Nano wood antiseptics and manufacturing method thereof

A wood preservative and nanotechnology, applied in the direction of wood impregnation, impregnating wood, manufacturing tools, etc., can solve the problems of deep color of wood and bamboo, poor resistance to loss, affecting the processing and application fields of wood and bamboo.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

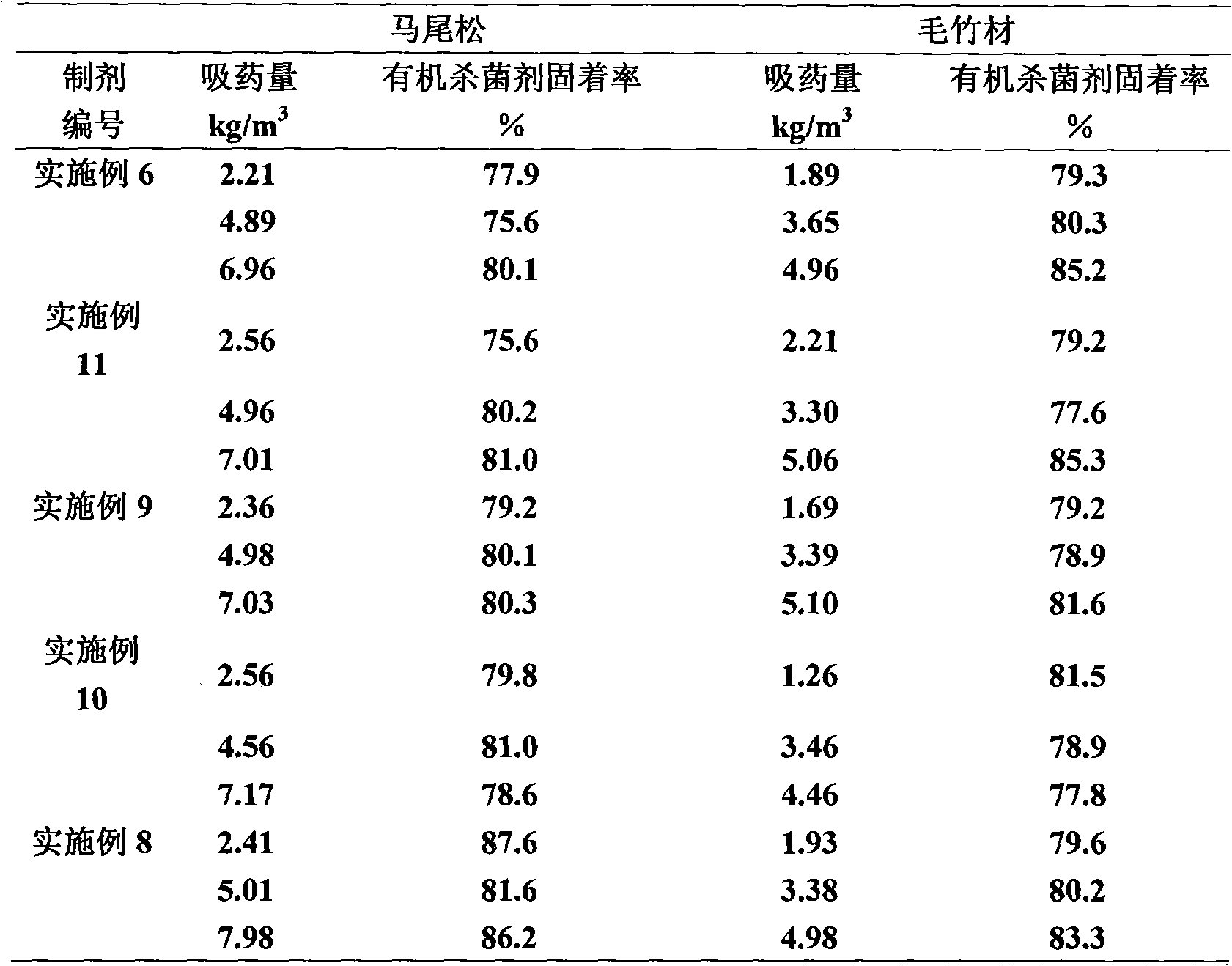

Examples

Embodiment 6

[0026] If you want to prepare 10.0kg of compound preservative mainly composed of propiconazole, tebuconazole and beta-cypermethrin, you should weigh 0.5kg of water-soluble polymer copovidone, fungicides propiconazole and tebuconazole Alcohol 0.1kg each, insecticide beta-cypermethrin 0.03kg, stirred at 45°C, dissolved in 0.68kg organic solvent n-butanol; then add 0.45kg of surfactant lauryl polyoxyethylene ether phosphate, dodecane Calcium phenylsulfonate 0.05kg, stir to dissolve; keep the temperature at 25°C, and add 8.09kg of water dropwise at a speed of 5L / min under stirring at a speed of 200 rpm. After adding water, continue stirring for 0.5h to prepare 10kg of preservative solution whose main components are propiconazole, tebuconazole and beta-cypermethrin, which can be directly used for antiseptic treatment or further diluted for reuse.

Embodiment 9

[0028] To prepare 9.81kg of compound preservative mainly composed of propiconazole, dithiocyanomethane and imidacloprid, the organic solvent n-octanol 0.53kg should be weighed accordingly, and 0.55kg of water-soluble polymer styrene- Acrylate polymer, dissolved in it at 45°C, then add 0.16kg each of the fungicide propiconazole and dithiocyanomethane, and 0.05kg of the insecticide imidacloprid, stir to dissolve; then add surfactant three 0.38kg of styrylphenol polyoxyethylene ether phosphate, 0.05kg of calcium dodecylbenzenesulfonate, stir and dissolve; keep the temperature at 28°C, stir at a speed of 300r / min, and add 7.93kg dropwise at a speed of 1L / min After adding water, continue to stir for 0.5h to obtain 9.81kg of preservative solutions whose main components are propiconazole, dithiocyanomethane and imidacloprid, which can be directly used for antiseptic treatment or further diluted for reuse.

