Patents

Literature

39results about How to "Ensure safety and control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

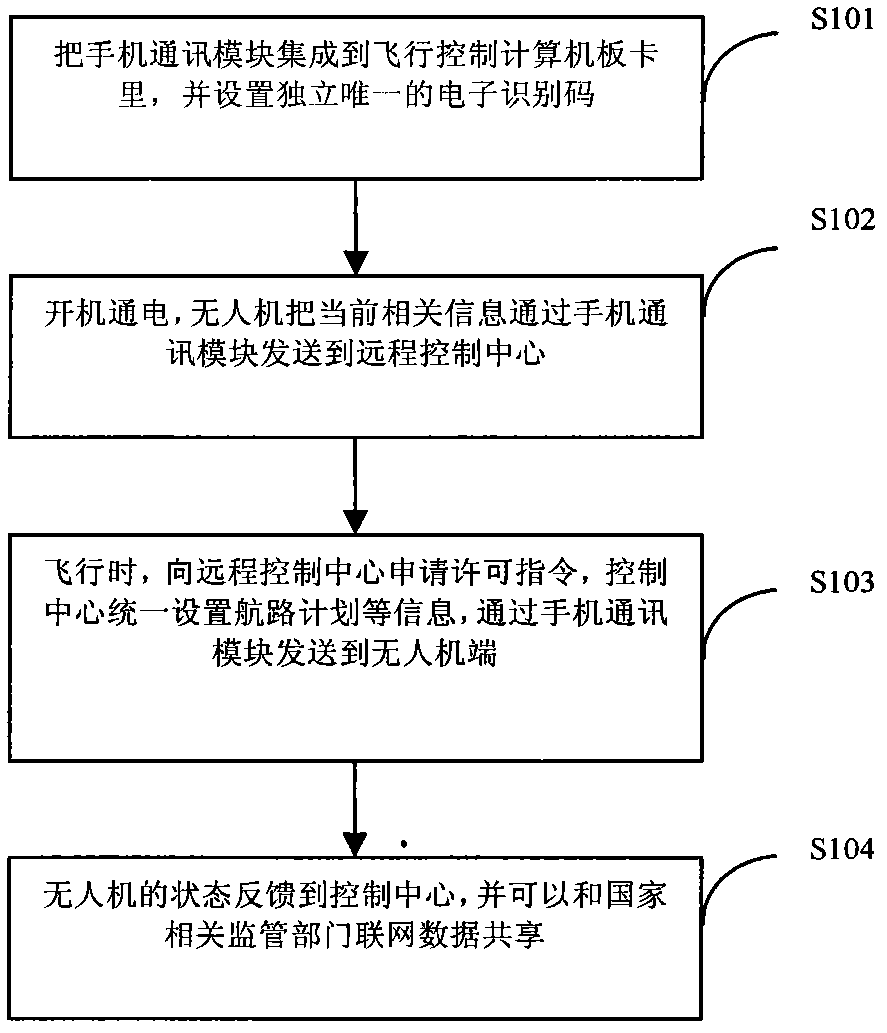

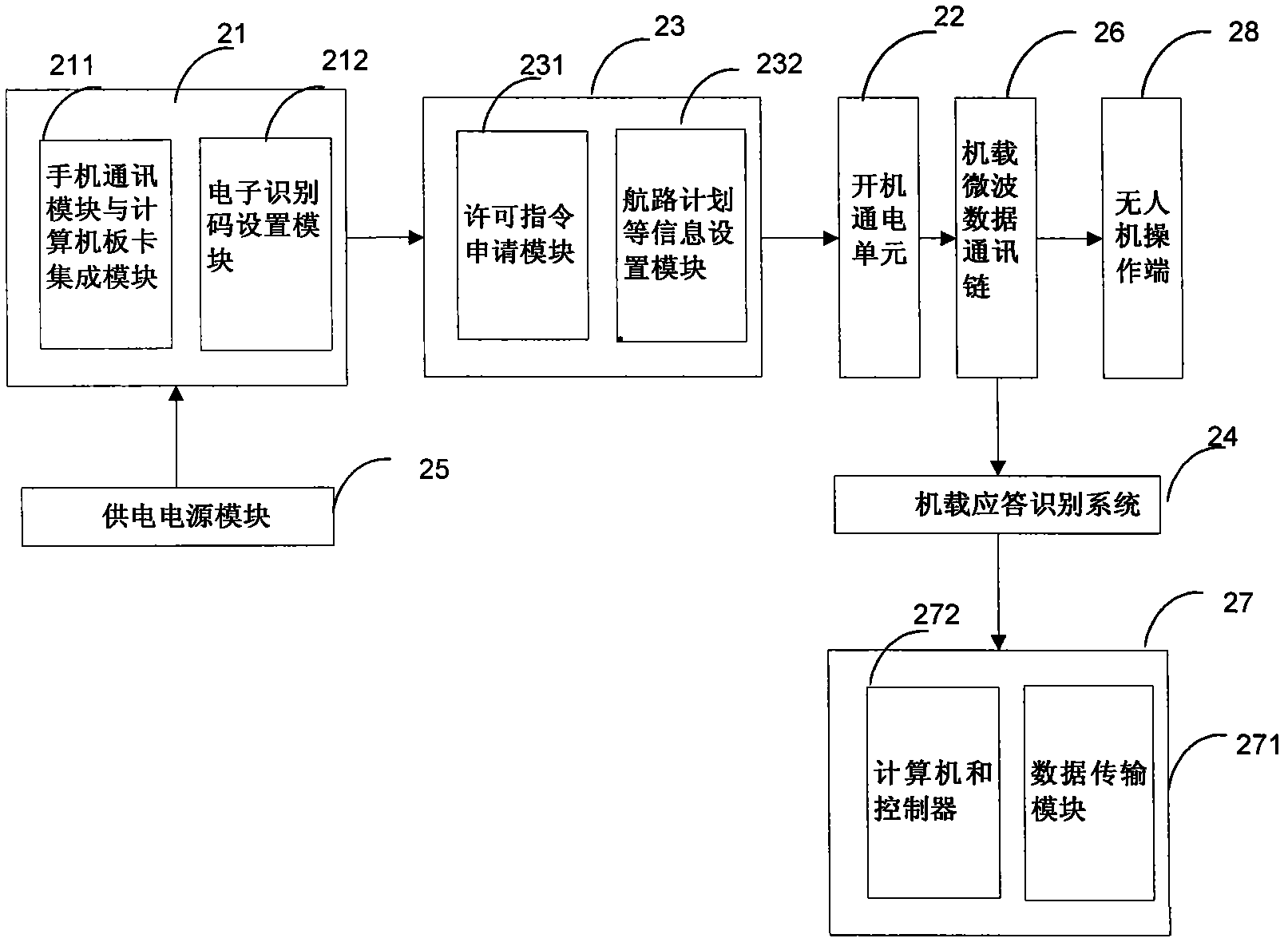

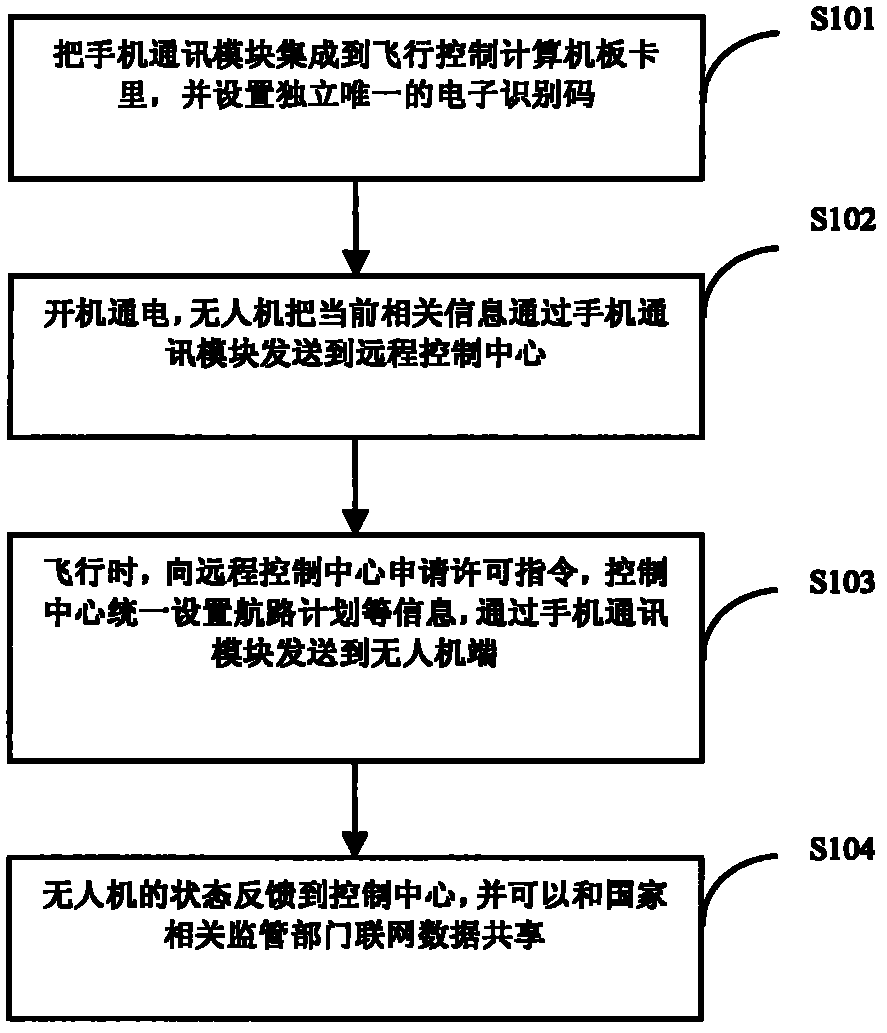

Remote unmanned aerial vehicle cluster control method and system based on 3G (the 3rd Generation Telecommunication) and GPRS (General Packet Radio Service) cell phone communication

InactiveCN102637023AEnsure safety and controlUnified supervision and dispatchSubstation equipmentTotal factory controlGeneral Packet Radio ServiceElectronic identification

The invention provides a remote unmanned aerial vehicle cluster control method and system based on 3G (the 3rd Generation Telecommunication) and GPRS (General Packet Radio Service) cell phone communication and belongs to the technical field of unmanned aerial vehicles. Each unmanned aerial vehicle is provided with an independent unique electronic identification code by integrating a cell phone communication module into a flight control computer board card; as long as the system is started and electrified, the current relevant information of the unmanned aerial vehicle is transmitted to a remote control center; a permission instruction is necessarily applied from a control center for each flight; information such as an airway plan is made uniformly in the control center; and the information is transmitted to an operation terminal of the unmanned aerial vehicle through a cell phone communication module. Consequently the unmanned aerial vehicle cannot fly away without a headquarter control instruction. The state of each unmanned aerial vehicle is fed back to the control center and can be shared with networked data of relevant national supervision departments so as to play roles in unified supervision and scheduling. In addition, the on-site operation personnel do not need professional knowledge such as airway point setup; and the unmanned aerial vehicle can be operated by common people subjected to simple training, so that the problem of staff shortage in unmanned aerial vehicle control is solved.

Owner:WUHAN AI BIRD UAV

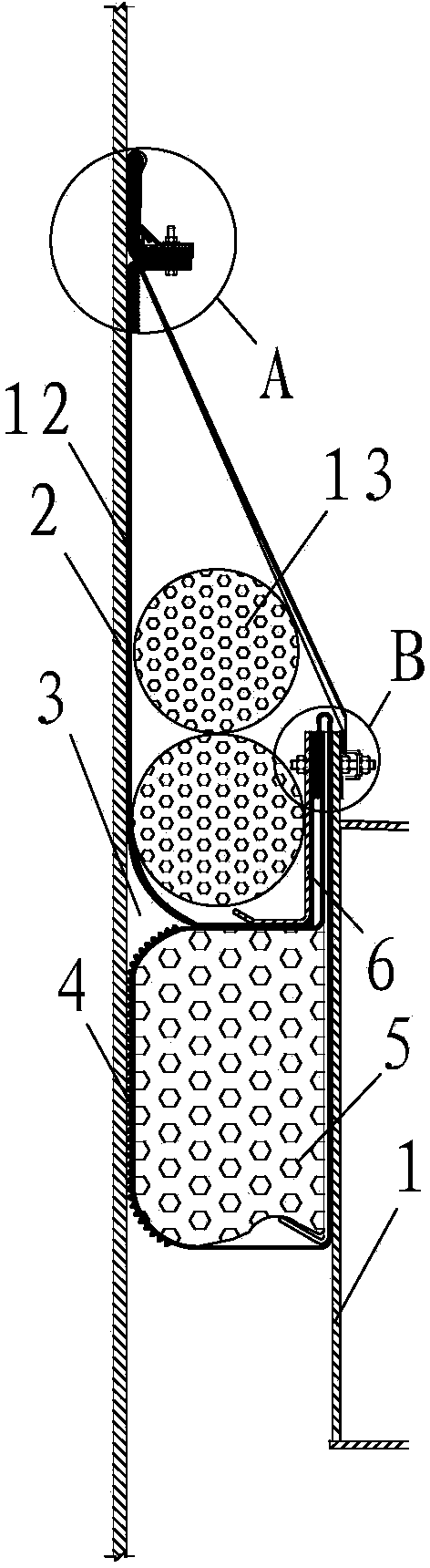

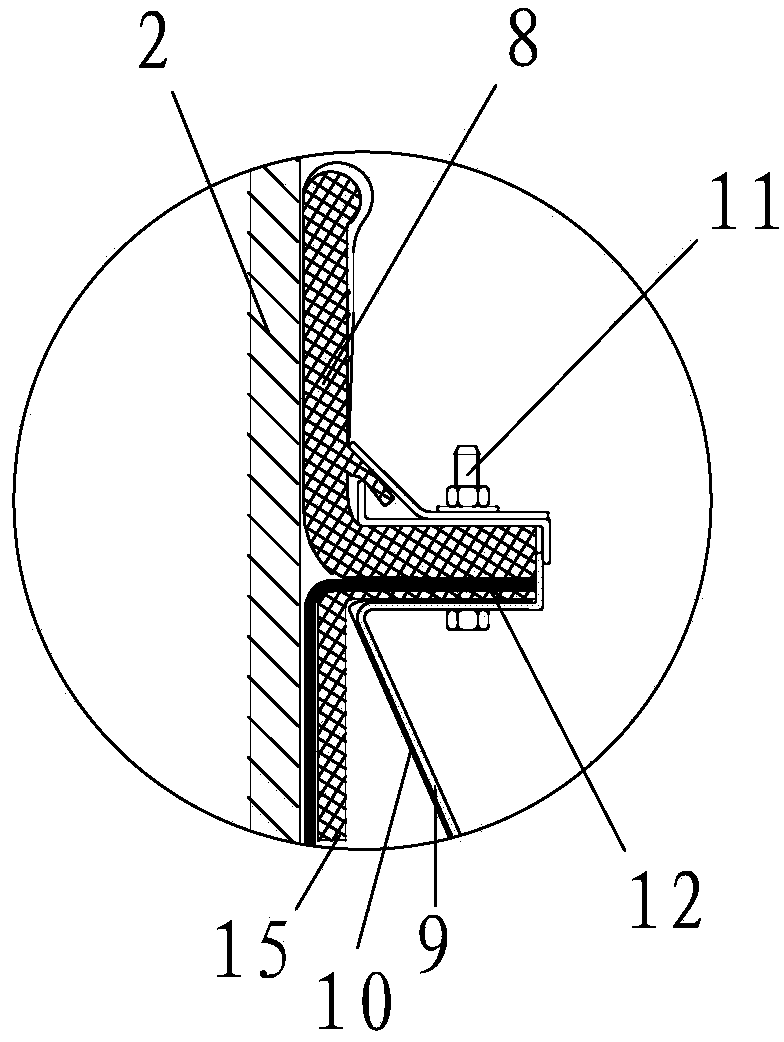

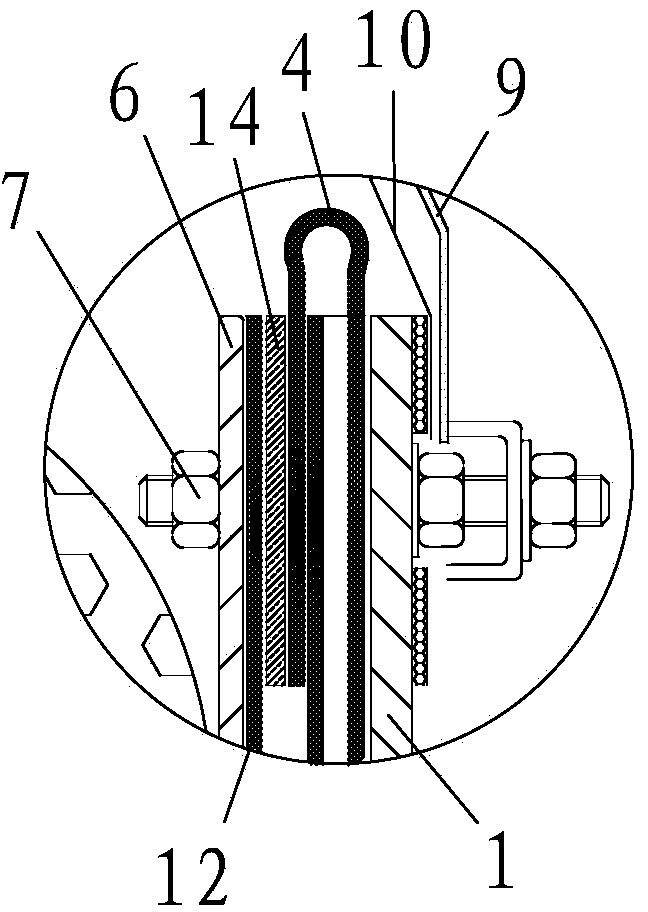

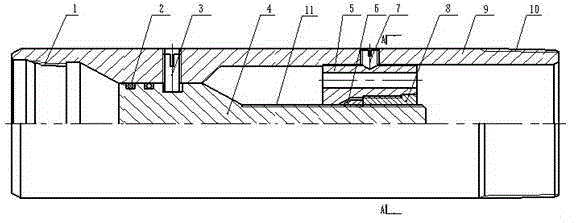

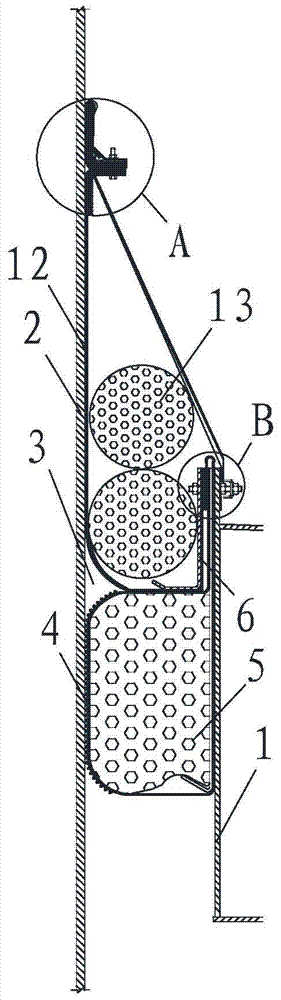

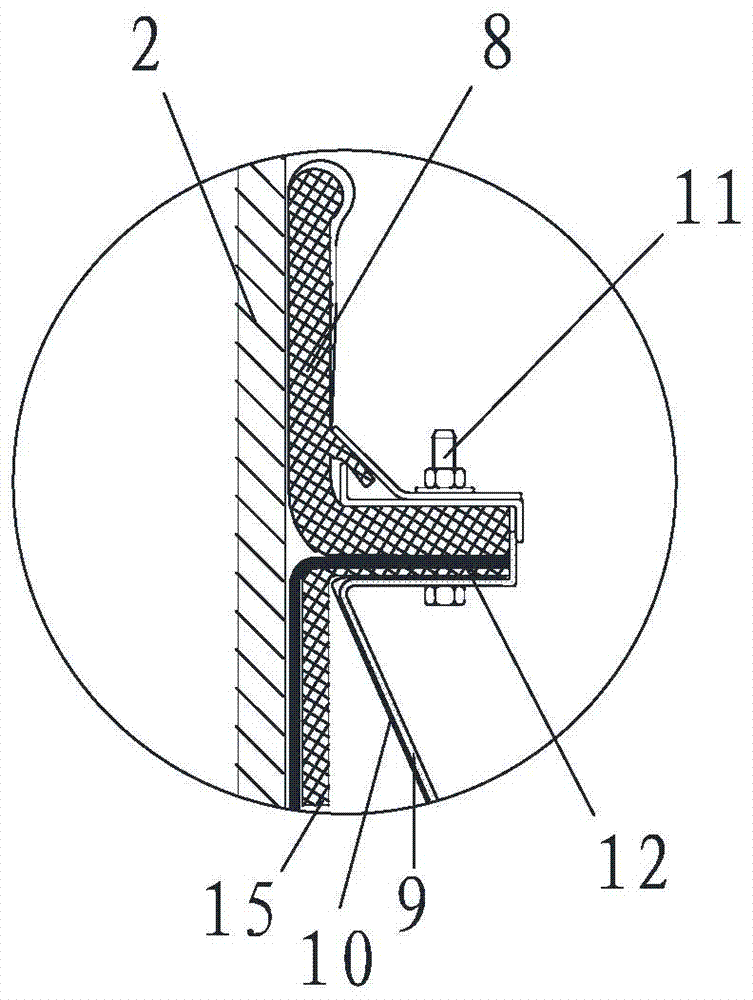

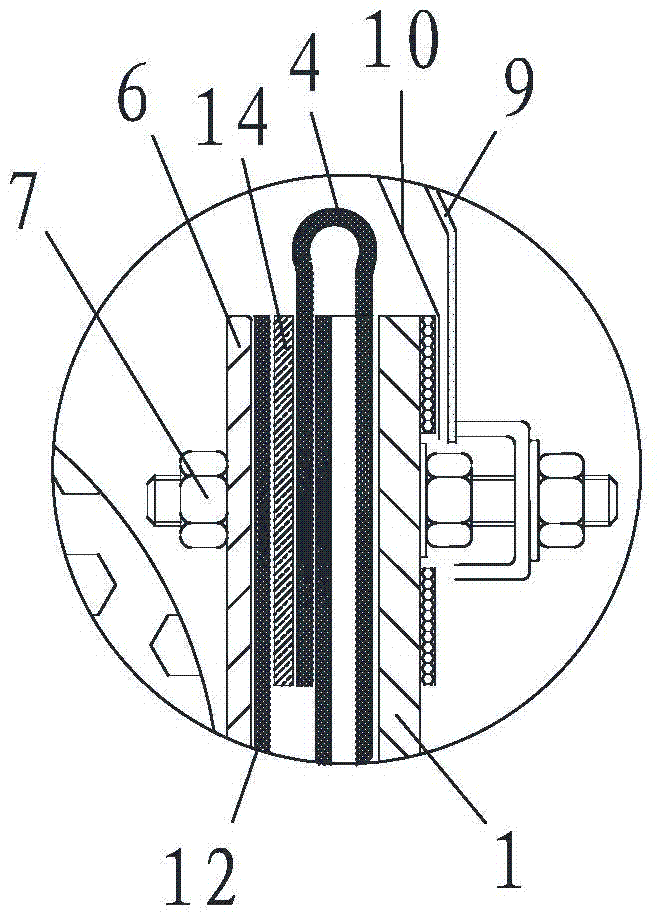

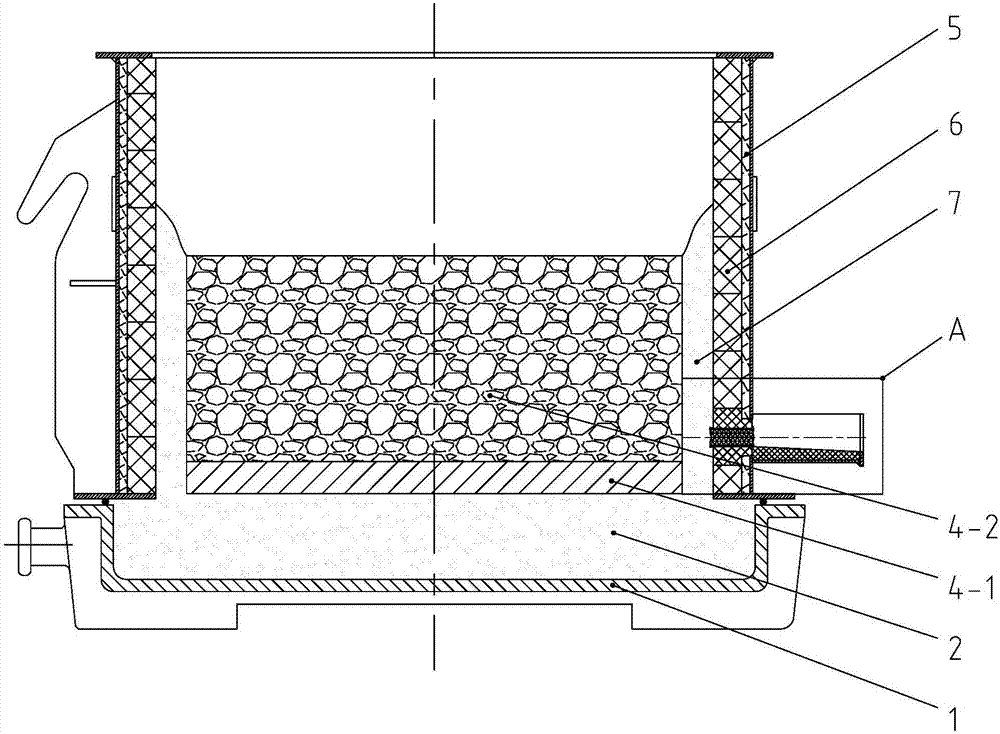

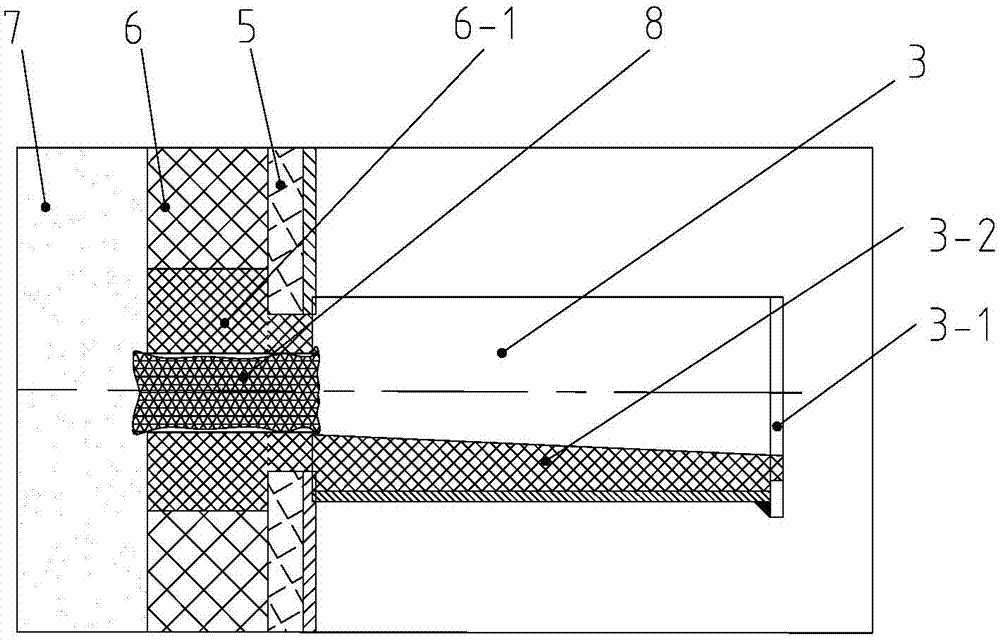

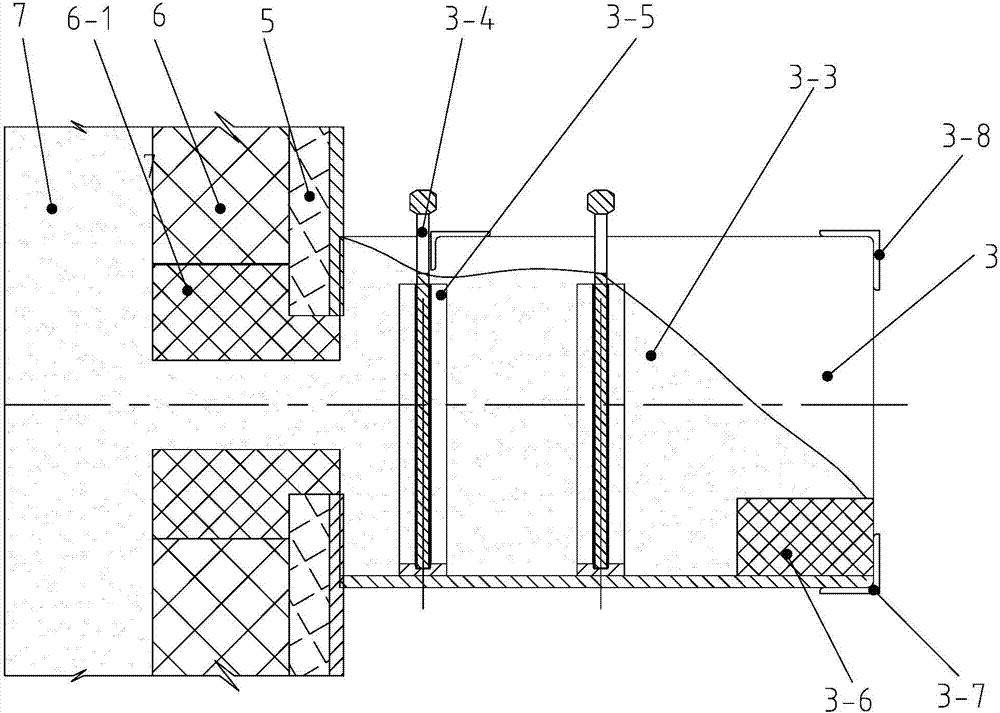

Sealing device between floating disc and tank wall of external floating roof tank and mounting method of sealing device

