Non-diaphragm electrochemical waste water treatment device

A wastewater treatment and electrochemical technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high price, wear and tear, affecting devices, etc., and achieve high inertia and high efficiency. The effect of operating, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

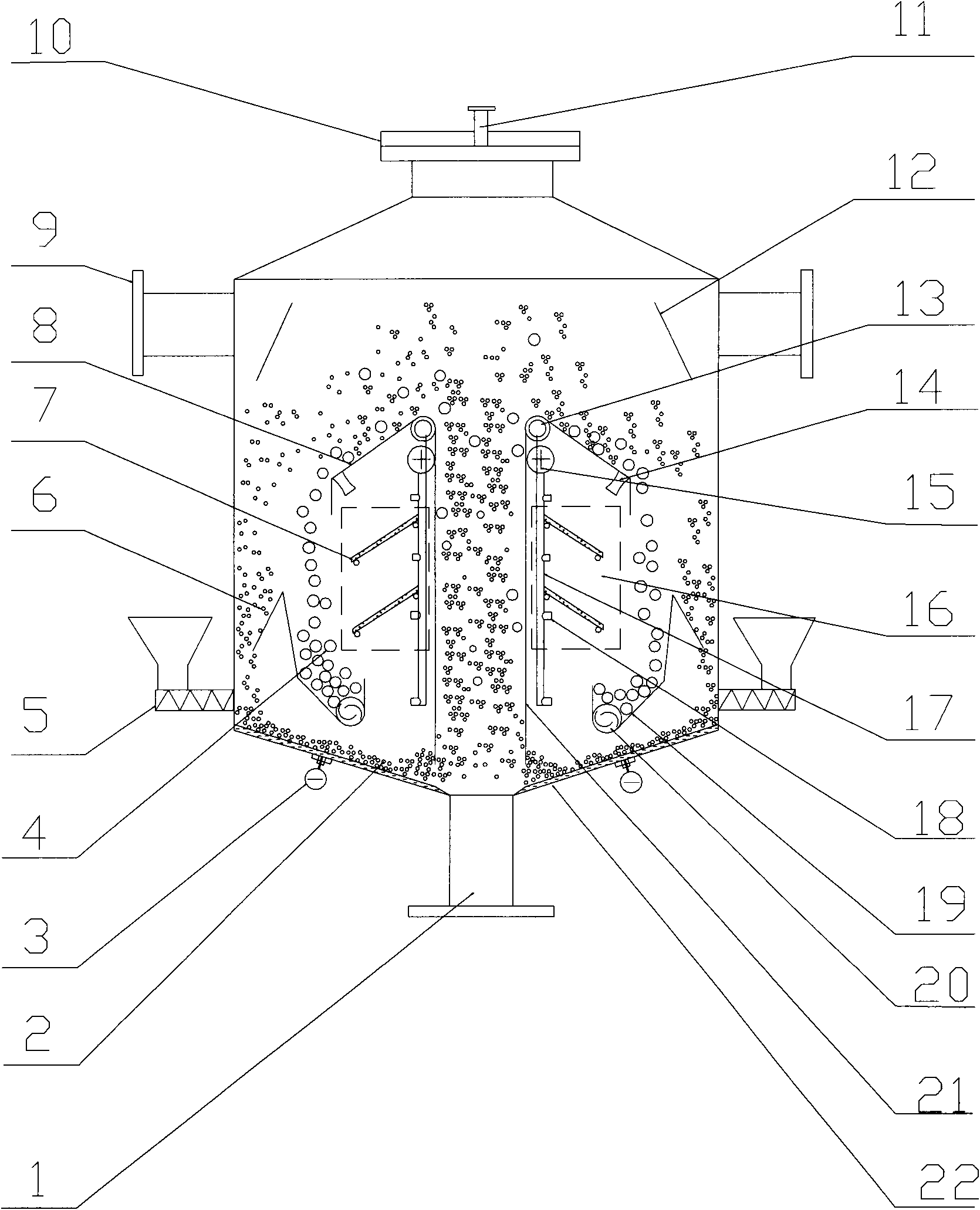

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The membrane-free electrochemical wastewater treatment method of the present invention introduces the wastewater to be treated into the electrode reactor, and makes the particles in the wastewater to be treated in a fluidized state. The anode protection baffle divides the interior of the electrode reactor into a relatively independent cathode reaction area and anodic reaction area, and the fluidized bed material required by the electrode reactor is input to realize the recovery of metal particles corresponding to the fluidized bed material in the wastewater to be treated .

[0027] In order to realize the above-mentioned wastewater treatment method, the present invention provides a membrane-free electrochemical wastewater treatment device, such as figure 1As shown, the diaphragmless electrochemical wastewater treatment device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com