Method and arrangement for minimizing need for safety gases

A safe gas and demand technology, applied in the field of equipment and methods that minimize the demand for safe gas, can solve problems such as not being able to be used in this way, achieve the effect of saving physical size and reducing the risk of anodic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

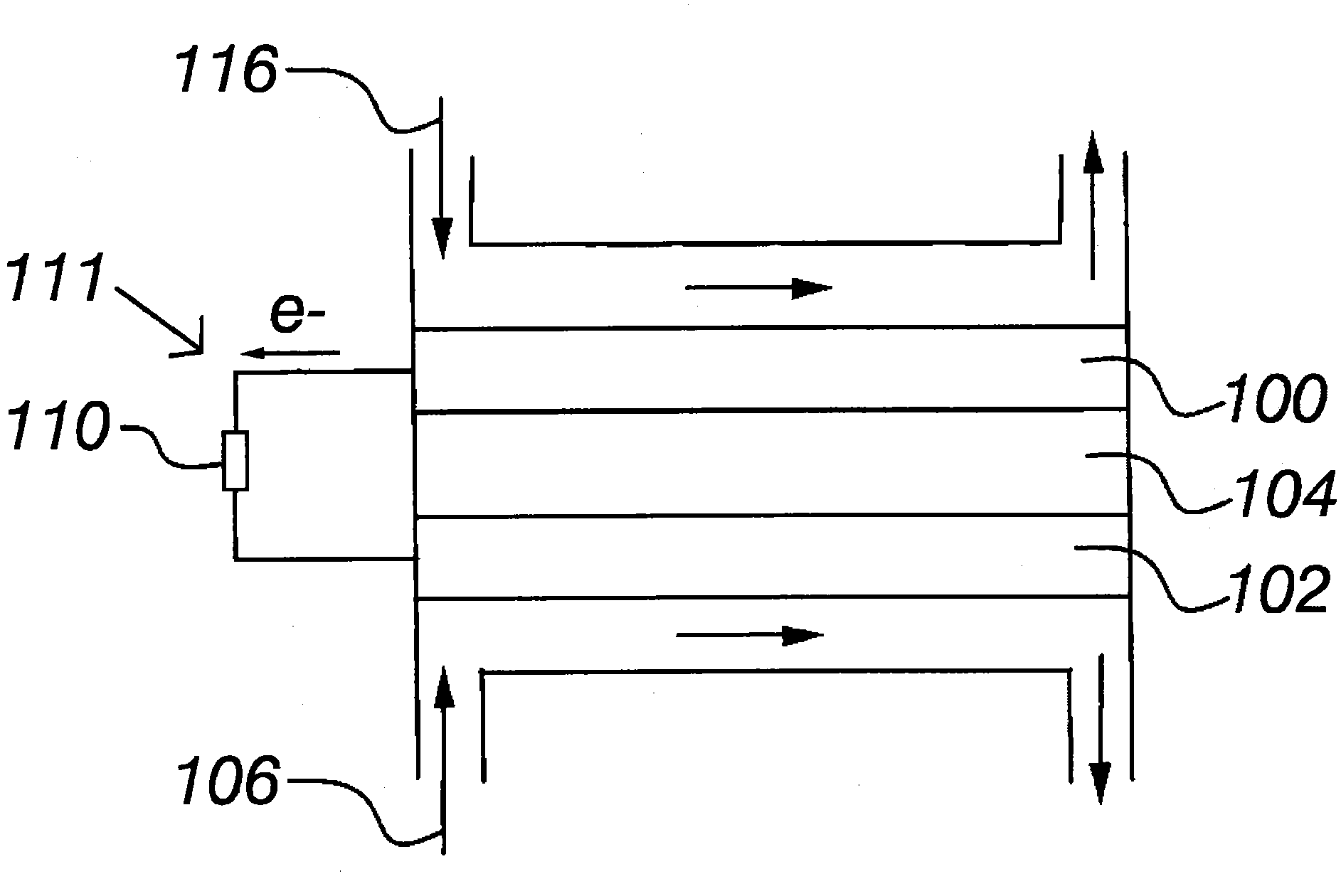

[0021] Solid oxide fuel cells (SOFCs) are available in a variety of geometries. plane geometry ( figure 1 ) is a typical sandwich type geometry employed by most types of fuel cells, with the electrolyte 104 sandwiched between the electrodes (anode 100 and cathode 102). SOFCs can also be fabricated in tubular geometries where, for example, air or fuel passes through the inside of the tube and other gases pass along the outside of the tube. Tubular design is better in air and fuel barrier. In conclusion, the performance of the planar design is better than that of the tubular design because the planar design has relatively low resistance. Other SOFC geometries include modified planar cells (MPC or MPSOFC), where a wave-like structure replaces the flat structure of conventional planar cells. These designs are allowed because they have both the advantages of planar cells (low resistance) and tubular cells.

[0022]The ceramics used in SOFCs cannot become ionically active unless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com