Removal device and method for mercury in mercury-containing pollutant

A pollutant and removal technology, applied in the direction of solid waste removal, combustion method, separation method, etc., can solve the problems of high energy and resource consumption, high processing cost, difficult to achieve the effect of treatment, etc., to reduce energy consumption, The effect of improving the reaction rate, good environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

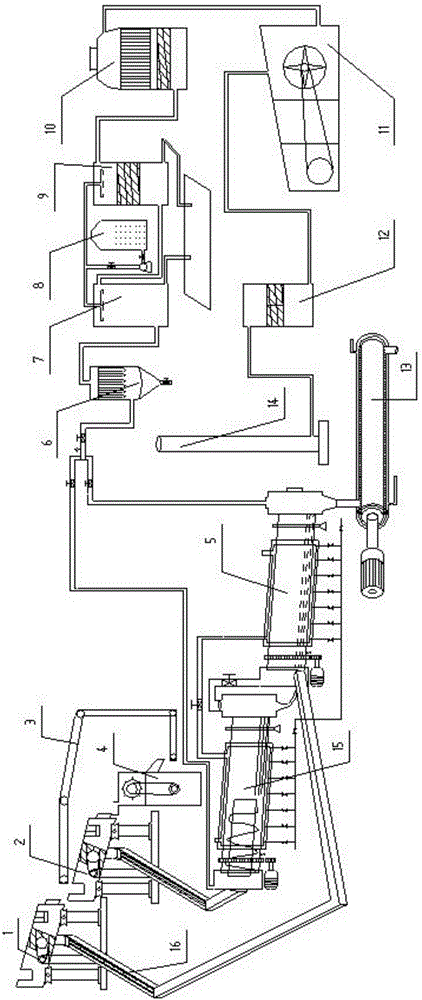

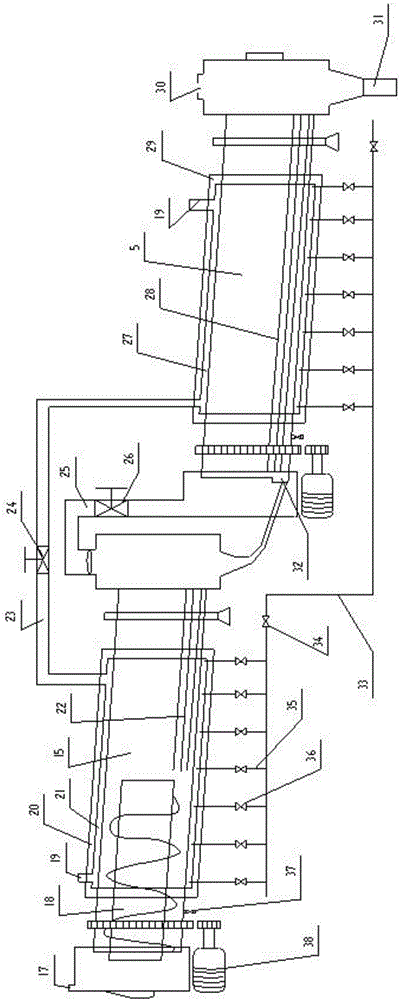

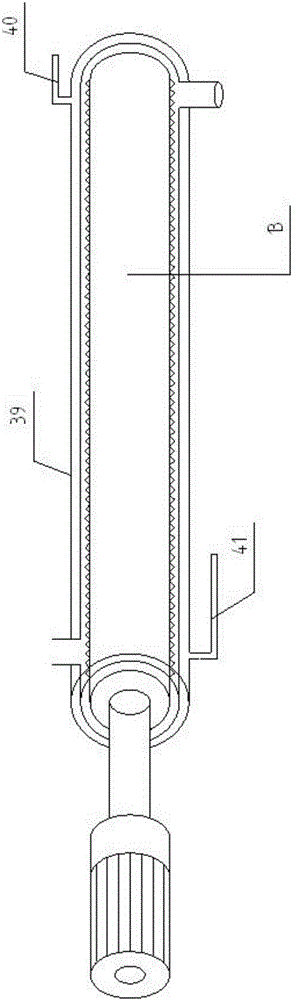

[0042] A device for removing mercury in mercury-containing pollutants, consisting of a material preparation system, a preheating drying system, a thermal analysis system, a residue cooling and conveying system, and a flue gas purification system. The material preparation system consists of a vibrating screen A(1) , vibrating screen B (2), crusher (4) and screw conveyor (16), the sieve hole diameter of described vibrating screen A is 5mm, and the outlet of vibrating screen A sieve is connected to the vibrating screen B inlet, vibrating The undersize of the sieve A is sent to the thermal analysis system by the screw conveyor; the sieve aperture of the vibrating screen B is 10mm, the oversize of the vibrating screen B enters the crusher for crushing, and the undersize of the vibrating screen B is conveyed by the screw The machine is sent to the preheating drying system; the material crushed by the crusher is sent to the vibrating screen B by the belt conveyor (3) for secondary scr...

Embodiment 2

[0061] A device for removing mercury in mercury-containing pollutants, consisting of a material preparation system, a preheating drying system, a thermal analysis system, a residue cooling and conveying system, and a flue gas purification system. The material preparation system consists of a vibrating screen A, a vibrating screen B. Crusher and screw conveyor, the aperture of the vibrating screen A is 5mm, the outlet of the vibrating screen A is connected to the vibrating screen B inlet, and the vibrating screen A is sent to the hot water by the screw conveyor. Analysis system; the sieve hole diameter of the vibrating screen B is 10mm, the oversize of the vibrating screen B enters the crusher for crushing, and the undersize of the vibrating screen B is sent to the preheating drying system by a screw conveyor; the crushing The material crushed by the machine is sent to the vibrating screen B by a belt conveyor for secondary screening, and the screw conveyor is a twin-screw conve...

Embodiment 3

[0078] A device for removing mercury in mercury-containing pollutants, consisting of a material preparation system, a preheating drying system, a thermal analysis system, a residue cooling and conveying system, and a flue gas purification system. The material preparation system consists of a vibrating screen A, a vibrating screen B. Crusher and screw conveyor, the aperture of the vibrating screen A is 5mm, the outlet of the vibrating screen A is connected to the vibrating screen B inlet, and the vibrating screen A is sent to the hot water by the screw conveyor. Analysis system; the sieve hole diameter of the vibrating screen B is 10mm, the oversize of the vibrating screen B enters the crusher for crushing, and the undersize of the vibrating screen B is sent to the preheating drying system by a screw conveyor; the crushing The material crushed by the machine is sent to the vibrating screen B by a belt conveyor for secondary screening, and the screw conveyor is a twin-screw conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com