Patents

Literature

30 results about "Cigarillo" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cigarillo (from Spanish cigarrillo, meaning "cigarette", in turn from cigarro ("cigar") + -illo (diminutive suffix), pronounced [siɣaˈriʝo] in parts of Latin America or [θiɣaˈriʎo] in Spain) is a short, narrow cigar. Unlike cigarettes, cigarillos are wrapped in tobacco leaves or brown, tobacco-based paper. Cigarillos are smaller than regular cigars but usually larger than cigarettes. Cigarillos are usually made without filters, and are meant to be smoked like a cigar and not inhaled (except those made in this form only for specific tax issues).

Smoke-free substitute cigarette product

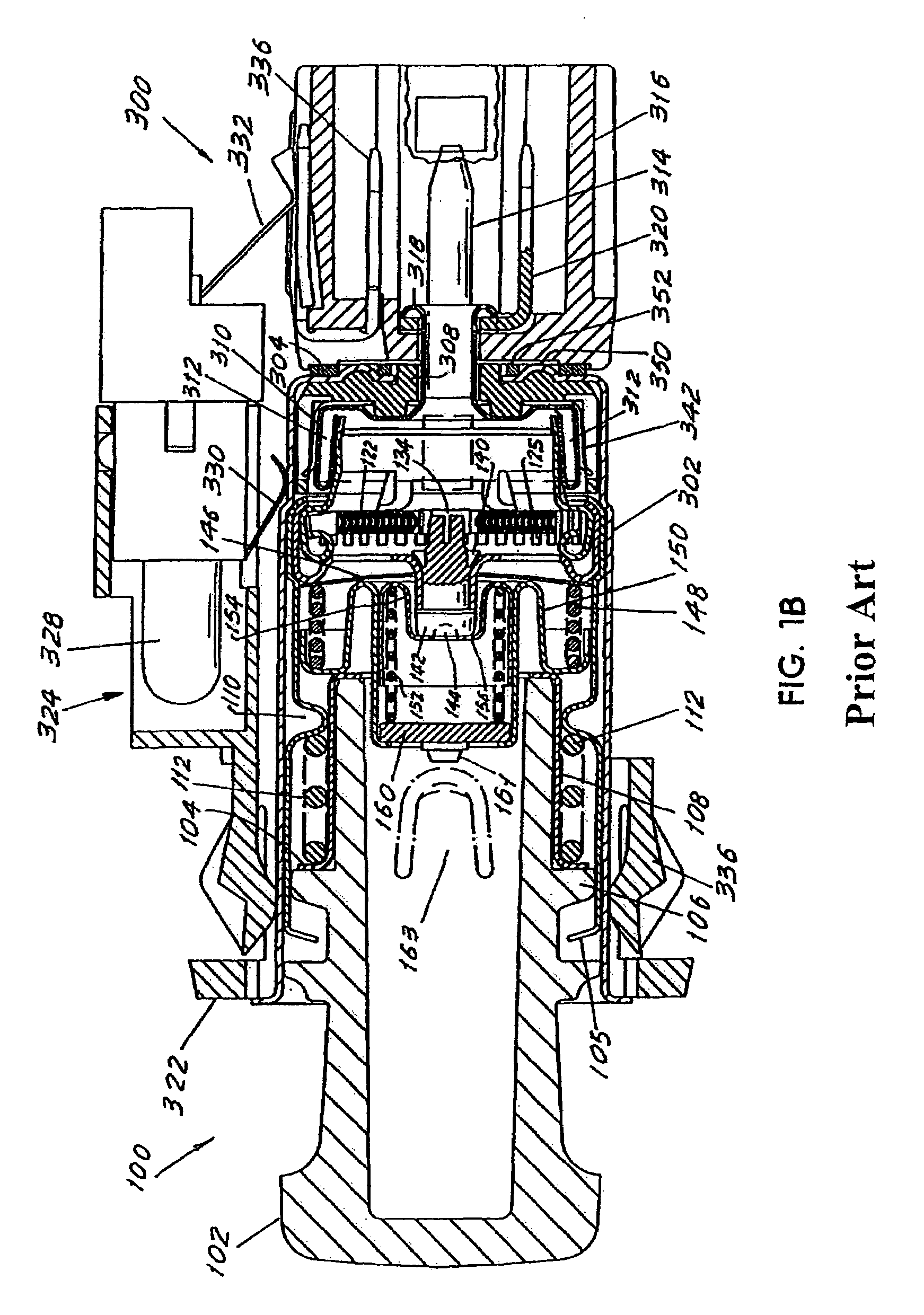

ActiveUS20100126505A1Straightforwardly be carriedReduce weightTobacco treatmentTobacco devicesFlammable gasCigarillo

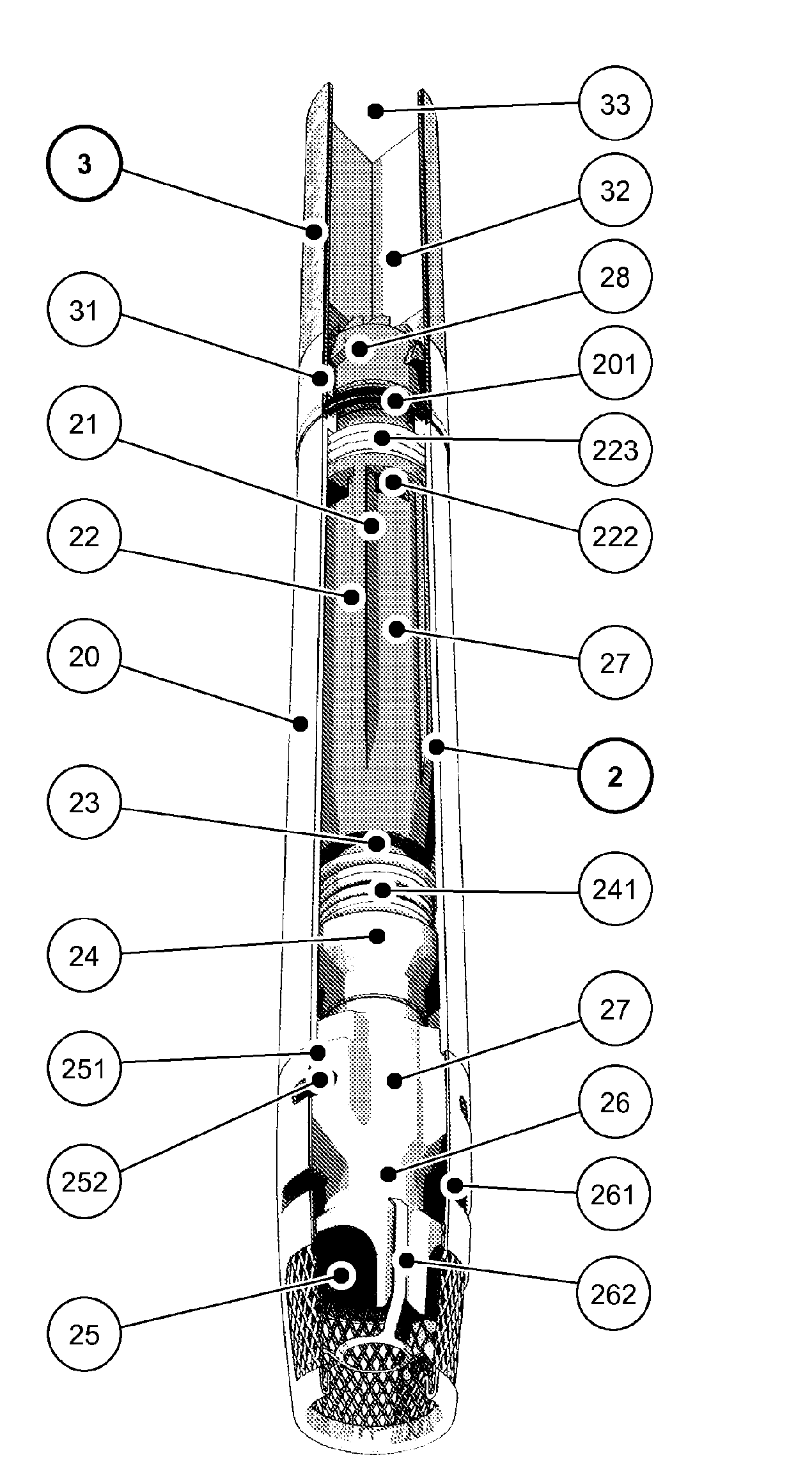

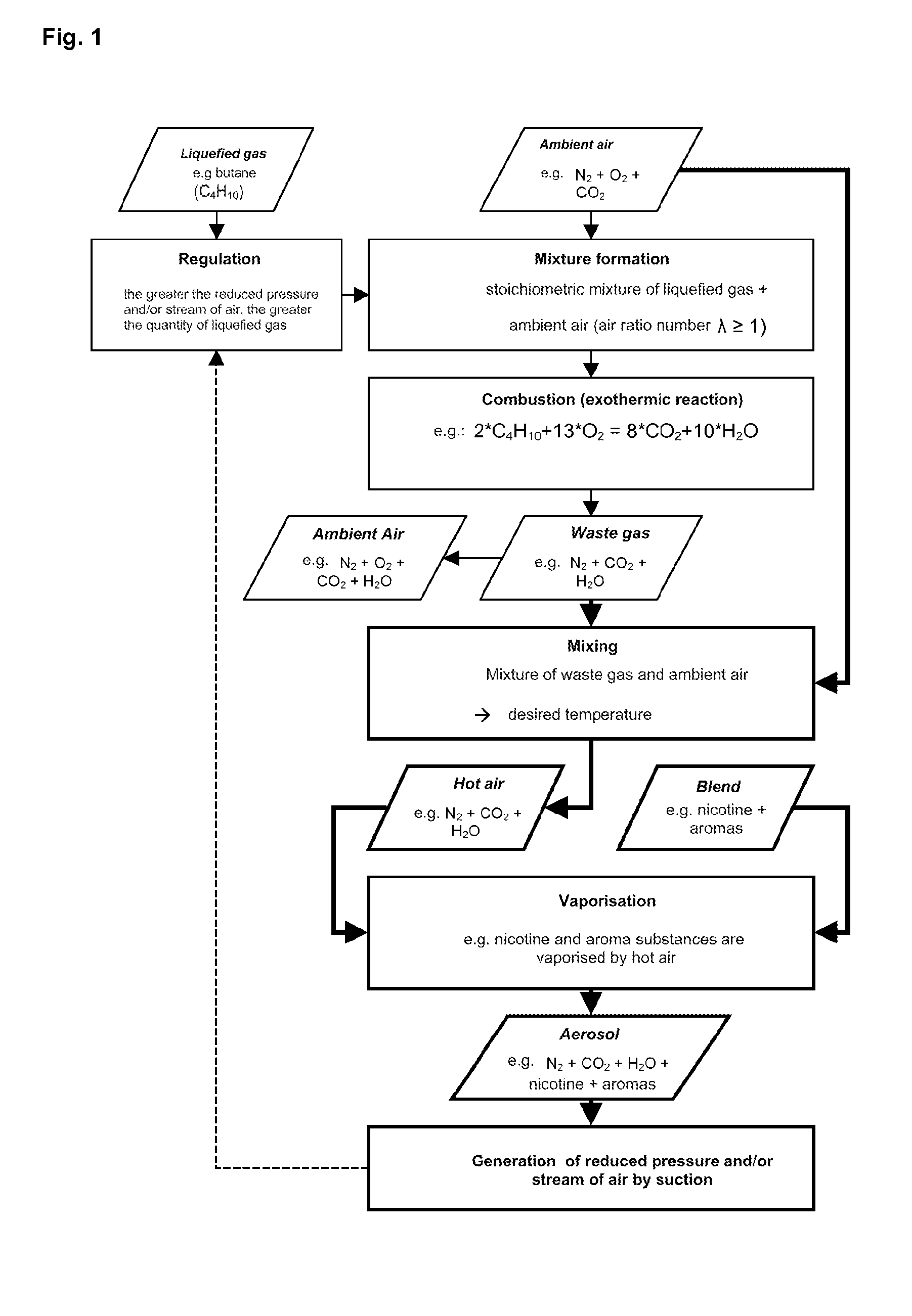

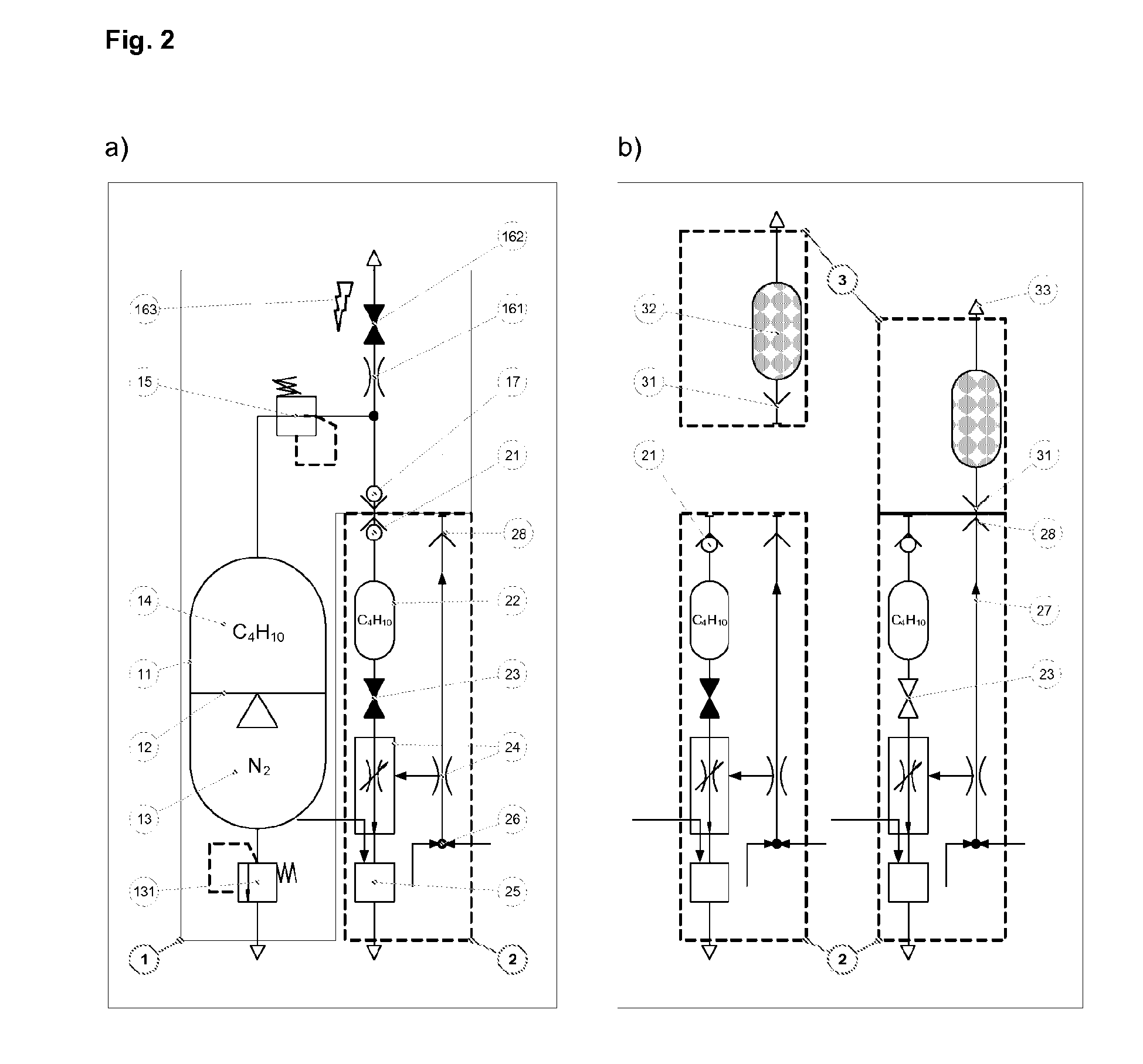

A method for volatilising active and / or aroma substances for the purpose of releasing an inhalable aerosol, wherein combustion gases of a flammable gas, which is preferably combusted with an excess of air, are passed partially or entirely, optionally mixed with ambient air, through an active and / or aroma substance depot and wherein a desired temperature is selectable by the proportion of combustion gases and optionally by the mixing ratio of said combustion gases with ambient air and the device implementing the method in the shape and dimensions of a cigarette or cigar for releasing an inhalable aerosol, comprising a mouthpiece (3) containing an active and / or aroma substance depot (32), a heating member (2) with a housing sleeve with one or more air inlets and one or more hot air outlets at the mouthpiece end, a filling valve (21) for filling a gas tank (22) with a flammable gas, preferably propane or butane gas, a regulating valve (24) for the controlled release of the gas from the gas tank (22) to a burner (25) and a mass transfer exchanger (26) for heating the air by the hot combustion gases produced by means of the burner (24), wherein the mouthpiece (3) is detachably connected to the heating member (2) and control of the regulating valve (24) is effected by means of the reduced pressure and / or stream of air generated by a user's suction on the mouthpiece (3). Fuelling station for such a device.

