Method of protecting corrosion proof pipeline joint internal wall using sacrificing anode

A sacrificial anode protection and sacrificial anode technology is applied in the field of using sacrificial anodes to protect the inner wall of anti-corrosion pipeline joints, which can solve the problems of restricting the promotion of new anti-corrosion coatings, clogging of mud and sand, and inability to repair the joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

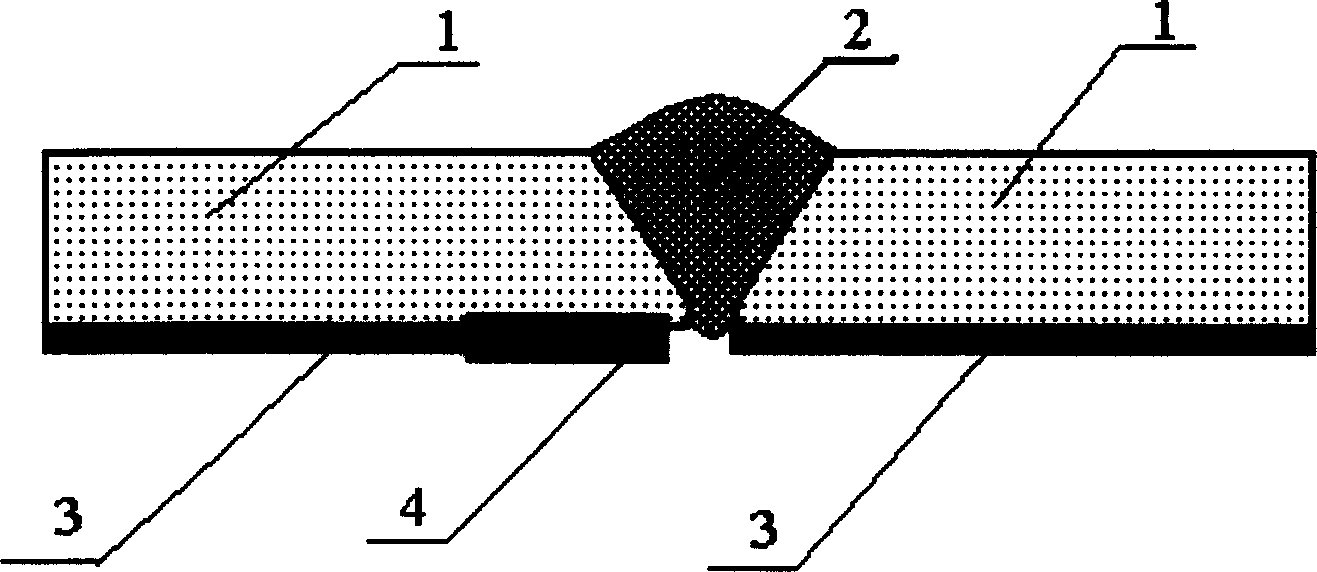

[0018] In actual design and construction, the designer of the present invention realizes the technical characteristics of the present invention by following specific operations: 1. at first prepare the special alloy of sacrificial anode: its composition range is: zinc 2.0%~7.0%, preferably 4.0%; magnesium 1.0% to 5.0%, preferably 2.0%; other elements and additives 0.01% to 2%; aluminum balance. The aluminum-zinc-magnesium alloy is then fabricated into a ring-shaped sacrificial anode.

[0019] 2. First fix the aluminum-zinc-magnesium alloy sacrificial anode on the inner wall of the steel pipe to be treated by welding, bonding, mechanical inlay, interference fit, etc. at one end (or both ends) of the steel pipe, then carry out the inner wall anticorrosion, and finally use The current welding process is used for welding. This technology uses the potential difference between the aluminum-zinc-magnesium alloy and the base metal of the steel pipe and the weld seam to achieve the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com