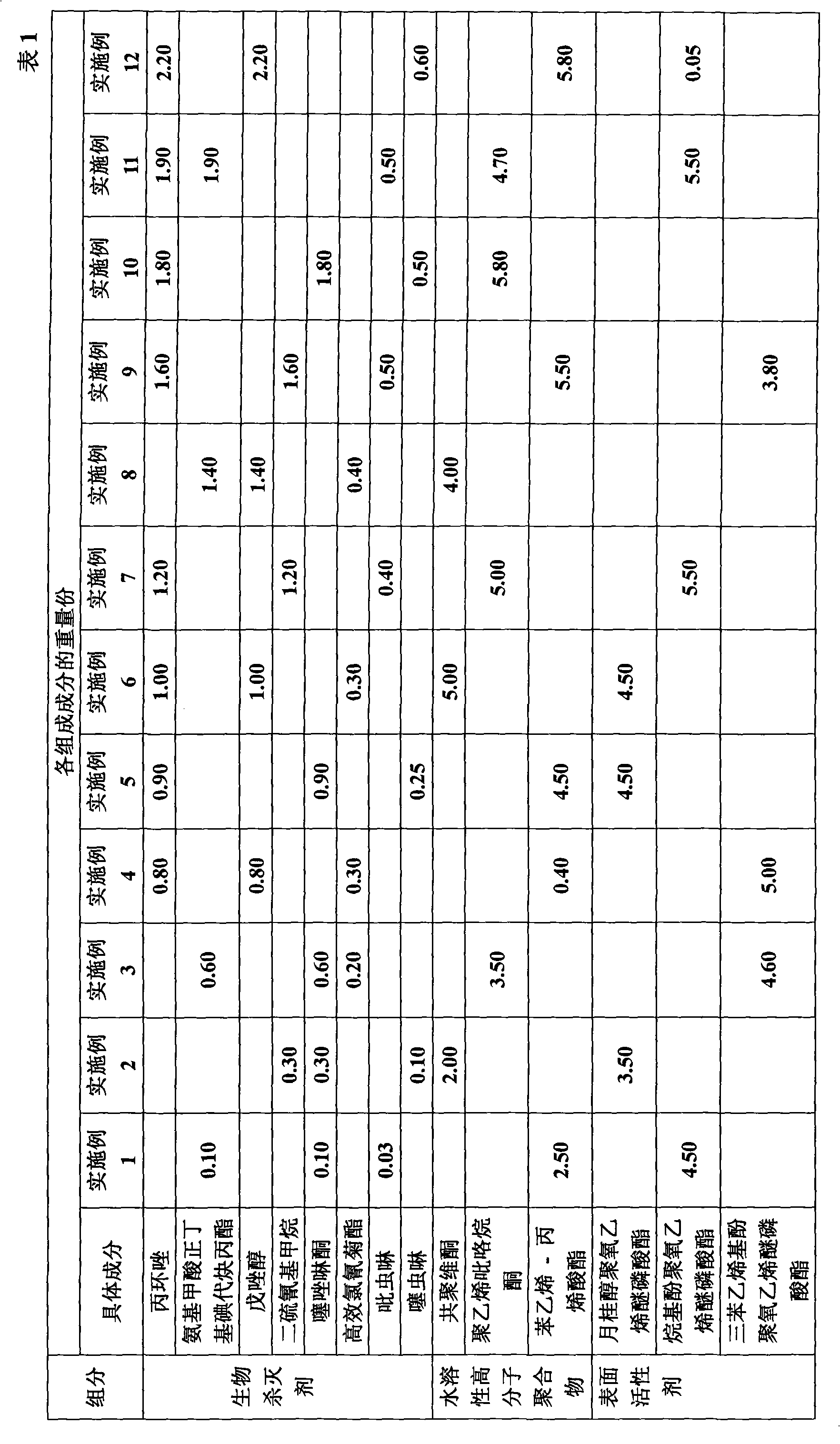

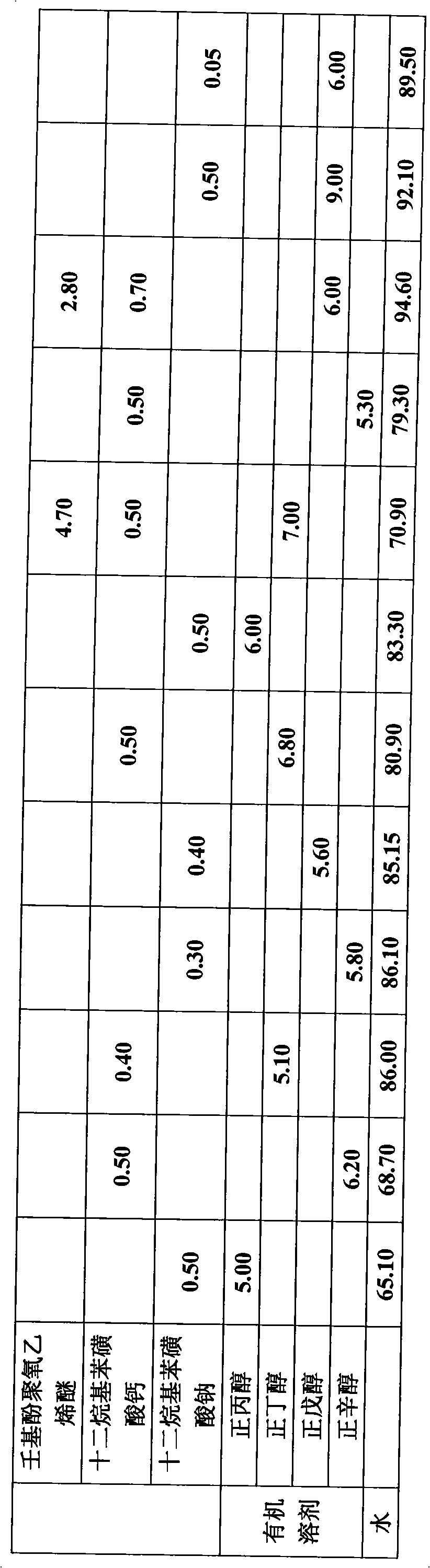

[0029] The components and parts by weight of other examples listed in Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com