Owner:PHILIP MORRIS PROD SA

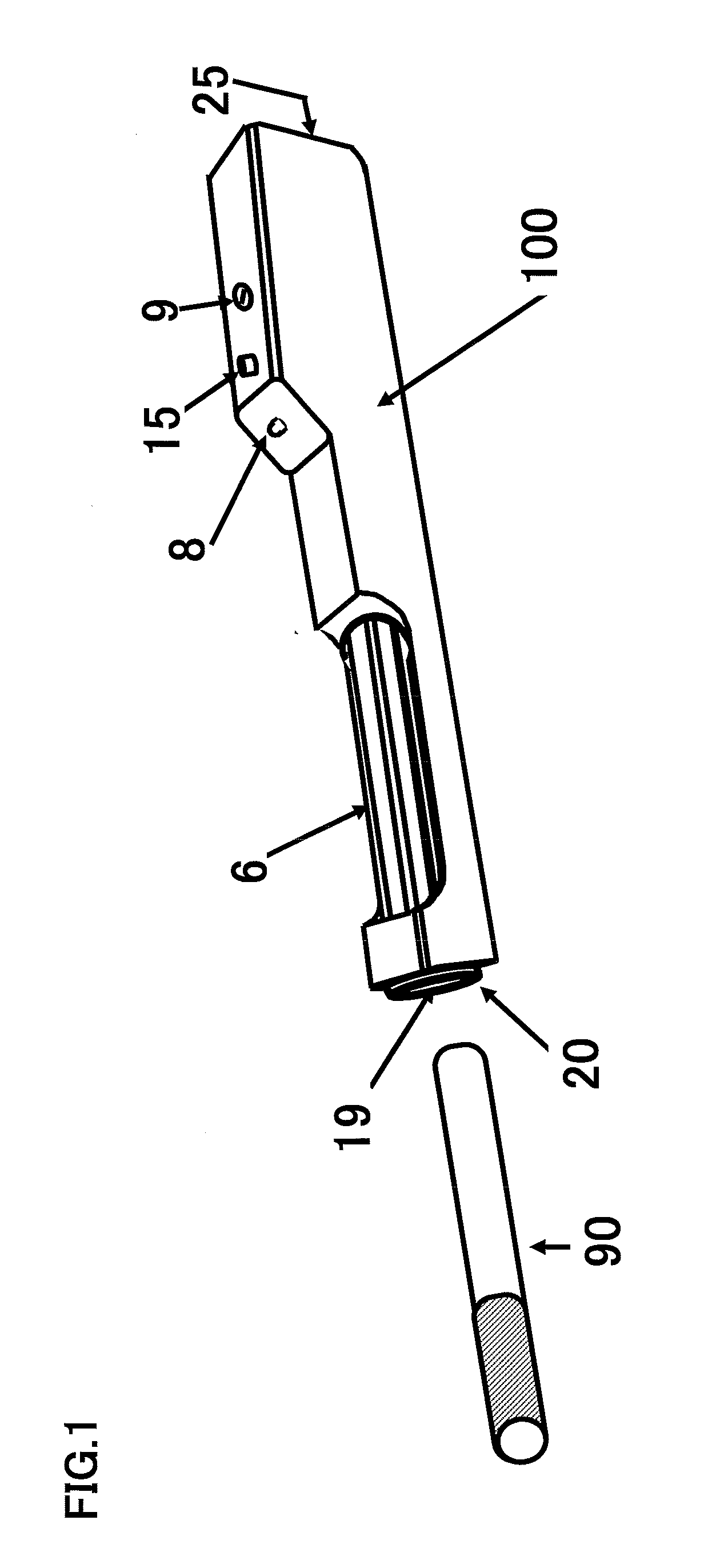

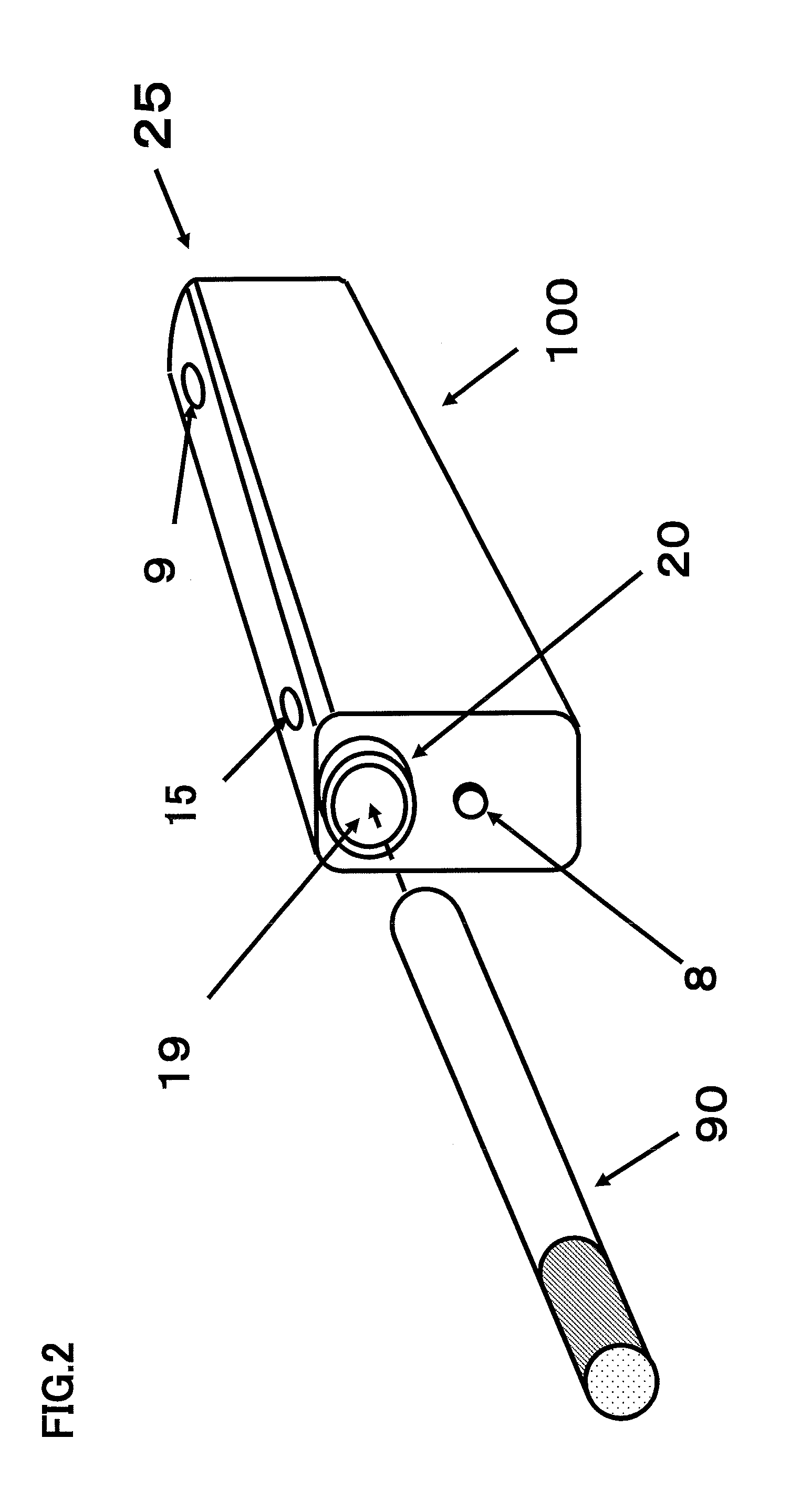

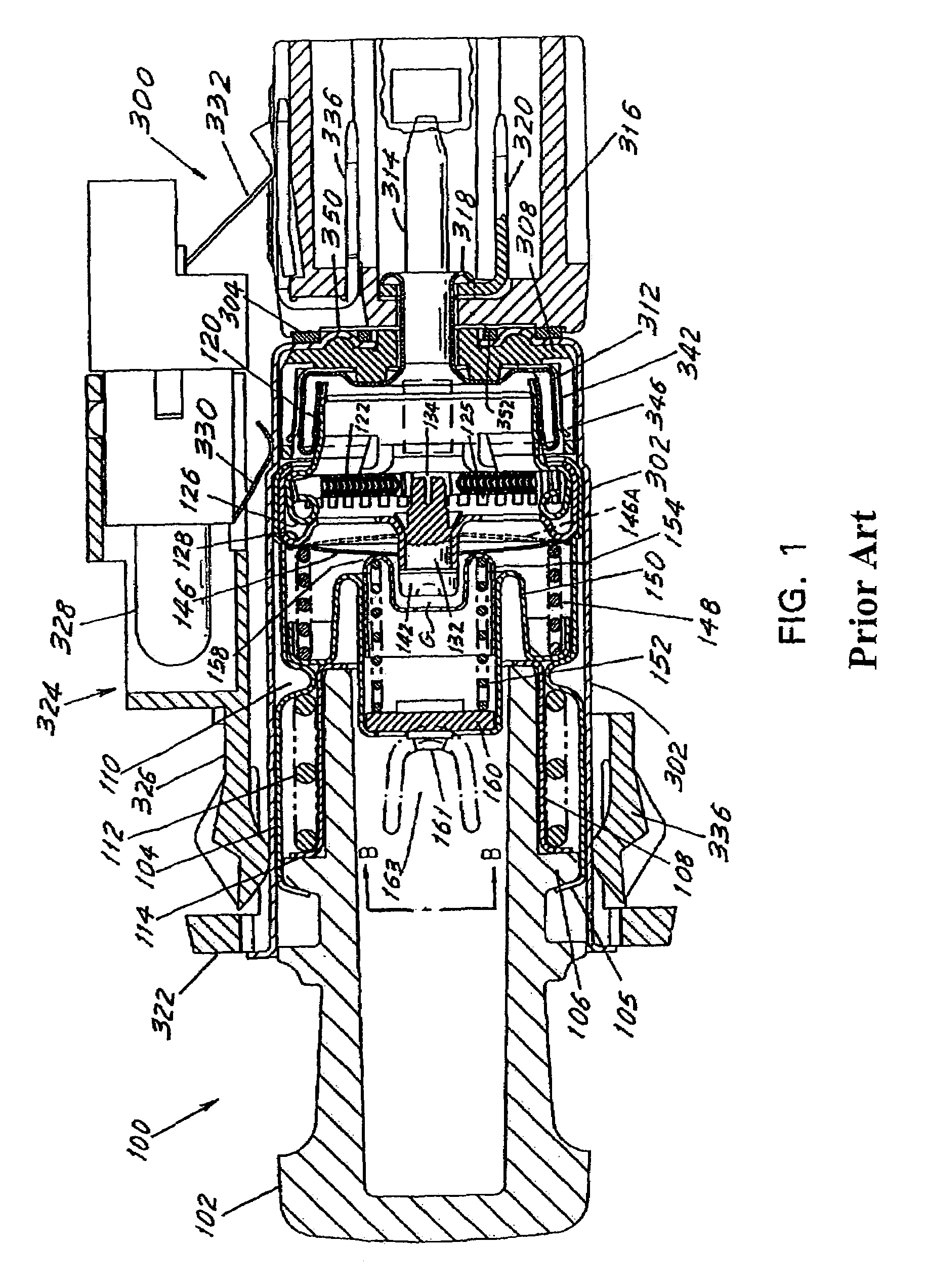

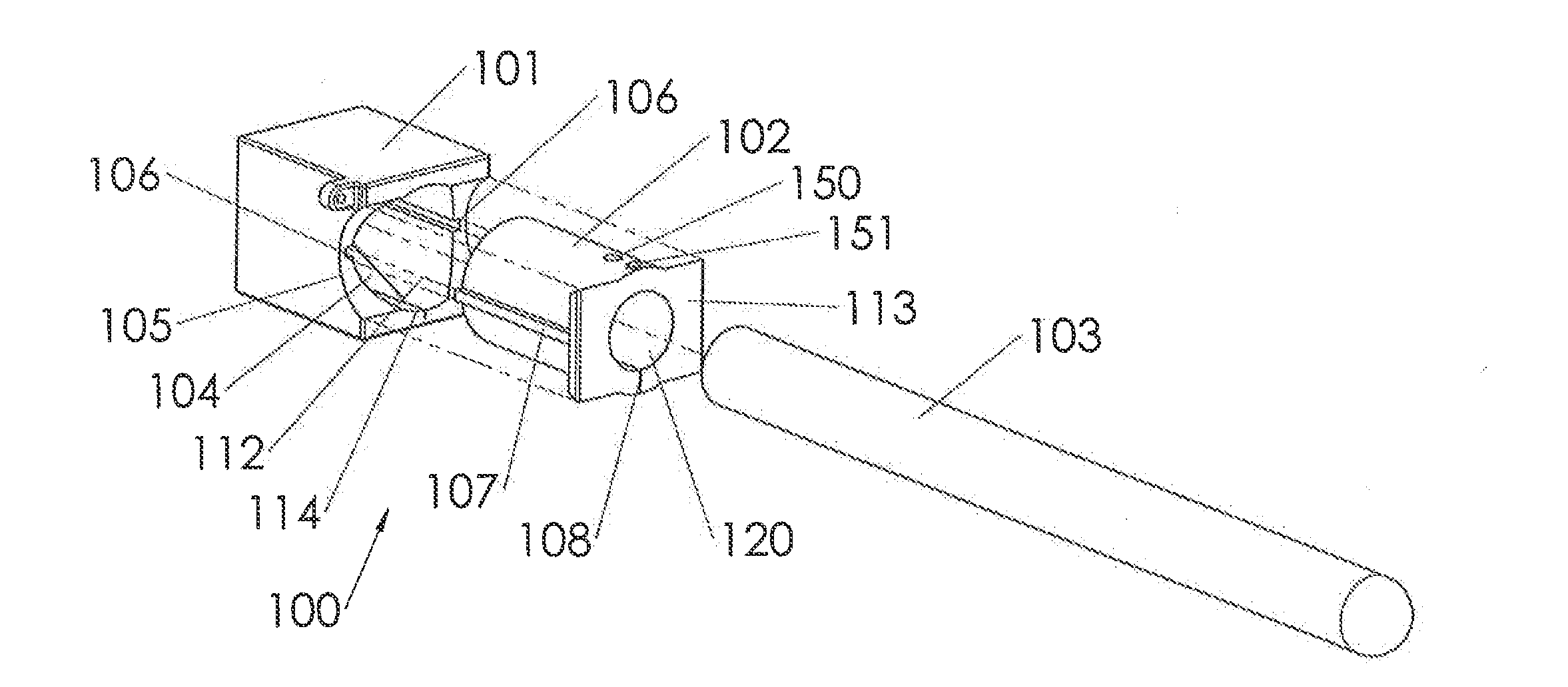

Non-Combustion Smoking Tool

InactiveUS20120234821A1Effectively “vaporized”Novel structureTobacco pipesTobacco devicesCombustionInhalation

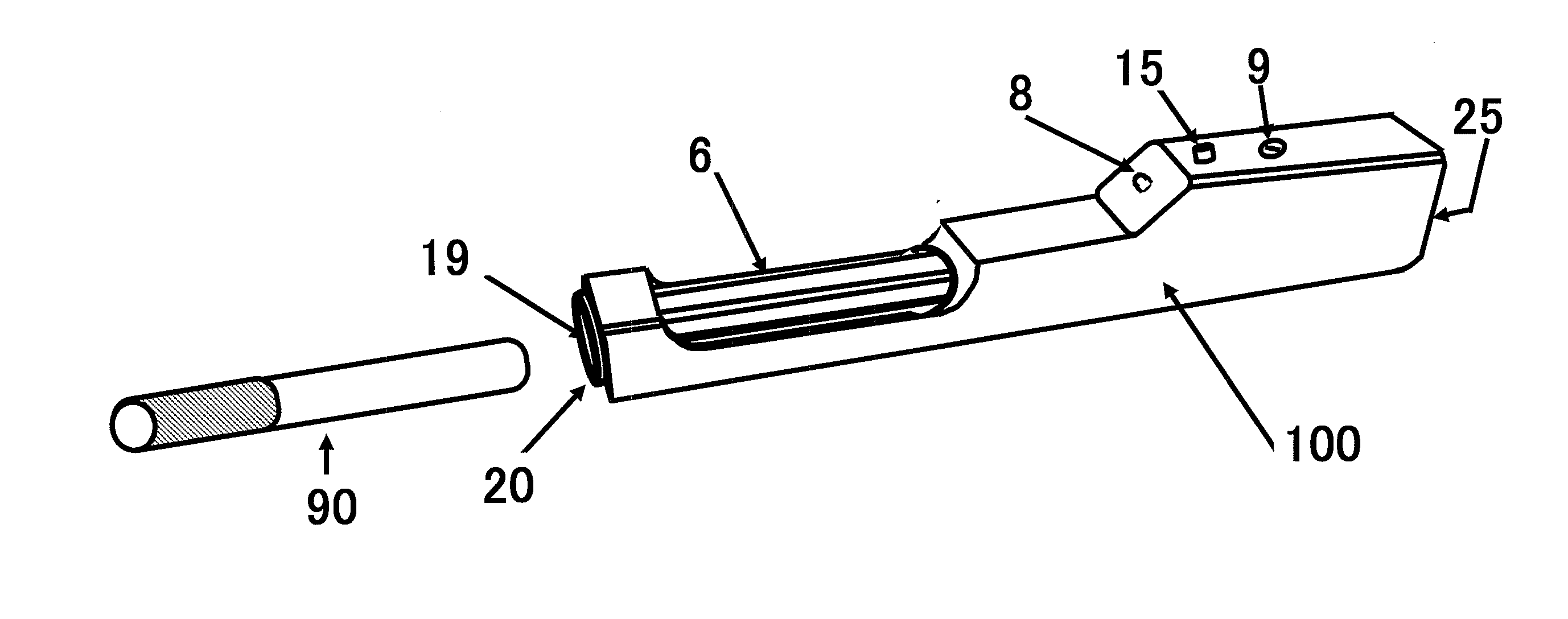

A non-combustion smoking tool is usable with a commercial cigarette or cigar as it is, the tool vaporizes nicotine from the tobacco leaves and enables inhalation of the vaporized nicotine without burning the product. The non-combustion smoking tool has a heater to be used which includes a coil part and a linear part to be inserted into a commercial cigarette or cigar, wherein the linear part preheats the tobacco leaves, and the coil part heats air around the coil part so that, when a smoker inhales, the heated air around the coil part passes through the tobacco leaves so as to vaporize nicotine contained in the tobacco leaves and enable inhalation of the vaporized nicotine.

Owner:SHIMIZU KAZUHIKO

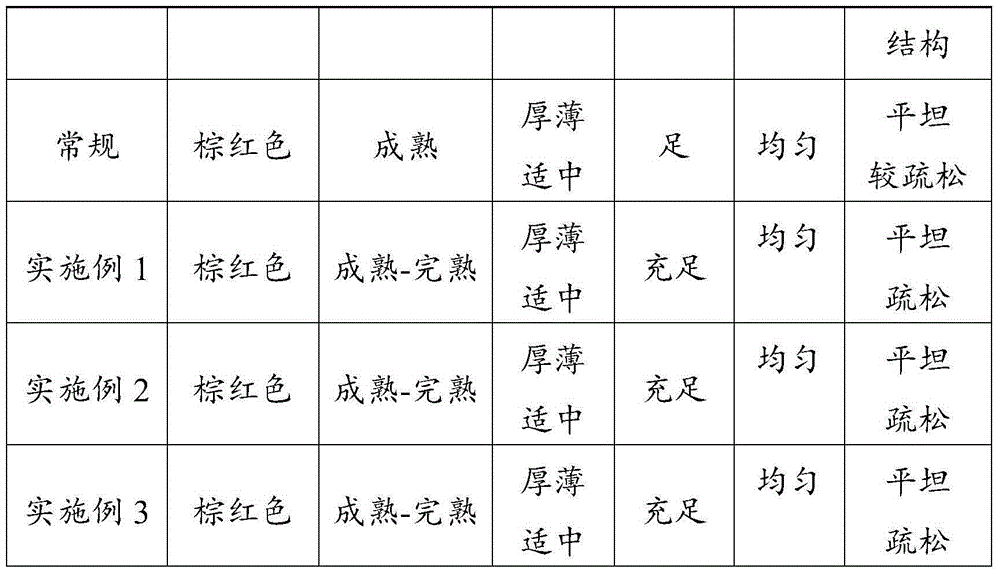

Preparation method of cigar wrapper tobacco

A preparation method of cigar wrapper tobacco comprises the following steps: (1) preparation of extract liquid of cigar raw materials: selecting the cigar raw materials, soaking the cigar raw material in 70 percent of ethyl alcohol for 4 to 6 hours, then heating and boiling for 20 to 40 minutes, filtering, reducing pressure and concentrating an ethanol solution to obtain the extract liquid of the cigar raw materials; (2) flue-cured tobacco air-curing: harvesting and stringing 3 to 5 tobacco leaves at the lower part and 6 to 8 tobacco leaves in the middle at one step after the tobacco leaves at the lower and middle parts of the flue-cured tobacco mature, and air-curing by referring to a cigar modulation standard; (3) extract liquid spraying: uniformly spraying the extract liquid of the cigar raw materials obtained in the step (1) onto the front and back faces of the air-cured leaves, ventilating properly and airing, maintaining 16 to 18 percent of moisture, finishing and fermenting the cigar wrapper tobacco. By adopting the preparation method of the cigar wrapper tobacco, the flue-cured tobacco can be prepared into the satisfactory cigar wrapper tobacco, and the demand of wrapper tobacco raw materials of a cigar can be met, meanwhile, the range of application of the flue-cured tobacco is widened, and the production cost of a cigarette industrial enterprise is reduced.