ActiveCN104355004AHarm reductionEnsure safety and controlLarge containersEngineeringMembrane configuration

The invention discloses a sealing device between a floating disc and a tank wall of an external floating roof tank. The device comprises an edge plate of a floating disc and the tank wall, wherein a primary sealing part and a secondary sealing part are arranged between the edge plate of the floating disc and the tank wall, and oil and gas spaces are formed among the primary sealing part, the edge plate of the floating disc, the secondary sealing part and the tank wall; the secondary sealing part comprises a secondary sealing rubber gasket, a secondary sealing pressing plate and a secondary sealing membrane, and the secondary sealing membrane is arranged on the surface of the inner side of the secondary sealing pressing plate; filling devices are arranged in the oil and gas spaces, and the filling devices comprise flexible wear-resisting bag belts and bag belt fillers; the flexible wear-resisting bag belts sequentially expend along the edge plate of the floating disc, the upper surface of the primary sealing part, and the tank wall, cavity bodies without oil or gas are formed between the flexible wear-resisting bag belts and the secondary sealing membrane, the bag belt fillers are positioned in the flexible wear-resisting bag belts, the reduction of the oil and gas space between the primary sealing part and the secondary sealing part is facilitated, the oil and gas content in the oil and gas space is reduced, and the harm caused by the blast accident of sealing rings is furthest reduced.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +2

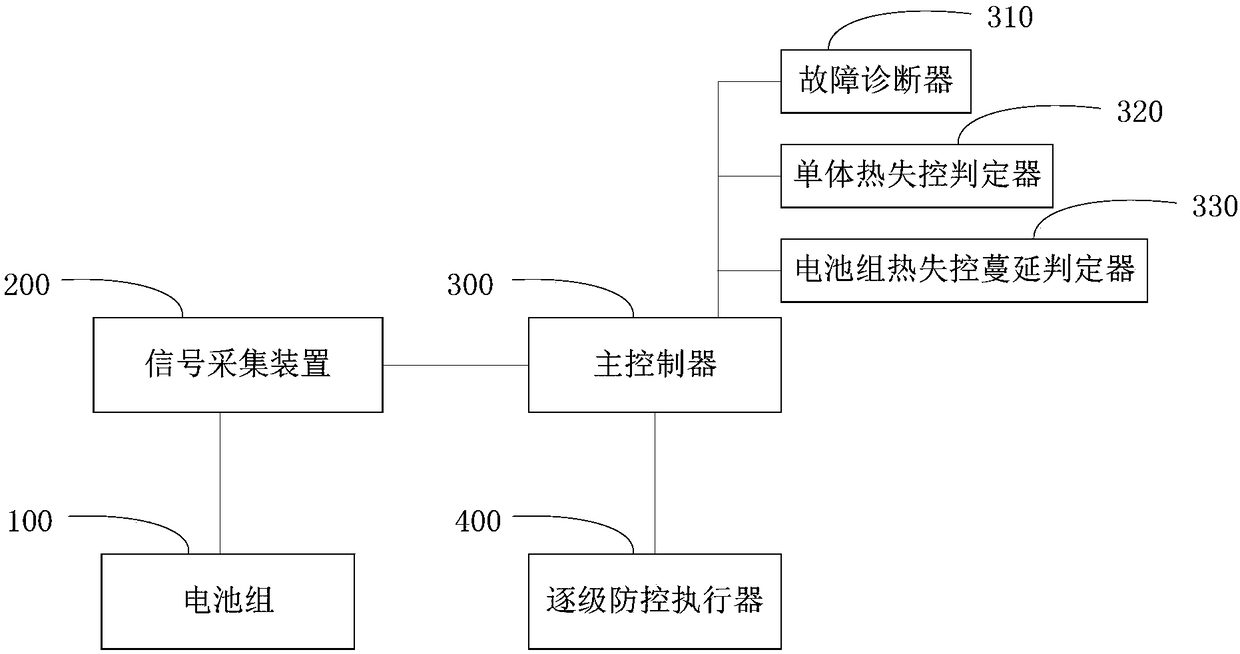

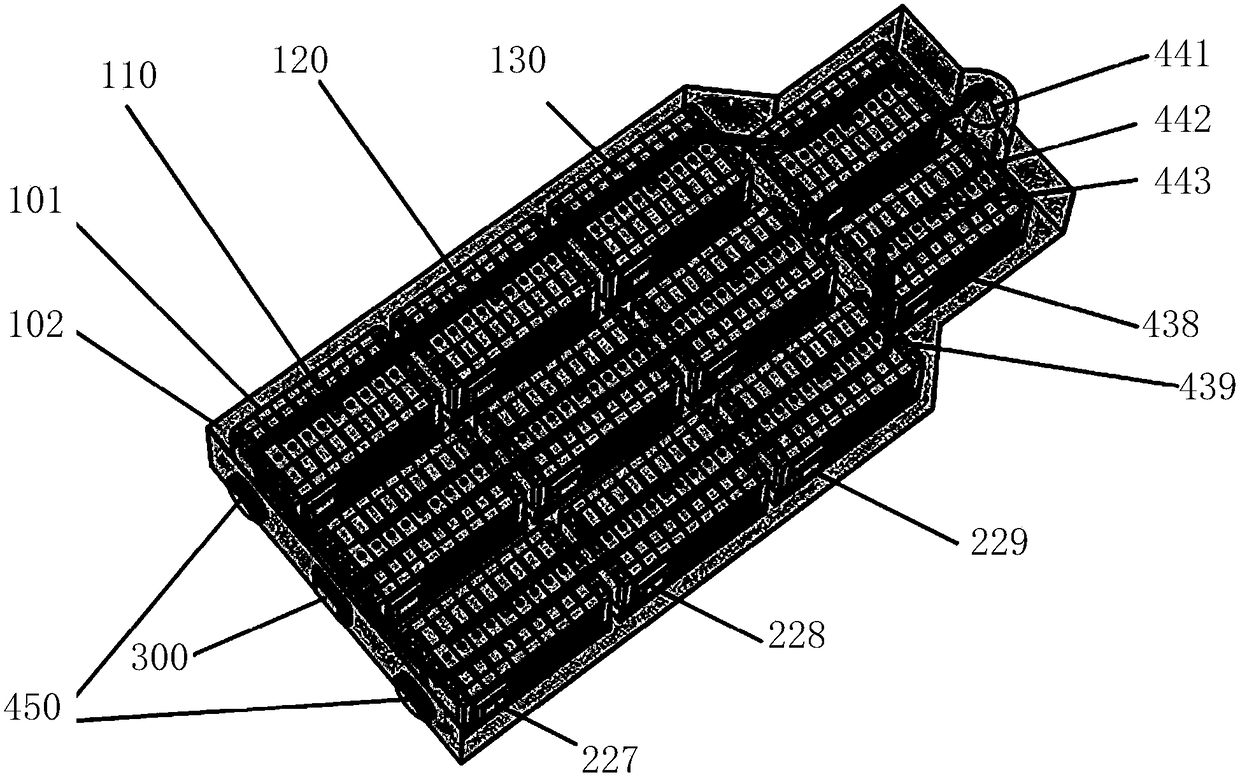

Power battery pack safety preventing and controlling system for electric vehicle

PendingCN108091947ASolve the problem of security prevention and controlEnsure safetyBatteries circuit arrangementsCell temperature controlElectricityPower battery

The invention relates to a power battery pack safety preventing and controlling system for an electric vehicle. The power battery pack safety preventing and controlling system comprises a signal collecting device, a main controller and a stepwise preventing and controlling executor. The main controller comprises a fault diagnosis device, a single thermal runway judging device and a battery pack thermal runway spreading judging device which are electrically connected with the stepwise preventing and controlling executor separately and send different control instructions to the stepwise preventing and controlling executor. The stepwise preventing and controlling executor can execute different levels of preventing and controlling motions according to different control instructions sent by thefault diagnosis device, the single thermal runway judging device and the battery pack thermal runway spreading judging device. By means of the power battery pack safety preventing and controlling system for the electric vehicle, an active preventing and controlling measure and a passive preventing and controlling measure can be provided, a preventing and controlling mechanism can be accurately started in combination with the preventing and controlling capability of the preventing and controlling system aiming at actual situations of specific accidents, the safety protecting effect is maximized, and the passenger safety of the electric vehicle is guaranteed.

Owner:TSINGHUA UNIV

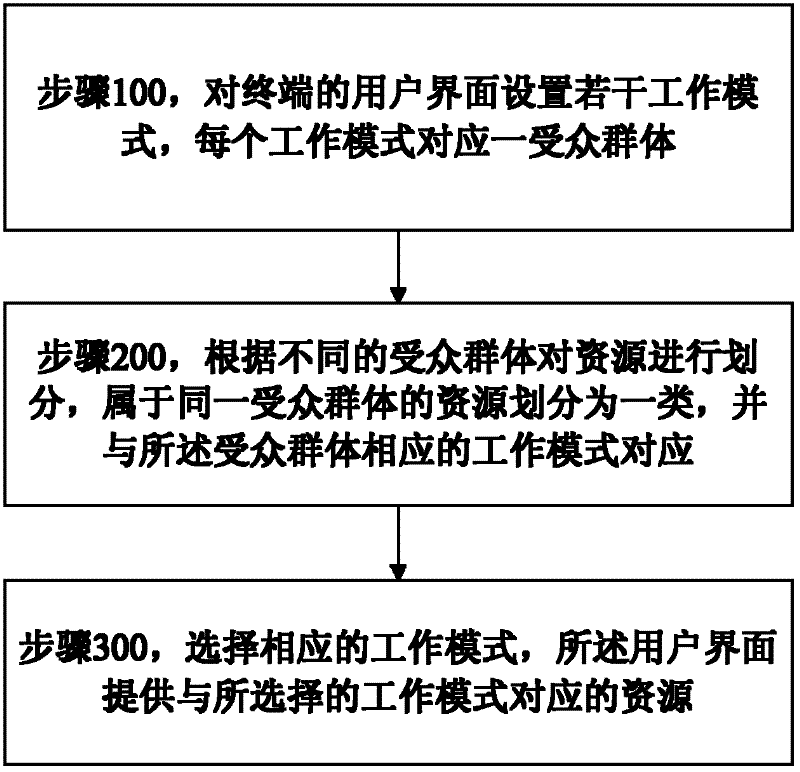

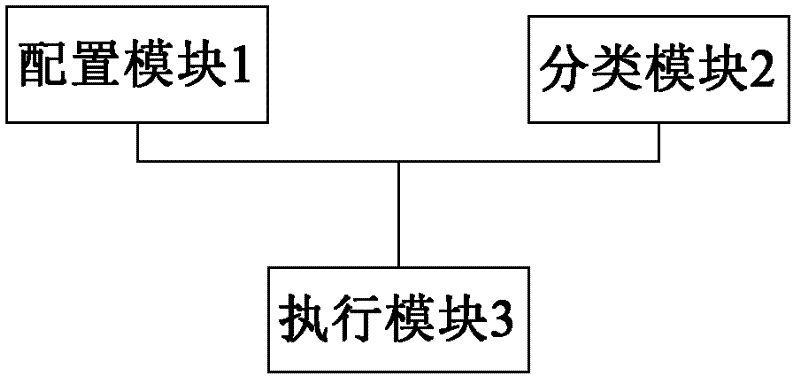

Mode adapting method and mode adapting system for user interface

ActiveCN102650955AGuaranteed independence and securityEnsure safety and controlProgram initiation/switchingUser interfaceHuman–computer interaction

The invention discloses a mode adapting method and a mode adapting system for a user interface. The mode adapting method comprises the following steps of: setting a plurality of work modes for the user interface of a terminal and enabling each work mode to correspond to an audience; dividing resources according to different audiences, dividing the resources belonging to the same audience into one category and enabling the divided resource to correspond to a corresponding work mode of the audience; and selecting corresponding work modes and providing resources corresponding to the selected work modes by the user interface. According to the mode adapting method and the mode adapting system disclosed by the invention, a user belonging to any audience can respectively and freely switch to the accordant work modes according to personal use demands to enjoy resources suitable for the user under the provided the work mode.

Owner:BEIJING QIHOO TECH CO LTD

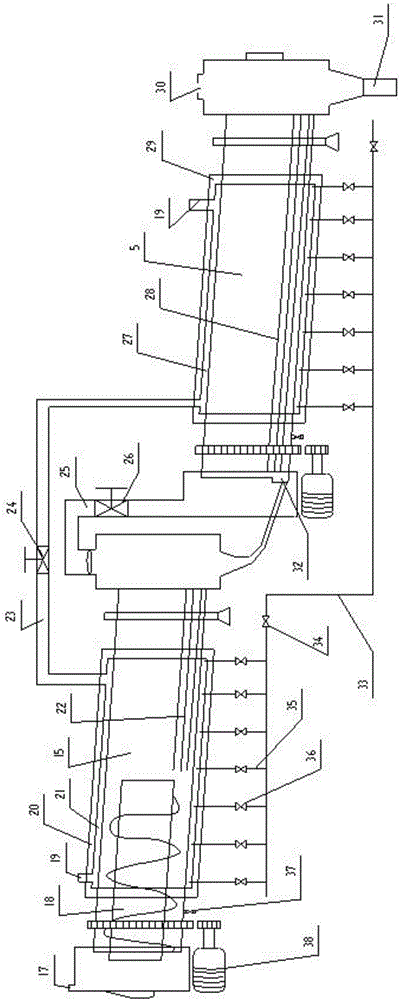

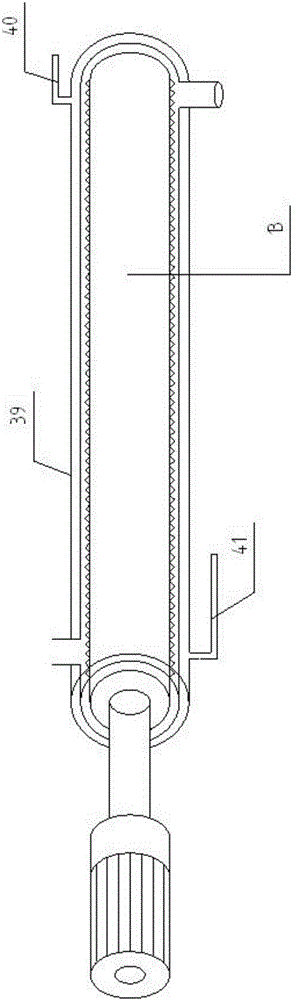

Removal device and method for mercury in mercury-containing pollutant

ActiveCN106439842ASolve difficultySolve the costSolid waste disposalDispersed particle separationReaction rateFlue gas

The invention belongs to the technical field of solid waste treatment, and particularly relates to a removal device and method for mercury in a mercury-containing pollutant. The removal device for the mercury in the mercury-containing pollutant consists of a material preparing system, a pre-heating drying system, a thermal desorption system, a residue cooling conveying system and a flue gas purifying system. The removal method for mercury in the mercury-containing pollutant comprises the following steps of: pre-treating, pre-heating and drying, desorbing and mercury-removing, mercury-containing flue gas purifying. According to the removal device and the removal method, mercury resources further can be recycled while pollutant treatment is realized, so that materials can be sufficiently reacted, and therefore, a reaction rate is increased; the whole system adopts sealed treatment, so that mercury-containing flue gas does not leak in a reaction process, and therefore, safety is improved; energy consumption needed for heating and drying cold flue gas is reduced, and energy consumption needed for cooling high-temperature flue gas is also reduced, so that production cost is greatly reduced; the production process is guaranteed to be safe and controllable; and process flow is shortened, and energy consumption is reduced.

