Slagging device and slagging method for ferromolybdenum smelting furnace

A smelting furnace and ferromolybdenum technology, which is applied in the field of ferromolybdenum smelting metal, can solve the problems of high skill requirements for blocking slag discharge openings, easy operator injury, and high labor intensity of workers, so as to eliminate the bonding phenomenon and avoid The effect of escaping ferromolybdenum slag and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

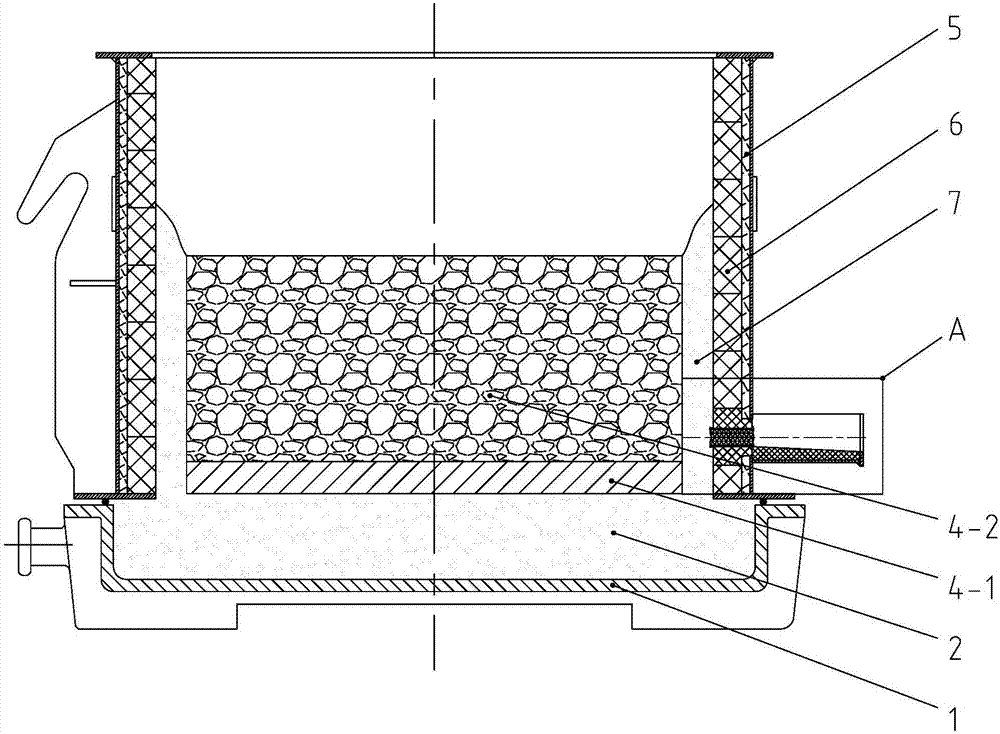

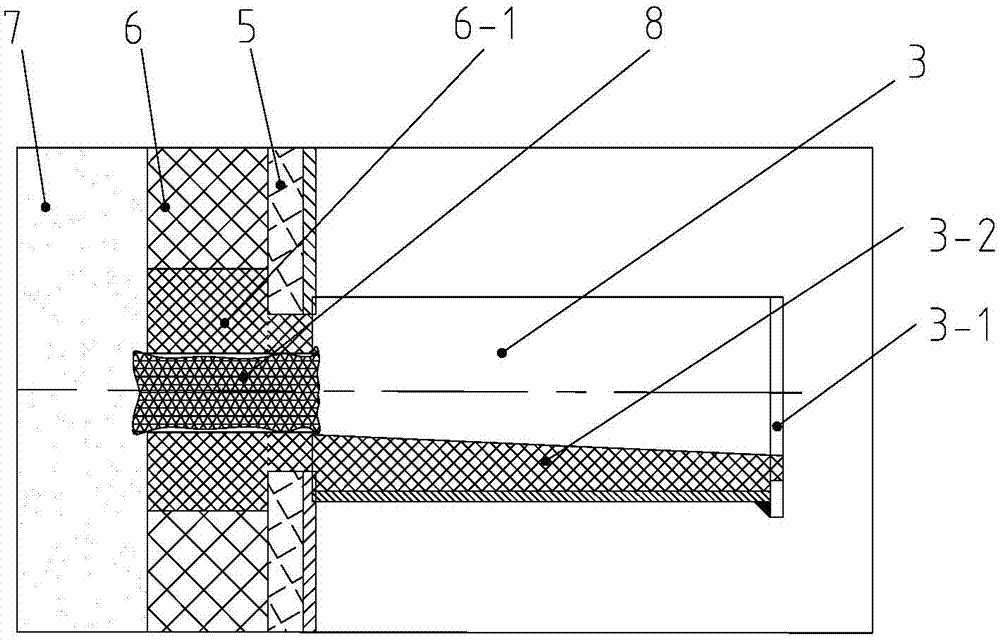

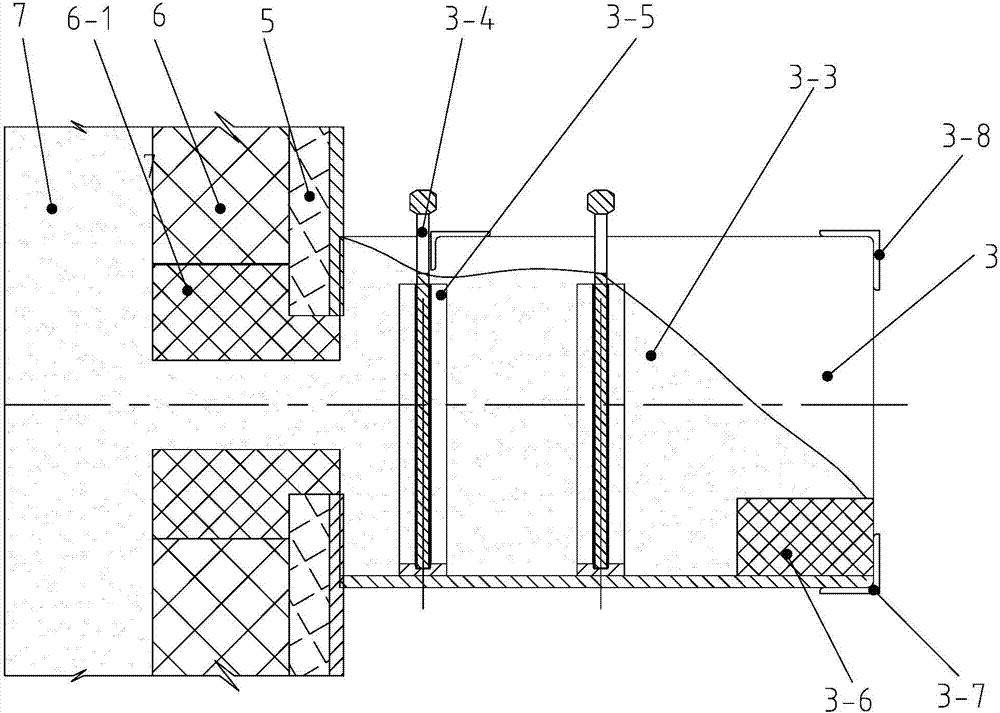

[0038] Such as image 3 , Figure 4 and Figure 5 A kind of slagging device of ferromolybdenum smelting furnace shown, comprises the slag outlet 10 that is opened on the lower side wall of ferromolybdenum smelting furnace, and described slag outlet 10 is connected with slag discharge chute 3, and described slag discharge chute 3 tops The lower part of the opening is closed, and the slag discharge chute 3 is provided with a flashboard 3-4 for dividing it into multiple sections. Quartz sand 3-3 is all filled in the mouth 10 and the slag discharge chute 3 bottoms.

[0039]The present invention fills the slag discharge port 10 and the lower part of the slag discharge chute 3 with quartz sand 3-3, fully utilizes the good temperature resistance, fluidity and low heat conduction of the quartz sand 3-3, and can realize the tight sealing of the slag discharge port 10 Plugging and timely filling of pores can ensure that the slag outlet 10 is reliably blocked. By movably inserting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com