Owner:HUBEI CHINA TOBACCO IND

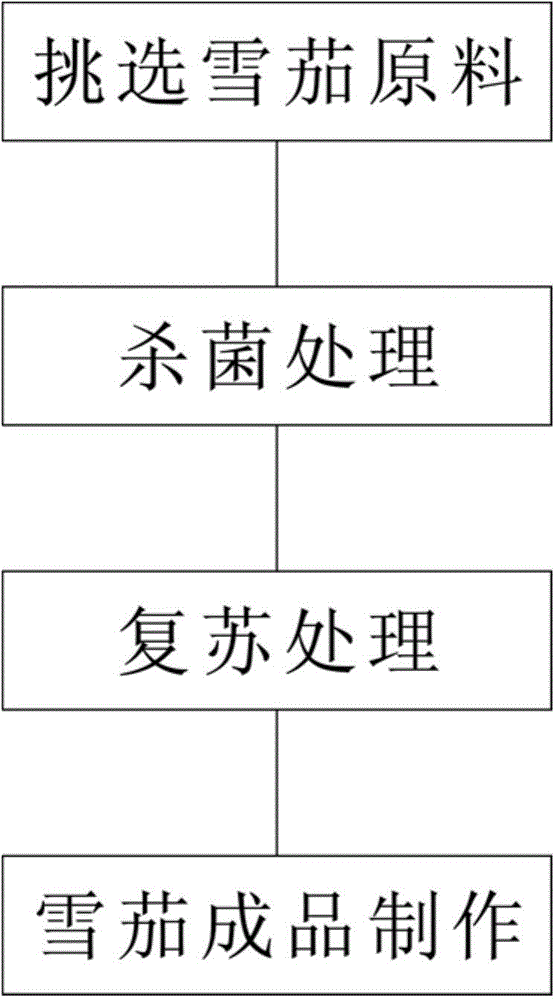

Cacao flavor formula and technique for producing cocoa-flavor cigar

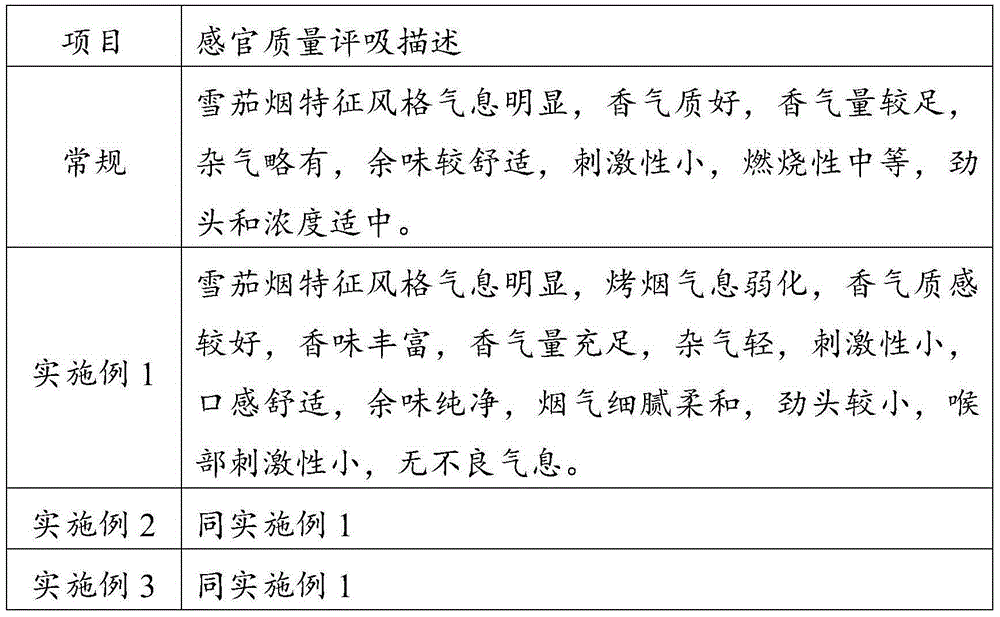

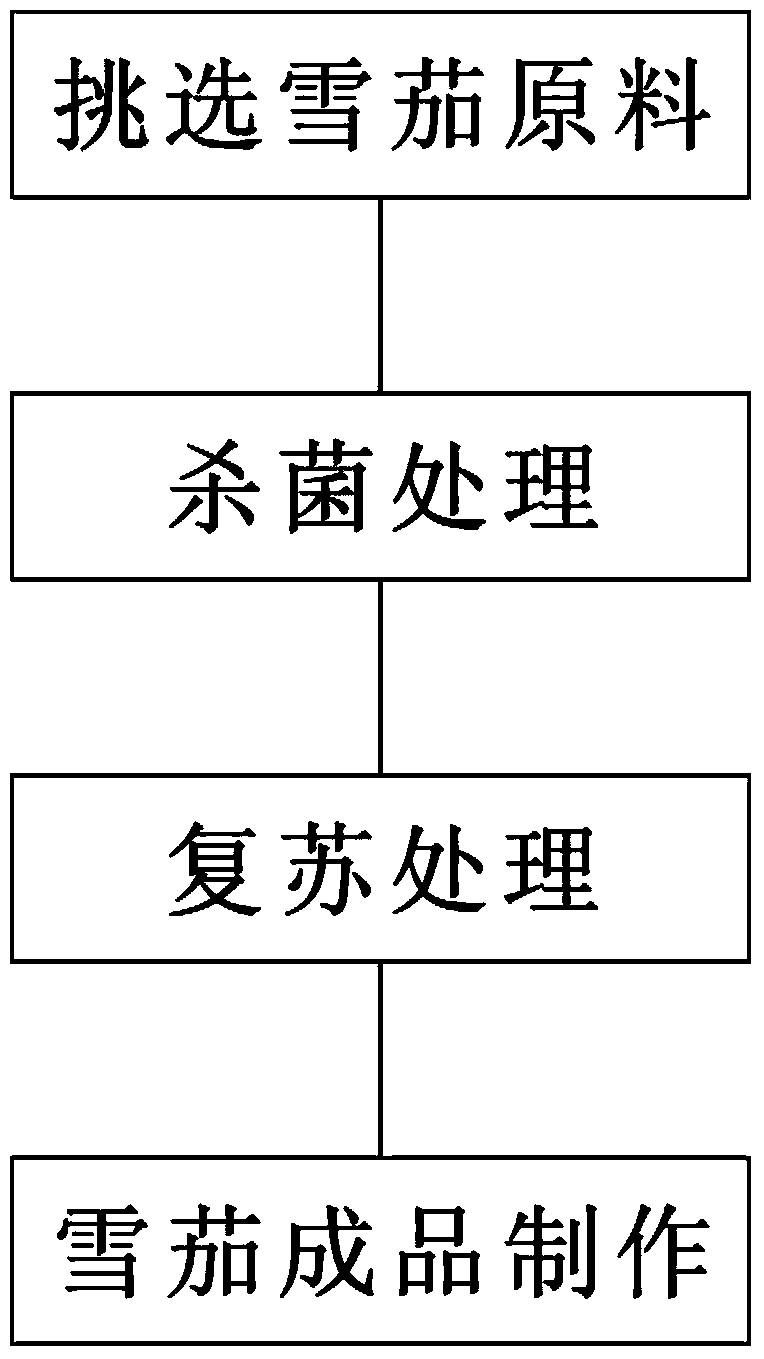

The invention discloses a cacao flavor formula and a technique for producing a cocoa-flavor cigar. According to the cacao flavor formula, a cacao flavor obtained according to the formula comprises, by weight, 25 parts to 30 parts of cacao extract, 5 parts to 8 parts of ketone spice, 30 parts to 40 parts of extract of natural plants, 20 parts to 30 parts of a thinner, and 2 parts to 5 parts of lipid spice. The technique for producing the cocoa-flavor cigar comprises the steps of (a) selection of cigar raw materials, (b) sterilization, (c) recovery treatment, and (d) production of the finished cigar. According to the cacao flavor formula and the technique for producing the cocoa-flavor cigar, through the study on the special cacao concentration and extraction technique and the study on addition of a cigar formula, a new type of thin cigars with special flavor obtained through infusion of cacao flavor and the natural fragrance of cigars are obtained.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Casing flavor for cigarette paper of cigars

ActiveCN105112161AUniform colorAdd special scentTobacco treatmentEssential-oils/perfumesCooking & bakingFlavor

The invention relates to application and development of flavoring essences or flavoring materials for tobacco and is especially applicable to the flavoring and casing of cigarette paper of cigars. The invention provides a casing flavor for the cigarette paper of the cigars, belongs to the field of application of tobacco flavors and relates to the flavoring and casing of the cigarette paper. The casing flavor is prepared through the following specific implementation steps of (1) selecting flavoring raw materials to form a flavoring essence formula according to a certain proportion; (2) carrying out cigarette paper casing: mixing the flavoring essence with coating liquid according to the ratio of 1: 1, and then, uniformly smearing the cigarette paper according to the casing quantity of 5%; (3) carrying out high-temperature hot-air seasoning: treating the cased cigarette paper in a baking oven with the constant temperature of 110 DEG C for 2 minutes; and (4) carrying out sensory quality evaluation: humidifying the cigarette paper to moisten the cigarette paper, then cutting tobacco leaves into shreds and making a cigar with the shredded tobacco leaves, and allowing professionals to make sensory evaluation on the cigar. The prepared casing flavor provided by the invention has an attractive scorched-bean fragrance and is added into the cigarette paper to cover relatively-heavy woody offensive odor, and the cigarette paper is endowed with the scorched-bean fragrance.

Owner:HUBEI CHINA TOBACCO IND +1

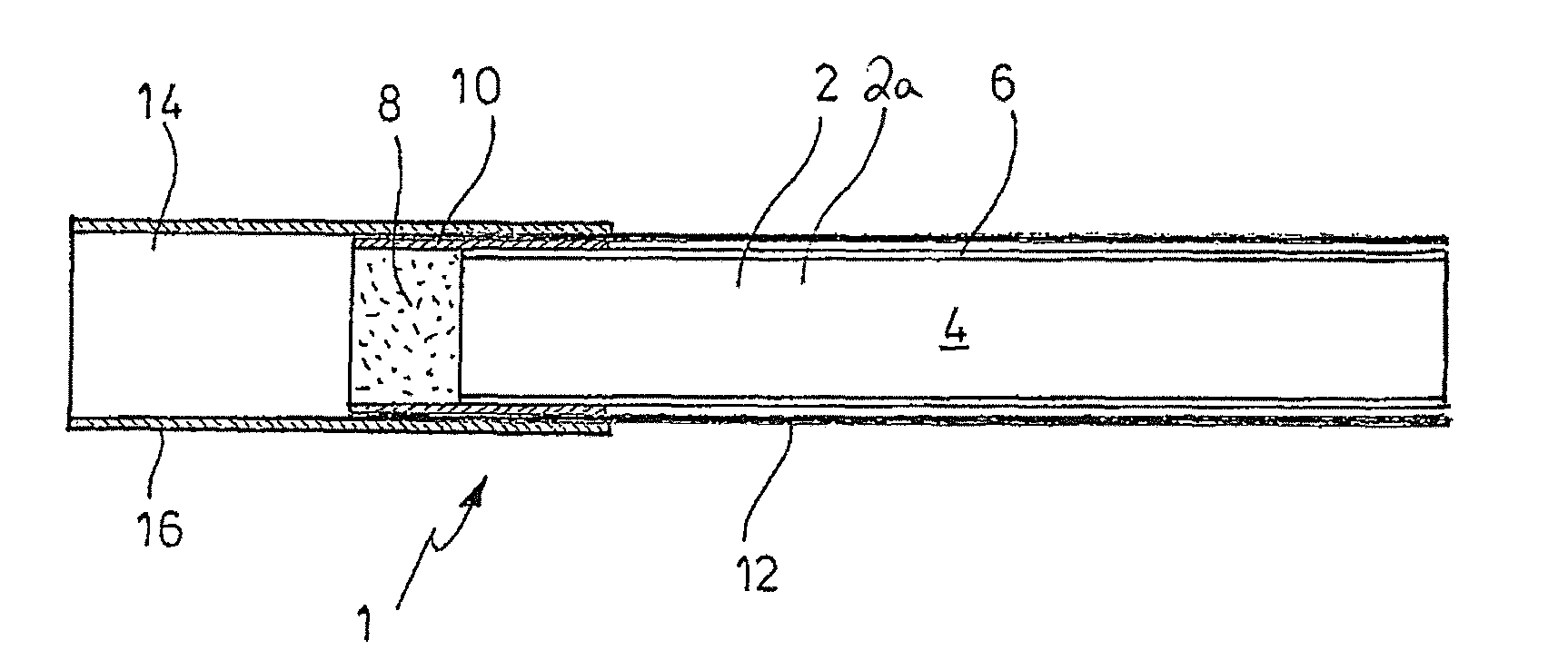

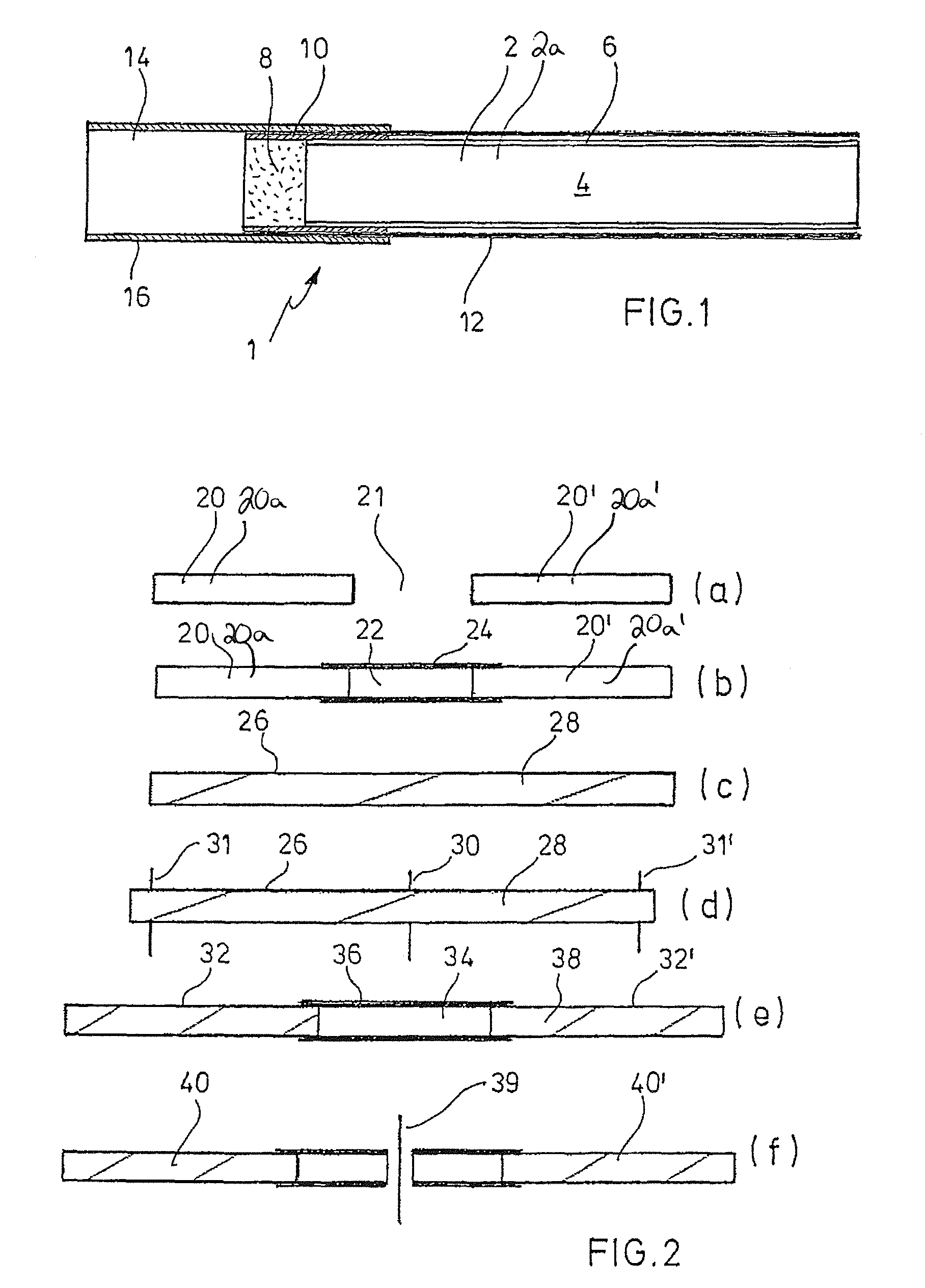

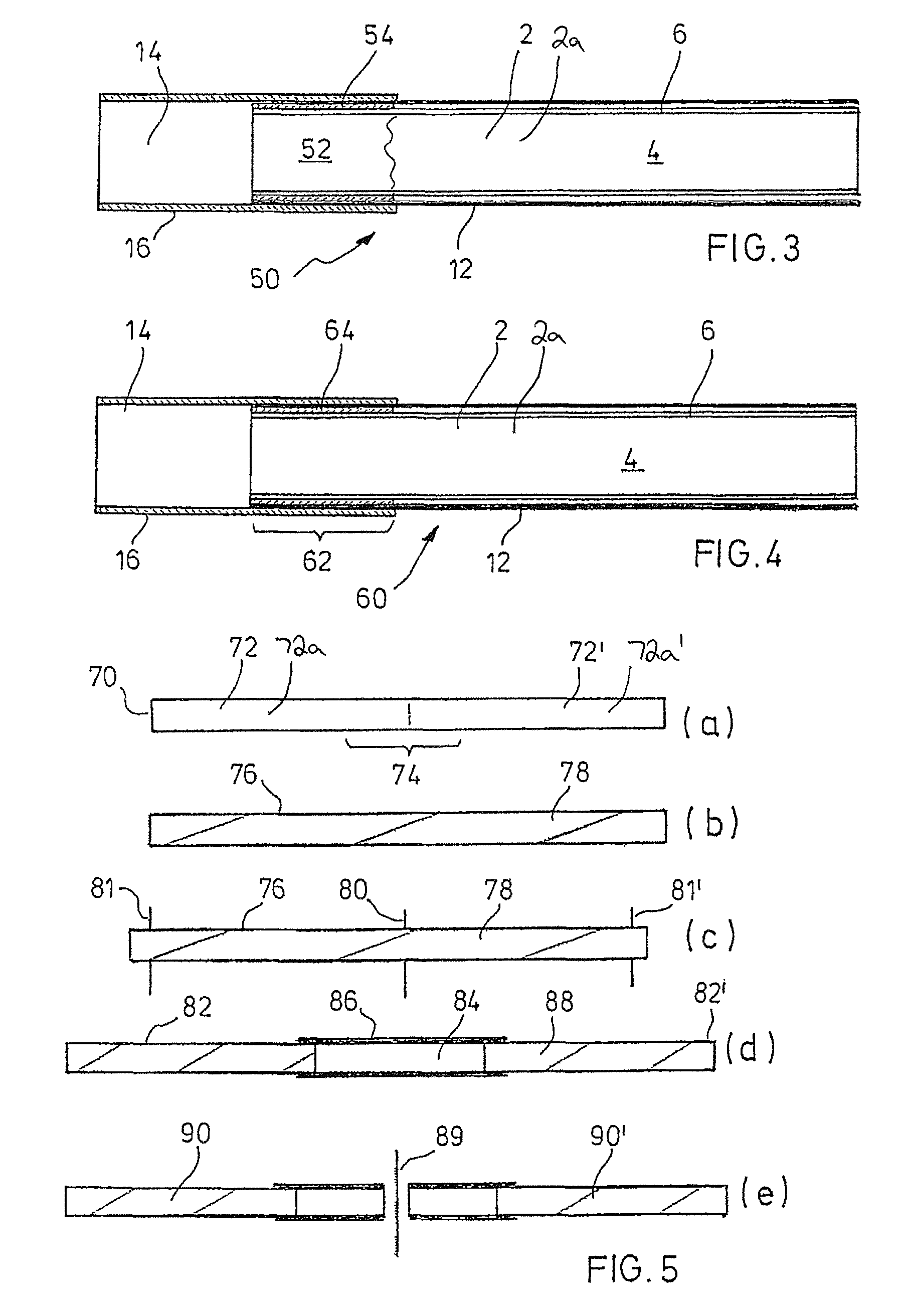

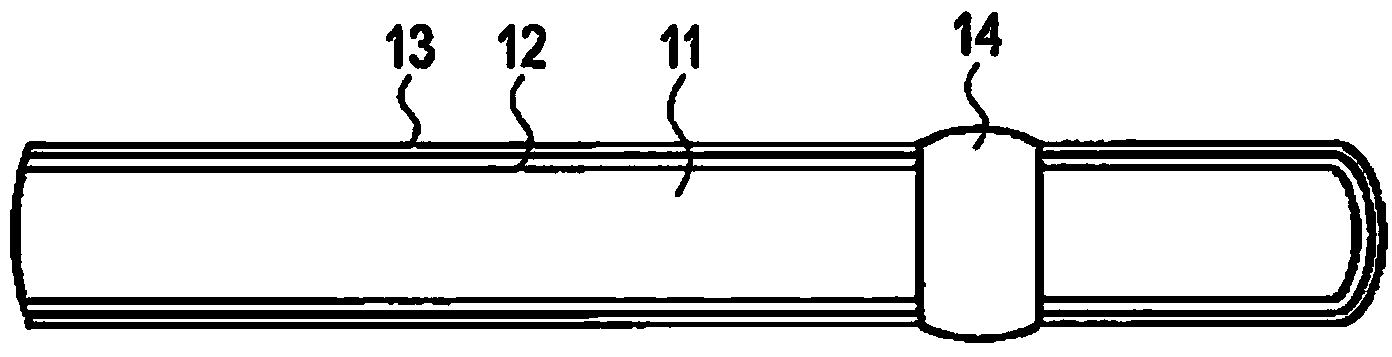

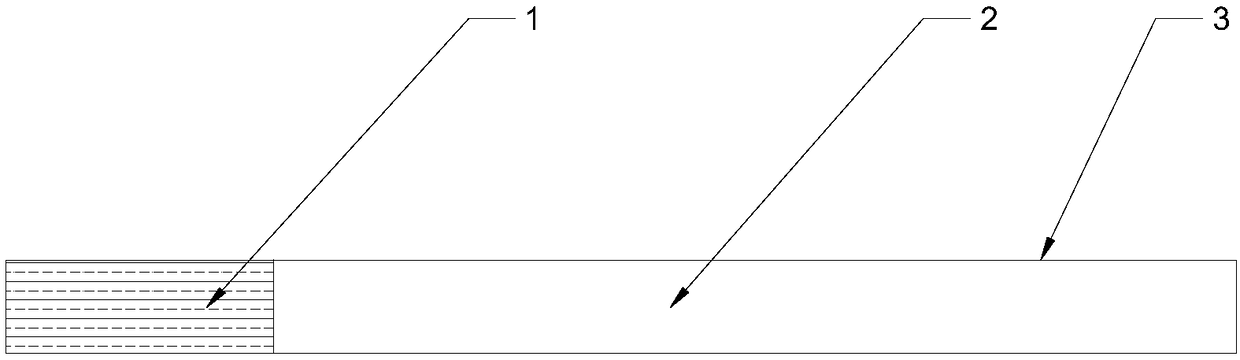

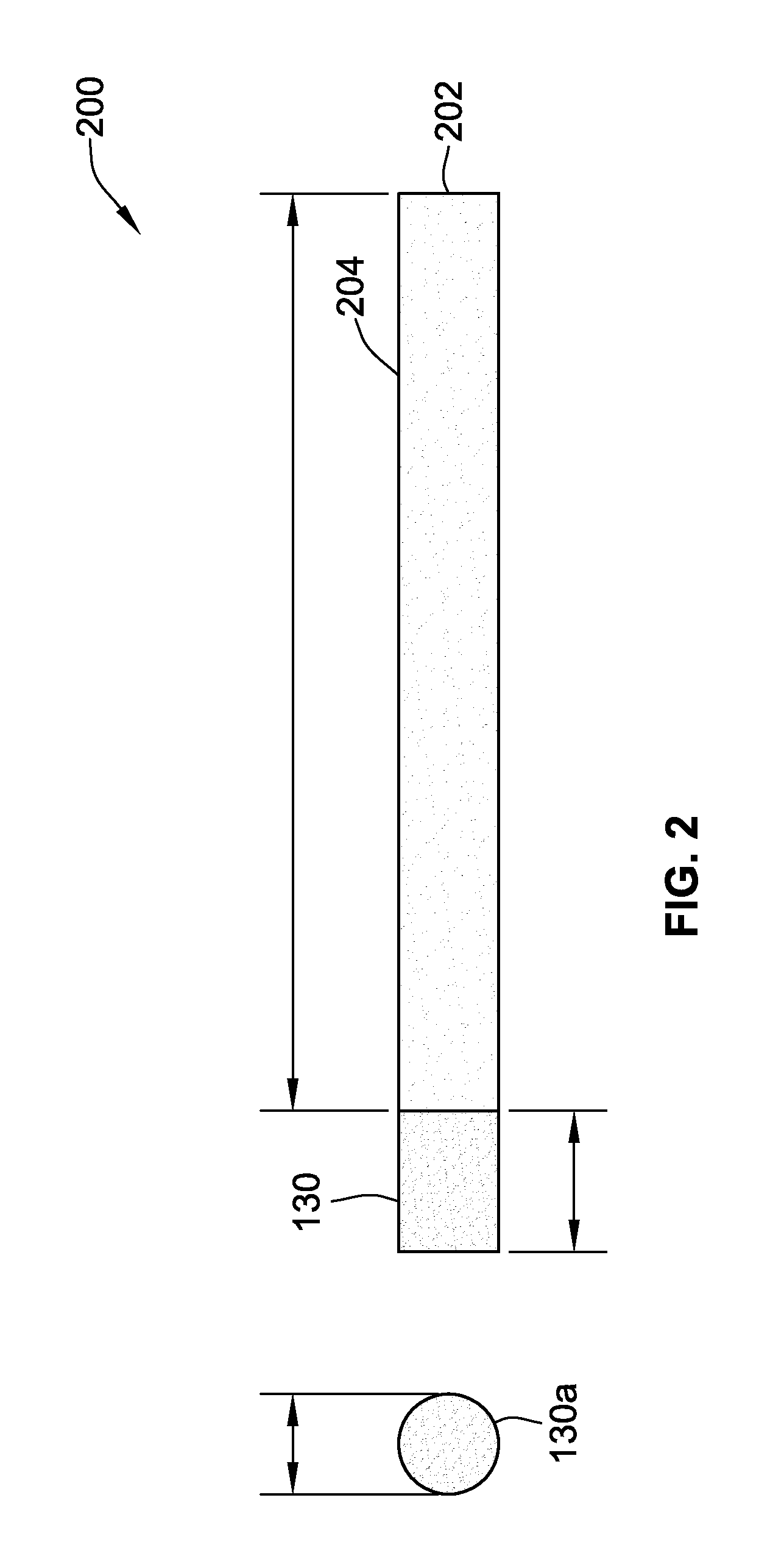

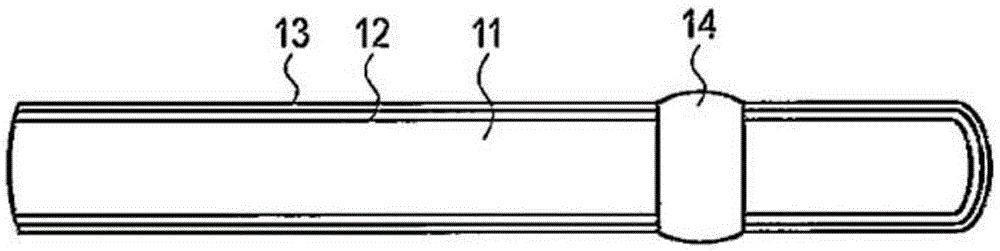

Filter cigarillo and process of manufacturing filter cigarillos

ActiveUS9326546B2Appealing designAvoid contactTobacco treatmentCigar manufactureBiochemical engineeringFilter material

A filter cigarillo comprises a bunch, which includes tobacco surrounded by a binder. A first section, different from a general bunch and providing some strengthening effect, is arranged at one end of the bunch. A natural-leaf wrapper surrounds the general bunch and the first section. A second section, which comprises filter material, is arranged downstream of the first section. The second section is connected to the natural-leaf wrapper by an outer tipping.