Owner:云南全周环境科技有限公司

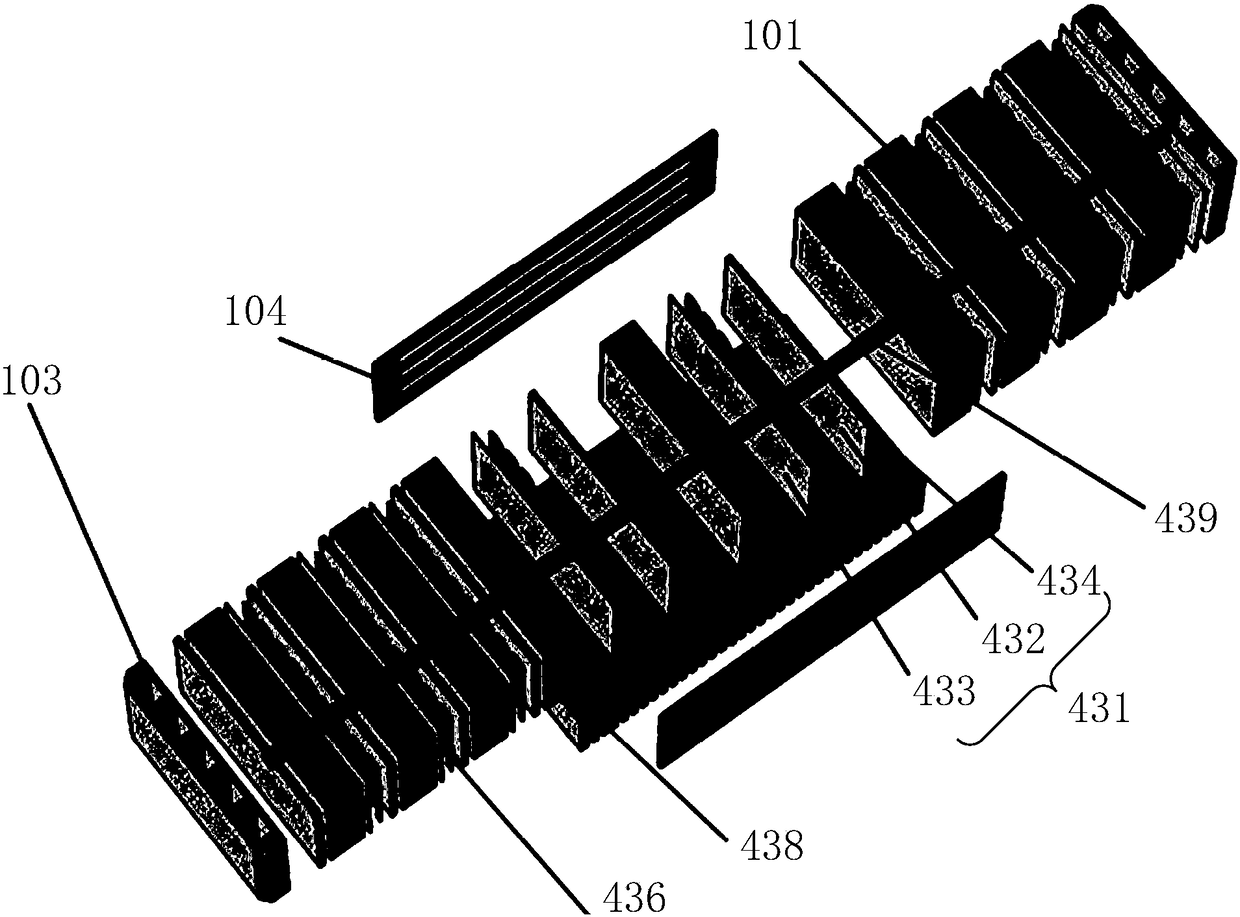

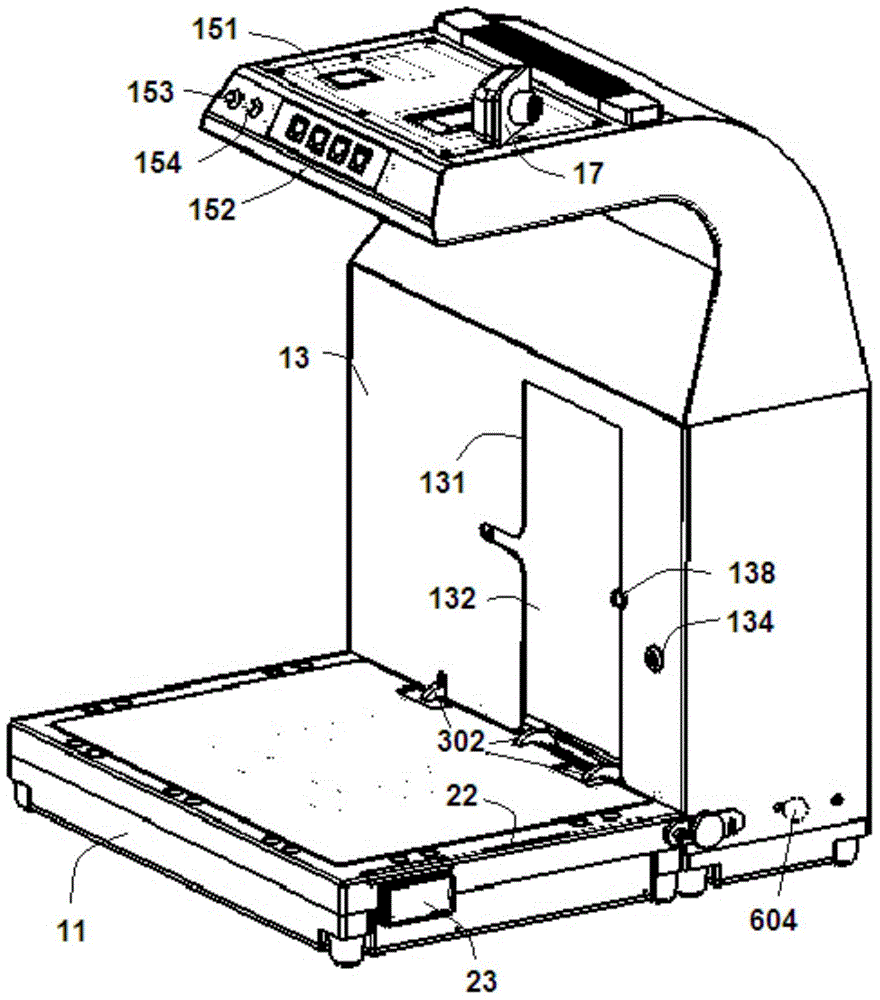

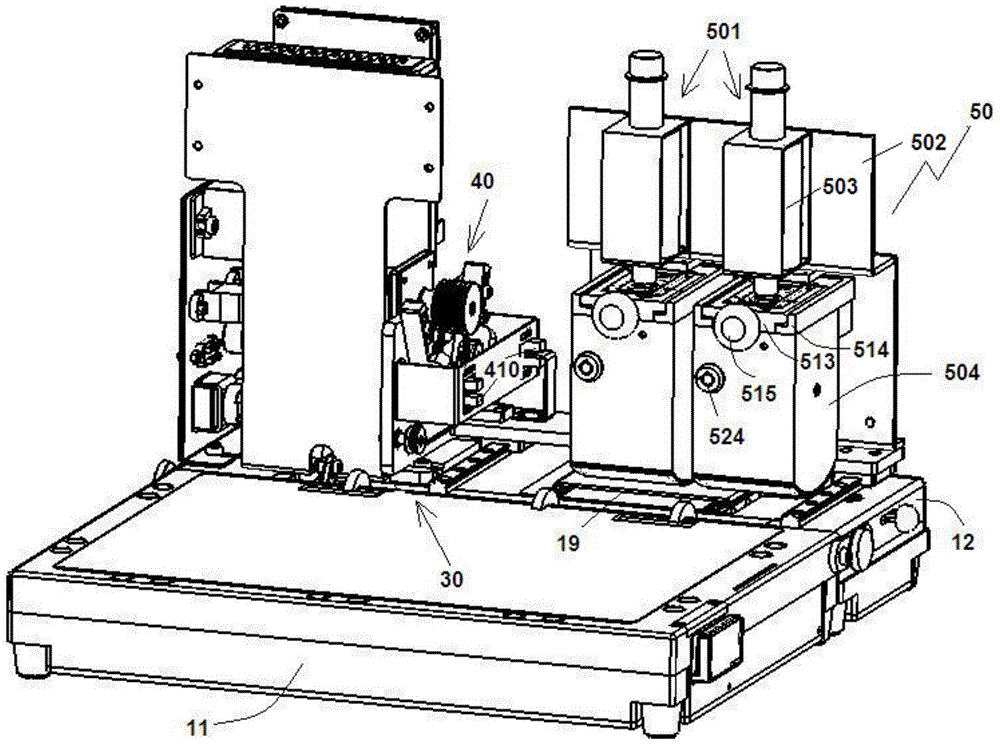

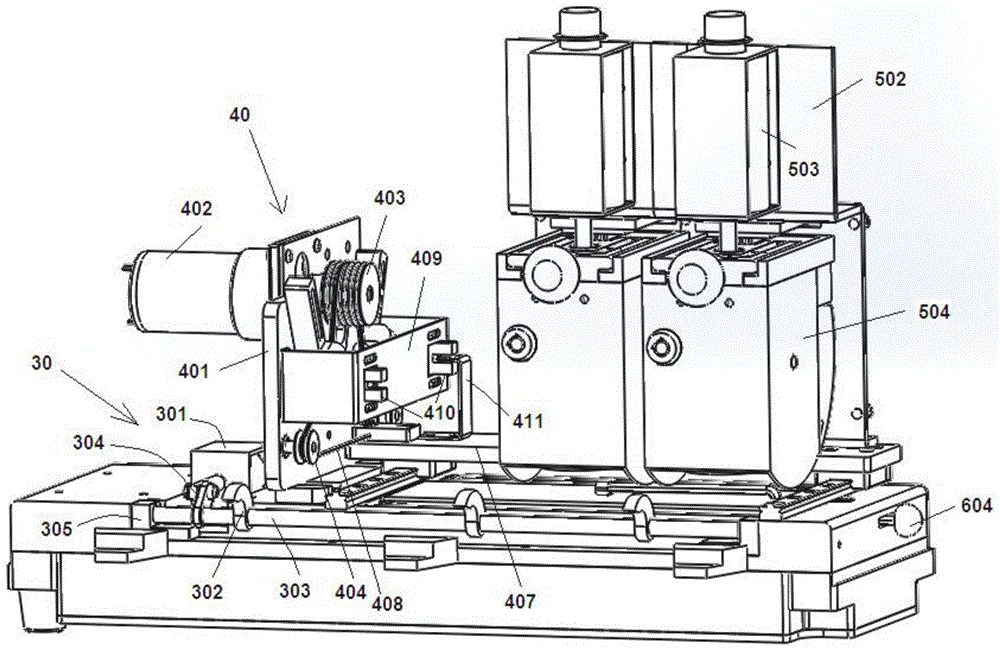

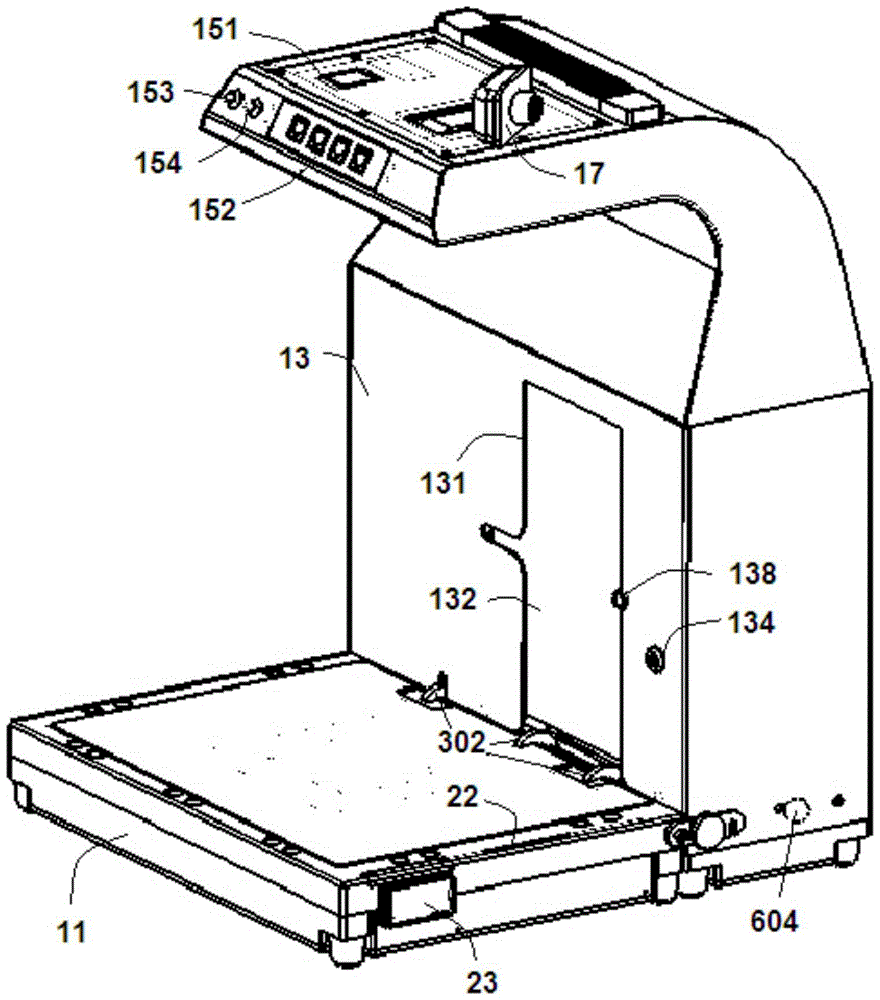

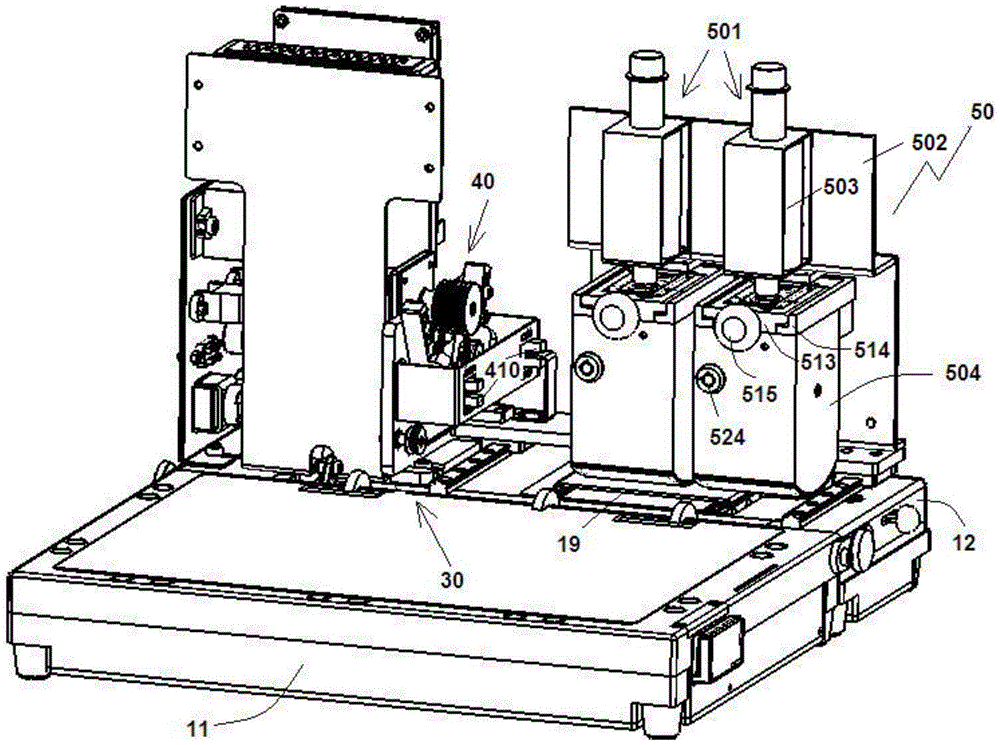

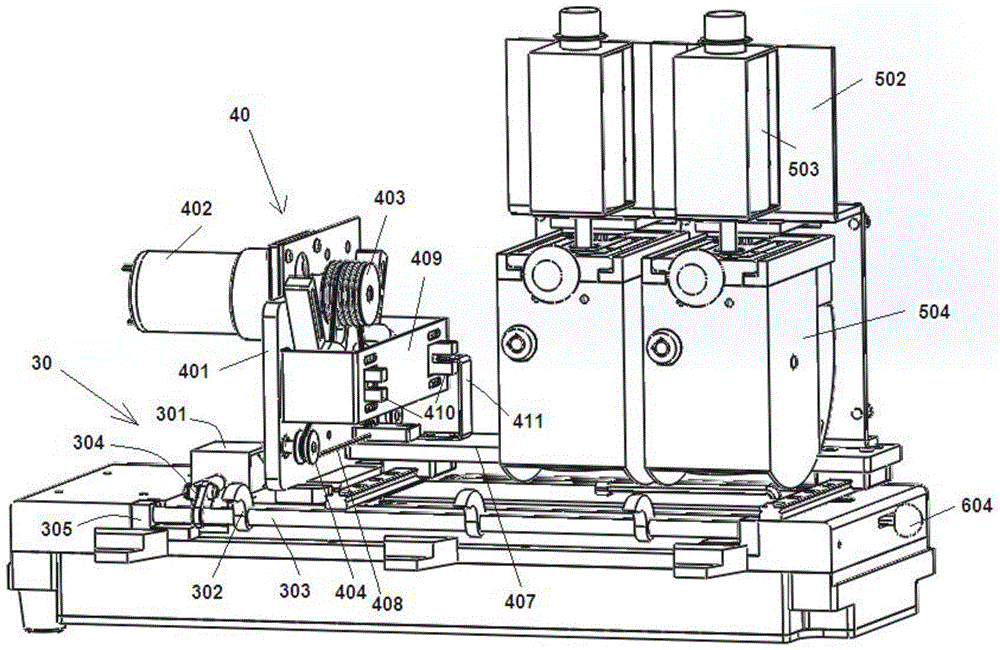

Stamping module for stamp control device

The invention discloses a stamping module for a stamp control device. The stamping module comprises a stamp box. The stamp box comprises a stamp shell, and an upper cover box and a stamp are arranged in the stamp shell. The stamp comprises a stamp handle and a stamp base. The upper surface of the upper cover box is fixedly connected with an opening in the upper surface of the stamp shell. The upper surface and the lower surface of the upper cover box are respectively provided with a central hole. A boss-shaped hand shank at the upper end of the stamp handle is arranged below the central hole in the upper surface of the upper cover box, and the lower end of the stamp handle penetrates through the central hole in the lower surface of the upper cover box and is connected with the stamp base. The diameter of the central hole in the upper surface of the upper cover box is smaller than that of the hand shank, and the diameter of the central hole in the lower surface of the upper cover box corresponds to that of the stamp handle. The position, between the boss-shaped hand shank and the lower surface of the upper cover box, of the stamp handle is further sleeved with a spring. The stamping module guarantees that safety of the stamp is controllable, and the risk caused by poor management of the stamp is reduced.

Owner:上海慧升智能科技股份有限公司

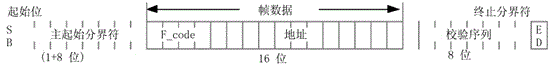

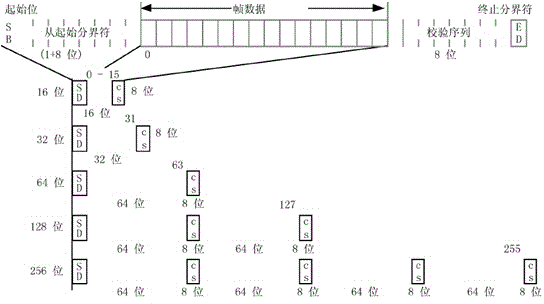

Safety output method based on MVB communication

ActiveCN104468301AShort response timeDoes not consume additional resourcesData switching networksComputer hardwareControllability

The invention discloses a safety output method based on MVB communication. A mode with an external processor interface is selected, and when the interruption time of prime frames in MVB communication is larger than t1 or the interruption time of frames of ports of polled specific device addresses is larger than t2, a specific numerical value is written into an MVB communication register; if communication is normal, another specific numerical value is written into the MVB communication register. An external processor can judge whether MVB communication is normal according to the numerical values of the MVB communication register, and if communication is normal, an output unit is controlled through network input data; if communication is abnormal, the output unit is shut down immediately, and therefore the safety and controllability of a train are guaranteed. According to the method, all the prime frames and the frames of the polled specific device addresses are monitored, if an MVB bus control device fails sending the prime frames of the specific device addresses for some reason, corresponding devices will not receive the frames containing the specific device addresses, output will be stopped after a specific period of time, and therefore the safety and controllability of the devices are guaranteed.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

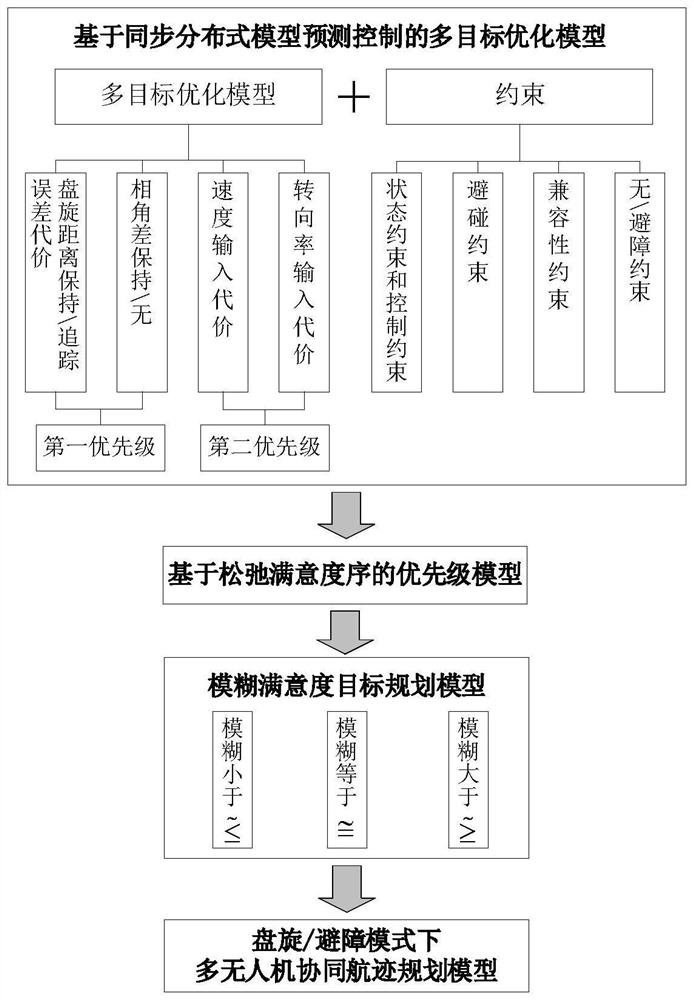

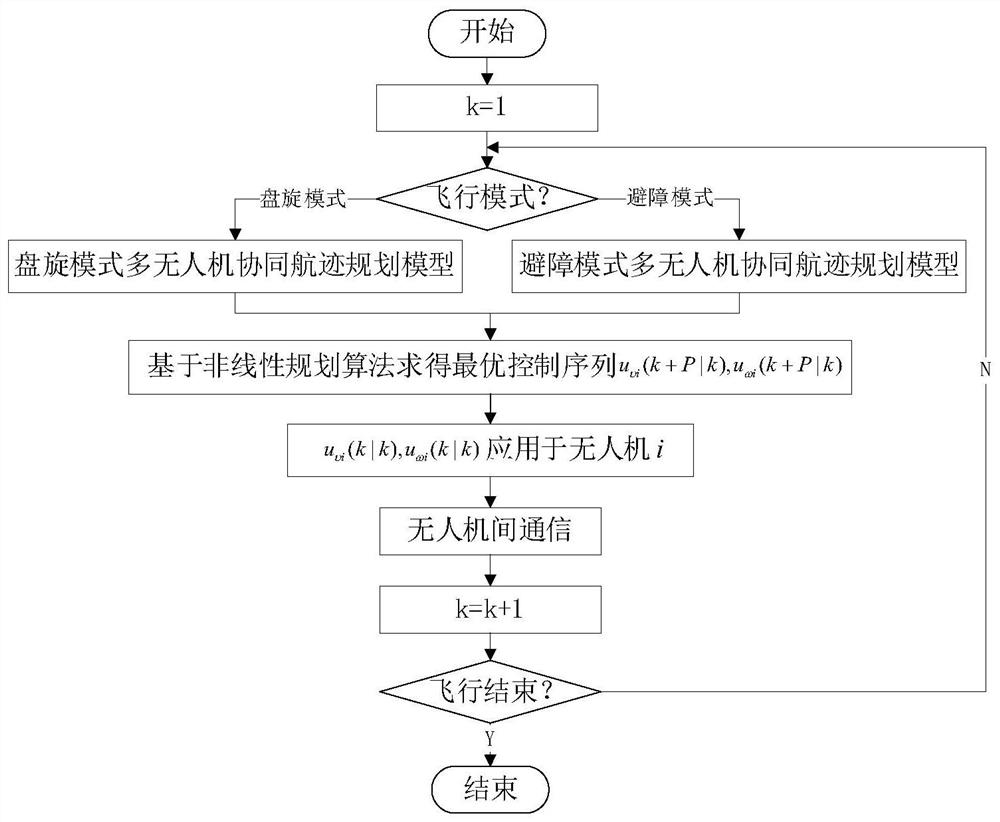

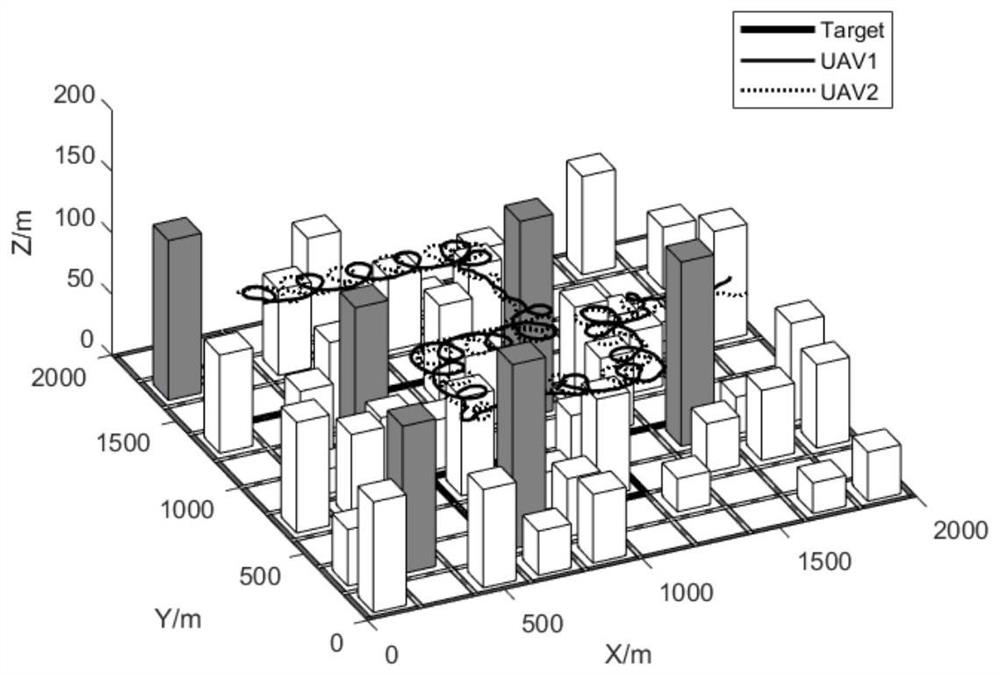

Multi-unmanned aerial vehicle cooperative route planning method for tracking ground target in dual-mode circling manner

ActiveCN112923925AAccurate trackingAccurate monitoringInternal combustion piston enginesNavigational calculation instrumentsObstacle avoidanceFlight safety

The invention discloses a multi-unmanned aerial vehicle cooperative route planning method for tracking a ground target in a dual-mode circling manner. An unmanned aerial vehicle kinematic model, a ground target motion model and a three-dimensional urban environment model are constructed; based on the obstacle avoidance requirements of the unmanned aerial vehicle and the high-rise building, a condition for switching between a circling mode and an obstacle avoidance mode is provided; a multi-objective optimization model is constructed under dual modes based on a multi-objective optimization algorithm of synchronous distributed model predictive control; a priority model is established based on a relaxation satisfaction sequence method to obtain a generalized fuzzy satisfaction target planning model; and based on the synchronous distributed model predictive control and fuzzy target planning method, the multi-unmanned aerial vehicle cooperative route planning model under dual modes is constructed. Tracking precision, energy saving and other performance indexes and different priority requirements are comprehensively considered, and based on the synchronous distributed model prediction control and fuzzy target planning method, a reliable flight path planning scheme is provided for multi-unmanned-aerial-vehicle cooperative target tracking on the premise that it is guaranteed that multi-unmanned-aerial-vehicle cooperative flight is safe and controllable.

