A tundish baking protection system and method

A protection system and tundish technology, applied in the direction of manufacturing tools, casting molten material containers, casting equipment, etc., can solve the problems of safety, lack of detection and unpredictability of installation command closing, and solve safety problems and solve manual ignition problems. The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

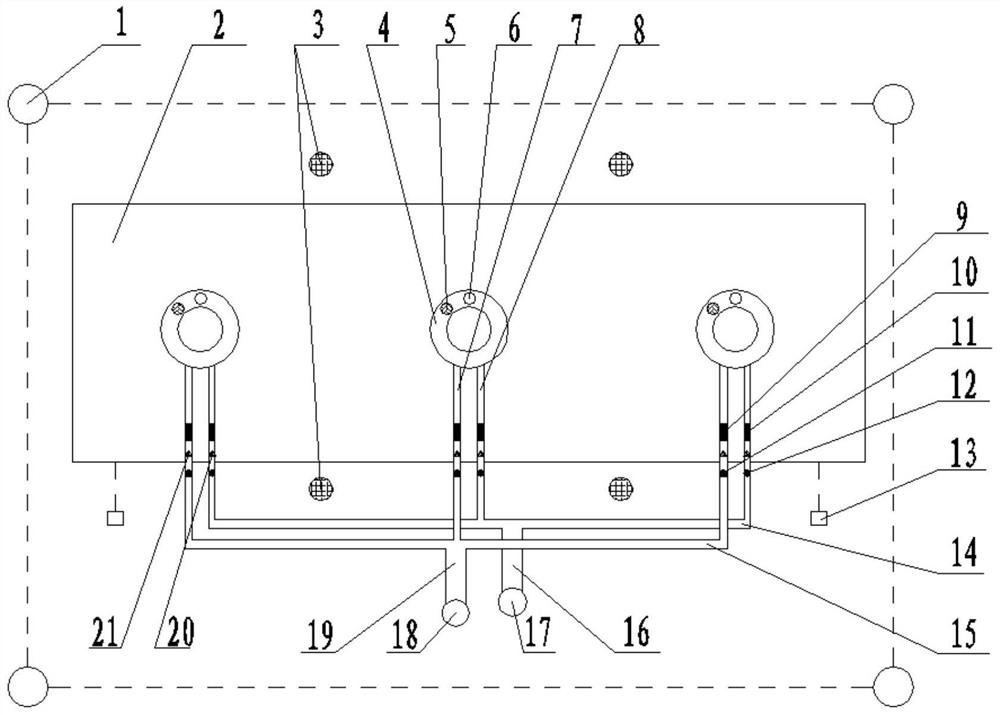

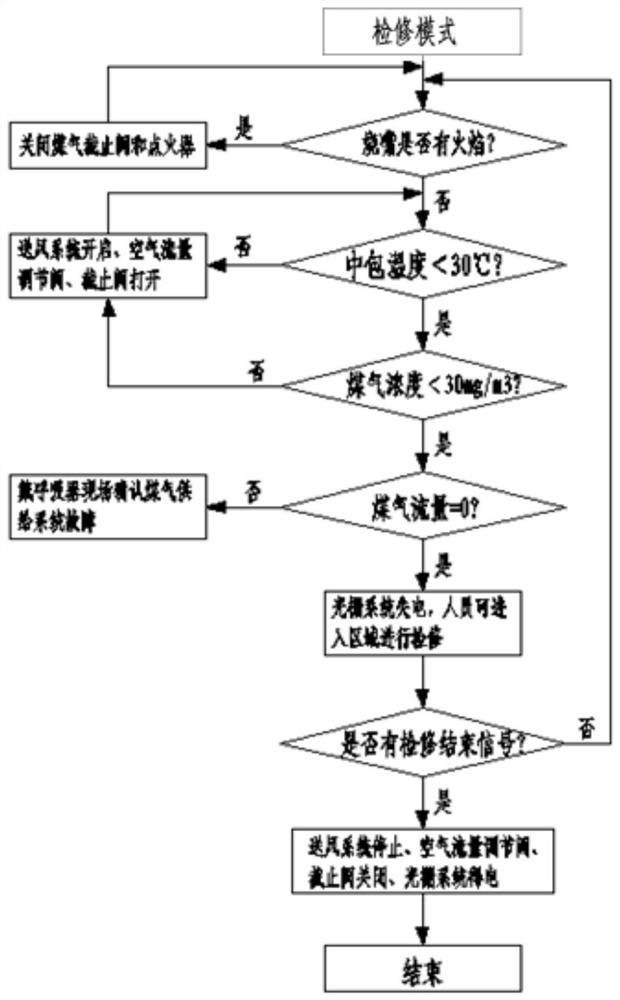

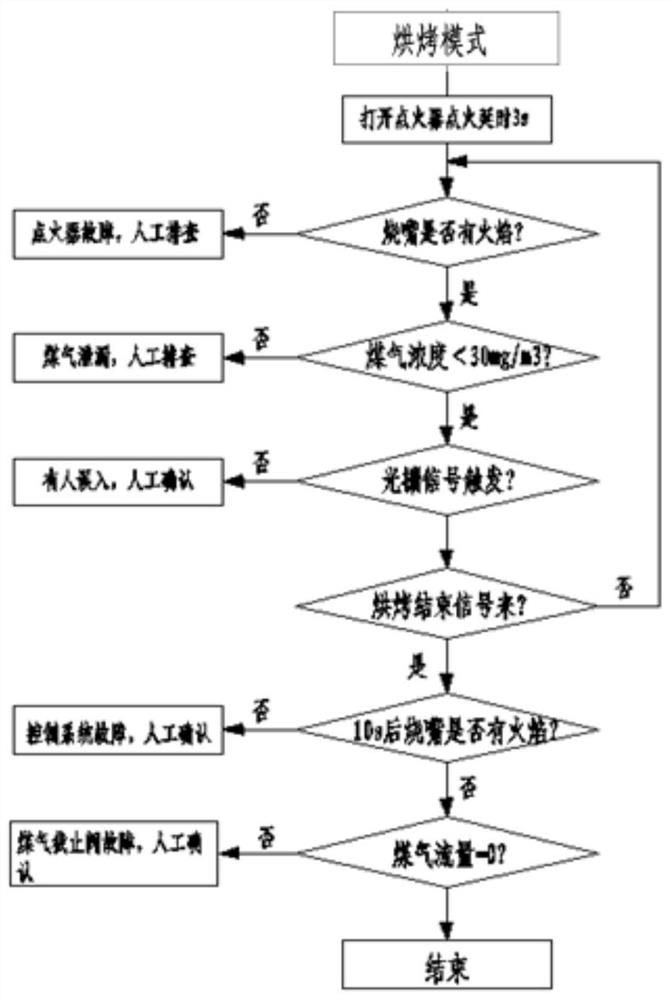

[0029] like figure 1 A tundish roasting protection system shown includes a roaster, a tundish 2 located below the roaster, and a PLC controller. The roaster includes a burner 4, a gas branch pipe 7 and an air branch pipe 8 , there are multiple burners 4, arranged at intervals along the length of the tundish 2 and in the center; the burners 4 are provided with an electronic igniter 5 and a flame detector 6, and the burners 4 are connected to the gas branch pipe 7, and the gas branch pipe 7 The gas branch pipe 15 is communicated with the gas main pipe 19, and the gas main pipe 19 is connected with the gas supply system 18; the gas flow detector 11, the gas shut-off valve 21 and the gas flow regulating valve 9 are arranged on the gas branch pipe 7; the burner 4 It communicates with the air bran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com