Owner:IMPERIAL TOBACCO LTD

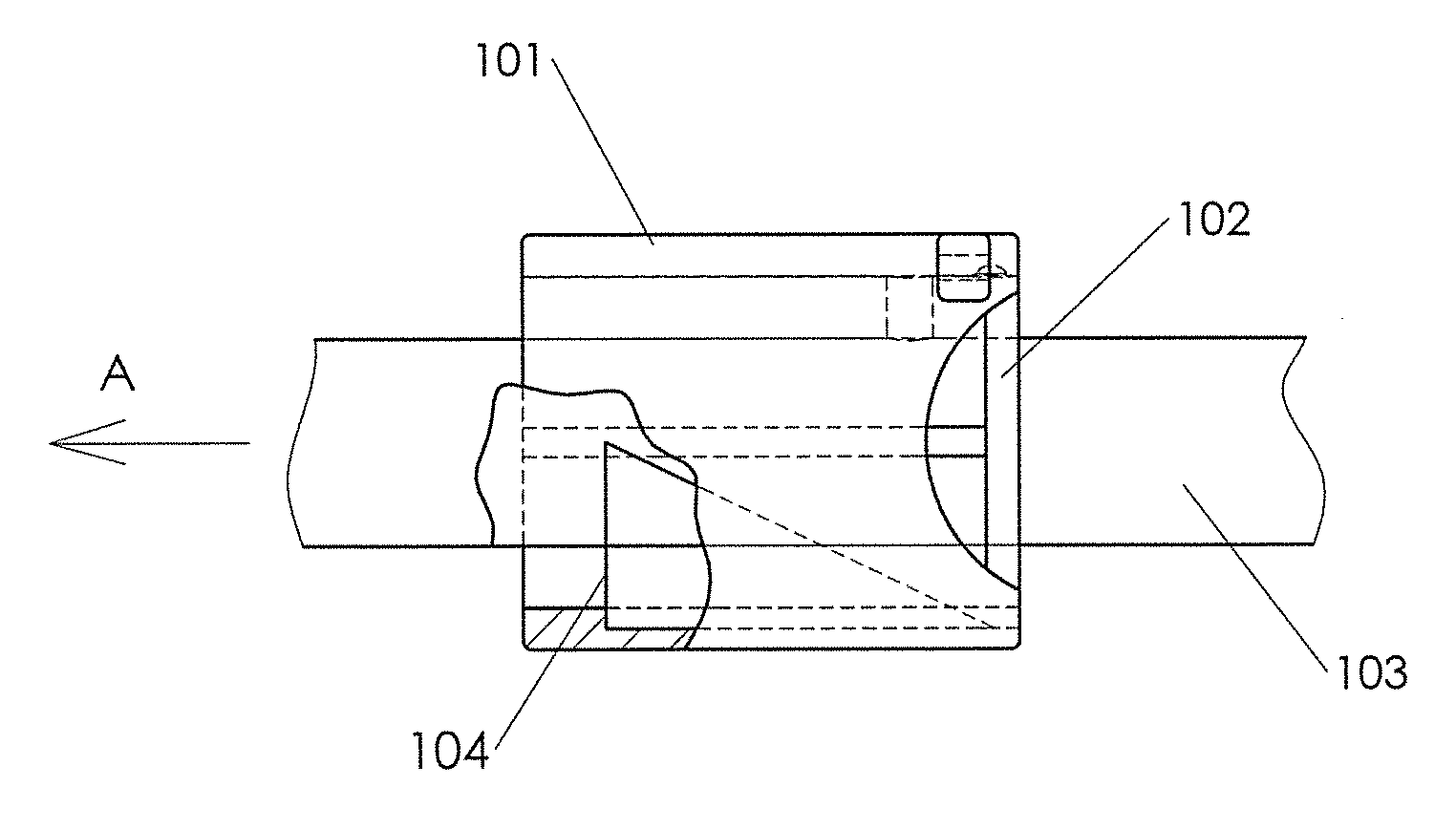

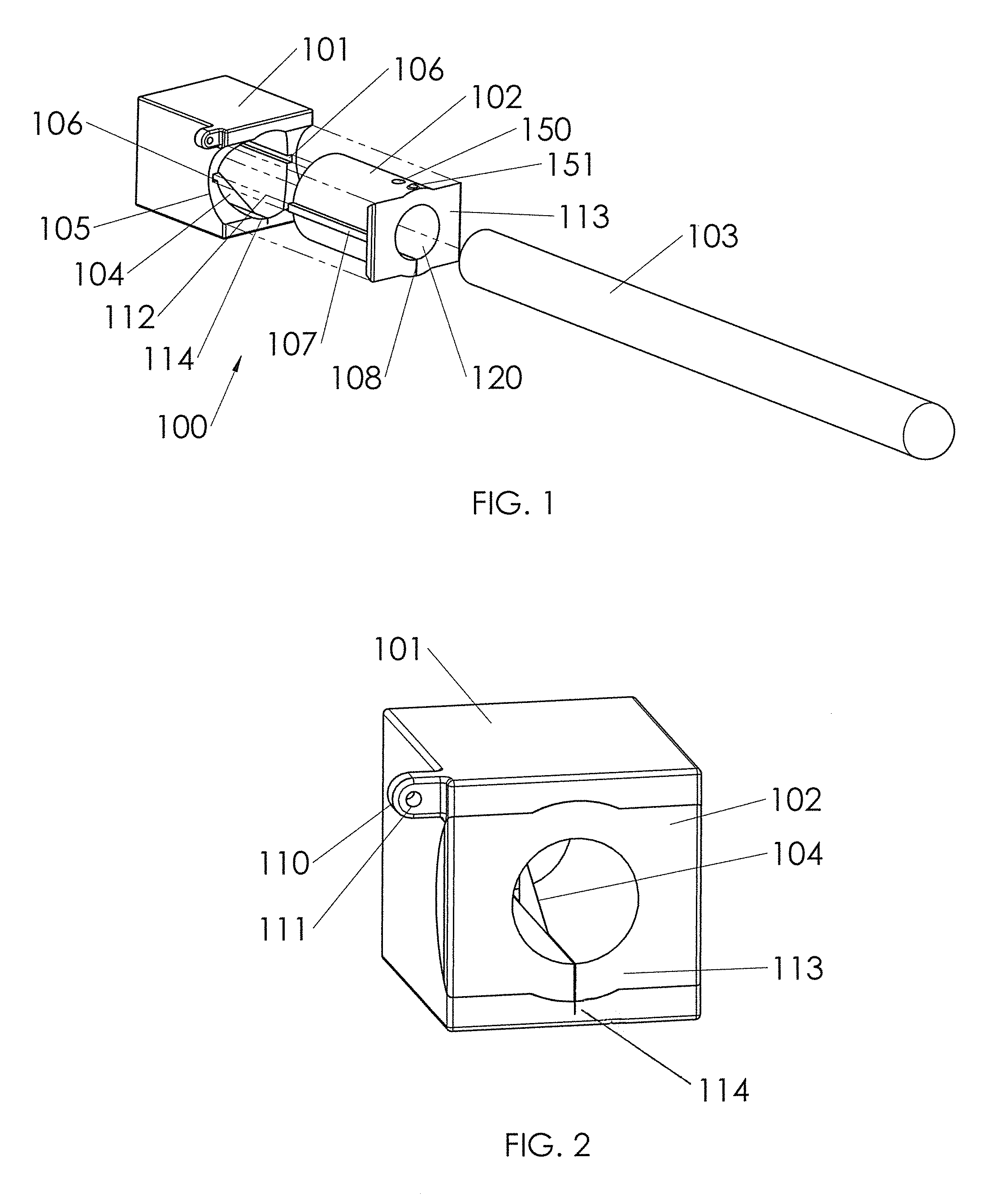

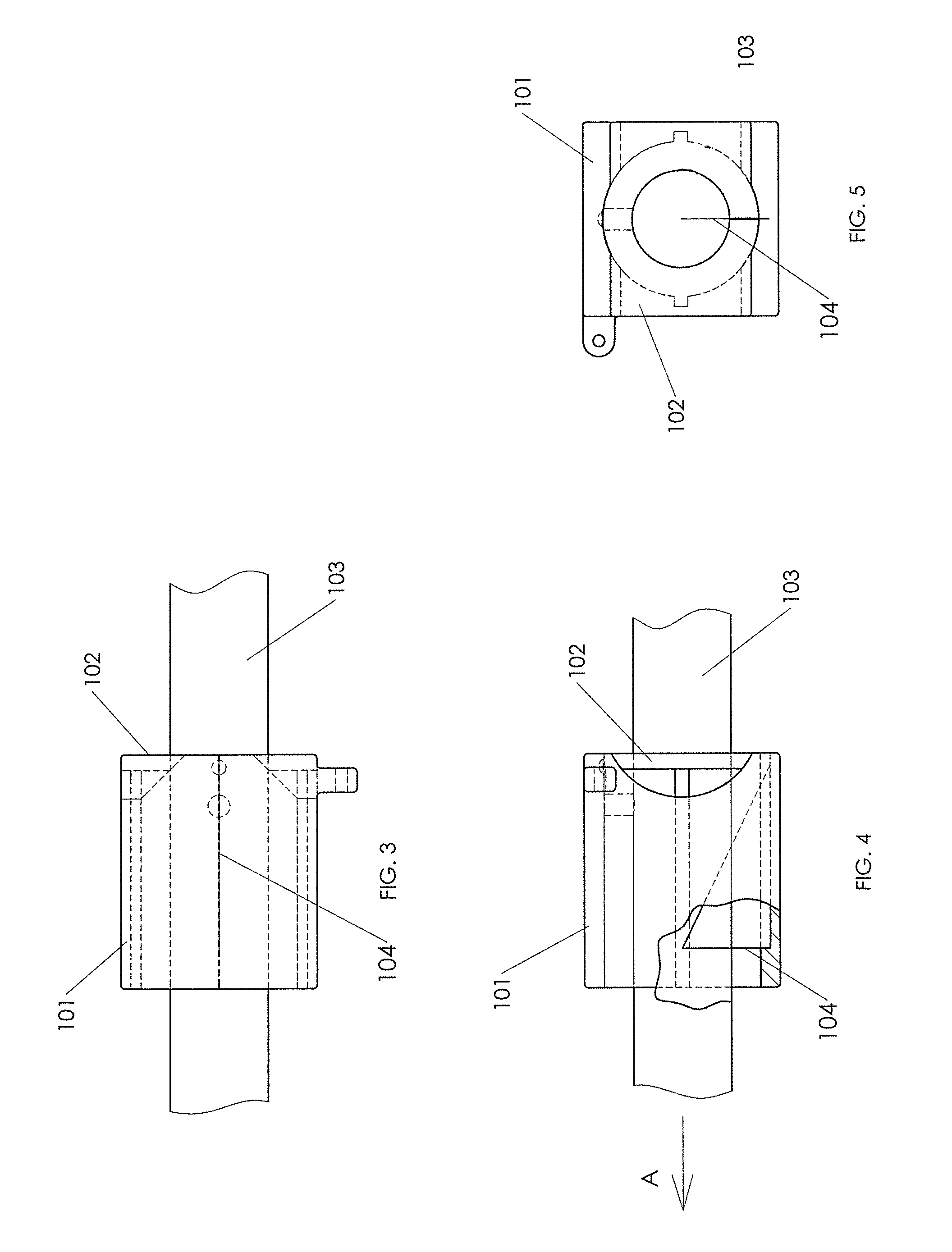

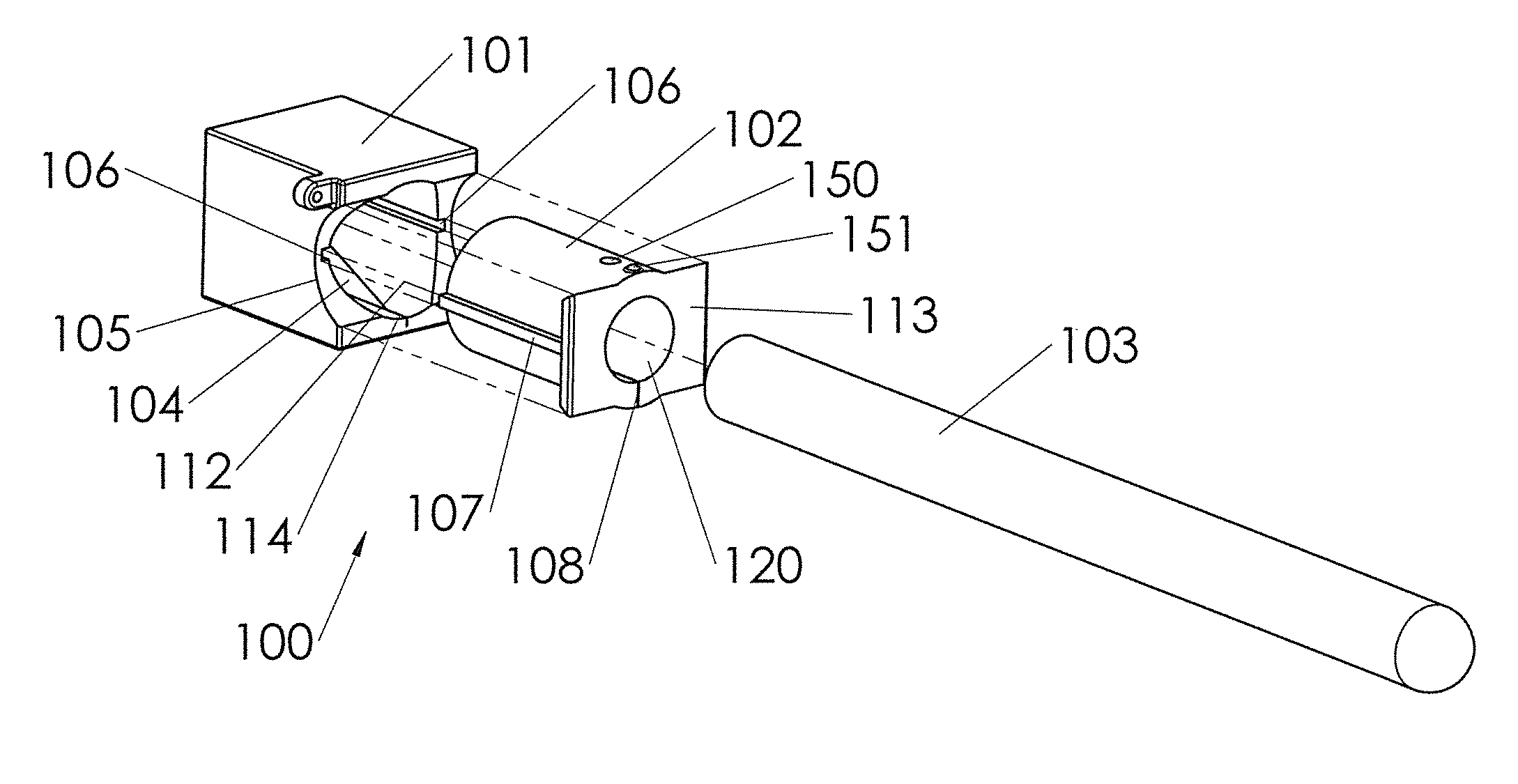

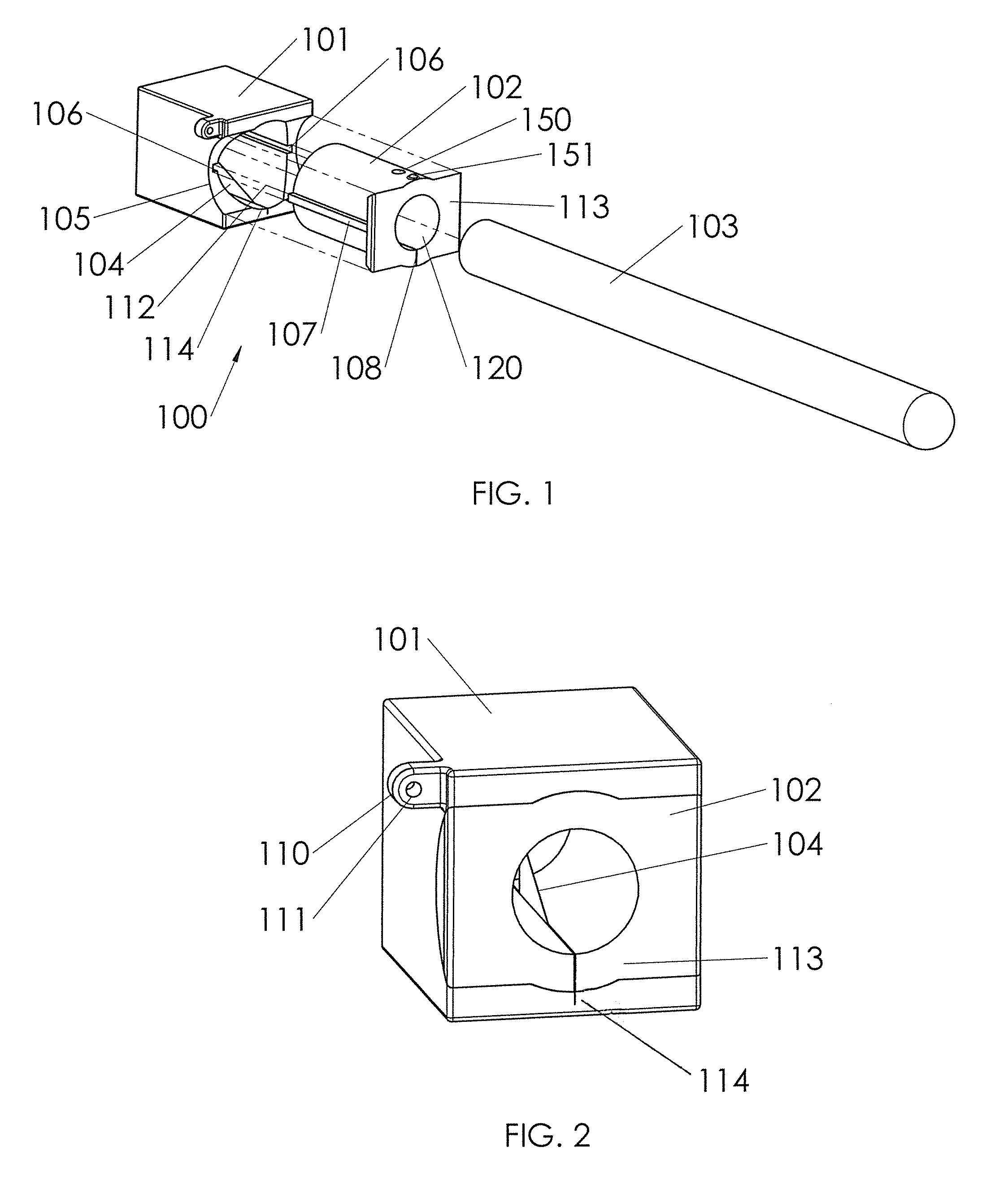

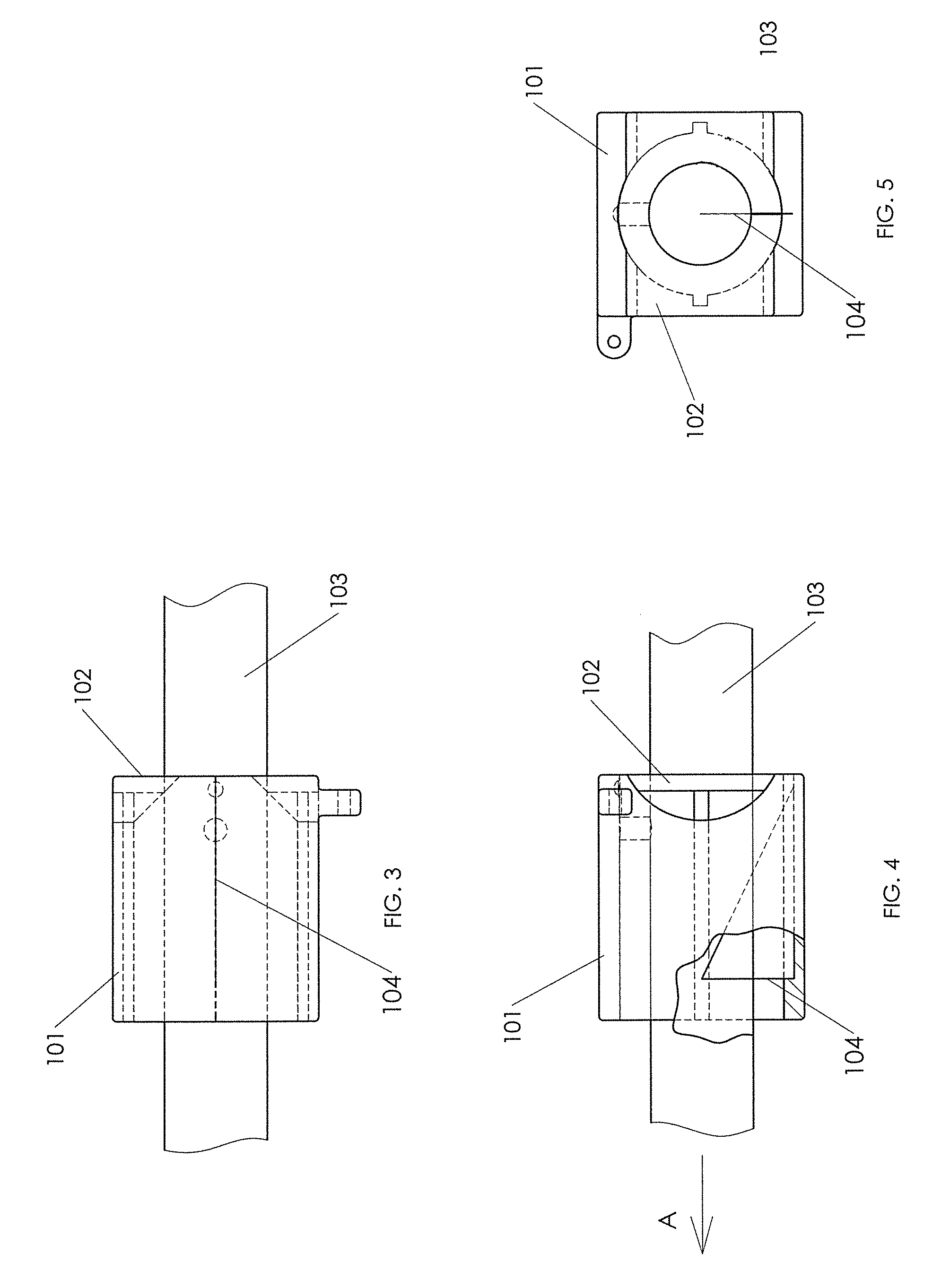

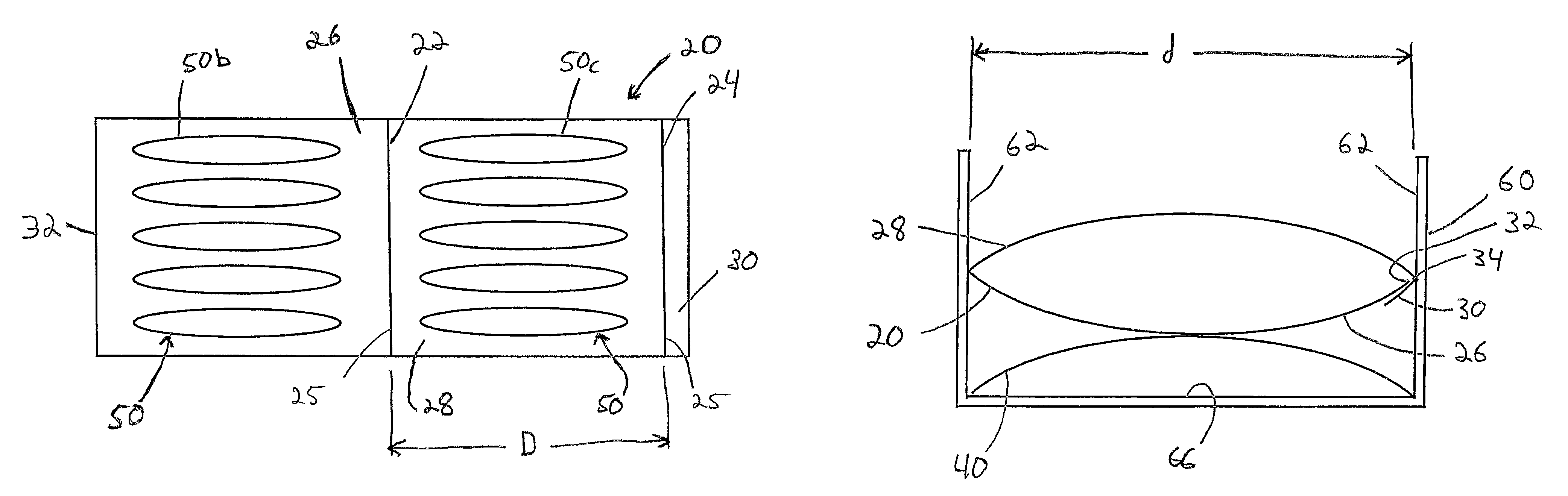

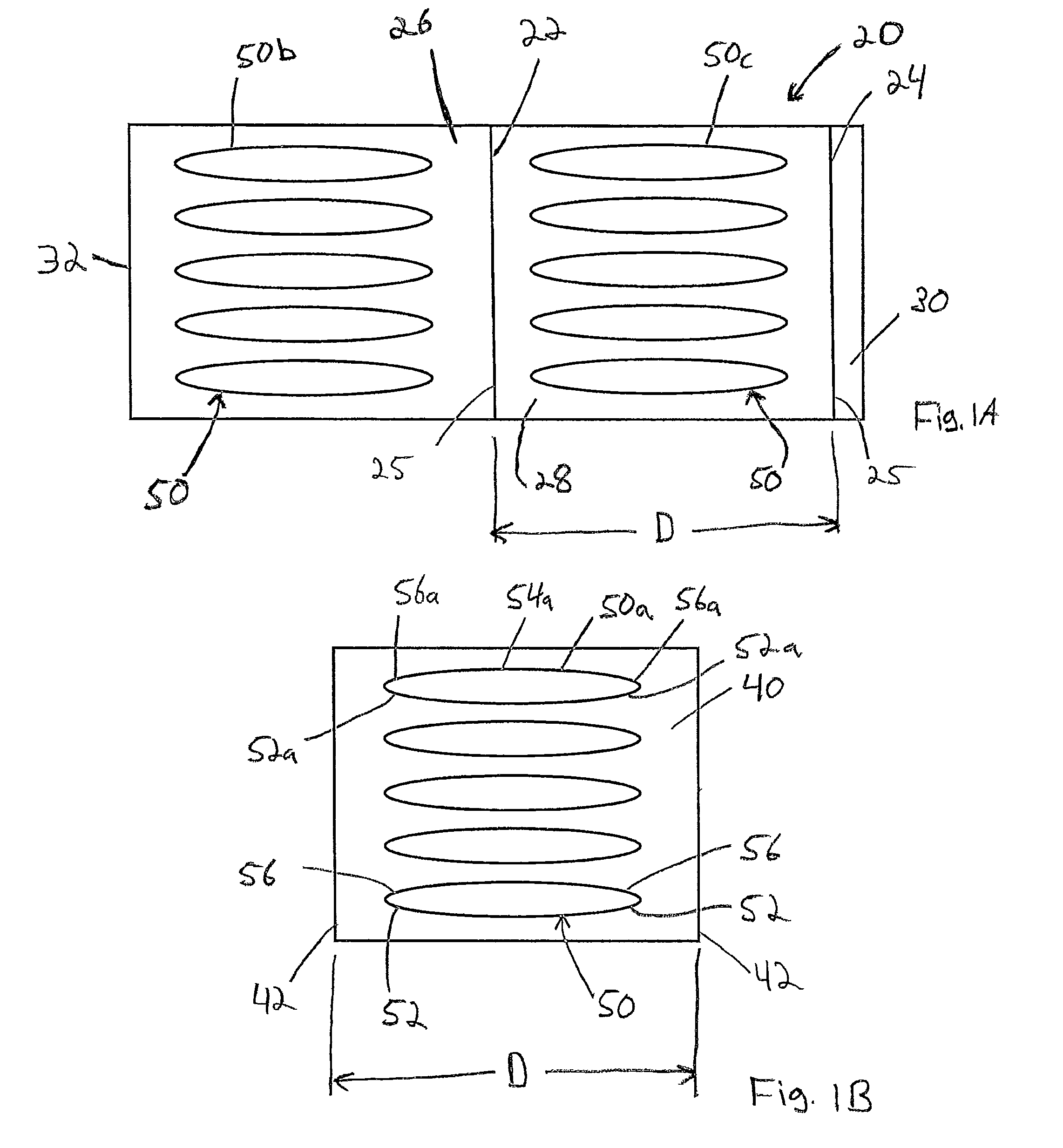

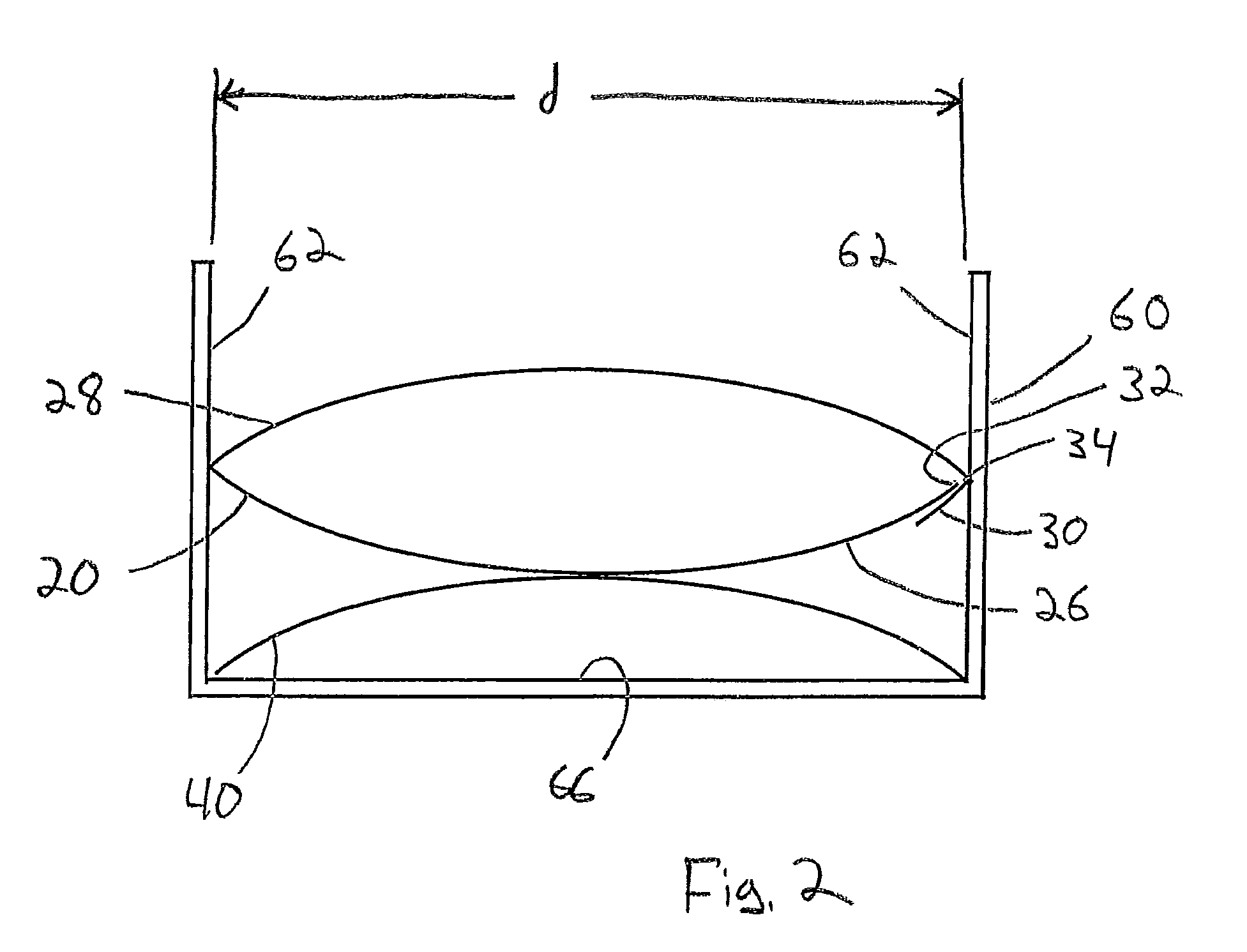

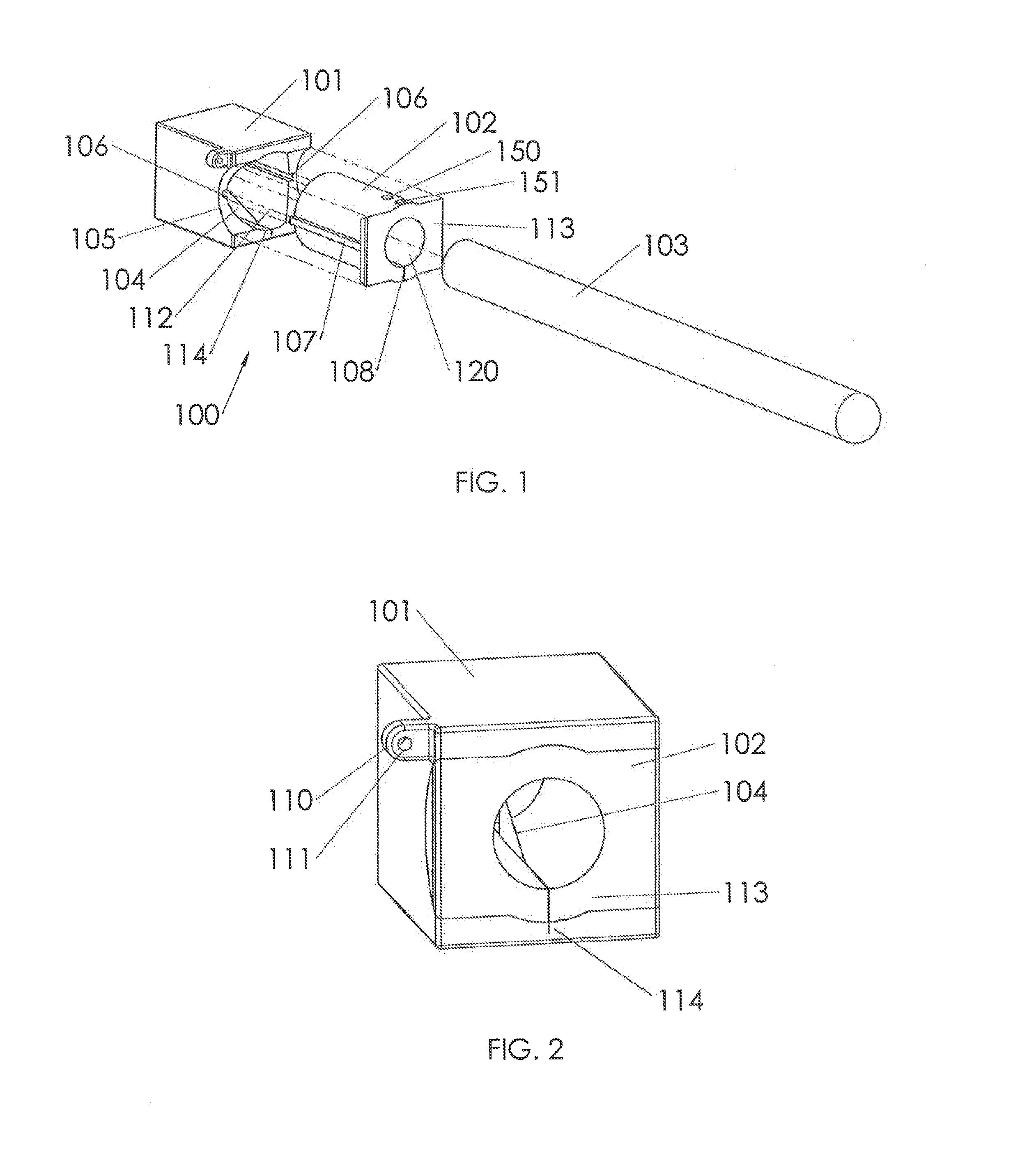