Owner:TIANJIN UNIV

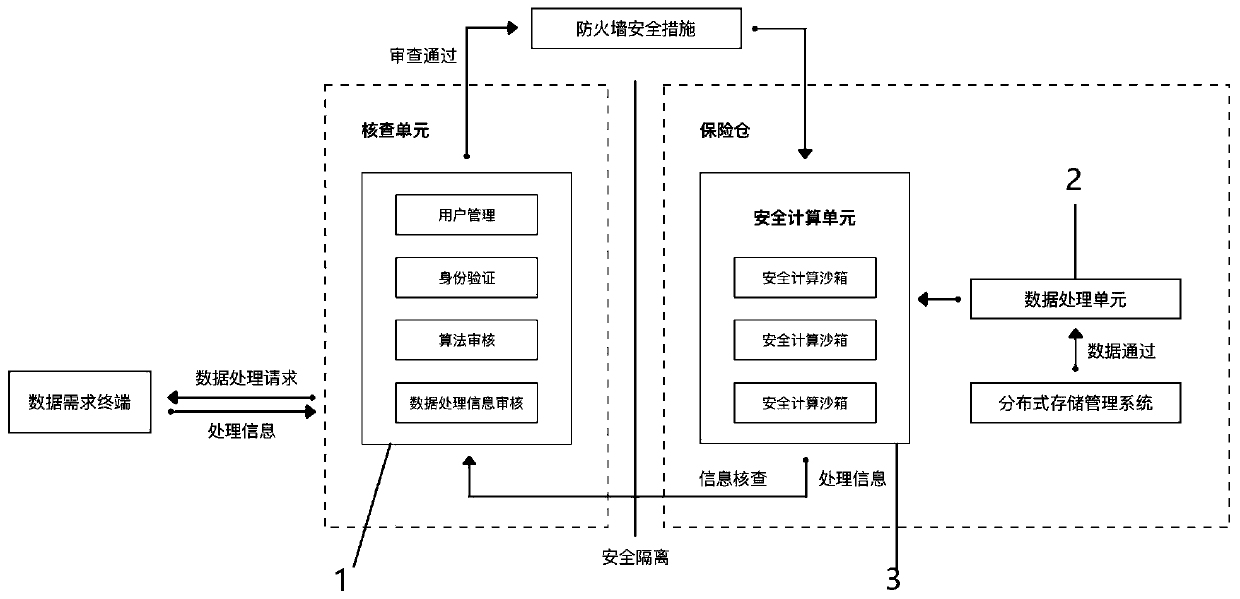

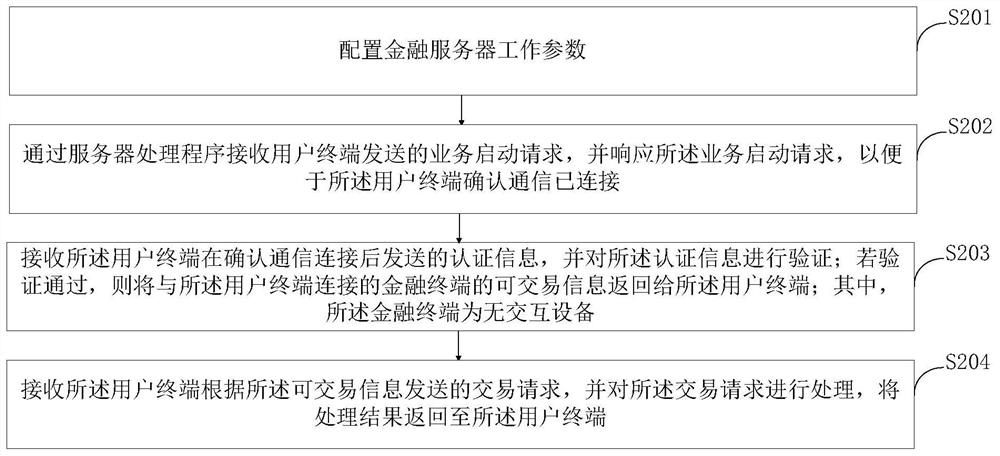

Data security system based on block chain and data security processing method

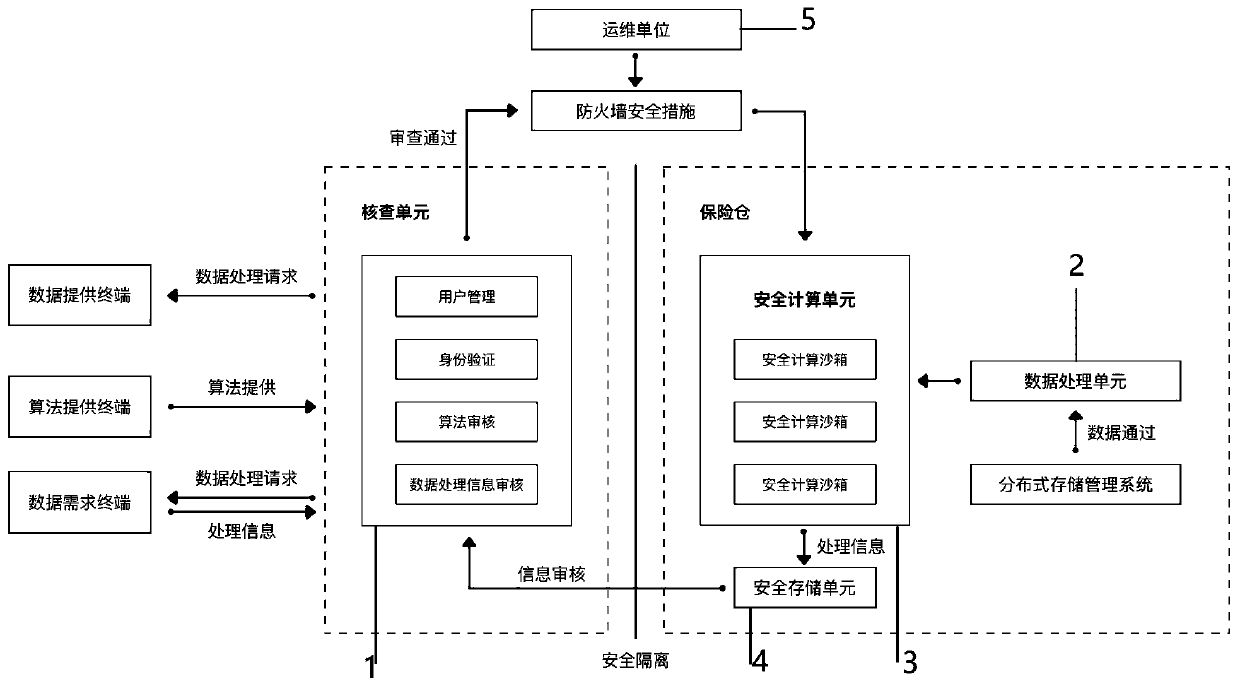

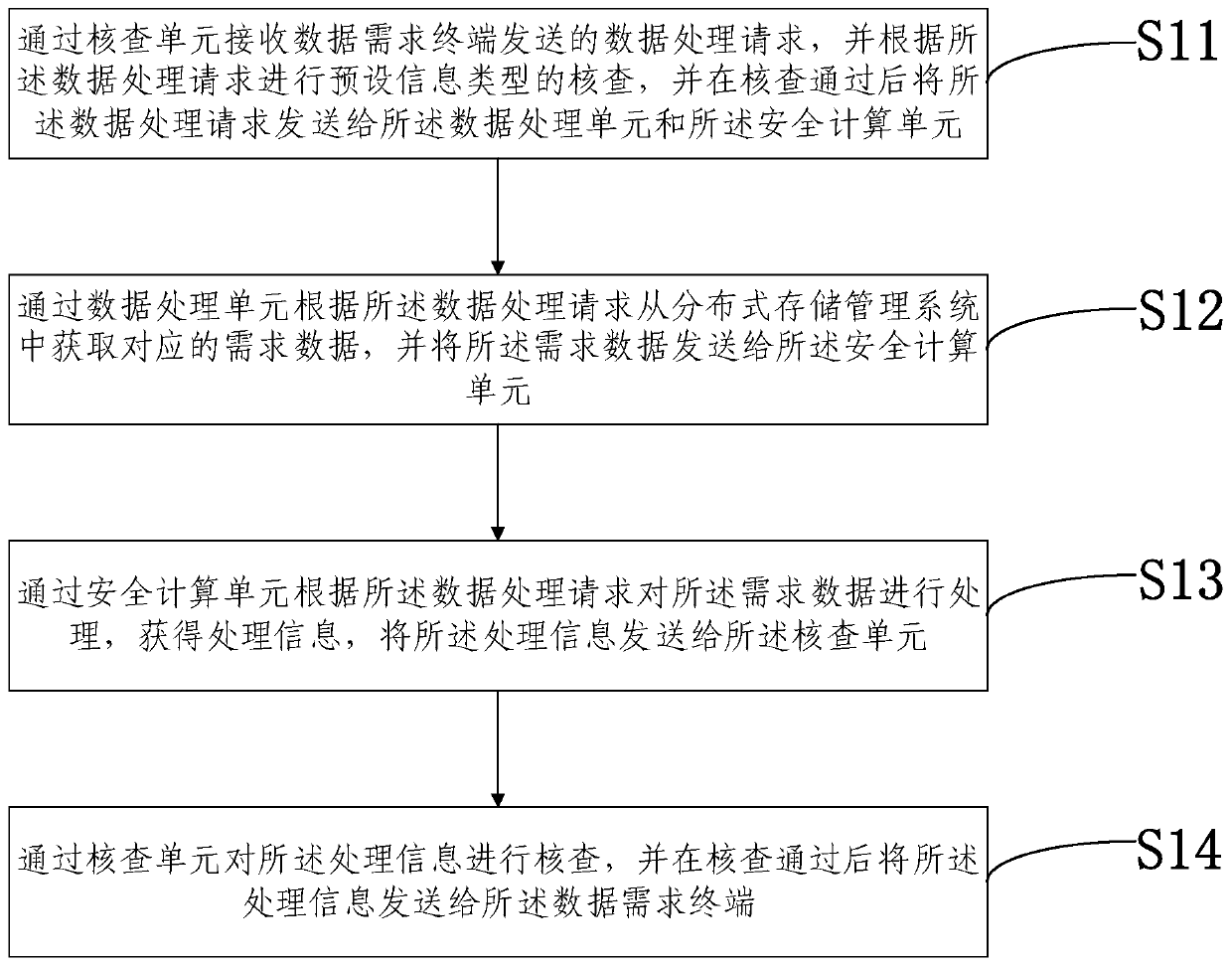

ActiveCN110290125AEasy to useEnsure safety and controlSecuring communicationData providerControllability

The embodiment of the invention provides a data security system based on a block chain and a data security processing method. The system comprises a checking unit, a security calculation unit and a data processing unit, the checking unit is used for receiving a data processing request sent by a data demand terminal, checking a preset information type according to the data processing request, and sending the data processing request to the data processing unit and the security calculation unit after the checking is passed; the data processing unit is used for obtaining corresponding demand data from the distributed storage management system according to the data processing request and sending the demand data to the security calculation unit; the security calculation unit is used for processing the demand data according to the data processing request, obtaining processing information, sending the processing information to the checking unit for checking, and sending the processing information to the data demand terminal after the checking is passed, thereby realizing the safe use of the shared data in a safe computing environment, and ensuring the safety and controllability of the data provider on the source data.

Owner:西安纸贵互联网科技有限公司

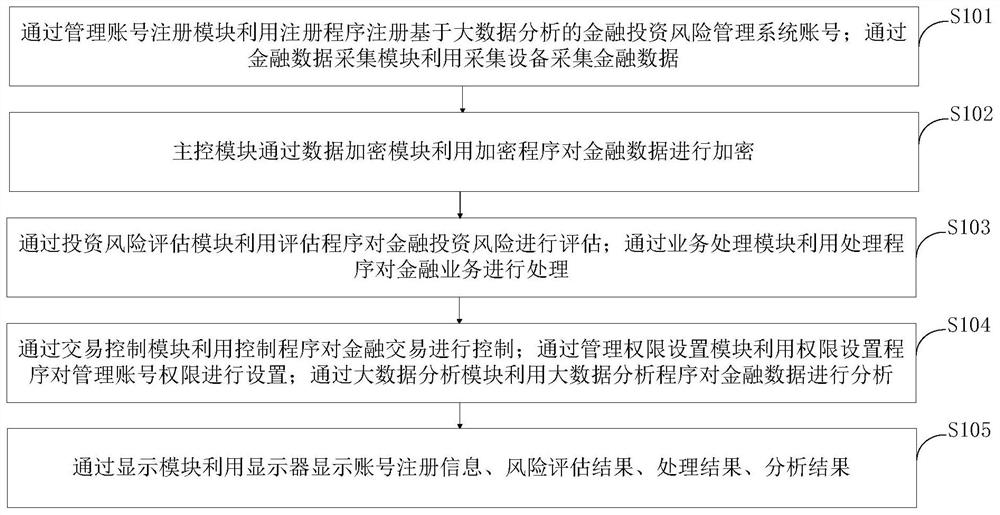

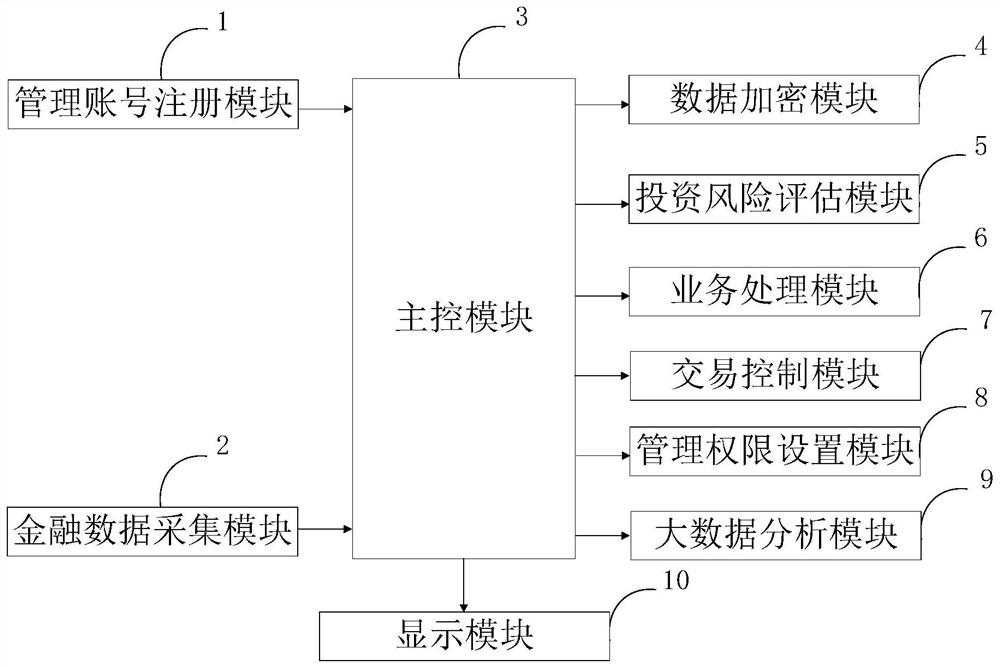

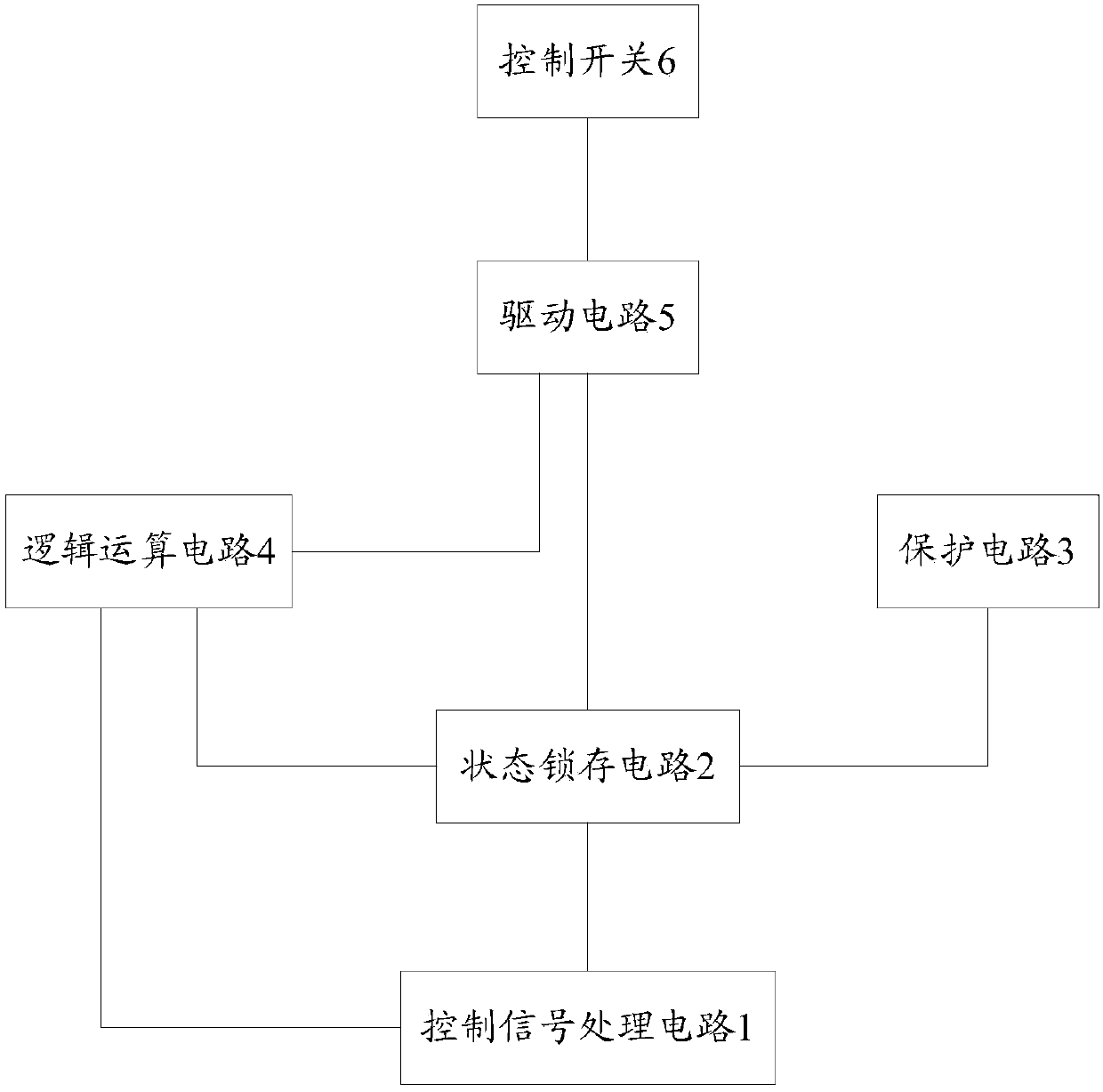

Financial investment risk management method and system based on big data analysis

The invention belongs to the technical field of financial investment risk management. The invention discloses a financial investment risk management method and system based on big data analysis. The financial investment risk management system based on big data analysis comprises a management account registration module, a financial data acquisition module, a main control module, a data encryptionmodule, an investment risk assessment module, a business processing module, a transaction control module, a management authority setting module, a big data analysis module and a display module. Through the service processing module, the problem that when a user uses the financial terminal, large potential safety hazards exist is effectively solved, and the safety and confidentiality of user information are improved; and meanwhile, various parameters are flexibly adjusted and configured through the transaction control module according to the supervision requirements of the internet electronic account, so that the flexibility and security requirements of internet finance are met, the security controllability of the internet finance is ensured, and the application range and security are improved.

Owner:曹明洲

Monomer limiting type down-hole sand jetting prevention stopper

InactiveCN106481301AEasy to install and disassemble on sitePrevent slippingWell/borehole valve arrangementsSealing/packingSnubbingEngineering

The invention discloses a monomer limiting type down-hole sand jetting prevention stopper which comprises a valve body, a suspension assembly and a stopper assembly. The stopper assembly is arranged in an inner cavity of the valve body, and the peripheral wall of the upper end of the stopper assembly is temporarily and fixedly connected with the valve body through a shearing pin, an annular part is formed between the inner wall of the valve body and the lower half section of the stopper assembly, and the suspension assembly is installed at the portion, between the inner wall of the valve body and the stopper assembly, at the bottom of the annular part. Zero-pressure non-jetting and non-overflowing of a tubular column at the upper portion of a tool are achieved, safety and controllability of lowering a drill are ensured, and the problem that a drill cannot be lowered when jetting and overflowing of the tubular column are caused due to the wellhead pressure condition of the snubbing service is solved. After the drill reaches the design position, hydraulic force is used for opening an overflowing channel, and construction of sand jetting or well washing or acidification or sand prevention or other follow-up technologies can be completed.

Owner:CHINA PETROLEUM & CHEM CORP +1

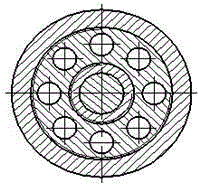

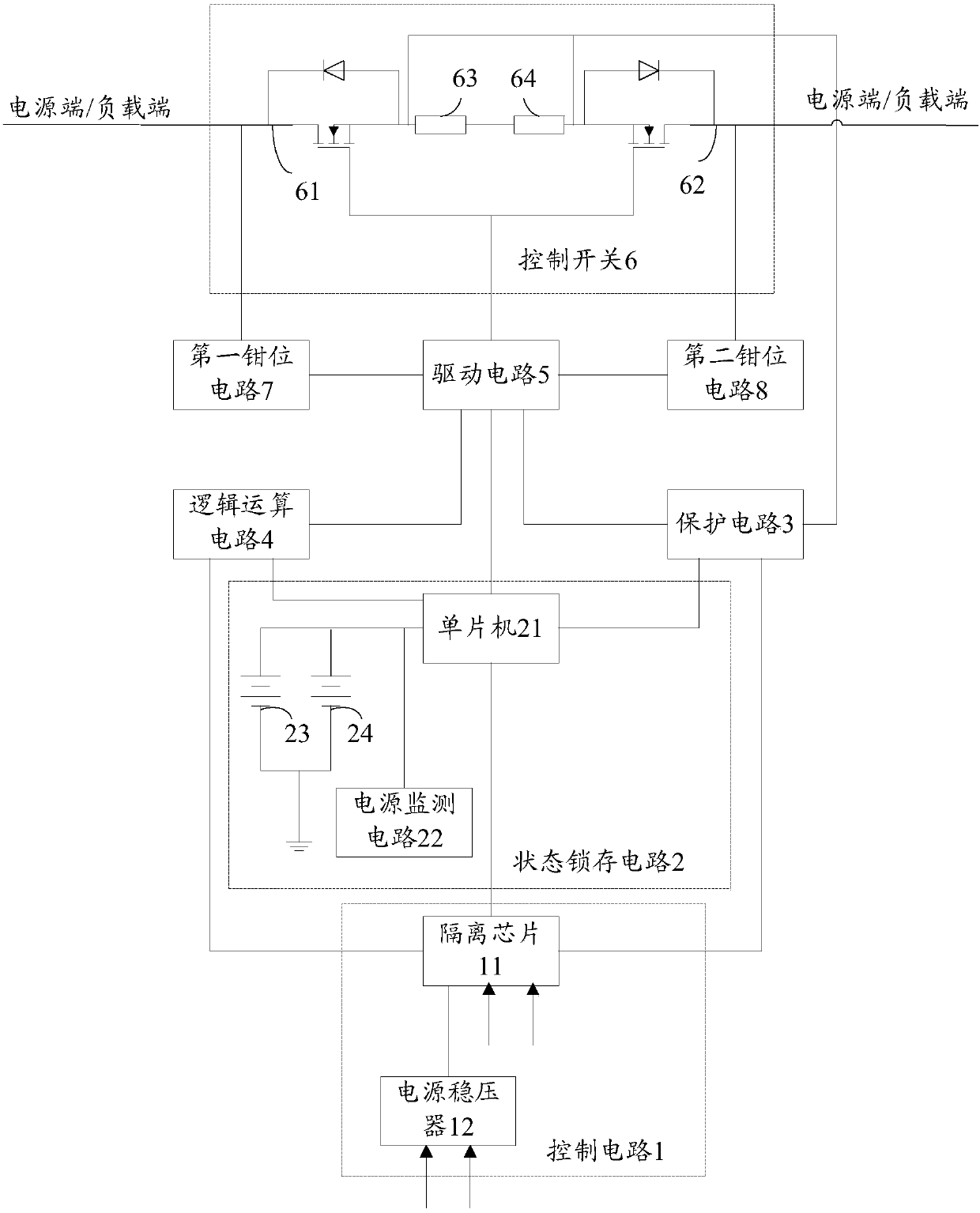

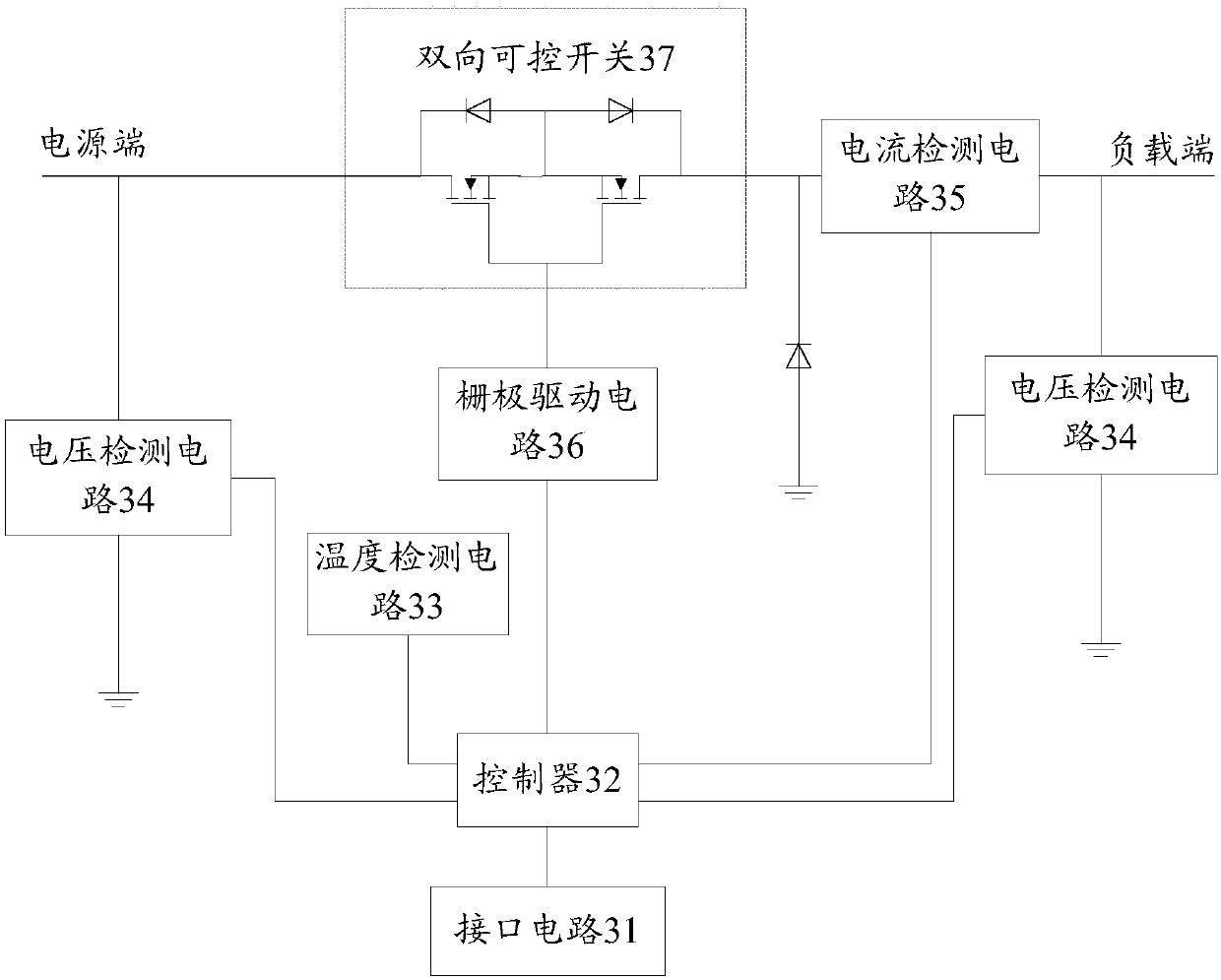

Solid-state relay

PendingCN107681996AWith status hold functionSave energyProgramme controlComputer controlSignal processing circuitsControl signal

The invention relates to a solid-state relay comprising a control signal processing circuit, a state latch circuit, a protection circuit, a logic operational circuit, a drive circuit and a control switch, wherein the state latch circuit is separately connected with the control signal processing circuit, the protection circuit, the logic operational circuit and the drive circuit; the control signalprocessing circuit is also connected with the logic operational circuit; the logic operational circuit is also connected with the drive circuit; and the drive circuit is also connected with the control switch. According to the solid-state relay provided by the invention, a previous connection or disconnection state of the control switch can also be kept even an external control power input is cutoff; the solid-state relay has a state keeping function, and needs extremely low energy when the state is kept, so as to be beneficial to prolonging the service life of the solid-state relay having the state keeping function.

