Blast furnace swing flow nozzle erosion state measuring method and device

A swing nozzle and state measurement technology, applied in blast furnaces, inspection devices, blast furnace details, etc., can solve problems such as process accidents due to erosion of nozzles that cannot be swung, and achieve convenient and quick measurement, save manpower and time, and avoid process accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

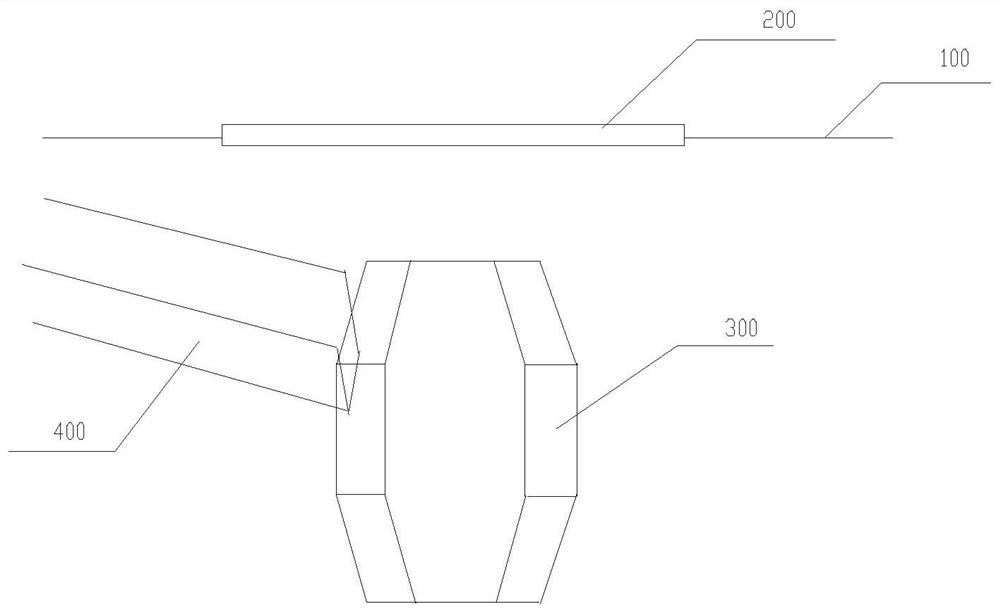

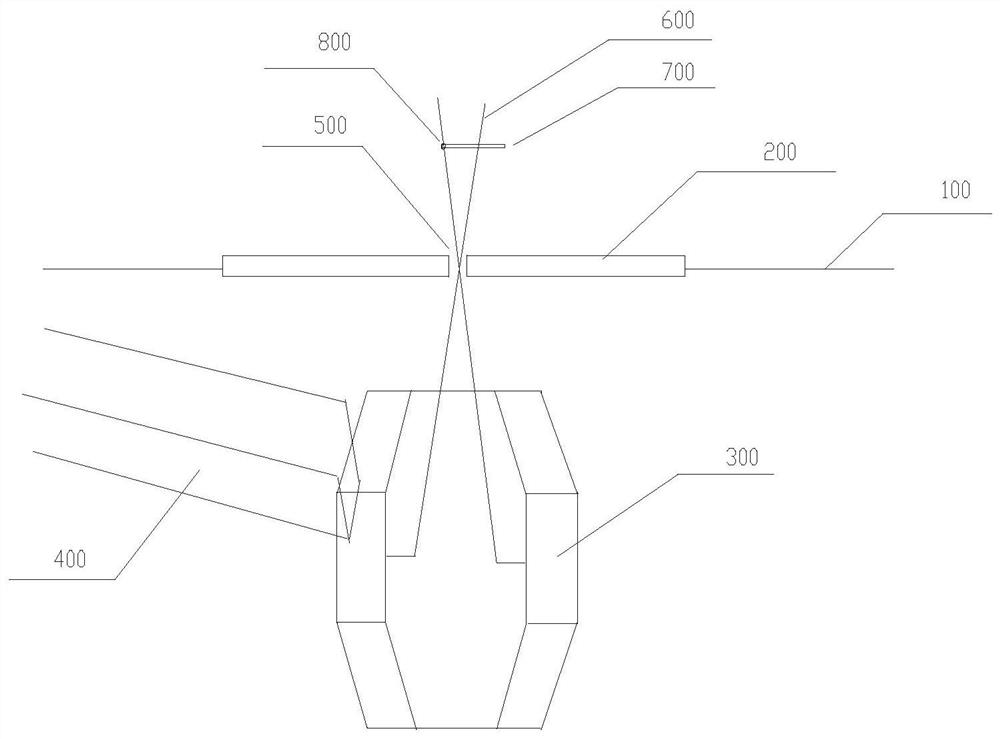

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0030] At present, sometimes the edge of the swing nozzle installed under the iron ditch of