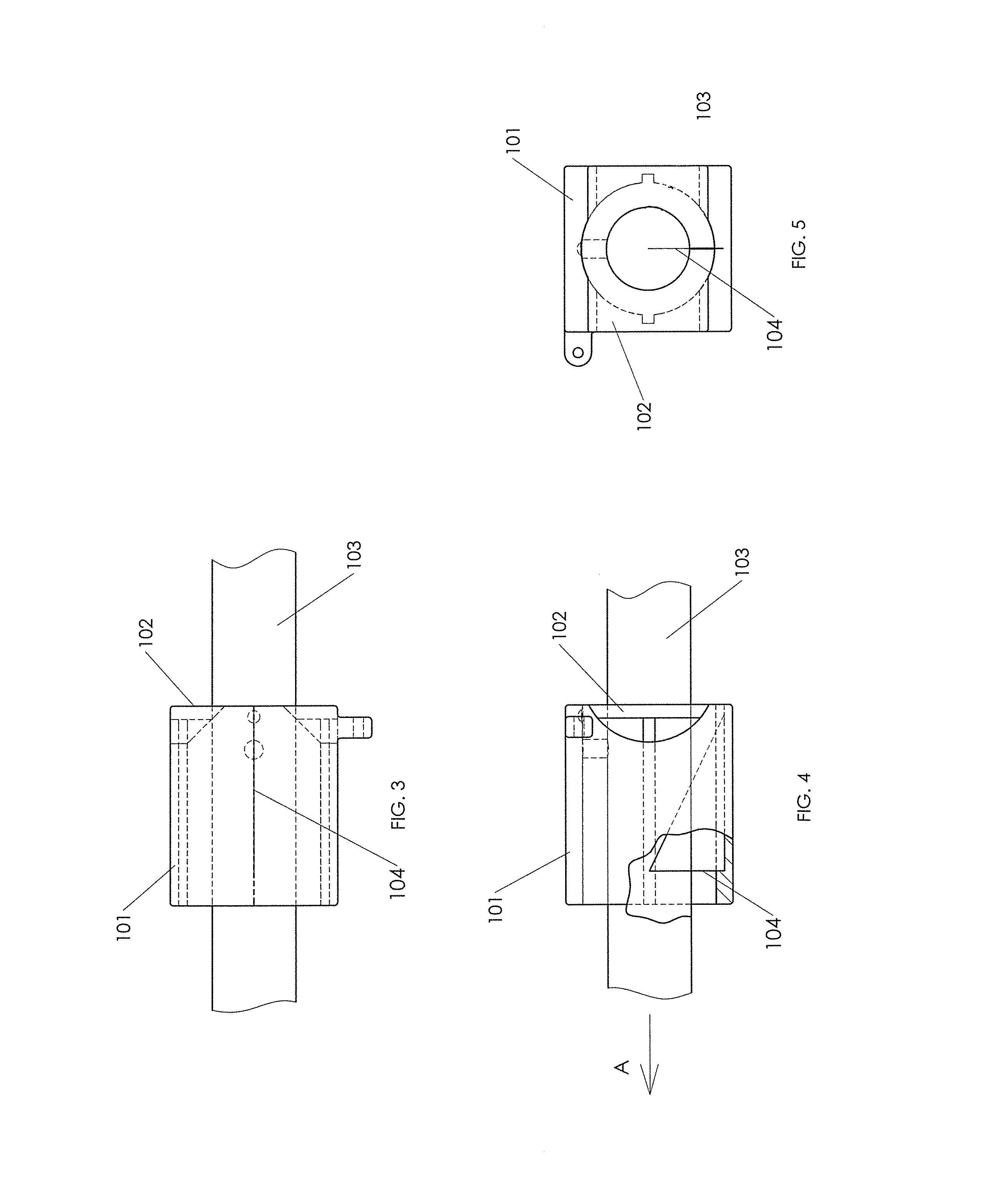

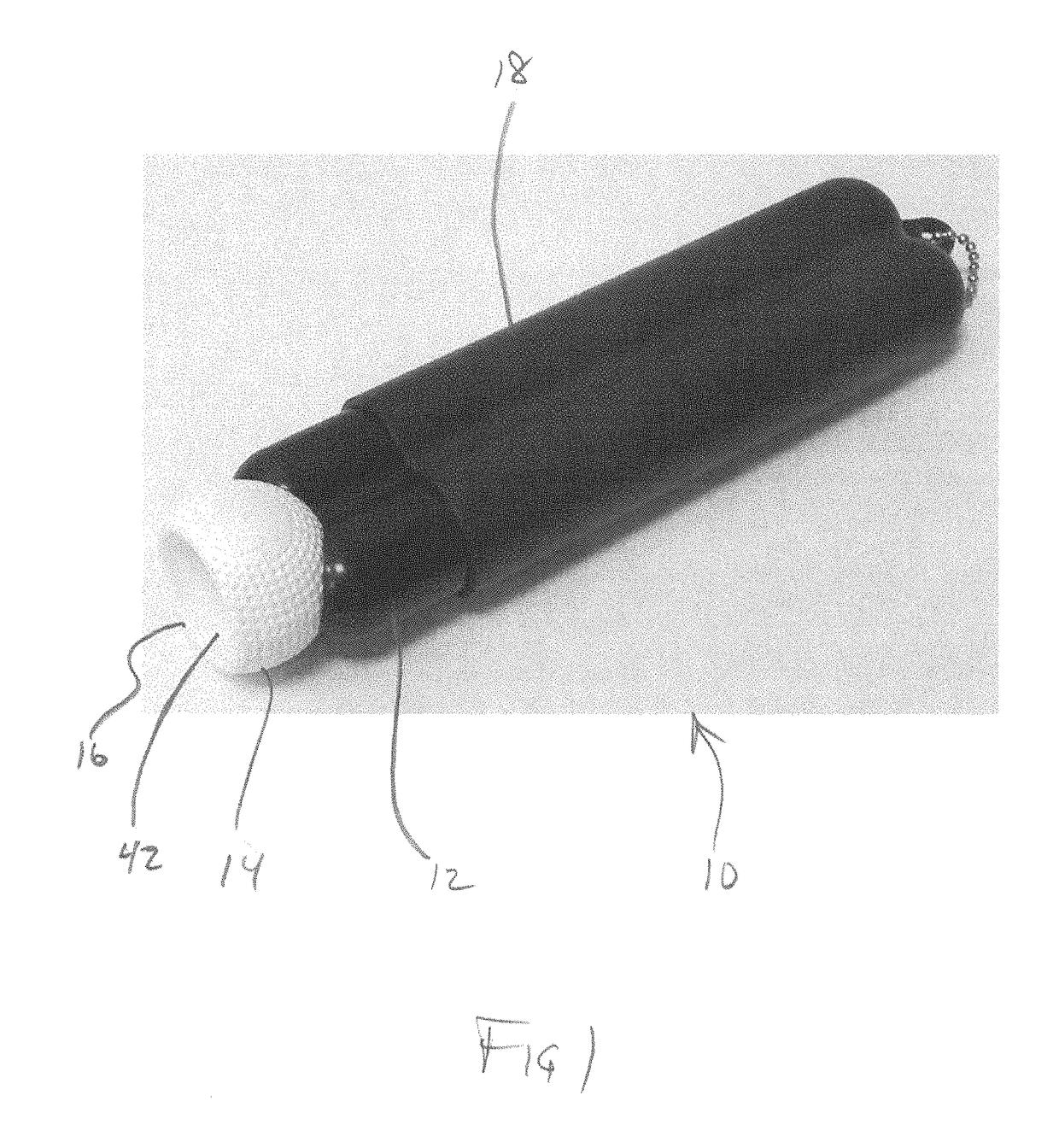

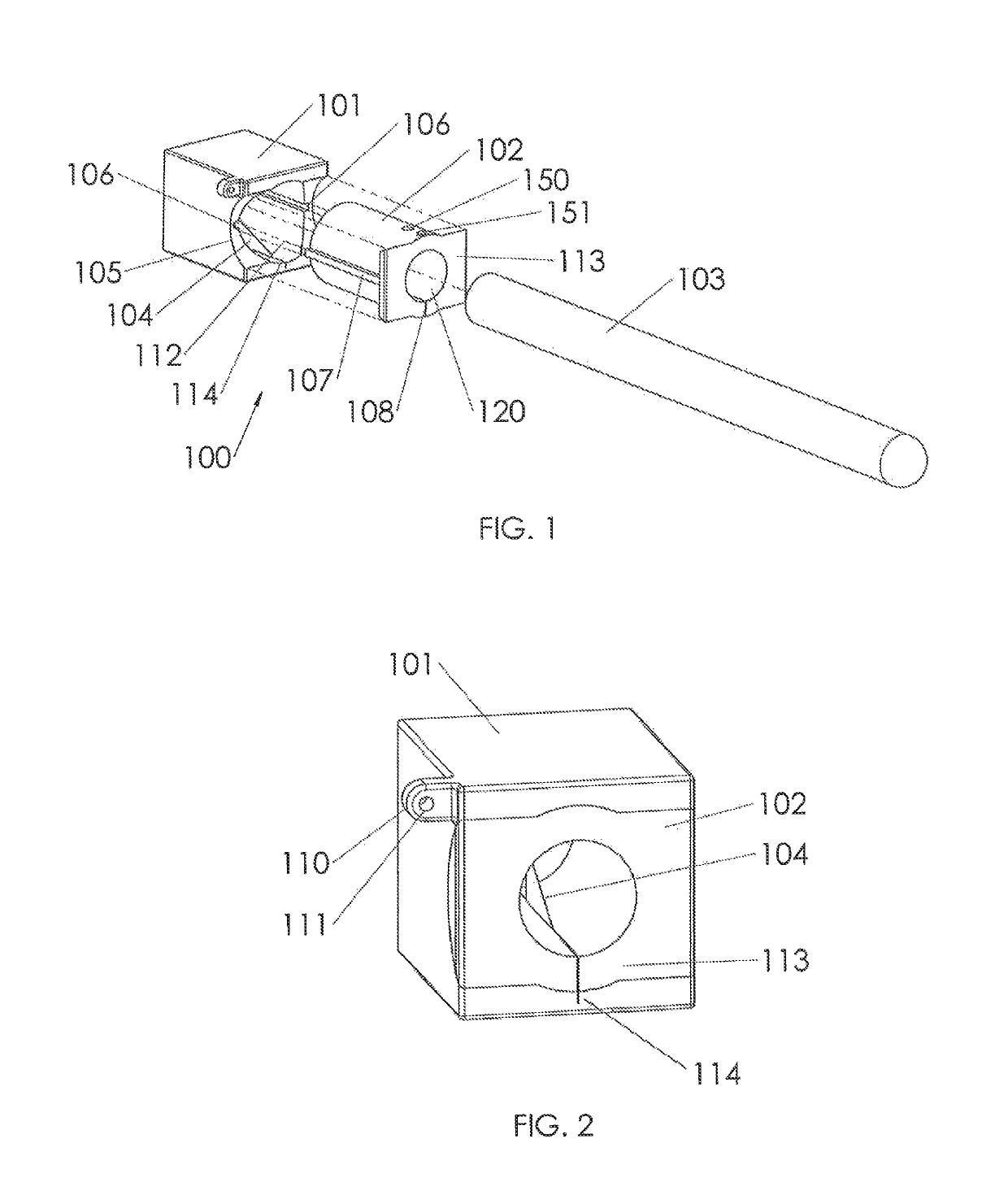

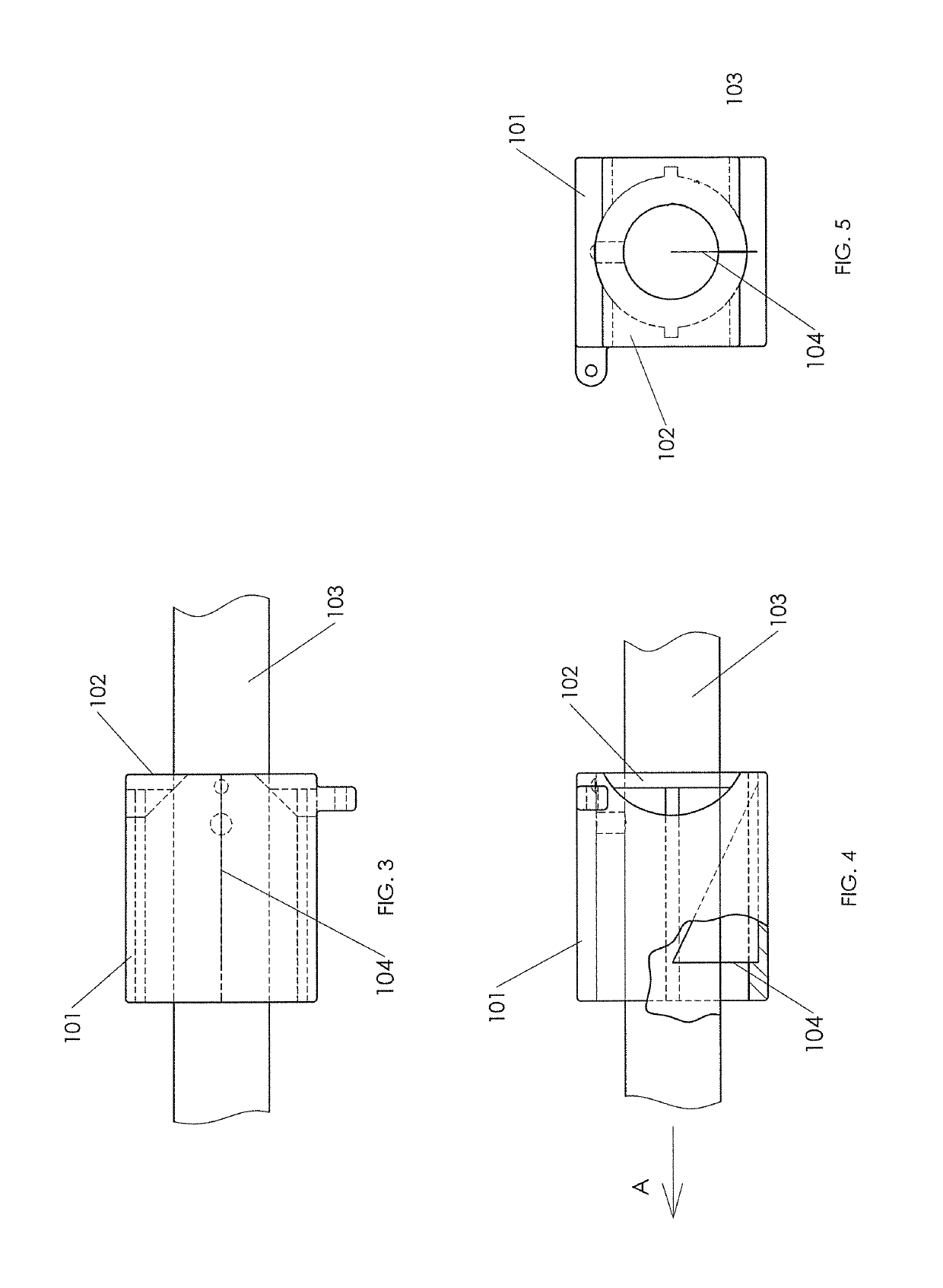

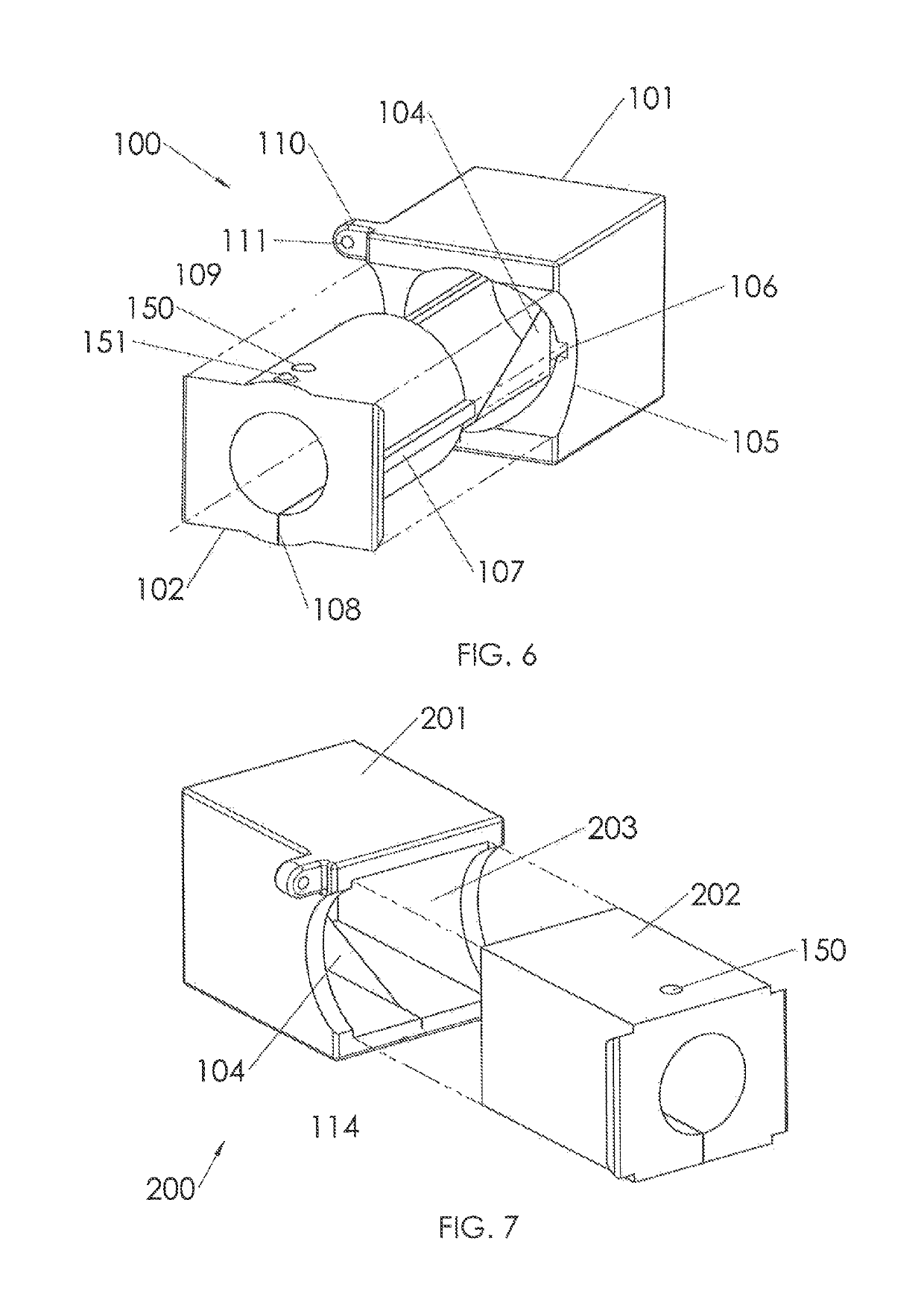

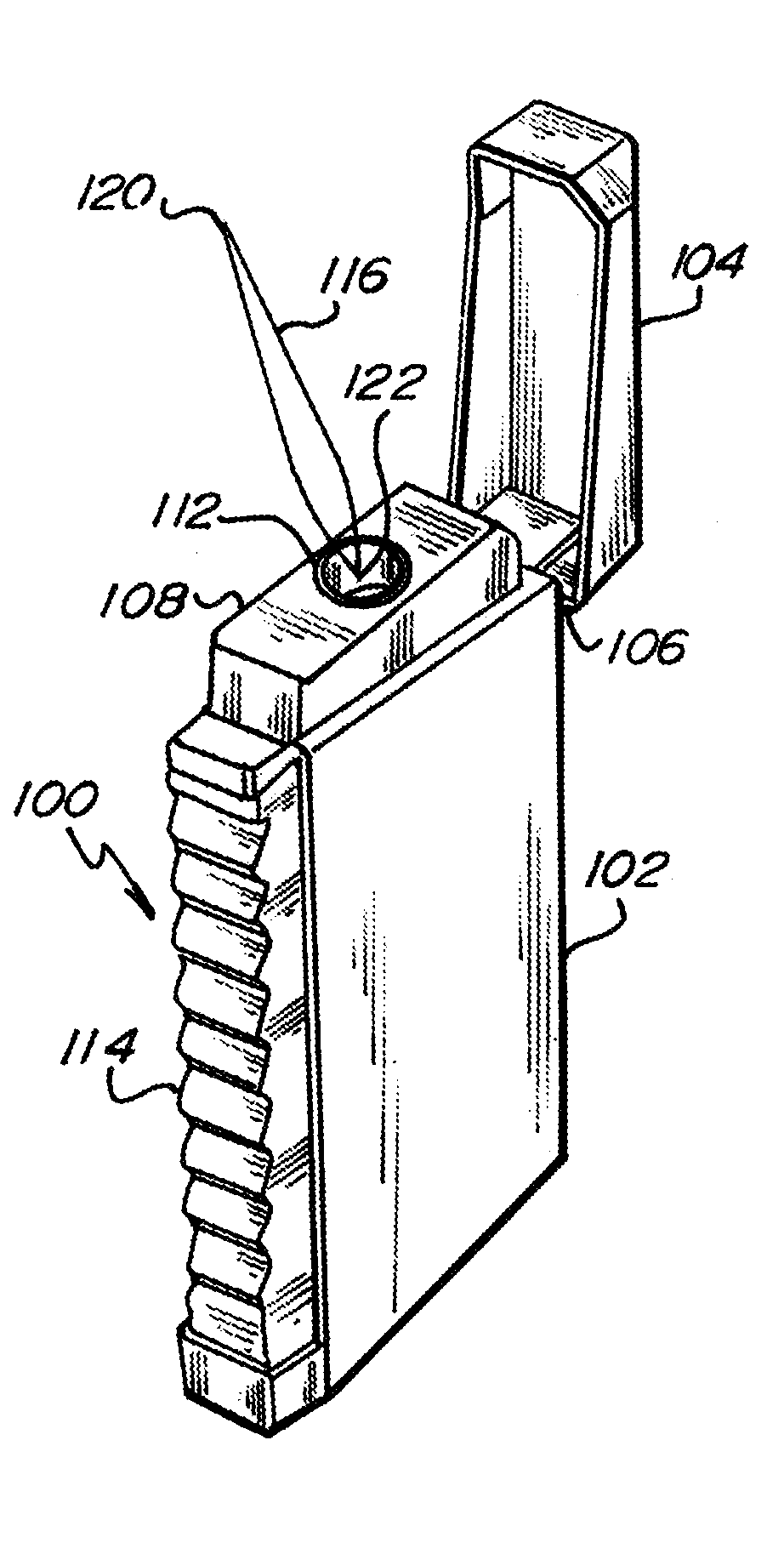

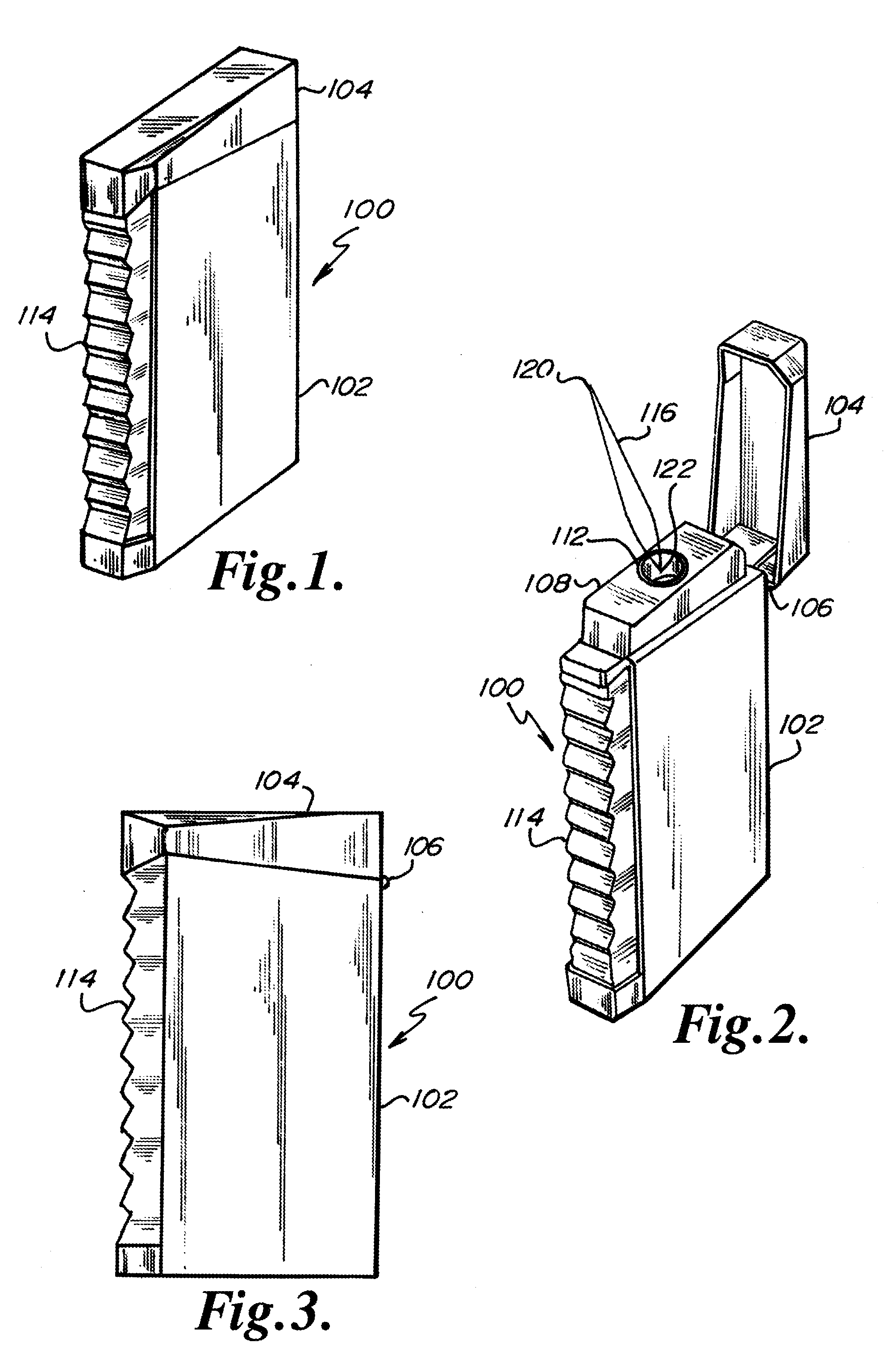

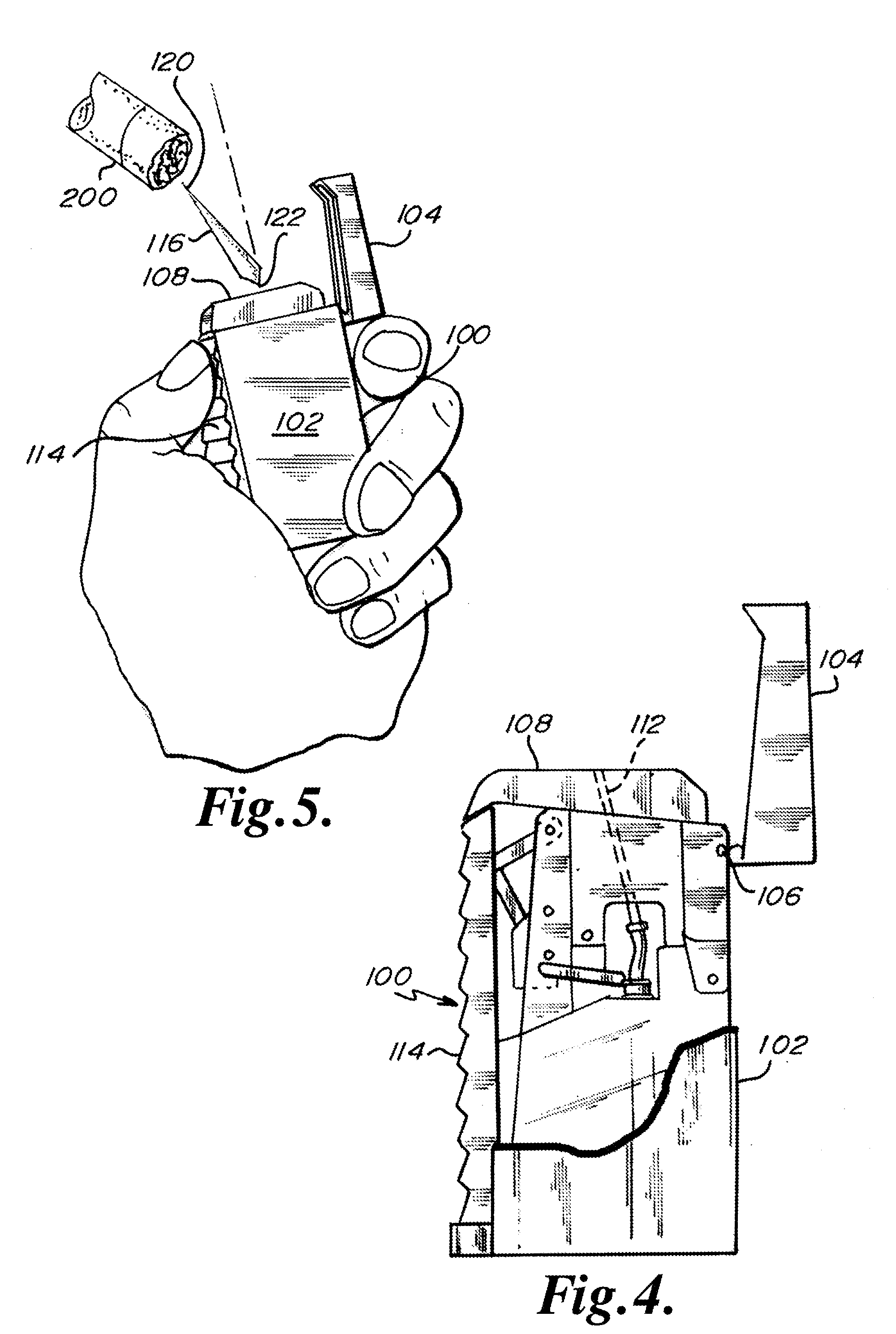

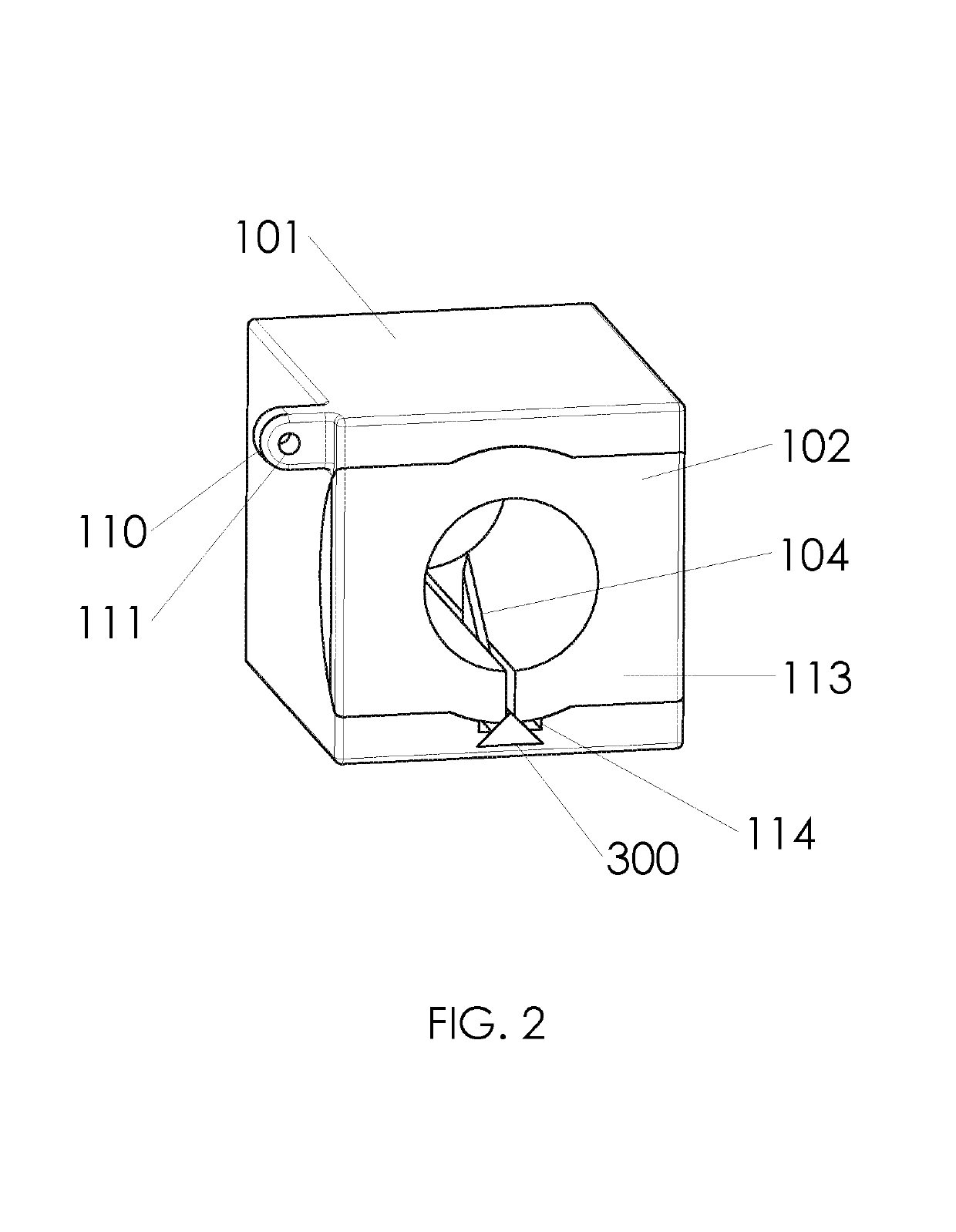

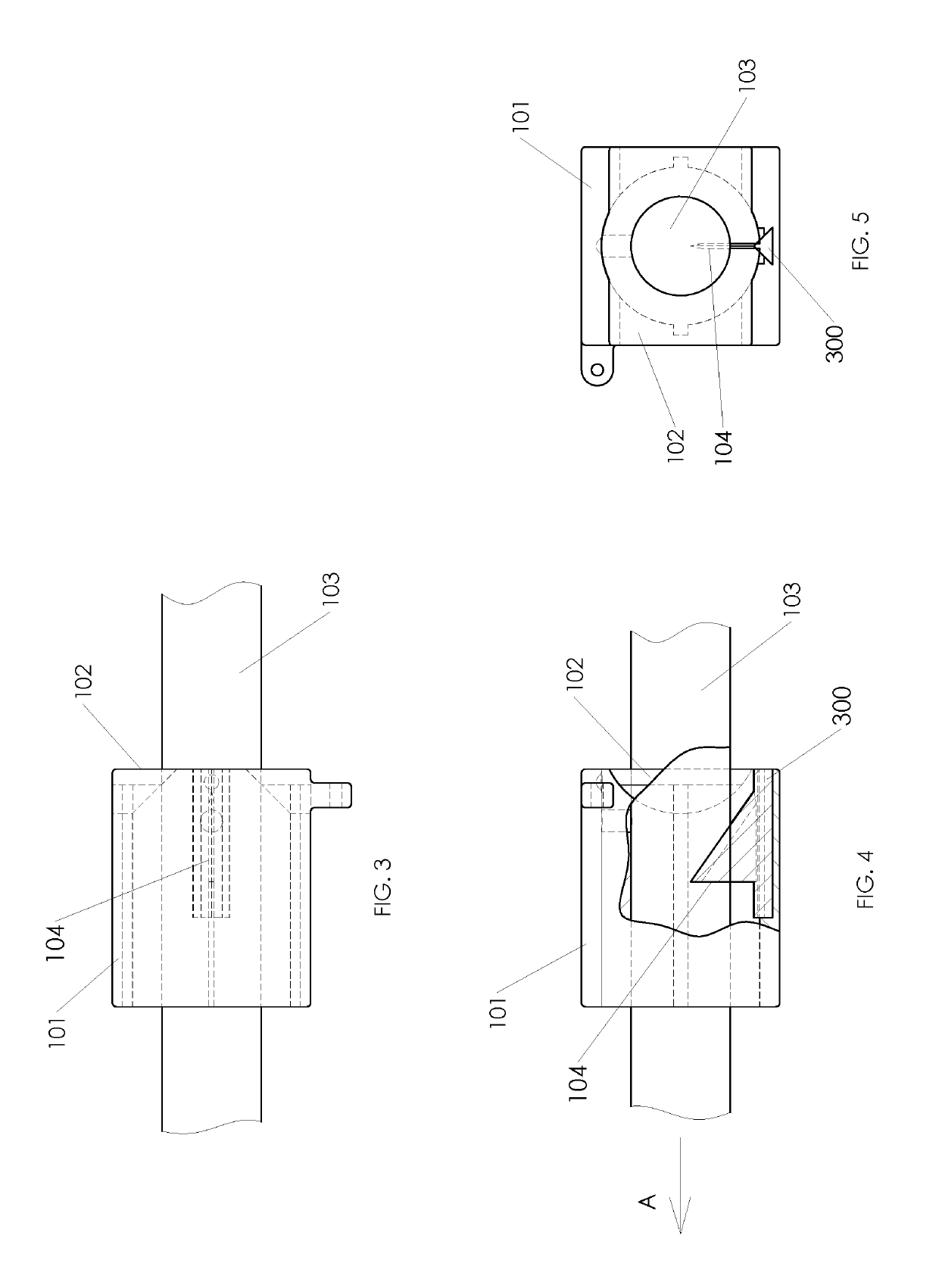

Size-adaptable cigar splitter apparatus

ActiveUS20130199549A1Easy to useSave effortFuel lightersTobacco pipesEngineeringMechanical engineering

An improved size adaptable cigar splitting apparatus comprising and outer body and an inner size adapting sleeve adapted to be slidingly engaged therewith and further comprising a cutting blade for splitting the wrapper and, if present, packaging of a cigar, cigarillo or other smoking device. In a preferred embodiment, the inner size adapting sleeve may be cylindrical in shape and is removable, allowing the invention to be adapted to various sizes of smoking devices. The cigar splitter apparatus of the invention is adapted to receive smoking devices of various diameters which include all common diameters of smoking devices currently in use. The improved size adaptable cigar splitter apparatus of the invention may further comprise a lanyard tang adapted to receive a necklace, lanyard, or similar structure to facilitate ease of carrying.