Owner:北京国科天宏自动化技术有限公司

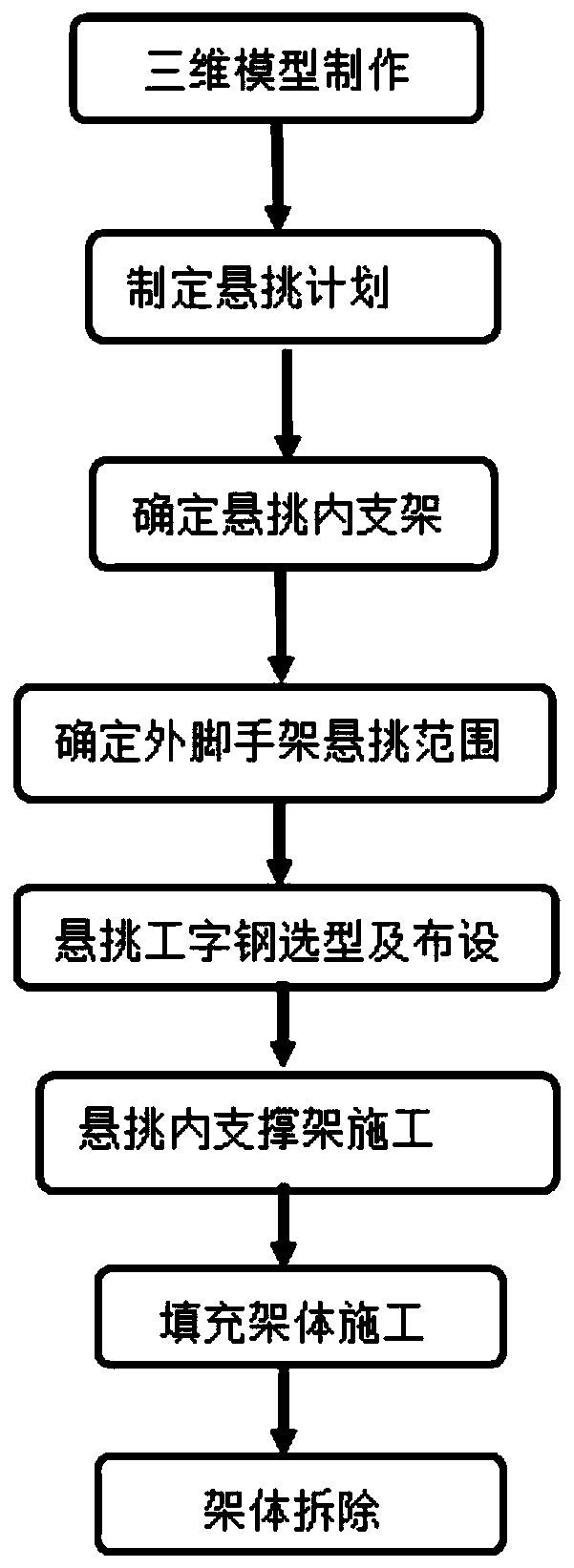

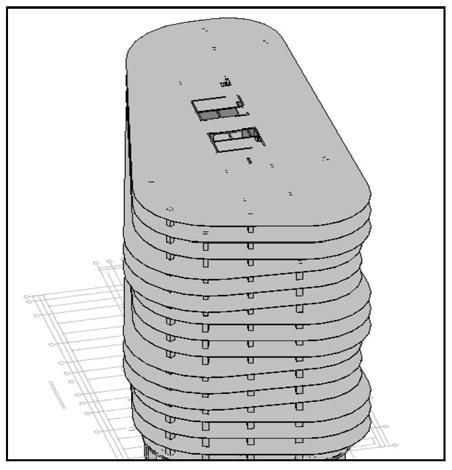

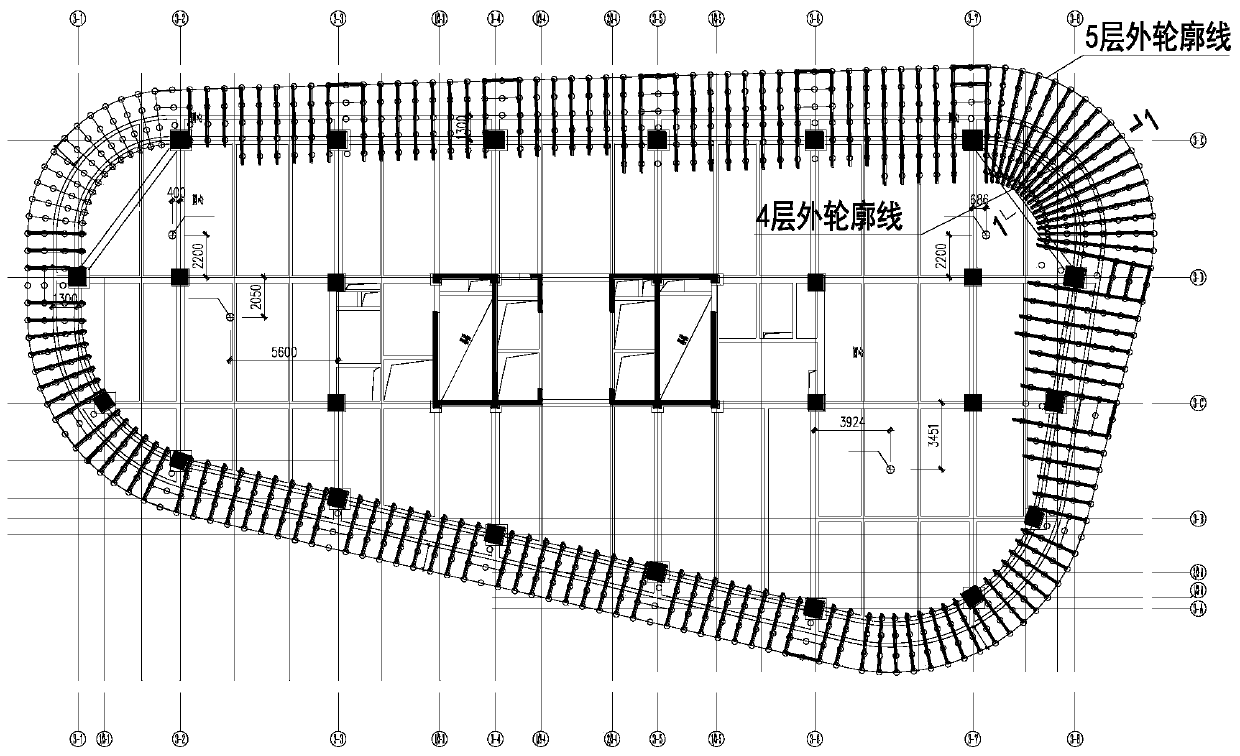

Construction method of irregular convex and concave facade structure scaffold

ActiveCN111395725AReliable protective measuresAvoid safety hazardsScaffold accessoriesBuilding support scaffoldsConstruction engineeringExternal cladding

The invention discloses a construction method of an irregular convex and concave facade structure scaffold, belongs to the field of building construction, and aims to solve the technical problem of how to set up an external scaffold and an external overhanging structure support system simultaneously. According to the technical scheme, the construction method is characterized in that the outer contours of all floors are overlapped and modeled through BIM and CAD software, an inner frame body and an outer frame body are integrally taken into consideration, and the ranges of the external scaffoldand an overhanging inner support frame are determined; and then electronic typesetting is carried out on arranging positions, length, angles and models of overhanging I-shaped steel so that materialscan be saved to the maximum extent. The construction method specifically comprises the following steps: 1, manufacturing a three-dimensional model, specifically, an appearance model of a building ismade in advance by utilizing BIM; 2, making an overhanging plan; 3, determining the overhanging range of the inner support frame; 4, determining the overhanging range of the external scaffold; 5, selecting and arranging the overhanging I-shaped steel; 6, constructing the overhanging inner support frame; 7, constructing a filling frame; and 8, dismantling a scaffold body, specifically, the scaffoldbody can be dismantled after the construction of outer wall decoration is finished.

Owner:CHINA CONSTR EIGHTH ENG DIV

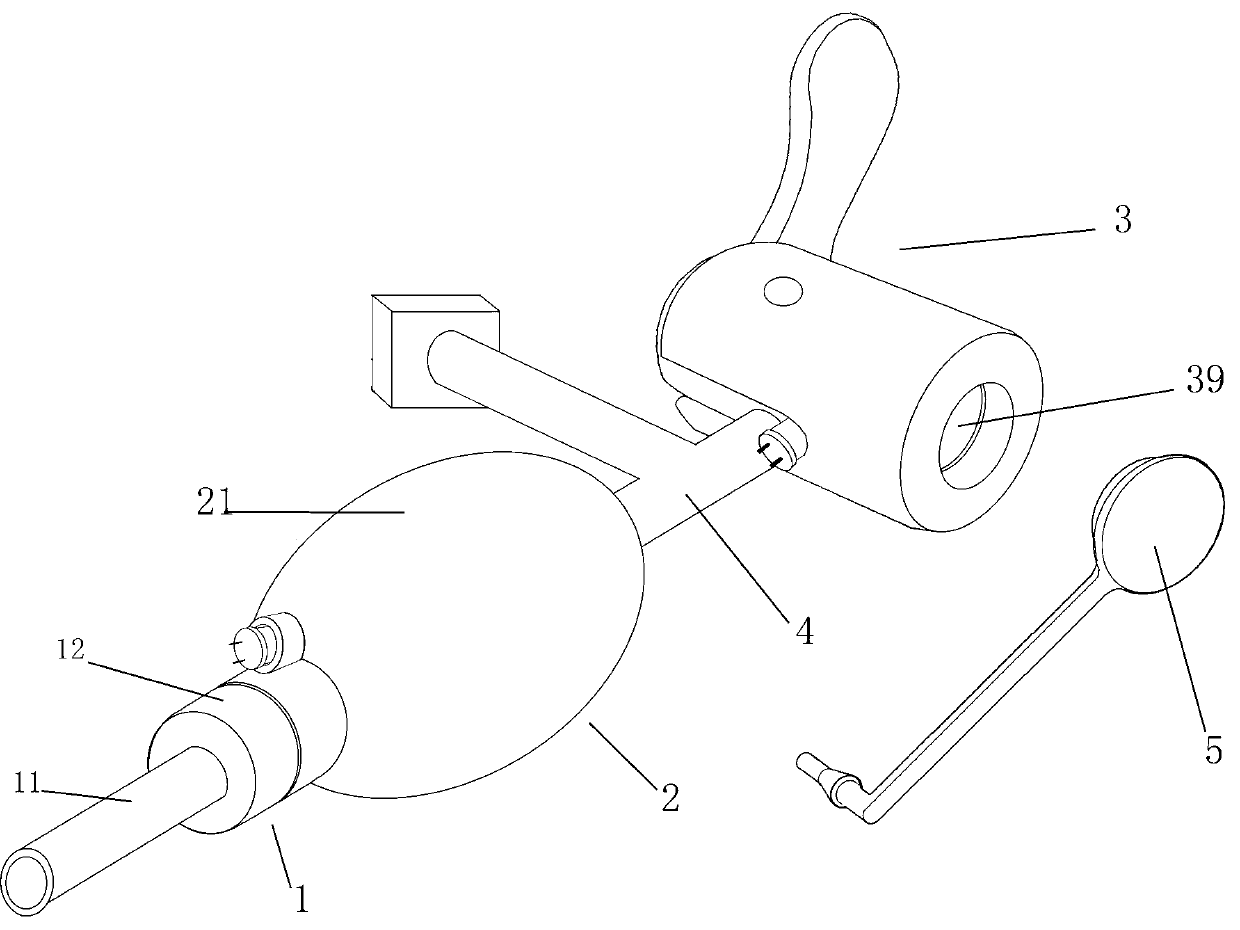

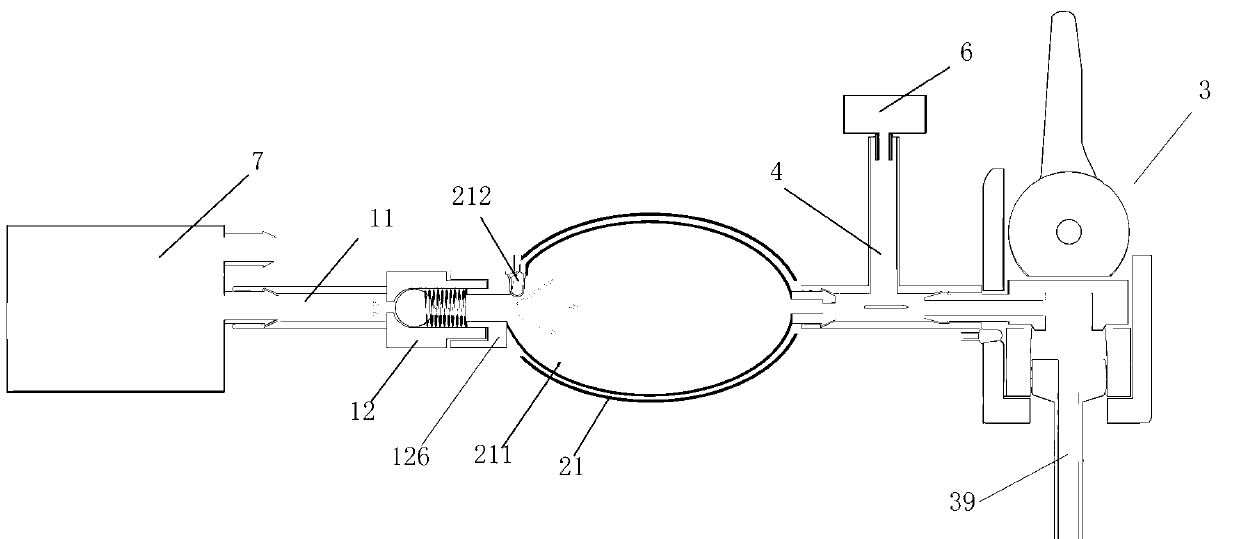

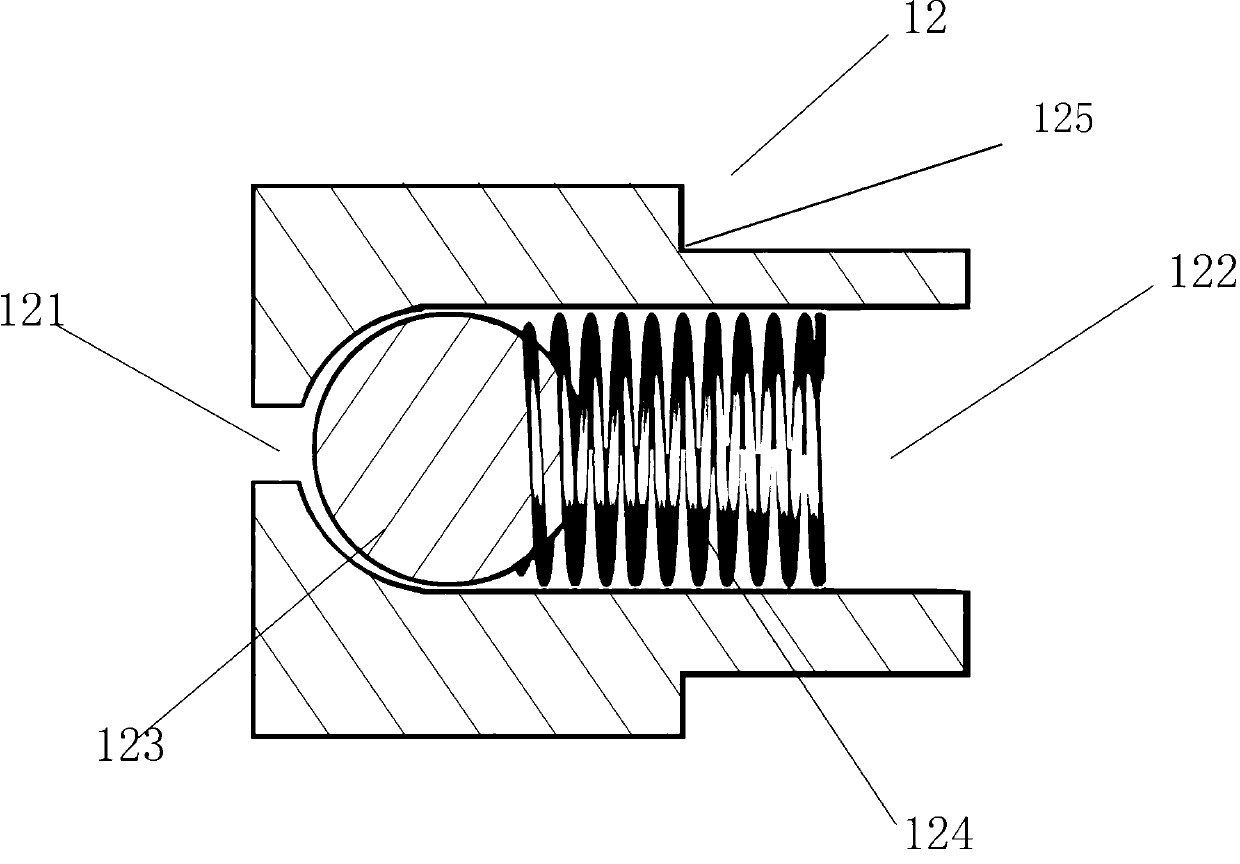

Air non-return pressure relief device

ActiveCN103100125AEnsure safety and controlGuaranteed air tightnessRespiratorsPressure infusionInductorCompound (substance)

The invention discloses an air non-return pressure relief device which comprises a non-return system, a pressure relief system and a switchover system, wherein the non-return system, the pressure relief system and the switchover system are communicated in sequence. The non-return system includes a connecting pipe and an air non-return valve which is communicated with one end of the connecting pipe. The pressure relief system comprises an energy-gathered pressure relief capsule which is communicated with the other end of the air non-return valve. The energy-gathered pressure relief capsule is connected with the switchover system through a transverse arm of a T-shaped three-way pipe, and a longitudinal arm of the T-shaped three-way pipe is connected with an air pressure inductor. According to the air non-return pressure relief device, the air non-return system, the pressure relief system and the switchover system are utilized. Not only can controllability and safety of the air be guaranteed, but also air impermeability is guaranteed. Meanwhile, pollution of air and chemical liquid caused by ray irradiation and air return is avoided.

Owner:SHENZHEN WANJUYUAN TECH

A sealing device between the floating plate and the tank wall of an outer floating roof tank and its installation method

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +2

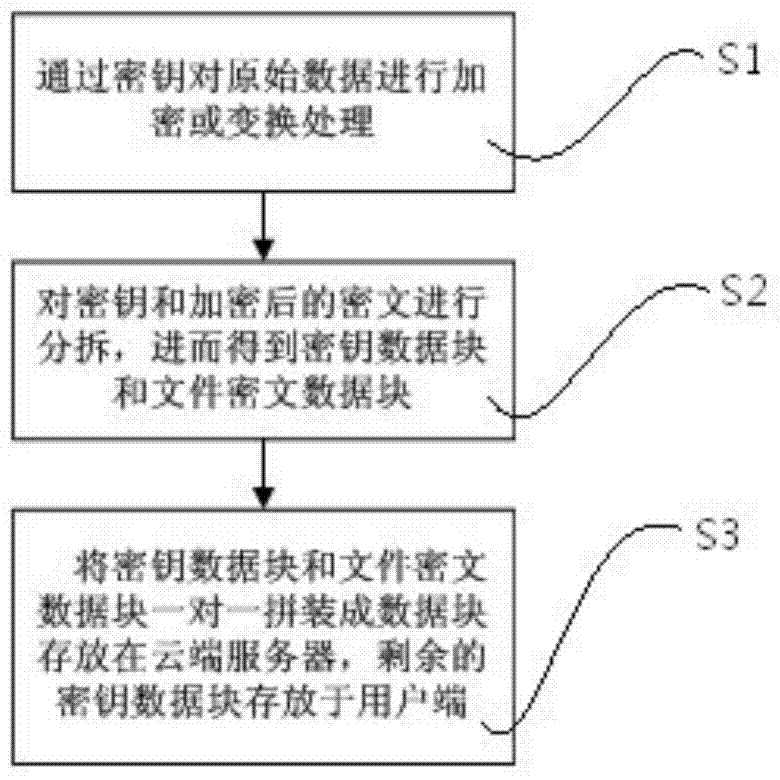

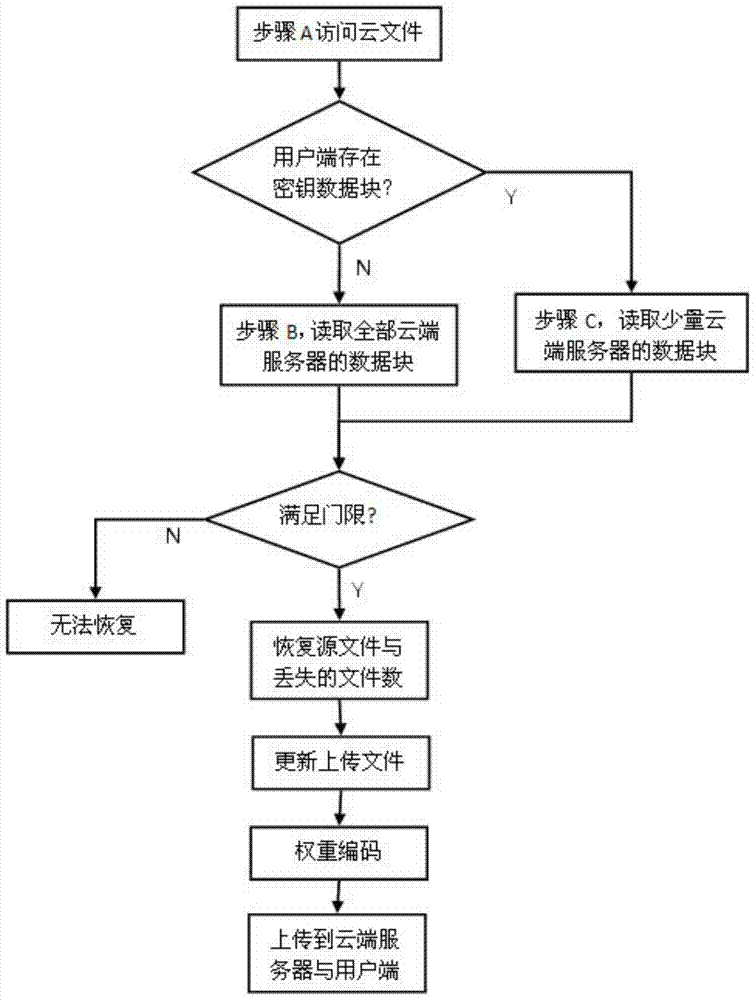

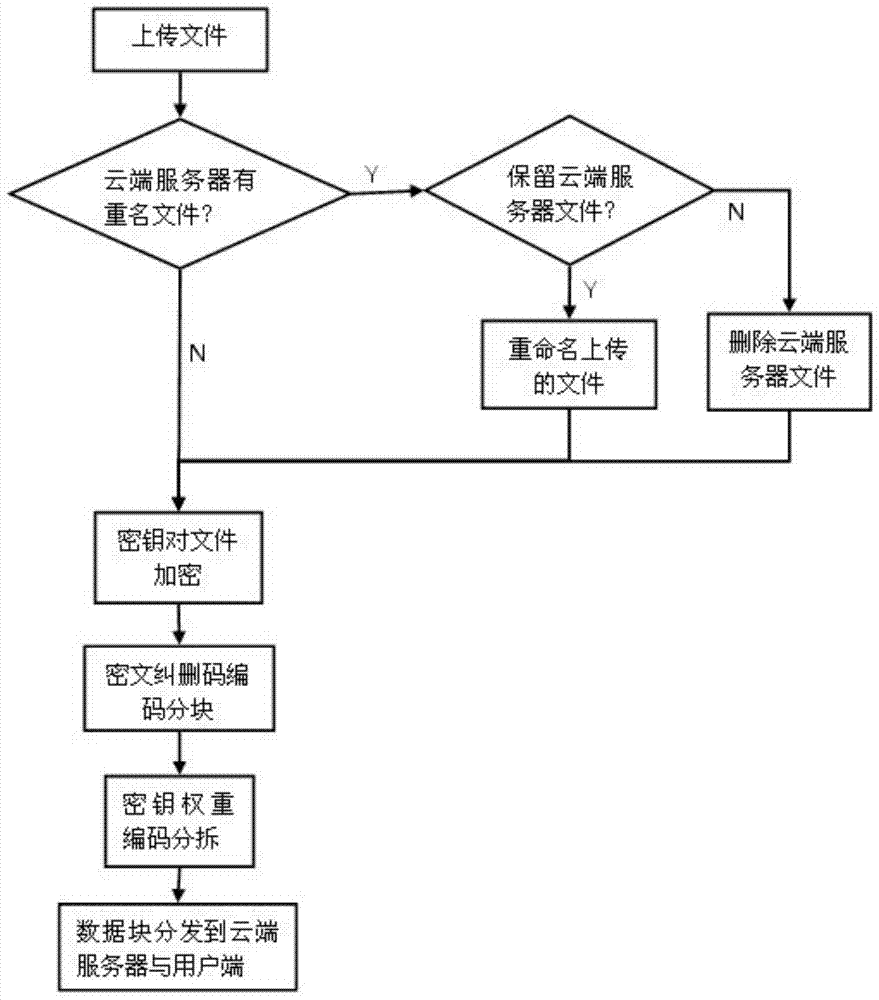

A Safe and Reliable Distributed Cloud Storage Method

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

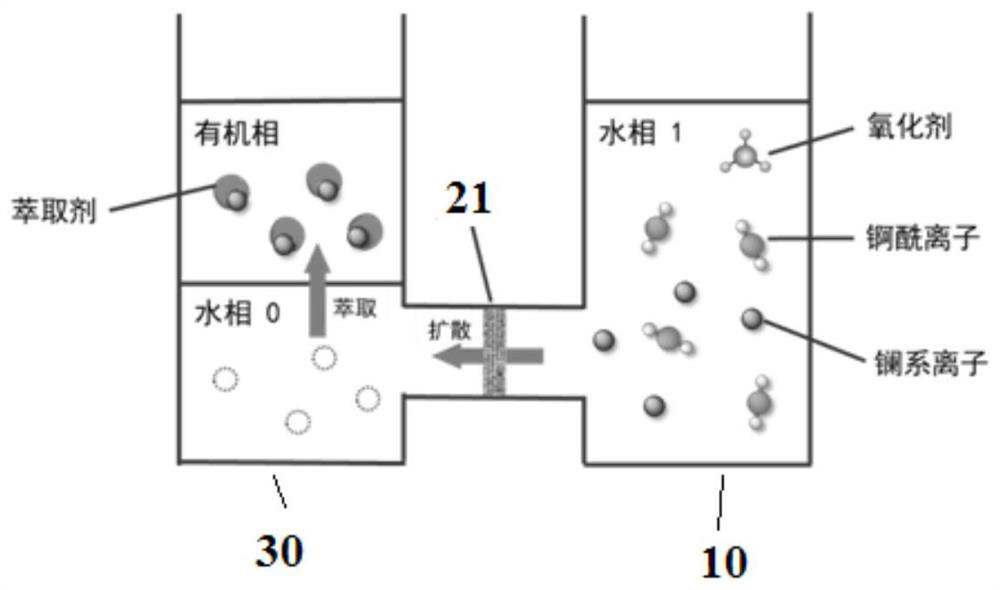

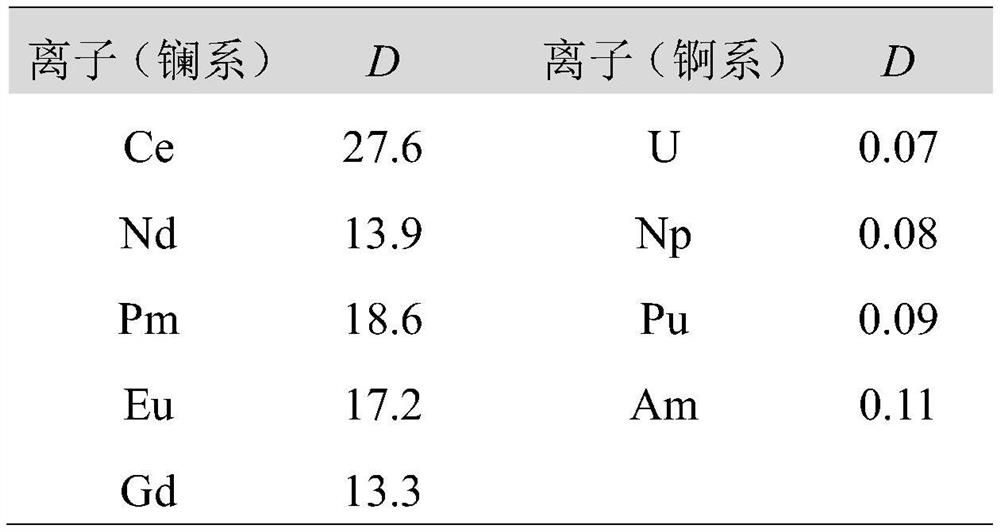

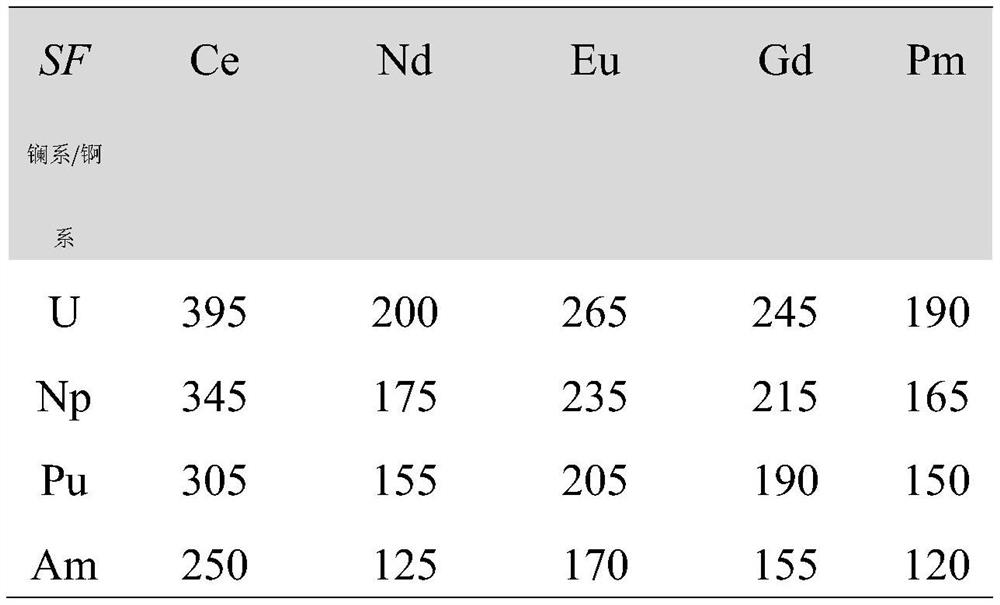

Lanthanum actinide group separation system and method based on oxidation, screening and extraction coupling

ActiveCN114107667AAchieving long-term shape constancyStable separationProcess efficiency improvementMembrane diffusionLanthanum

The invention discloses a lanthanum actinide group separation system and a lanthanum actinide group separation method based on oxidation, screening and extraction coupling. The system comprises a feed liquid area, a permeation area and a separation membrane for separating the feed liquid area from the permeation area, the actinide ions are oxidized into actinide ions by adopting an oxidizing agent in the feed liquid area, the oxidizing agent and the actinide ions in the feed liquid area are intercepted in the feed liquid area by a separation membrane, and the lanthanide ions in the feed liquid area continuously penetrate through the separation membrane to be diffused into a water phase in the permeation area and are extracted into an organic phase by an extracting agent; meanwhile, the organic phase in the permeation area cannot diffuse to the feed liquid area. According to the invention, the three different modules of oxidation, screening and extraction are effectively combined, and the separation of lanthanum and actinide elements is efficiently and stably realized in a manner of coupling and linking the three modules of oxidation, screening and extraction.