the casthouse is slagging, and the swing nozzle is prone to erosion too wide and too deep; once the swing nozzle burns through, it is easy to cause high-temperature molten iron accidents and other process accidents. The blast furnace was forced to stop the wind, etc.; it not only affects the technical and economic indicators of the blast furnace, but also consumes a lot of manpower and material resources.

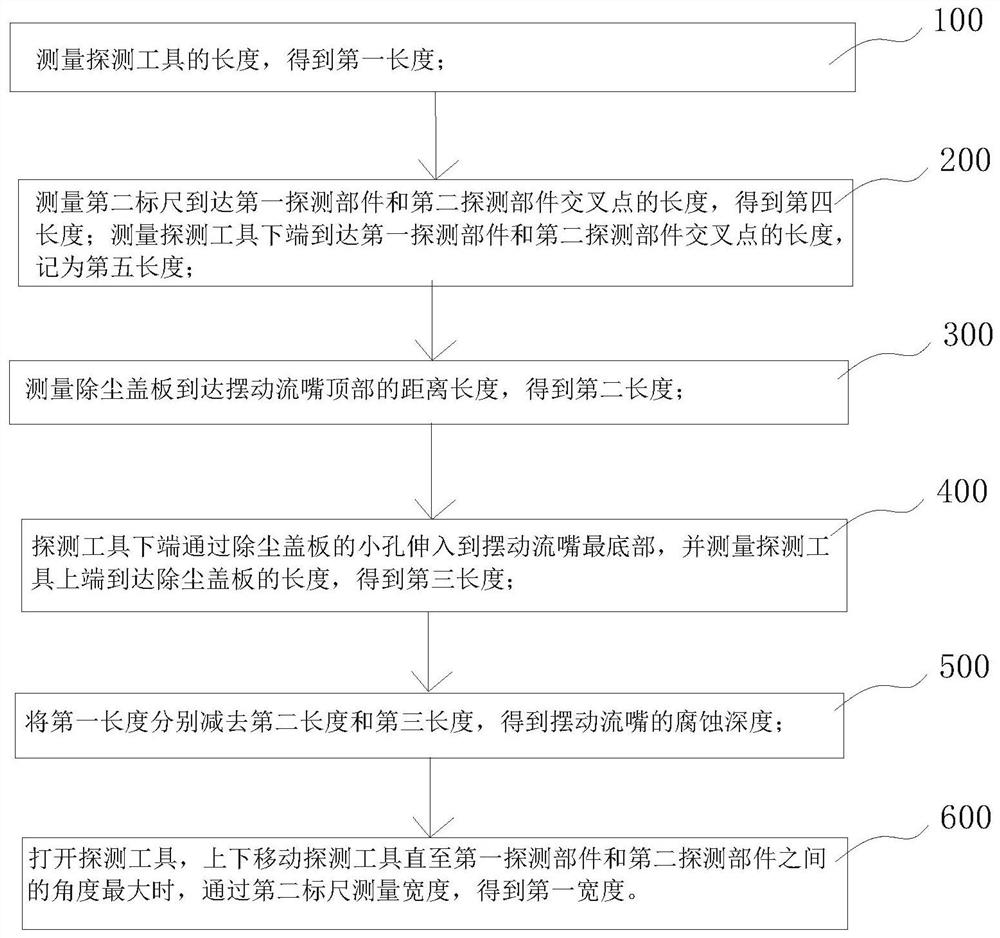

[0031] In view of this, the present invention proposes a method for measuring the erosion state of a blast furnace swing nozzle, which uses detection tools a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com