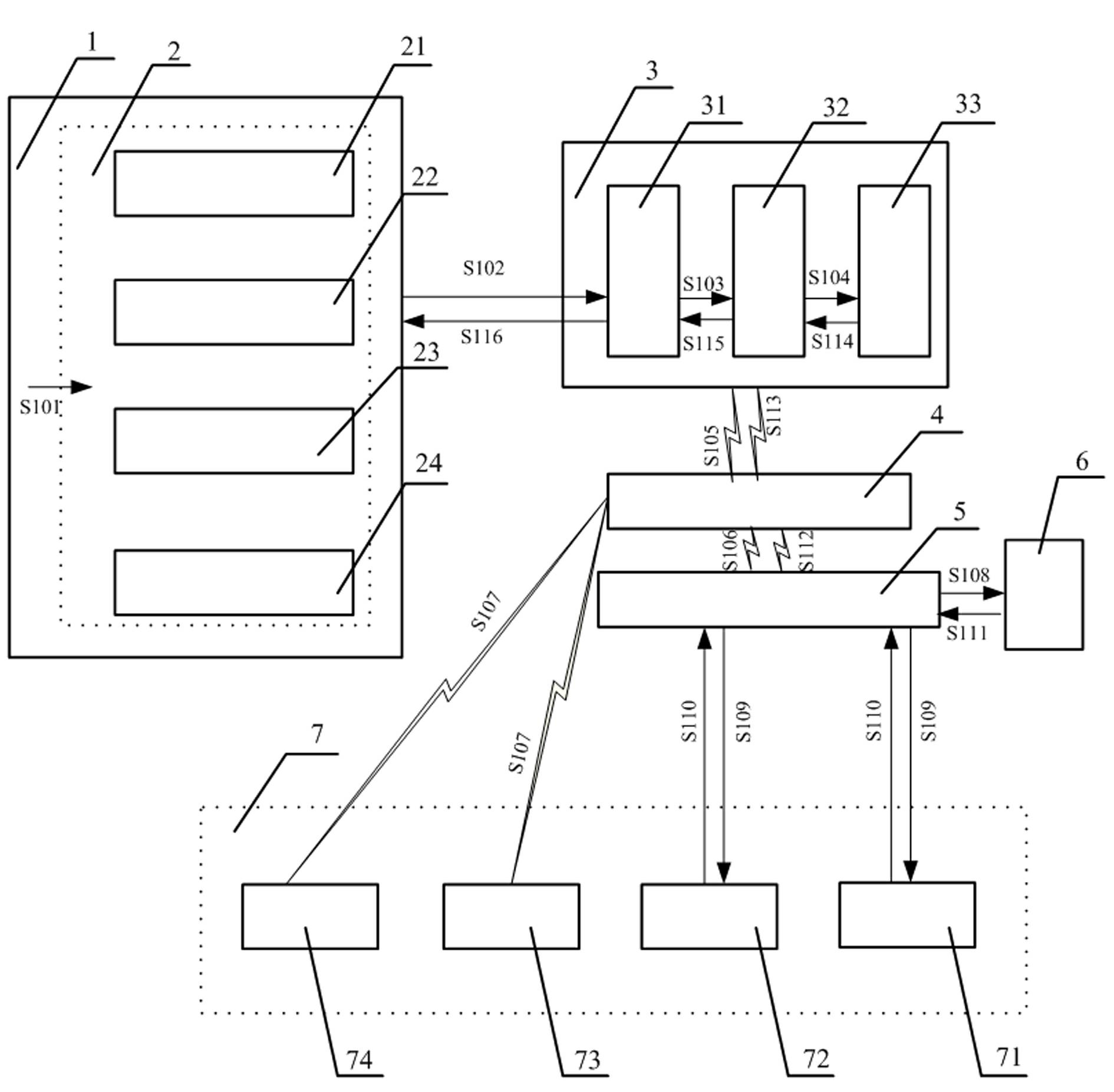

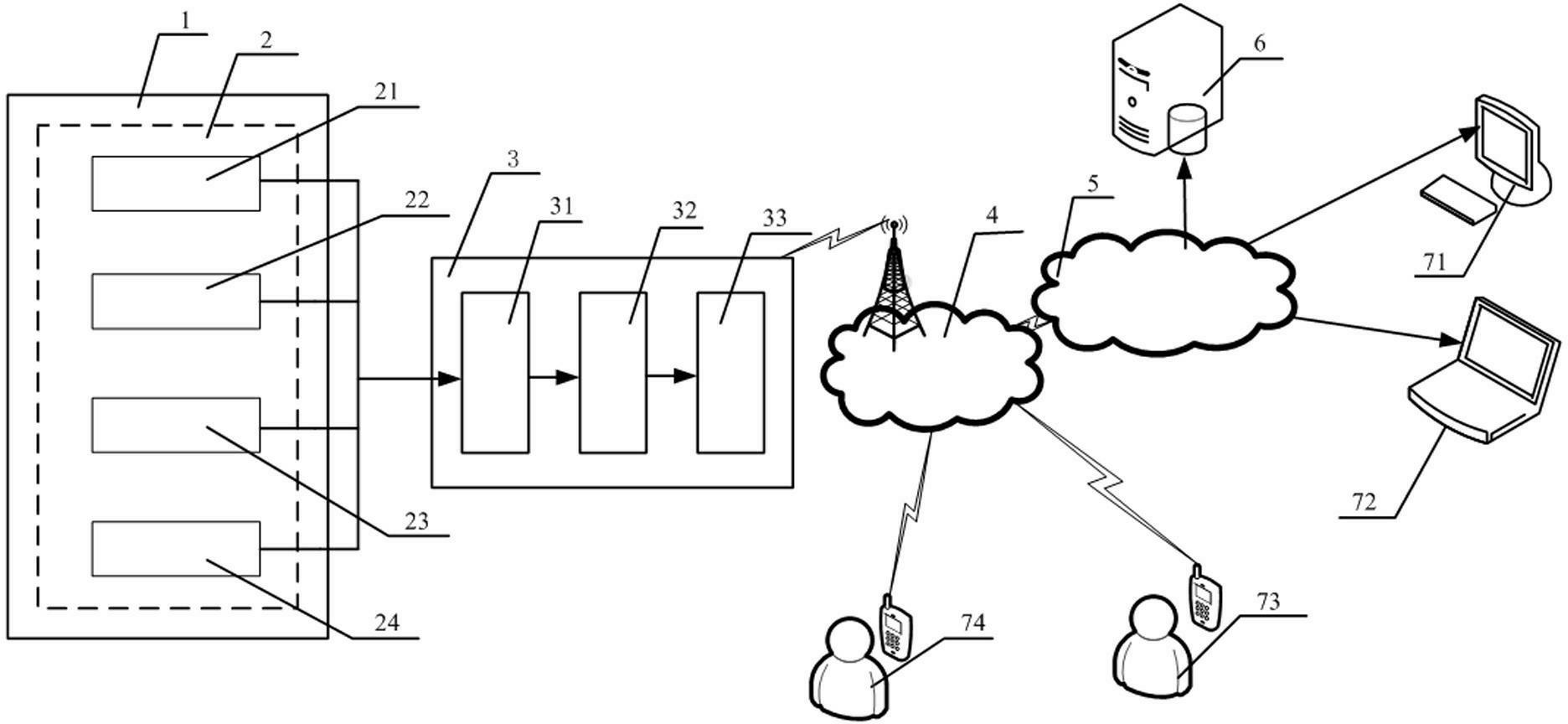

[0034] Such as figure 1 and figure 2 Shown: a remote monitoring, early warning and fault diagnosis system for anode protection equipment based on the Internet of Things, including a sensor device 2, a signal recognition device 3, a GPRS / CDMA network 4, an Internet network 5, a database server 6 and a monitoring terminal 7; Device 2 is wired with signal recognition device 3, and signal recognition device 3 is connected with GPRS / CDMA network 4 wireless signals; Monitoring terminal 7 includes equipment manufacturer monitoring terminal 71, customer monitoring terminal 72, equipment manufacturer engineer mobile phone monitoring terminal 73 and customer The engineer's mobile phone monitoring terminal 74; the GPRS / CDMA network 4 is connected with the equipment manufacturer's engineer's mobile phone monitoring terminal 73 and the customer engineer's mobile ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com