Owner:TSINGHUA UNIV

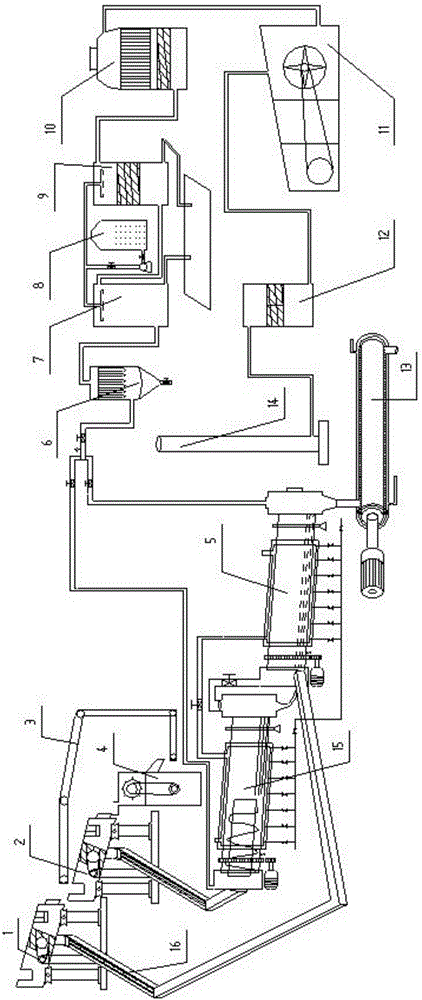

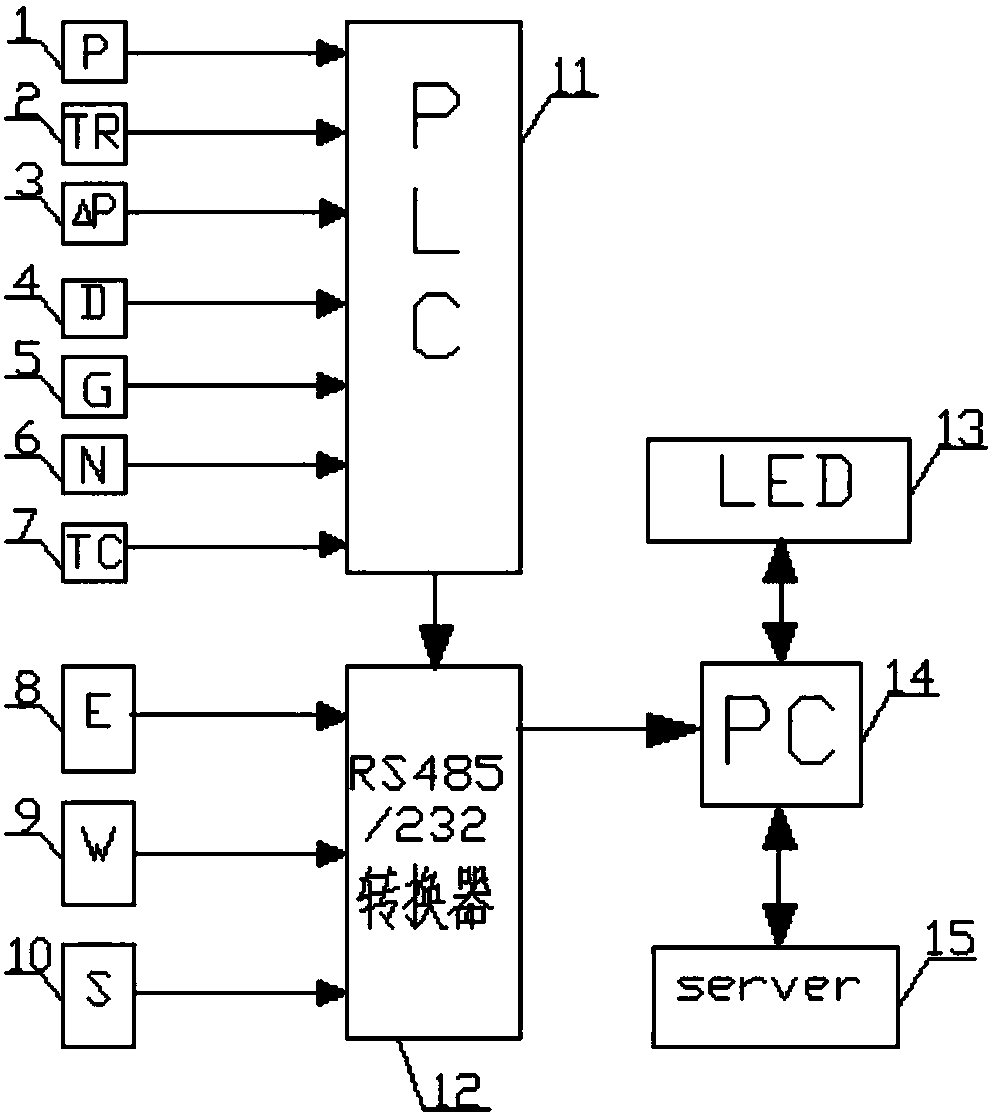

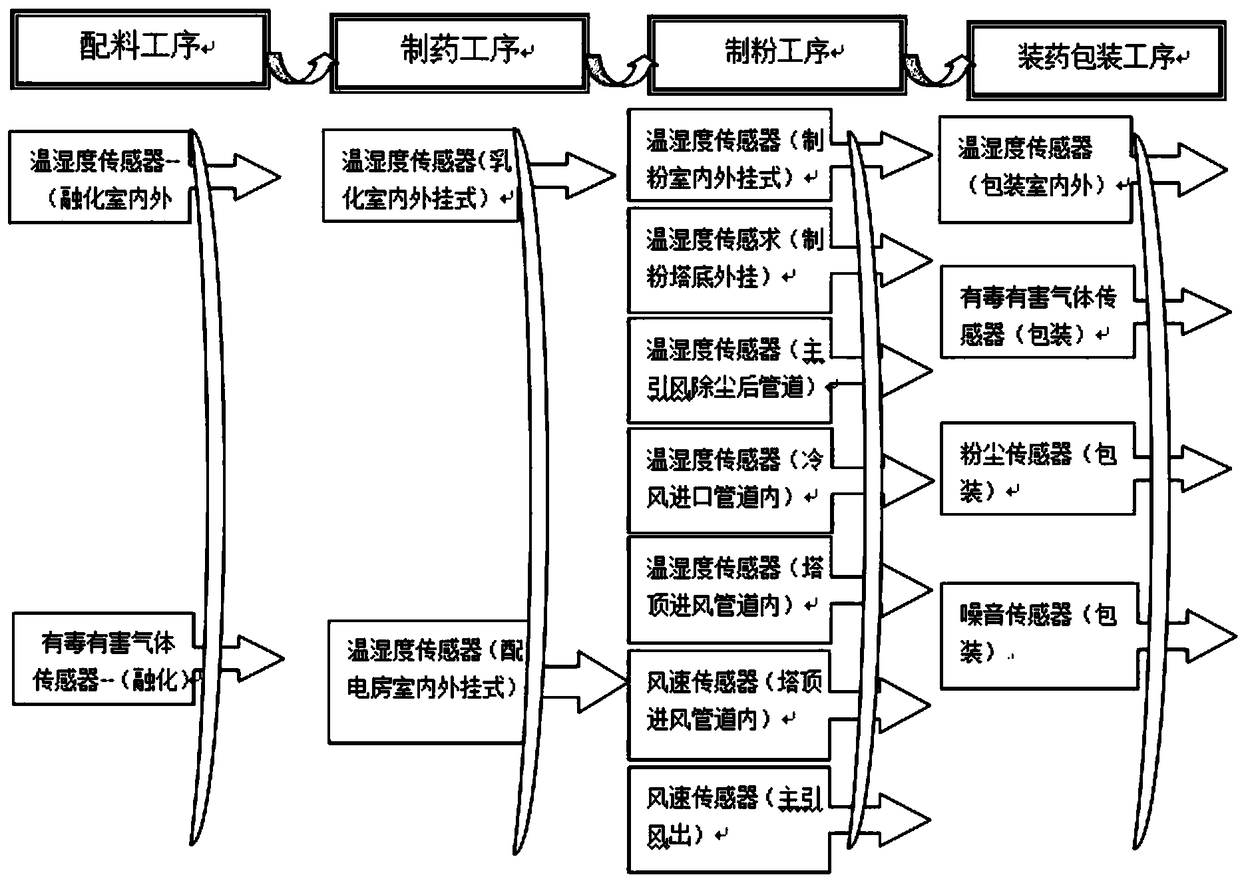

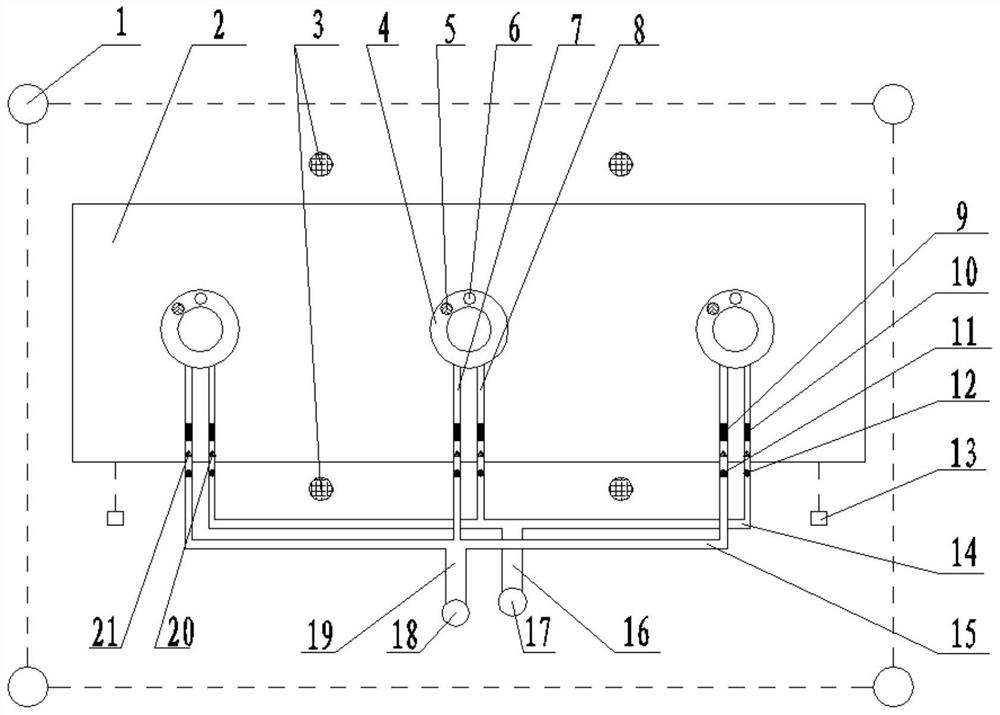

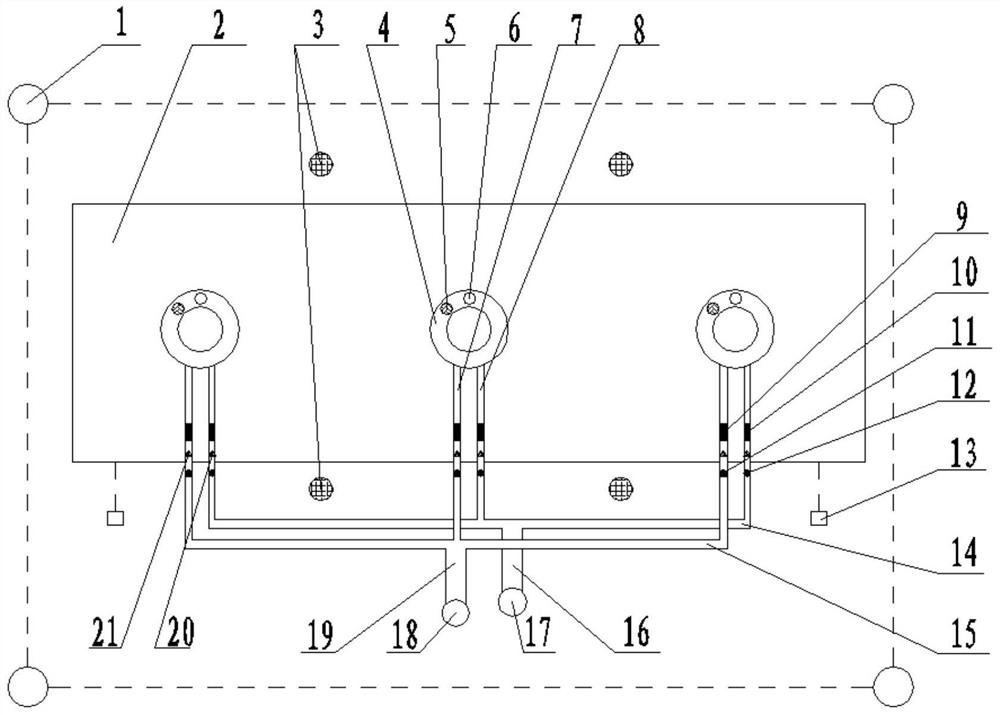

Explosive production line environment and energy consumption intelligent monitoring integration system

InactiveCN108415384APromotion of energy saving and emission reductionReduce the number of exceeding the standardEnergy industryTotal factory controlDifferential pressurePower detector

The invention discloses an explosive production line environment and energy consumption intelligent monitoring integration system which is composed of front-end monitoring devices and a rear-end controller. The front-end monitoring devices include a pressure sensor (1), a temperature and humidity sensor (2), a differential pressure transmitter (3), a dust sensor (4), a toxic and hazardous gas sensor (5), a noise sensor (6), a temperature compensation sensor (7), an intelligent power detector (8), a water flow accumulator (9) and a steam flow accumulator (10). The rear-end controller is composed of a PLC (11), an RS485 converter (12), a PC (14), a server (15) and an LED display screen (13) which are arranged in the control room on the explosive production line. The LC (11), the RS485 converter (12), the PC (14) and the LED display screen (13) are connected in turn. The server (15) is connected with the PC (14). The technical support can be provided for monitoring and early warning of the civil explosive enterprise production environment condition and energy consumption.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Stamp module for stamp control

The invention discloses a stamping module for a stamp control device. The stamping module comprises a stamp box. The stamp box comprises a stamp shell, and an upper cover box and a stamp are arranged in the stamp shell. The stamp comprises a stamp handle and a stamp base. The upper surface of the upper cover box is fixedly connected with an opening in the upper surface of the stamp shell. The upper surface and the lower surface of the upper cover box are respectively provided with a central hole. A boss-shaped hand shank at the upper end of the stamp handle is arranged below the central hole in the upper surface of the upper cover box, and the lower end of the stamp handle penetrates through the central hole in the lower surface of the upper cover box and is connected with the stamp base. The diameter of the central hole in the upper surface of the upper cover box is smaller than that of the hand shank, and the diameter of the central hole in the lower surface of the upper cover box corresponds to that of the stamp handle. The position, between the boss-shaped hand shank and the lower surface of the upper cover box, of the stamp handle is further sleeved with a spring. The stamping module guarantees that safety of the stamp is controllable, and the risk caused by poor management of the stamp is reduced.

Owner:上海慧升智能科技股份有限公司

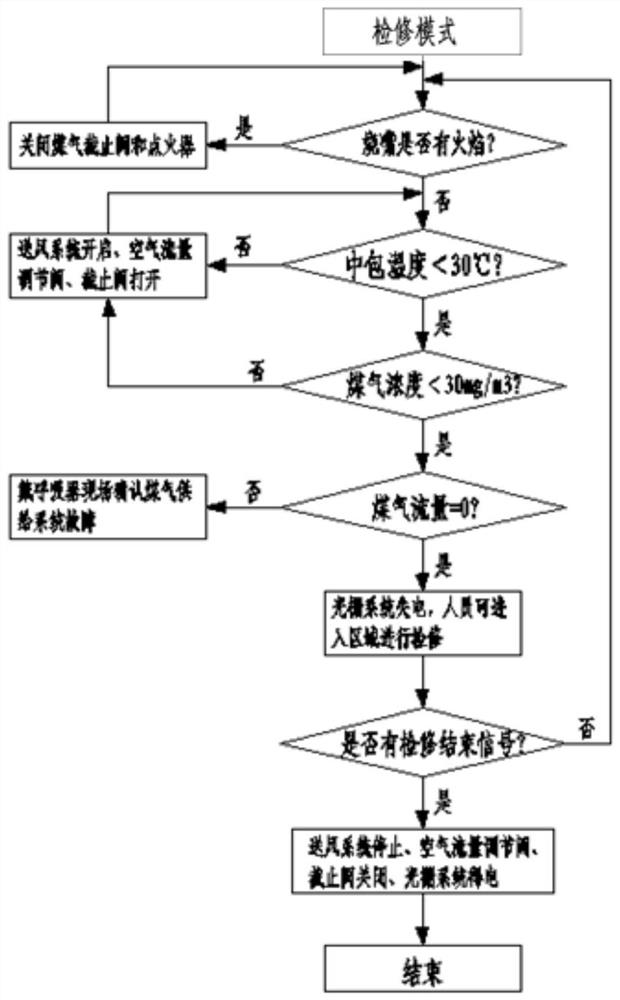

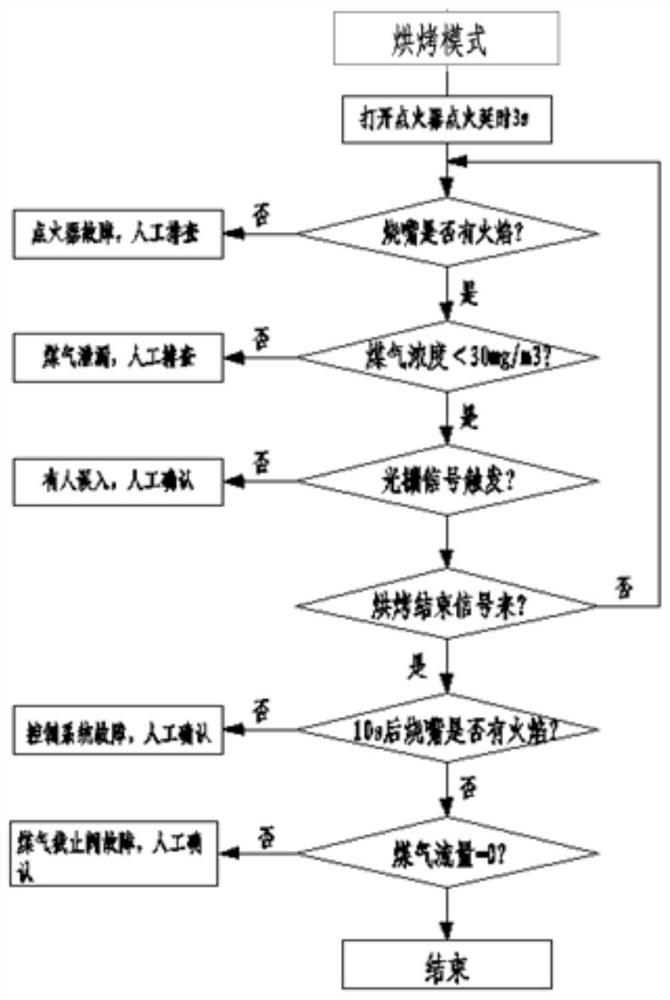

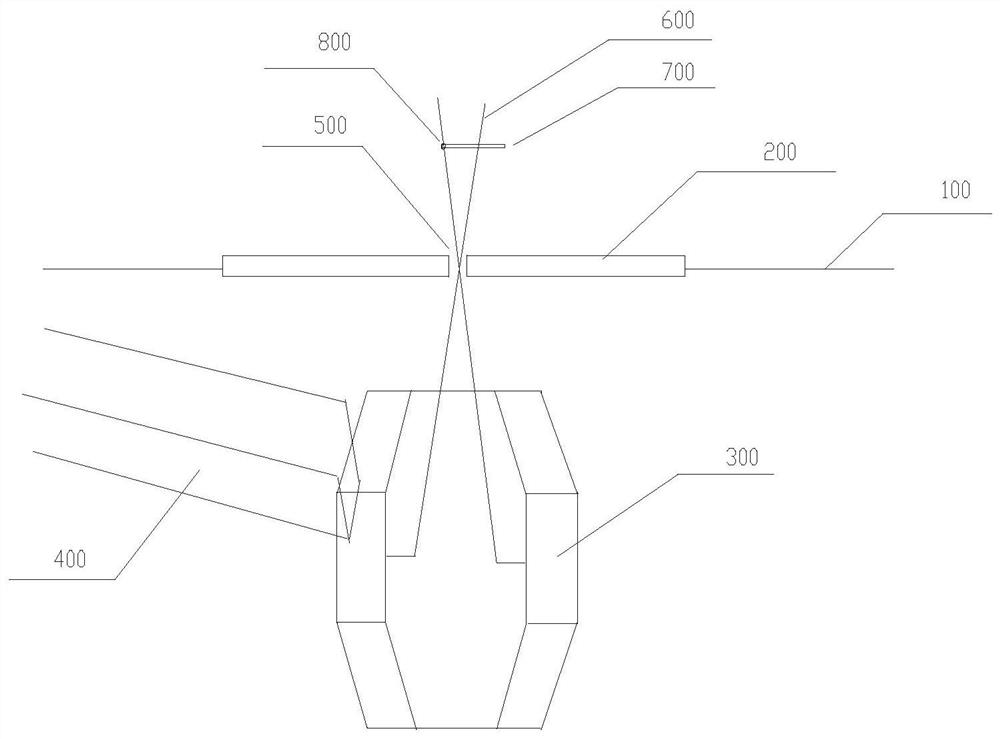

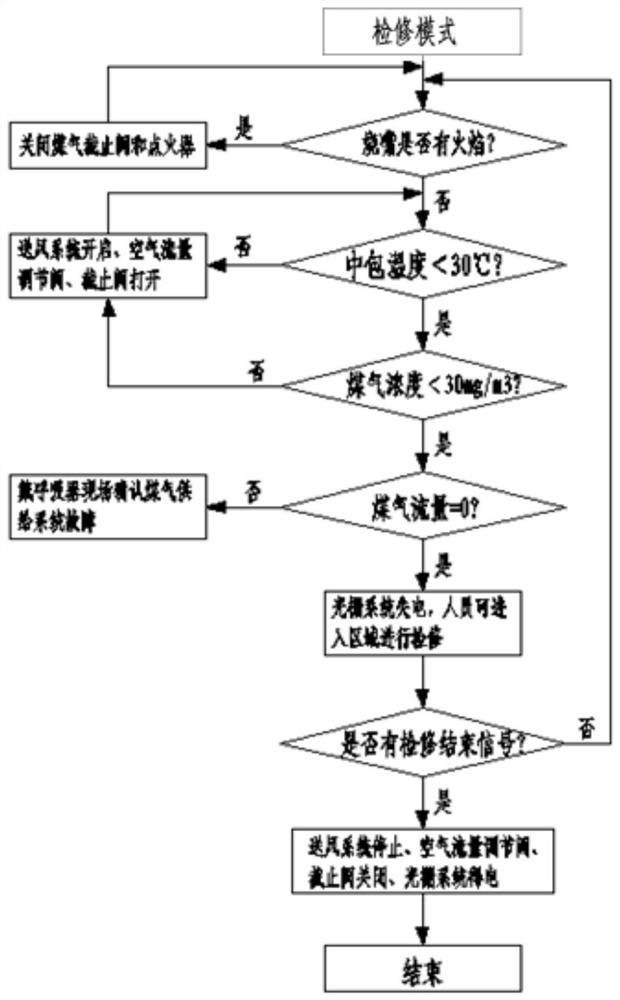

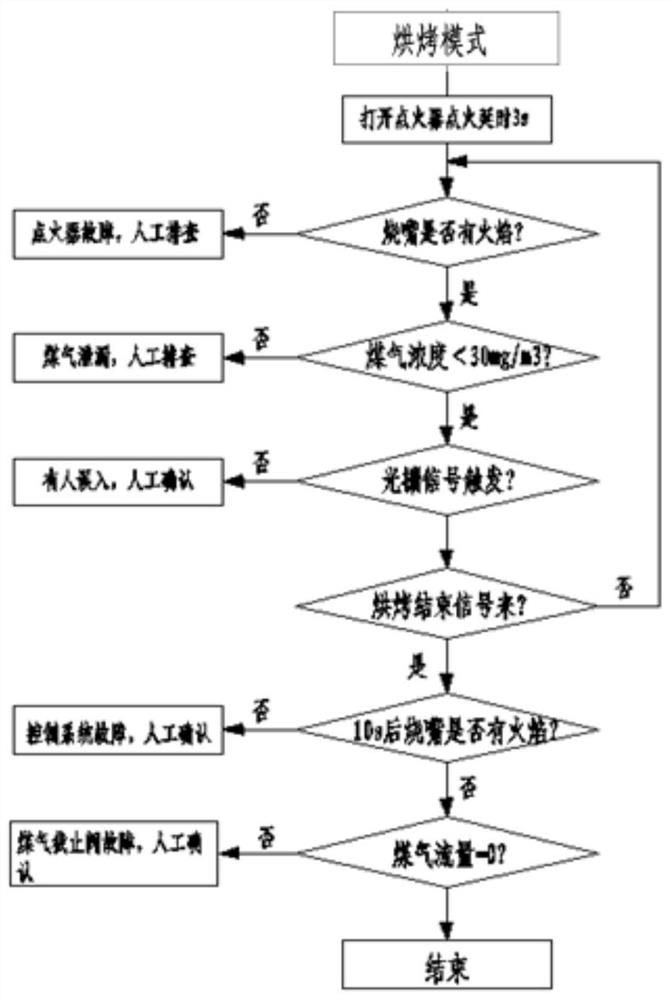

Tundish baking and protecting system and method

ActiveCN111604493AEnsure safety and controlRealize automatic ignition functionMelt-holding vesselsCasting safety devicesFlame detectionProcess engineering

The invention discloses a tundish baking and protecting system. The system comprises a baker, a tundish arranged below the baker, and a PLC. The baker comprises burners, a coal gas branch pipe and anair branch pipe. The multiple burners are arranged in the length direction of the tundish in a spaced and centered manner. An electronic igniter and a flame detector are arranged in each burner. The burners communicate with the coal gas branch pipe. The coal gas branch pipe is provided with a coal gas flow detector, a coal gas check valve and a coal gas flow adjusting valve. The burners communicate with the air branch pipe. An air flow detector, an air check valve and an air flow adjusting valve are arranged on the air branch pipe. All the detectors, all the valves and all the electronic igniters are connected with the PLC. The system has the beneficial effects that the protecting system can be used for protection for the overhauling mode and the baking mode, and safety control under all working states of a baking area of the tundish is effectively ensured.

Owner:武汉钢铁有限公司

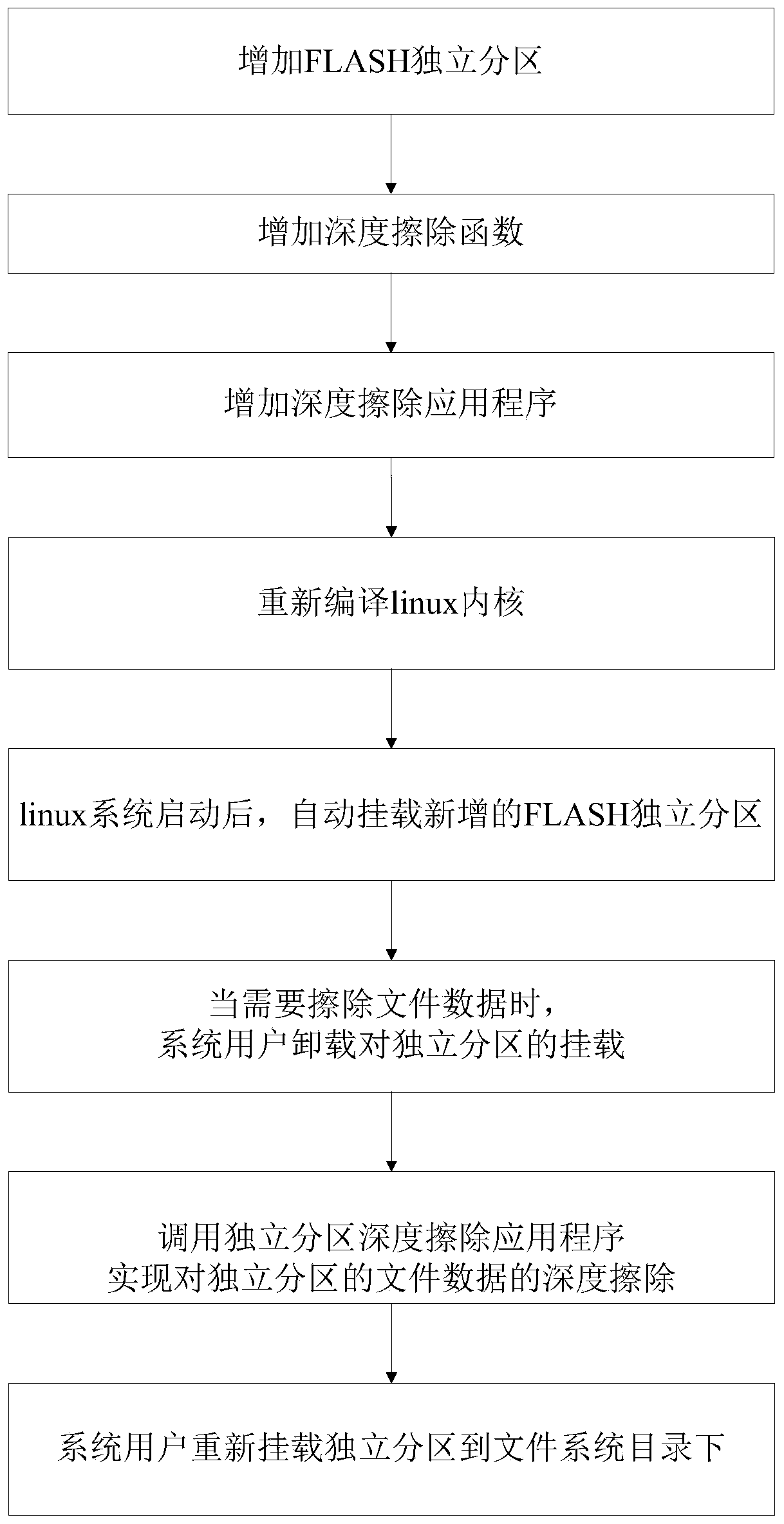

A method of deep erasing flash files online

ActiveCN106951189BAvoid risk of leakageEnsure safety and controlInput/output to record carriersFile systemGNU/Linux

The invention relates to the technical field of data storage, in particular to a method for deeply erasing an FLASH file online. The method comprises the following steps of adding a FLASH independent partition and a deep erasure function for the independent partition to a linux kernel, and adding an independent partition deep erasure application to an application space; re-compiling the linux kernel and performing updating to an embedded target board; after a linux system is started up, automatically mounting the added FLASH independent partition; and when file data needs to be erased, uninstalling the mounting of the independent partition by a system user, calling the independent partition deep erasure application to realize deep erasure of the file data of the independent partition, and re-mounting the independent partition to a file system directory by the system user, thereby obtaining the independent partition without any file. According to the method, the deep erasure function can take effect only when being called, so that normal use of other partitions of the system is not influenced, the operation is convenient, the file data in the whole independent partition can be deeply erased, and the risk of file data leakage is avoided.

Owner:DATA COMM SCI & TECH RES INST +1

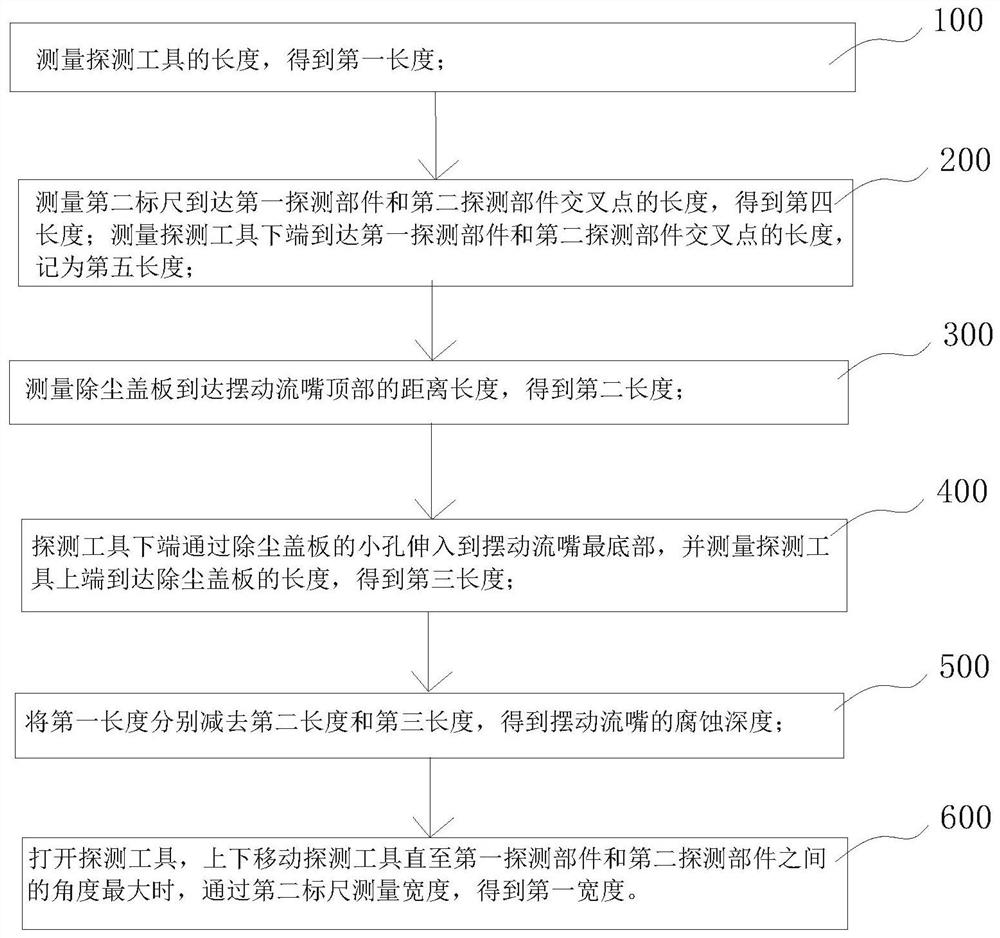

Blast furnace swing flow nozzle erosion state measuring method and device

InactiveCN112280920AReal-time monitoring of erosion statusEnsure safety and controlBlast furnace detailsChecking devicesDust controlEngineering

The invention relates to a blast furnace swing flow nozzle erosion state measuring method and device. The method comprises the following steps that the length of a detection tool is measured, and a first length is obtained; the distance length from a dust removal cover plate to the top of a swing flow nozzle is measured, and a second length is obtained; the lower end of the detection tool extendsinto the bottommost part of the swing flow nozzle through a measuring hole of the dust removal cover plate, the length from the upper end of the detection tool to the dust removal cover plate is measured, and a third length is obtained; and the second length and the third length are subtracted from the first length correspondingly, the corrosion depth of the swing flow nozzle is obtained. According to the blast furnace swing flow nozzle erosion state measuring method and device, the detection tool stretches into the bottom of the swing flow nozzle, the erosion depth of the swing flow nozzle ismeasured in real time, the erosion state of the swing flow nozzle is monitored in time, the blast furnace tapping process is guaranteed to be safe and controllable, occurrence of process accidents isavoided, meanwhile, measurement is convenient and rapid, and manpower and time are saved.

Owner:SGIS SONGSHAN CO LTD

A tundish baking protection system and method

ActiveCN111604493BEnsure safety and controlRealize automatic ignition functionMelt-holding vesselsCasting safety devicesFlame detectionEngineering

The invention discloses a tundish roasting protection system, which comprises a roaster, a tundish arranged under the roaster, and a PLC controller. The roaster includes a burner, a gas branch pipe and an air branch pipe. There are multiple burners, which are arranged at intervals along the length of the tundish; the burners are equipped with electronic igniters and flame detectors, and the burners are connected to gas branch pipes; gas flow detectors, gas A cut-off valve and a gas flow regulating valve; the burner is connected to the air branch pipe; an air flow detector, an air stop valve and an air flow regulating valve are arranged on the air branch pipe; each detector, each valve and the electronic igniter are respectively Connect with PLC controller. The beneficial effects of the present invention are: the protection system can be used for protection in the two modes of inspection mode and baking mode, effectively ensuring the safety and control of each working state in the tundish baking area.

Owner:武汉钢铁有限公司

Dangerous chemical road transportation environment risk early warning method

PendingCN112926849AEnsure safety and controlResourcesLogisticsEnvironmental resource managementTransport engineering

The invention discloses a dangerous chemical road transportation environment risk early warning method. The method comprises the following steps that an environment risk point database is established, the environment risk point database comprises position information and environment risk information of all dangerous environment risk points, According to the position information and the environment risk information of the dangerous environment risk points, the dangerous chemical road transportation environment risk early warning method is established; the influence range is determined; when dangerous chemicals are transported, a vehicle predetermined driving route is planned in advance, all the dangerous environment risk points of which the vehicle predetermined driving route falls into the influence range are found out from the environment risk point database, and a road environment risk report is generated; the road environment risk report comprises position information and environment risk information of dangerous environment risk points around a predetermined driving route of the vehicle. The invention provides a dangerous chemical road transportation environment risk early warning method.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

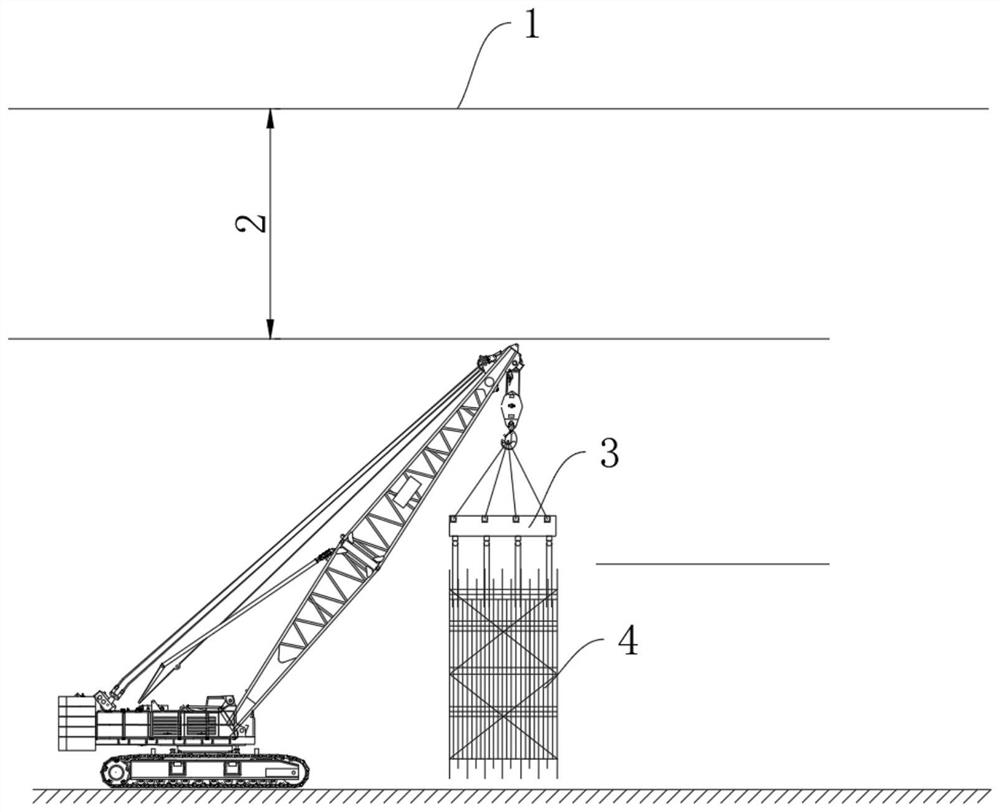

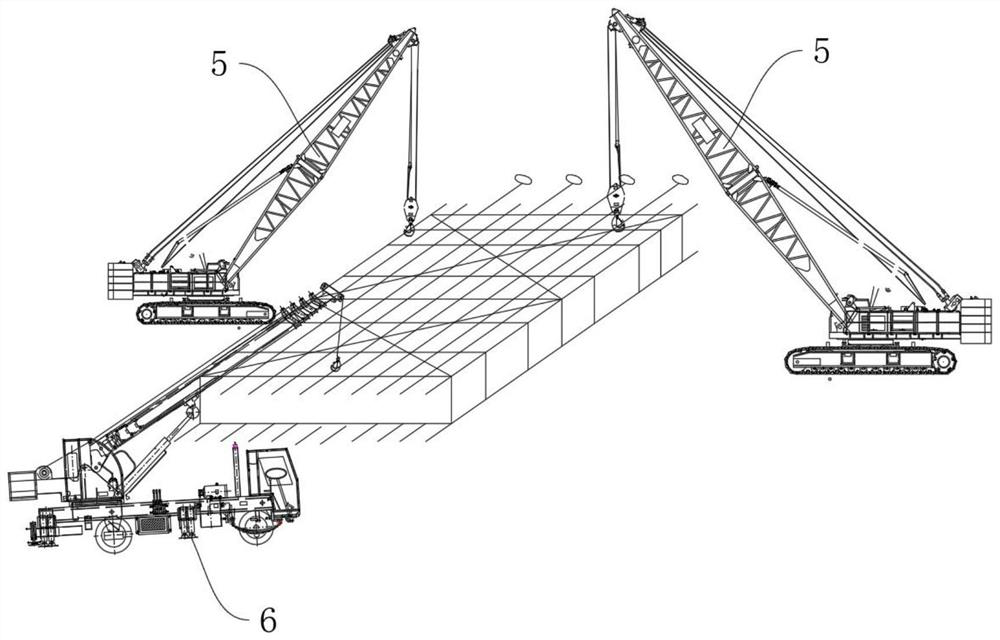

A hoisting method for reinforcement cages of underground diaphragm walls in height-limited areas

ActiveCN111411624BImprove construction progressSmall footprintLoad-engaging elementsCranesSlag (welding)Slurry wall

The invention provides a method for hoisting reinforcement cages of underground diaphragm walls in height-limited areas, which belongs to the field of underground diaphragm wall construction, and includes construction preparation procedures, hoisting procedures, synchronously advancing and lowering reinforcement cage procedures, and welding procedures for openings of reinforcement cages; hoisting procedures It includes the following steps: S31, three cranes are hoisted synchronously until the steel cage is lifted horizontally between 1.5 and 2.0m, the two main cranes continue to lift synchronously, and the auxiliary crane lowers the hook; S32, until the steel cage is completely straightened and After the weight of the steel cage is borne by the two main cranes, the hooks of the auxiliary crane are released; the existing hoisting method solves the problem of many times of hoisting, welding and lengthening, time-consuming, labor-intensive, cost-increased and poor integrity of the steel cage Problems such as the prolongation of the installation time of the reinforcement cage and the increase of the exposure time of the groove wall are too long, and the phenomenon of collapse of the groove wall, mud inclusion in the cage body, excessive sediment, etc. is easy to occur, which is unfavorable to the control of the construction quality of the underground diaphragm wall.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

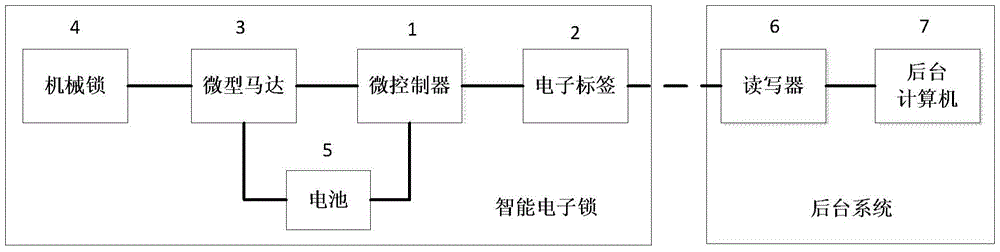

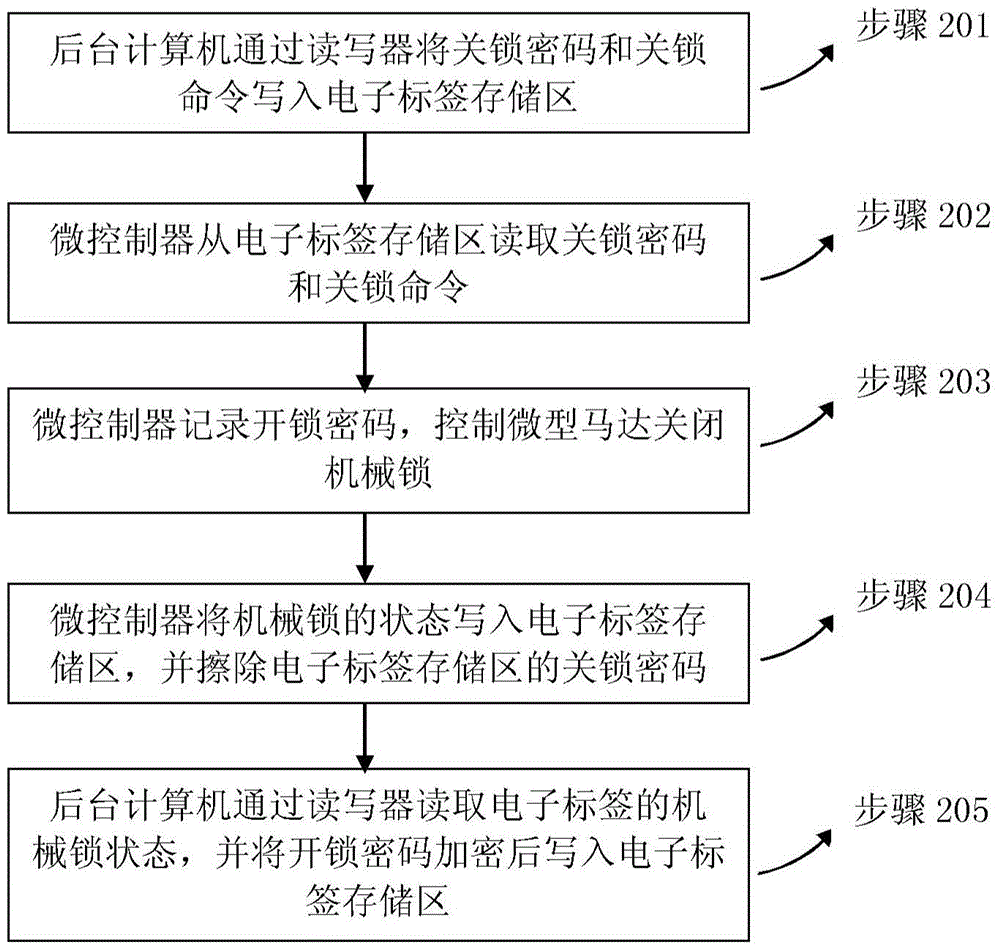

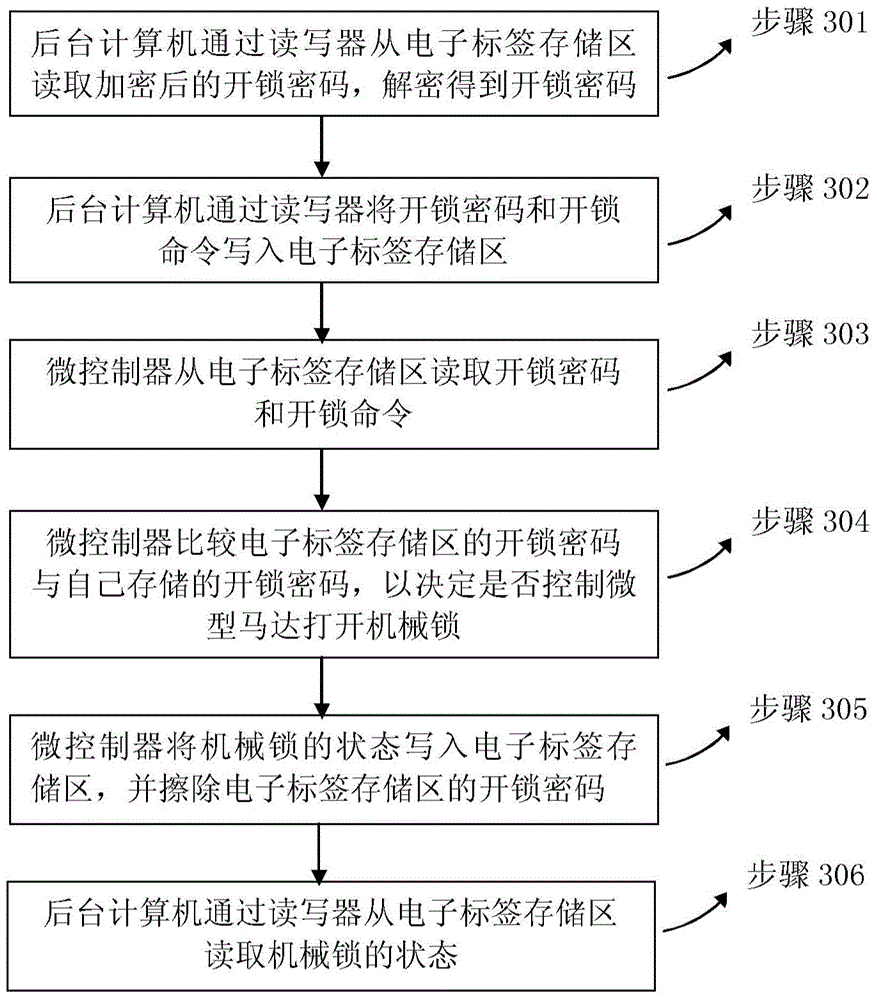

Lock switch method of intelligent electronic lock system with UHF radio frequency identification function

ActiveCN104563654BTake advantage ofNo additional costNon-mechanical controlsElectric permutation locksMicrocontrollerOperational costs

The invention discloses an intelligent electronic lock system with an ultrahigh frequency radio frequency identification function as well as unlocking and locking methods of the intelligent electronic lock system, wherein the intelligent electronic lock system comprises an intelligent electronic lock and a background system, wherein the intelligent electronic lock comprises a mechanical lock, a micro motor, a microcontroller, an electronic tag and a battery, the background system comprises a reader-writer and a background computer, the background computer reads a memory area of the electronic tag through the reader-writer, the state of the mechanical lock is determined, and in addition, a control command is written into the memory area of the electronic tag; the microcontroller obtains the control command from the memory area of the electronic tag, the on-off state of the electronic lock is detected, the micro motor is driven to take locking and unlocking actions according to the control command, and in addition, the state information of the electronic lock is written into the memory area of the electronic tag. The system solves the problems that the disposable electronic lead seal cannot be repeatedly used in logistics industry in the prior art, and the operation cost is higher.

Owner:BEIJING INST OF COMP TECH & APPL

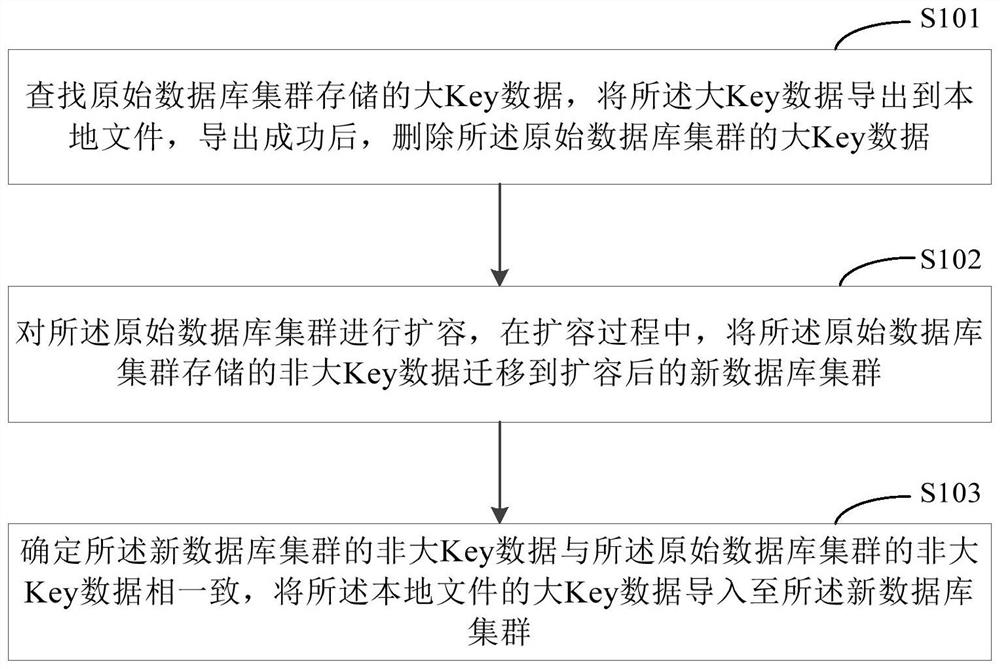

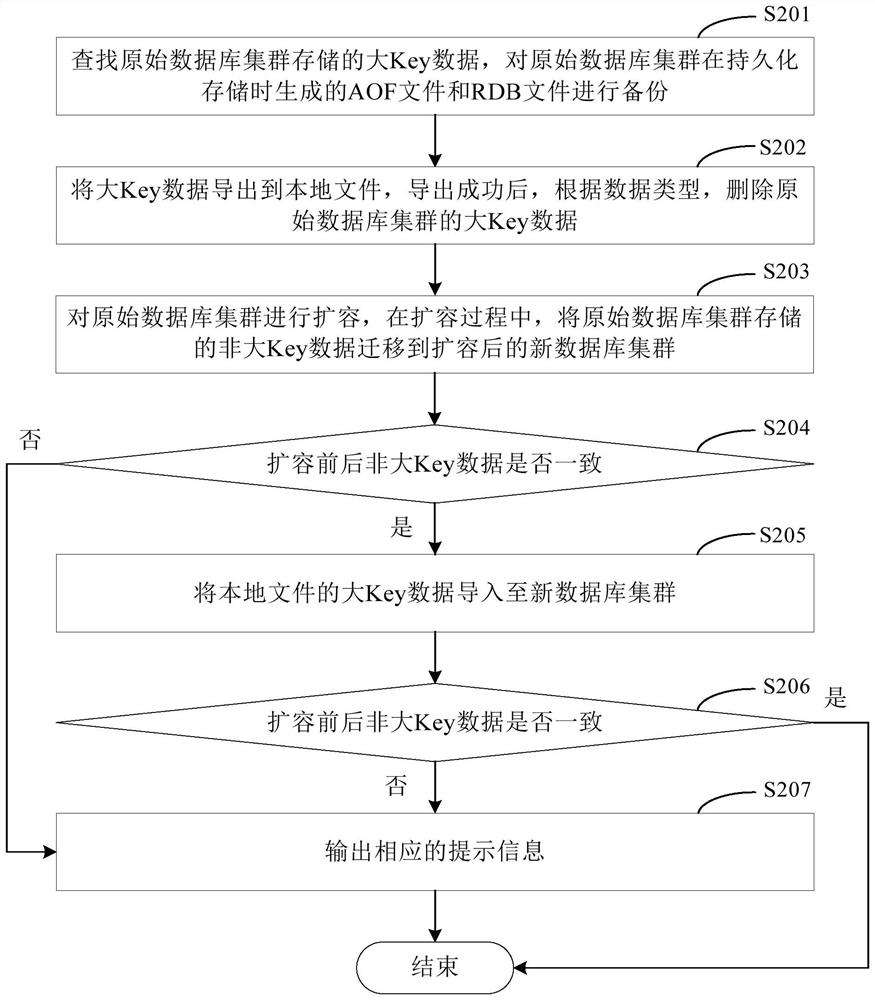

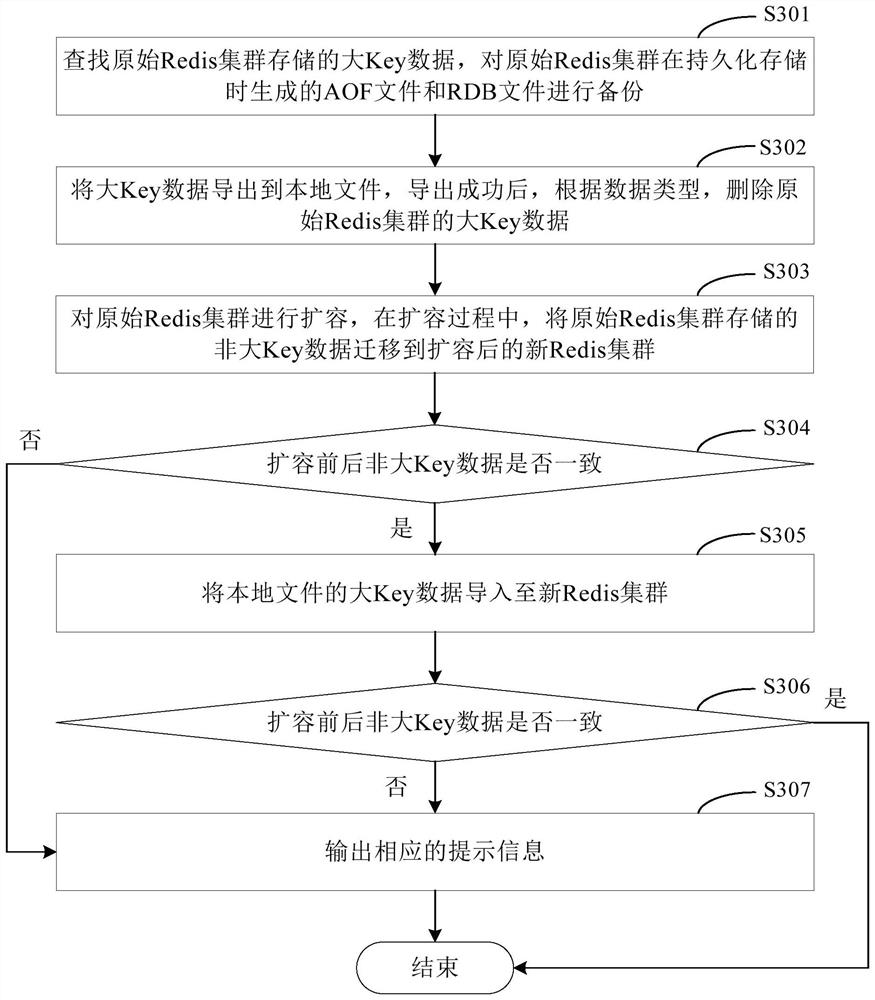

Capacity expansion method and device, electronic equipment and computer readable medium

PendingCN114281880AAchieve separate processingAvoid timeout failuresDatabase management systemsSpecial data processing applicationsOriginal dataSoftware engineering

The invention discloses a capacity expansion method and device, electronic equipment and a computer readable medium, and relates to the technical field of big data storage. A specific embodiment of the method comprises the following steps: searching big Key data stored in an original database cluster, exporting the big Key data to a local file, and deleting the big Key data of the original database cluster after the big Key data is successfully exported; expanding the original database cluster, and in the expansion process, migrating non-large Key data stored in the original database cluster to a new database cluster after expansion; and determining that the non-large Key data of the new database cluster is consistent with the non-large Key data of the original database cluster, and importing the large Key data of the local file into the new database cluster. According to the implementation mode, independent processing of the large Key data is achieved, timeout failure caused by the large Key data is avoided, and safe, controllable and stable operation of the capacity expansion process is guaranteed.

Owner:CHINA CONSTRUCTION BANK

Slagging device and slagging method for ferromolybdenum smelting furnace

ActiveCN106119675BEliminate stickingPrevent burn damageCharge manipulationCharge treatment typeSmelting processIsolation layer

The invention discloses a deslagging device of a ferromolybdenum smelting furnace. The device comprises a slag tap formed in the side wall of the lower portion of the ferromolybdenum smelting furnace, the slag tap is communicated with a deslagging chute, the lower portion of an opening in the upper portion of the deslagging chute is closed, inserting plates used for separating the deslagging chute into a plurality of sections are arranged in the deslagging chute and are movably inserted in the deslagging chute, and the slag tap and the lower portion of the deslagging chute are both filled with silica sand. The invention further discloses a deslagging method using the deslagging device. Through the structural improvement, the silica sand is adopted to serve as a blockage and obstruction material, an effective isolation layer can be formed, heat energy losses are reduced, the burning damage of a high-temperature melt to the deslagging chute is prevented, safety in the smelting process and the deslagging process is ensured, consumption of fireproof materials of the traditional technology is fully reduced, the deslagging operation is quite convenient, the labor intensity is low, and the device is simple, easy to implement, safe and reliable.

Owner:JINDUICHENG MOLYBDENUM CO LTD

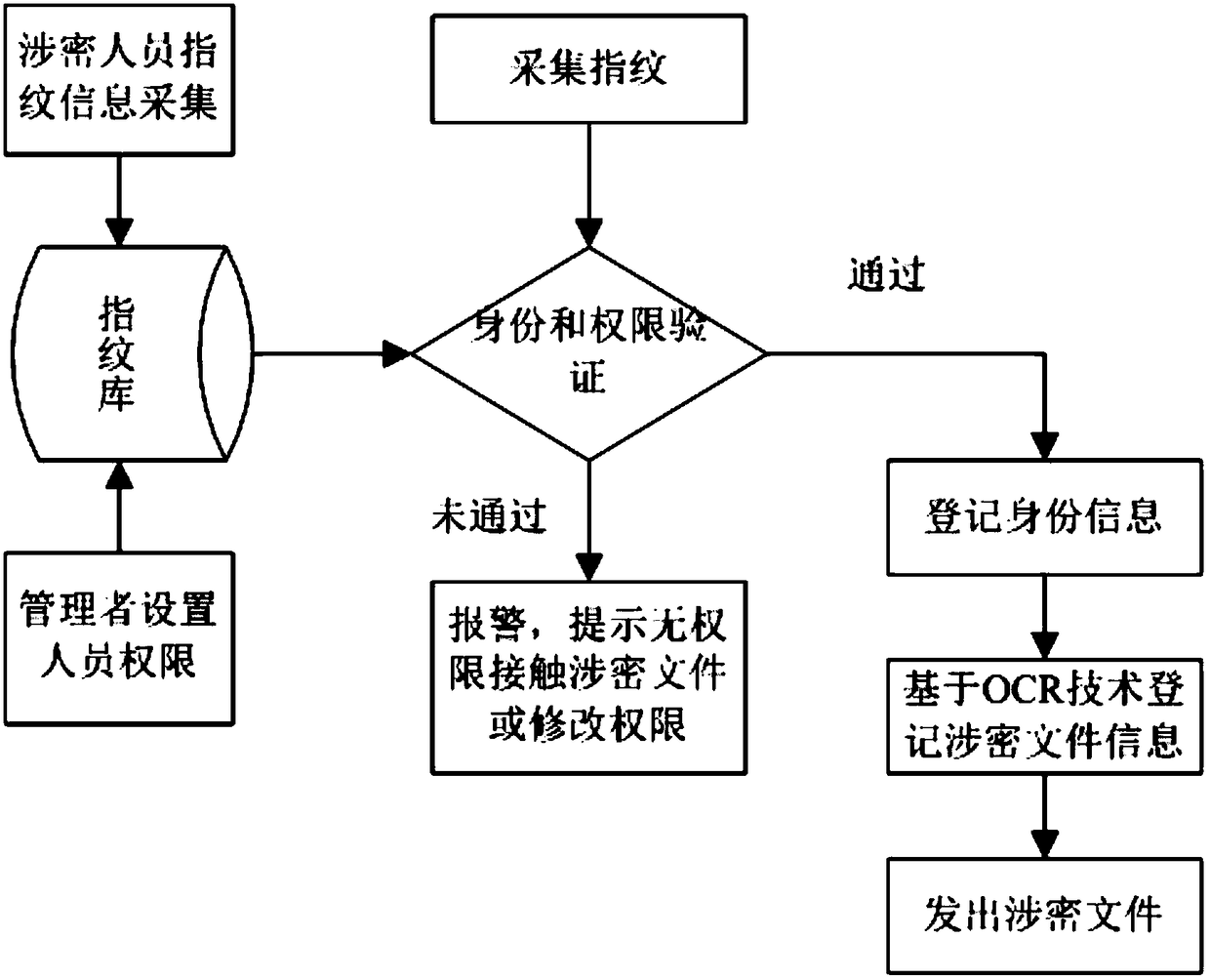

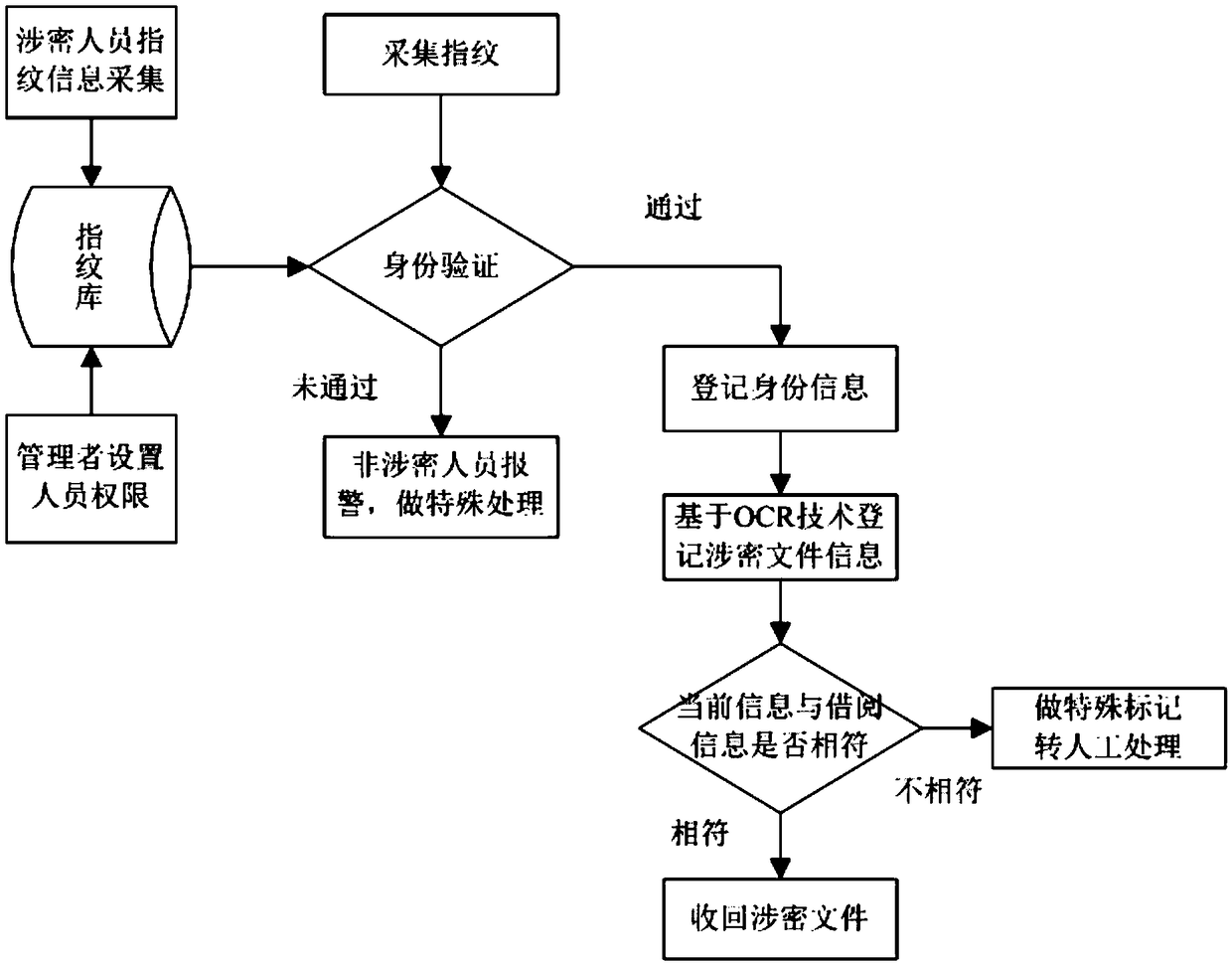

Secret-related carrier management method based on fingerprint identification and OCR technology

InactiveCN109376520AEase of operationImprove securityDigital data protectionDigital data authenticationFingerprintAuthority control

The invention relates to the technical field of secret-related carrier management, in particular to a secret-related carrier management method based on fingerprint identification and OCR technology, which mainly comprises an intelligent management flow of receiving and sending registration of secret-related carrier, a comprehensive management and application flow of secret-related carrier and an approval and review flow of work flow of secret-related carrier. The invention utilizes the centralized safety control and file access authority control mechanism of the power part of the confidentialarchives to implement the intelligent strict monitoring of the paper archives receiving and sending registration, and ensures the safety controllable, anti-diffusion, anti-leakage and intelligent responsibility recovery of the secret-related carrier borrowing process.

Owner:STATE GRID SHANDONG ELECTRIC POWER

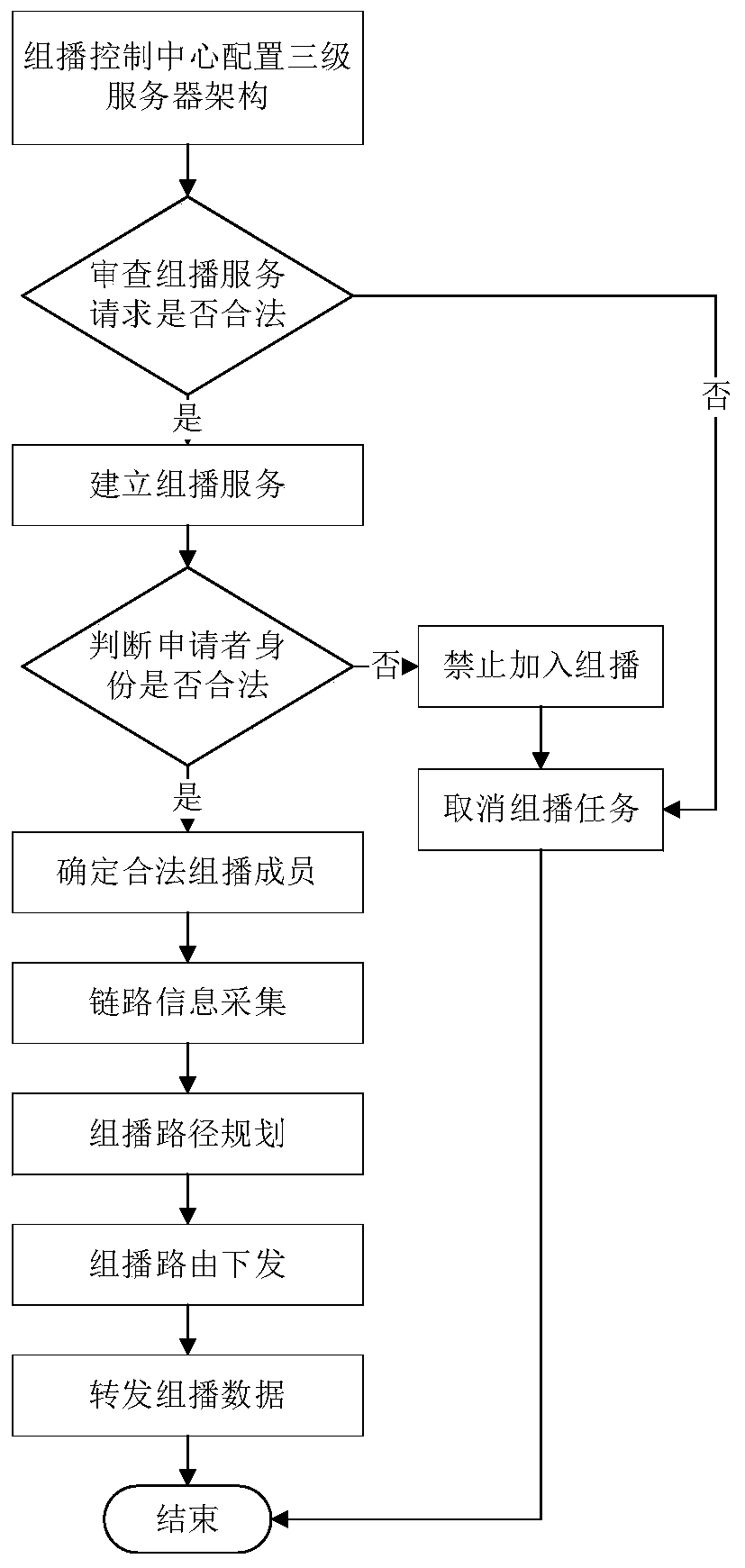

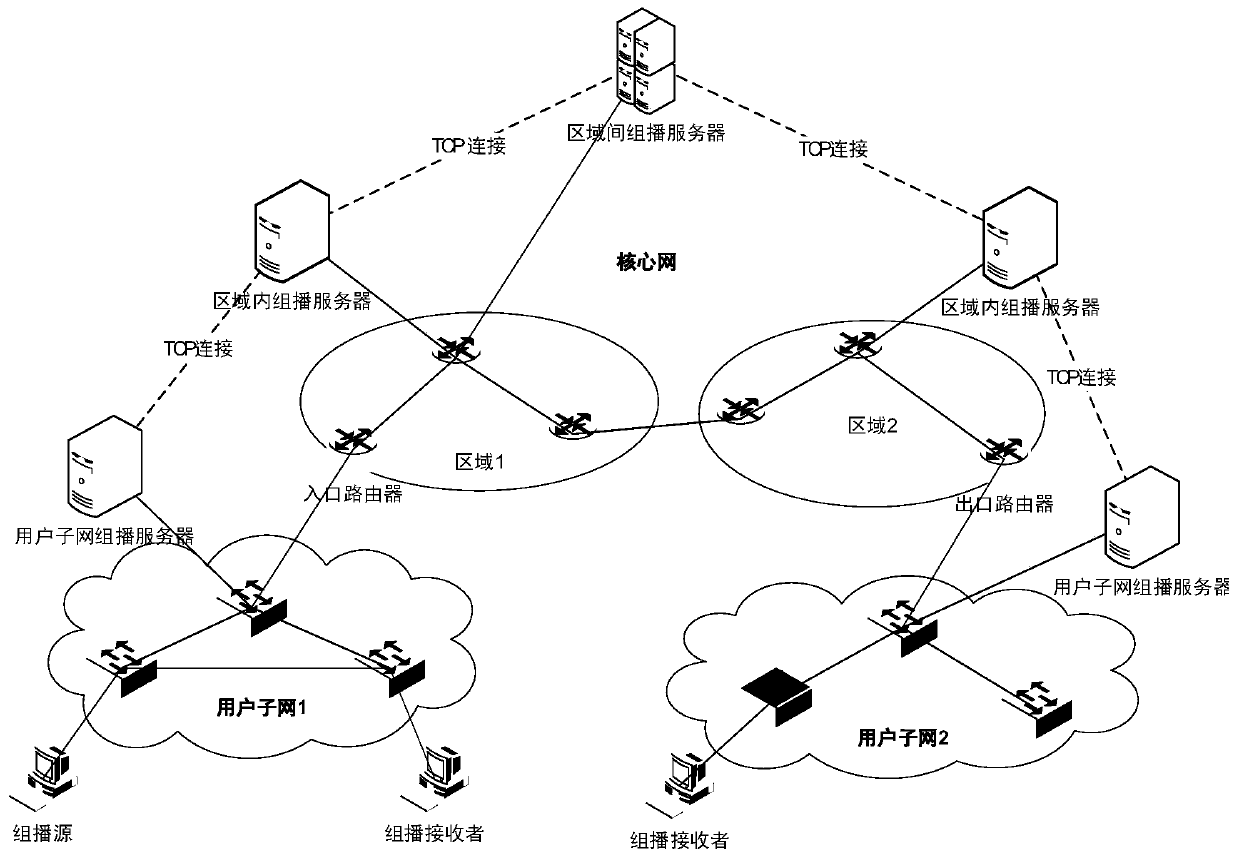

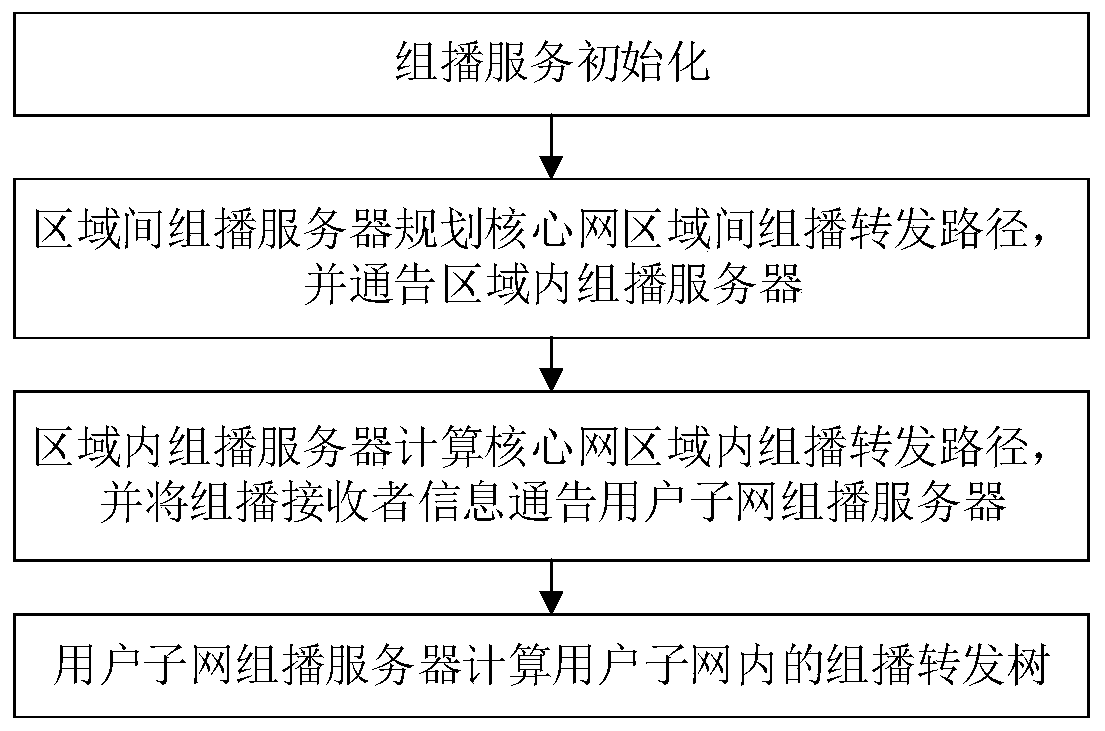

A centralized multicast control method based on software definition

ActiveCN108923946BRealize centralized planningEnsure self-definitionSpecial service provision for substationPathPingEngineering

The invention provides a software-defined centralized multicast control method, the steps of which are: S1: the multicast control center constructs a multicast centralized control architecture composed of three-level servers; S2: the multicast control center opens a group for legal multicast sources S3: The multicast control center determines the legal multicast members; S4: The multicast control center forms a multicast link database; S5: The multicast control center bases the Database, plan multicast path; S6: Multicast control center initiates multicast route delivery; S7: Multicast source forwards multicast data in user subnet, so that designated multicast receivers can receive multicast data; S8: End. The present invention performs global planning of multicast routing based on a software-defined manner, realizes self-defined multicast tasks in a network in which identification and routing are separated through a multicast routing centralized control mechanism, and ensures the safety and controllability of multicast data.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com