Owner:SPURLING GEORGE

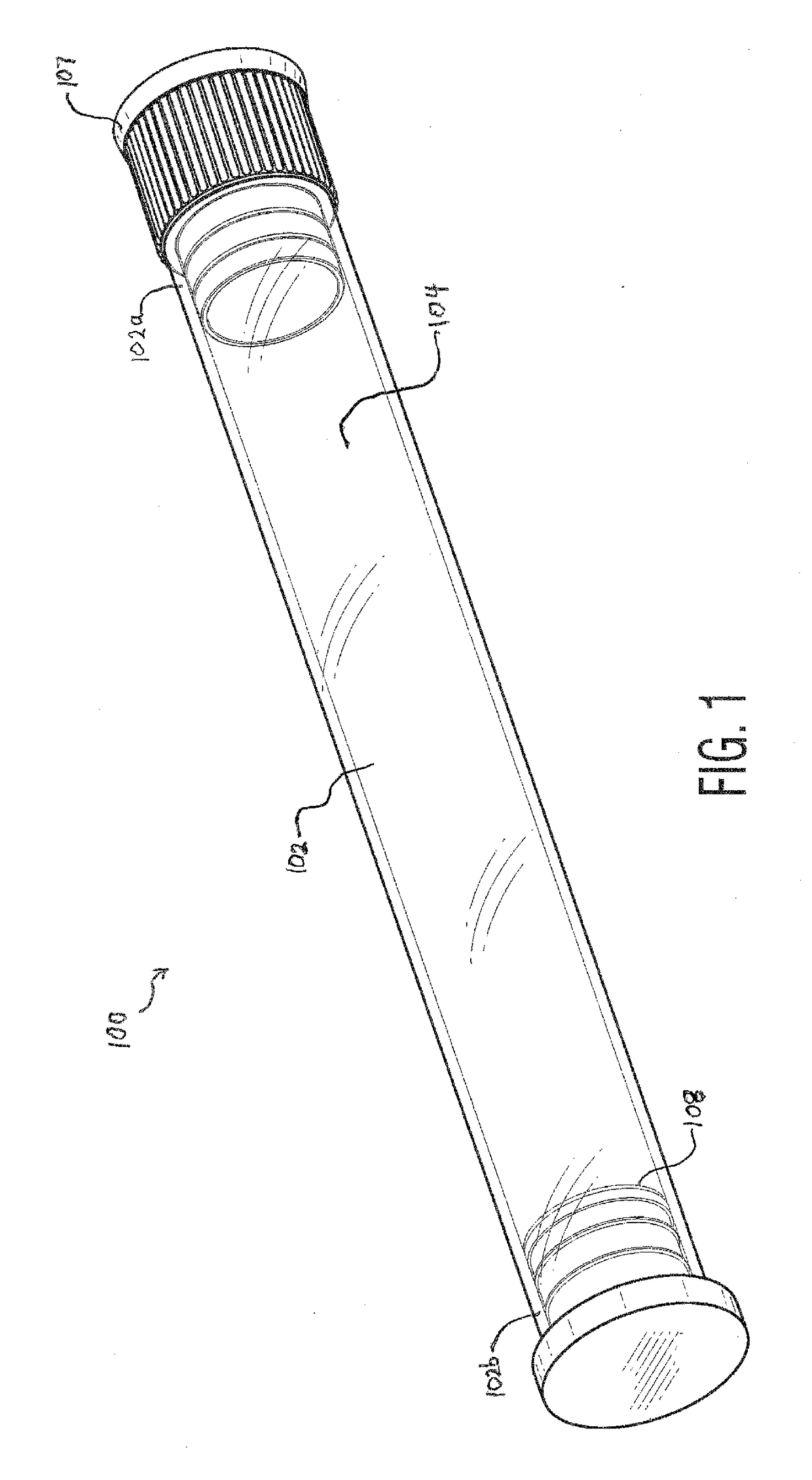

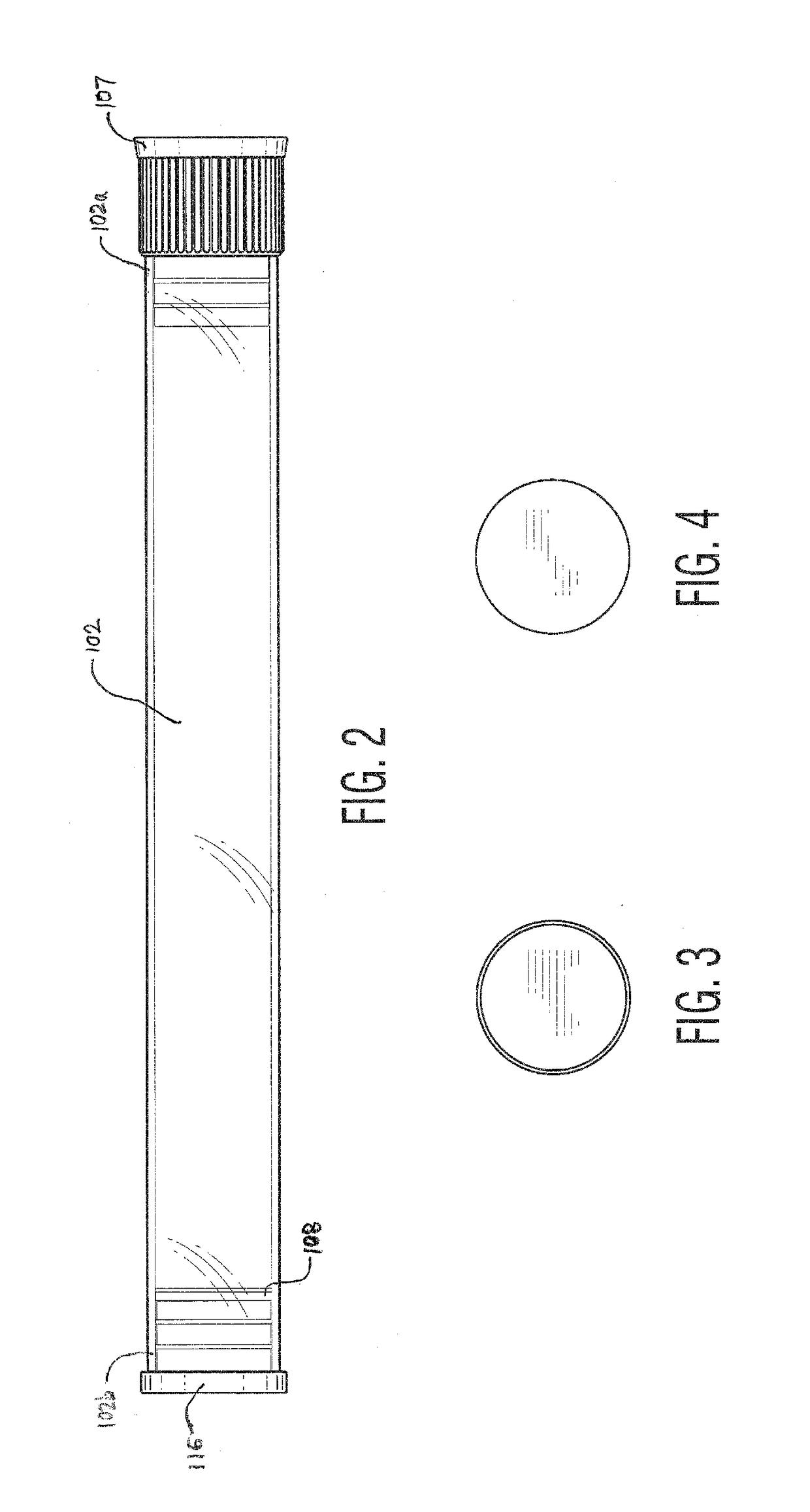

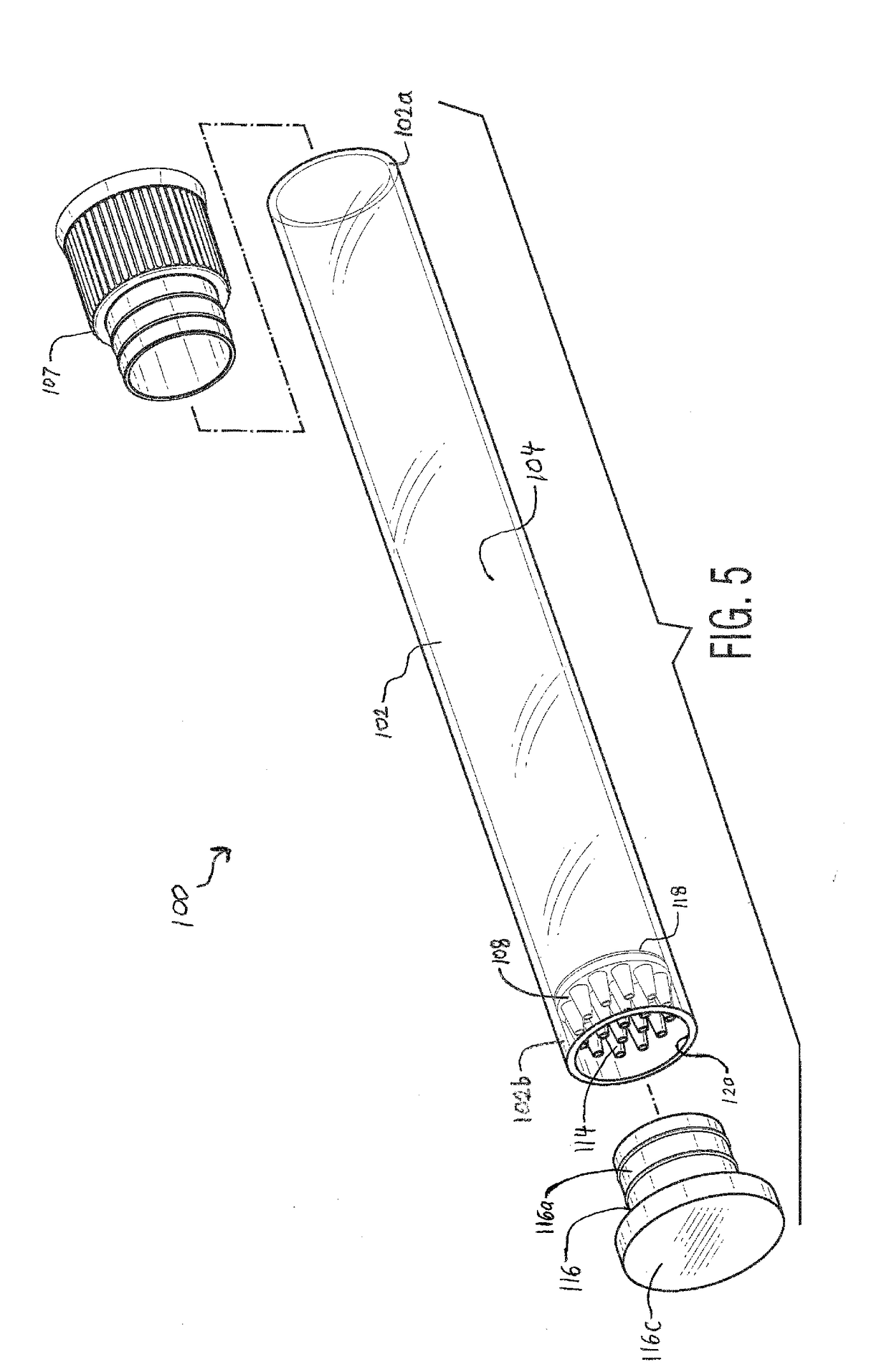

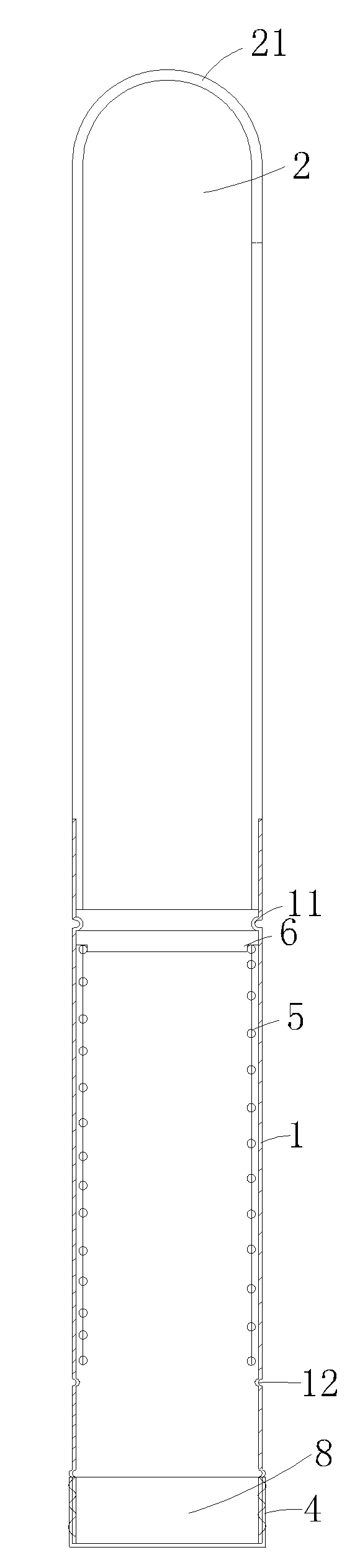

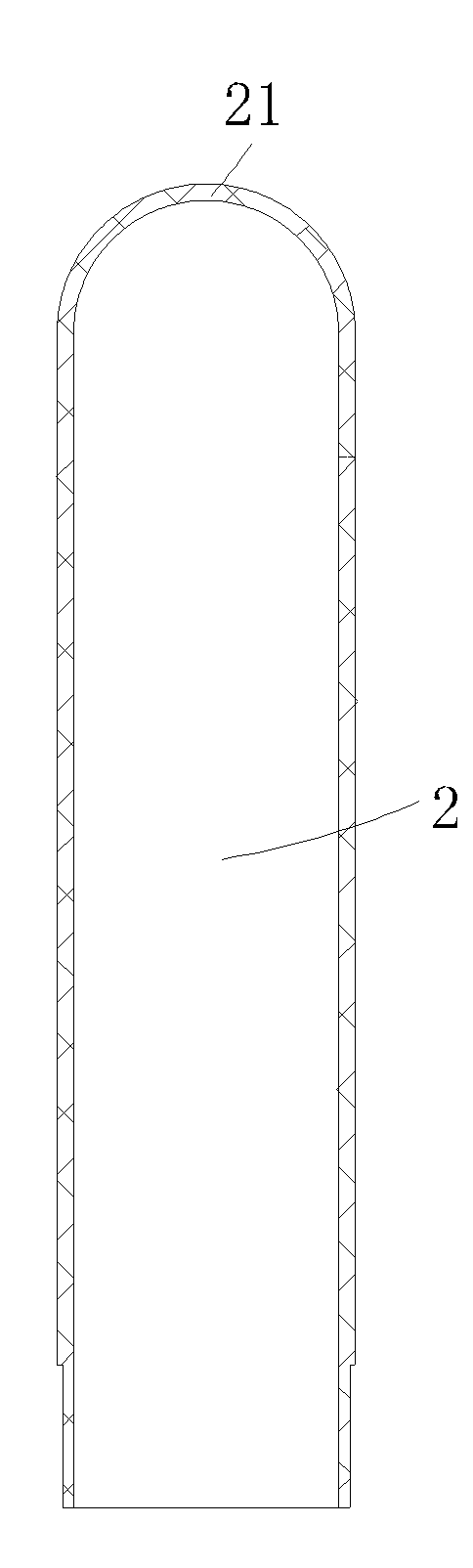

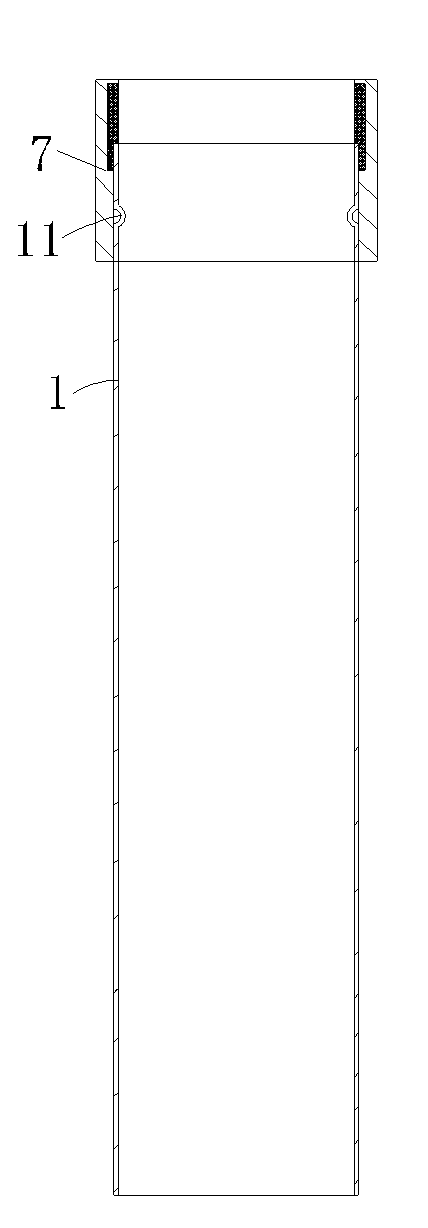

Cigar tube

ActiveUS20180360109A1Clean and efficient mannerPresent the rolling papers more easily to the userContainers for flexible articlesStampsCircular coneBody positions

A cigar tube is provided having an ash catcher and an ash collection cap, for receiving and containing lit or extinguished cigars for later consumption an elongated tubular member having opposite first and second ends and defining a hollow inner cavity disposed between the first and second ends adapted to receive and contain a cigar. The ash catcher is disposed within the inner cavity and has a generally planar body positioned transverse to the tubular member and has a plurality of apertures. A plurality of truncated cones project from the planar body such that each truncated cone preferably aligns with each respective aperture to provide substantially unidirectional ash passageways from the inner cavity to the ash collection cap. In a preferred embodiment, the truncated cones are characterized as having a length sufficient to provide air space between the cones and the ash collection cap for the collection of ashes and dissipation of heat. In one embodiment, a blade is attached to an interior surface of the tubular member and configured to slice longitudinally through an outer sheath of the cigar when inserted through said opening into the inner cavity.

Owner:THINGYMAJIGGY LLC

Size-adaptable cigar splitter apparatus

ActiveUS9486012B2Save effortShorten the timeFuel lightersTobacco pipesEngineeringMechanical engineering

Owner:SPURLING GEORGE

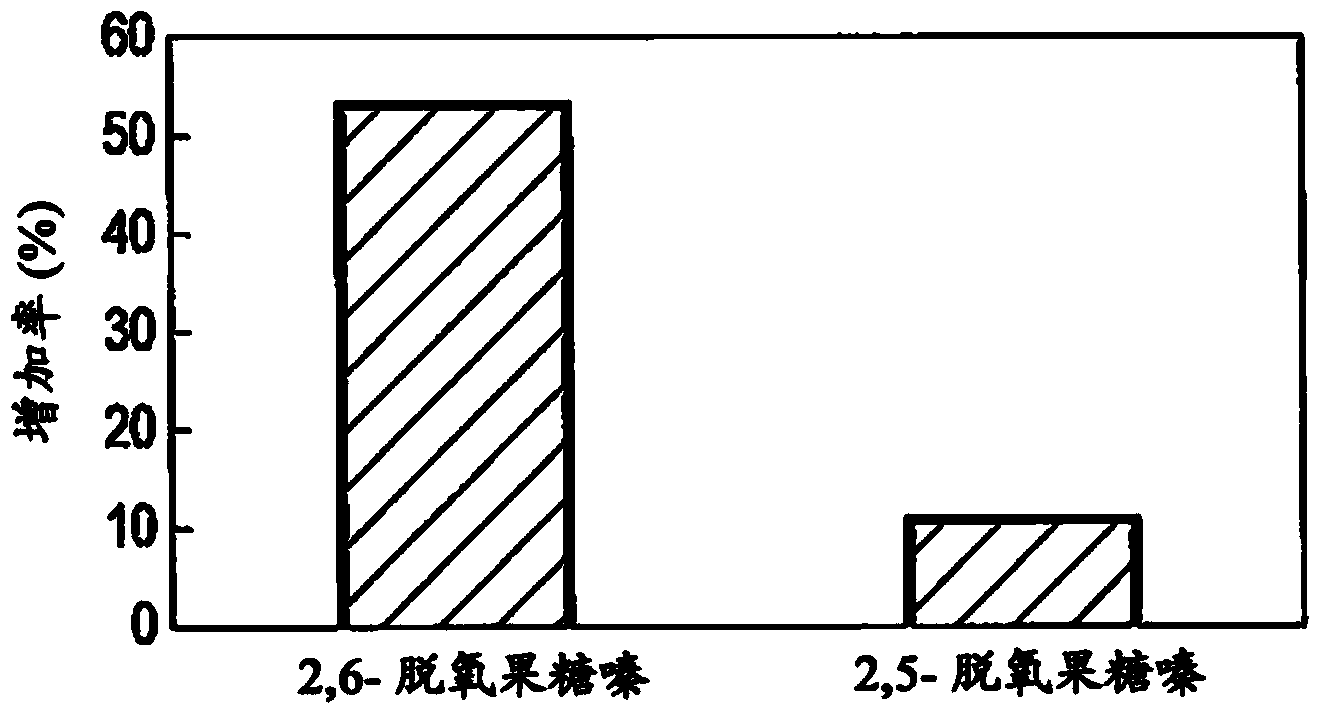

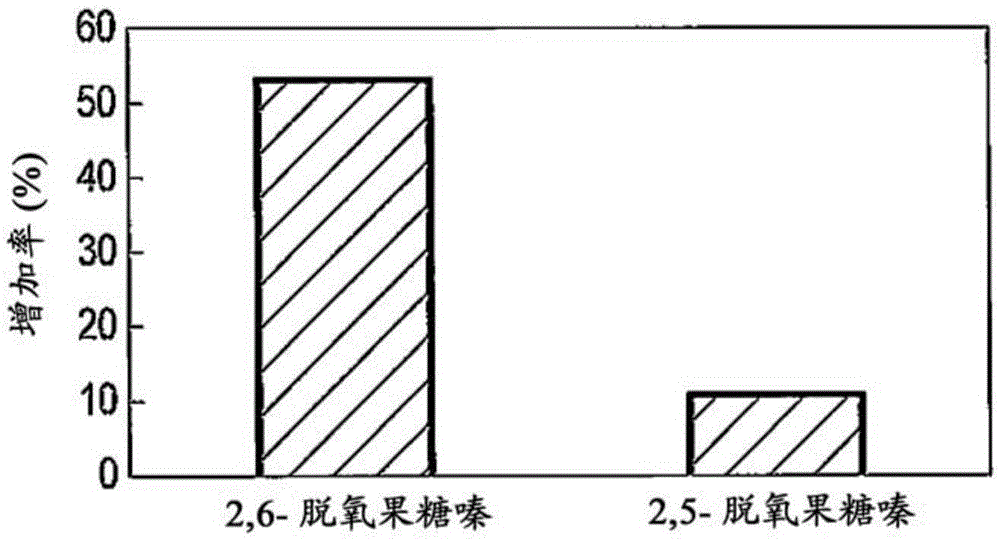

Method for augmenting component providing smoking flavor for tobacco product, tobacco raw material, cigarette, and cigar

ActiveCN103813725AUseful ingredients to enhance aroma and tasteIncrease the fragranceTobacco preparationTobacco treatmentFlavorSugar

A method for augmenting a component providing smoking flavor for a tobacco product, the method including: a step for preparing at least one raw material for flavor selected from the group consisting of natural sugars, the original form of a plant, and a liquid extract distilled or condensed from the original form of a plant; a step for accommodating the raw material in an oven at a volume ratio of 50-80 vol% relative to the oven capacity; a step for heating the raw material in the oven to 80-100 DEG C to increase the temperature at a rate of 1.0-2.0 DEG C / minute while stirring the raw material; and a step for cooling the contents of the oven after processing to a desired temperature at a rate of 0.4-0.85 DEG C / minute.

Owner:JAPAN TOBACCO INC

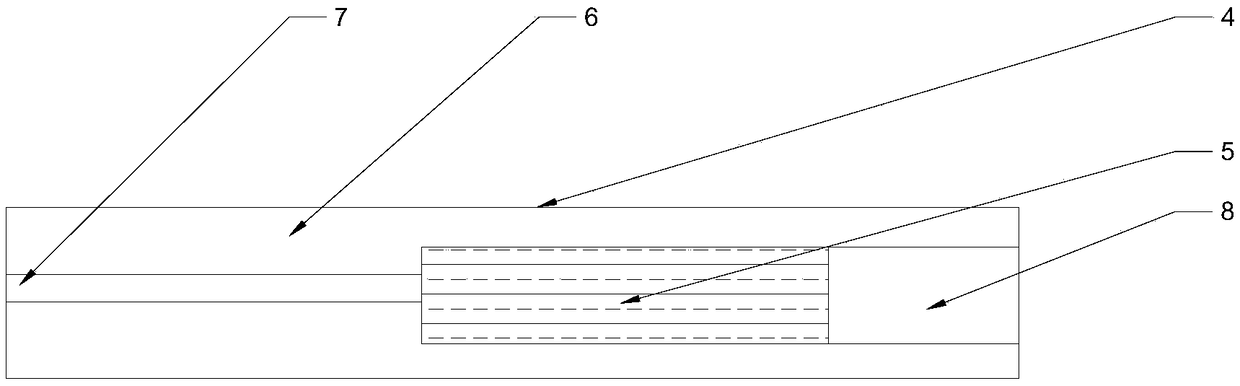

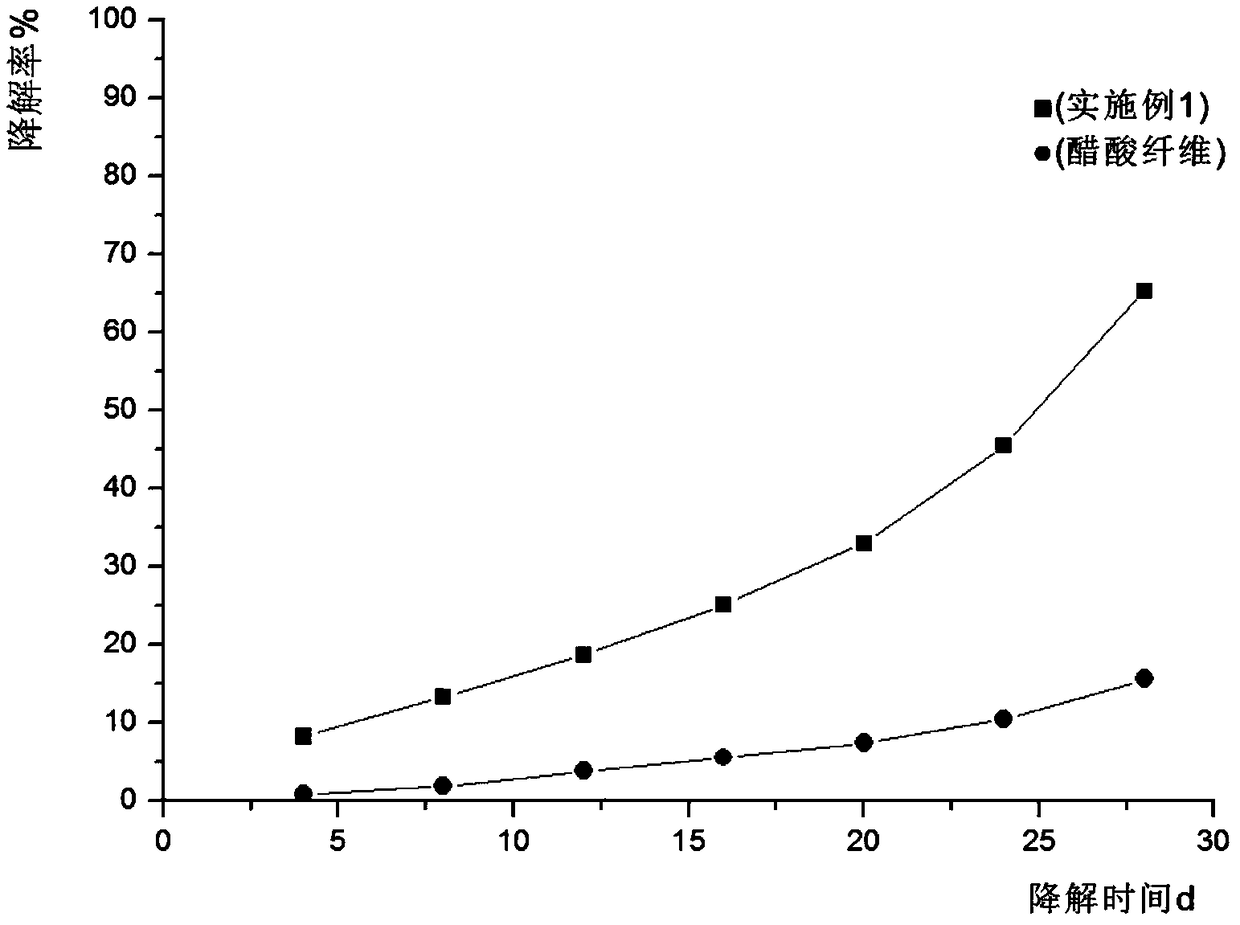

Cigarette/cigar filter tip stick prepared from natural materials

InactiveCN109363235ASolve the combustion will produce a lot of smoke,Solve the degradabilityCigarette manufactureTobacco smoke filtersFiberActivated carbon

The invention belongs to the technical field of tobaccos, and particularly relates to a cigarette / cigar filter tip stick prepared from natural materials. The cigarette / cigar filter tip stick is prepared from, by mass, 100-150 parts of active carbon granules, 60-90 parts of plant fibers, 110-140 parts of wheat, 50-80 parts of barley, 30-70 parts of corn, 40-60 parts of buckwheat, 10-40 parts of rice, 5-15 parts of sesame, 5-110 parts of a vegetable adhesive, 5-20 parts of a vegetable preservative, 30-150 parts of a plant fermentation agent and 10-25 parts of water. The problems are solved thatwhen an existing cigarette filter tip burns, a lot of smoke can be generated, and the filter tip is not easily degraded; through the cooperation of the natural materials and the active carbon, the filter tip stick is good in filter effect and high in environmental friendliness, and the cigarette / cigar filter tip stick achieves the effect of reducing the harm of the smoke to the human body.

Owner:陶祖岐

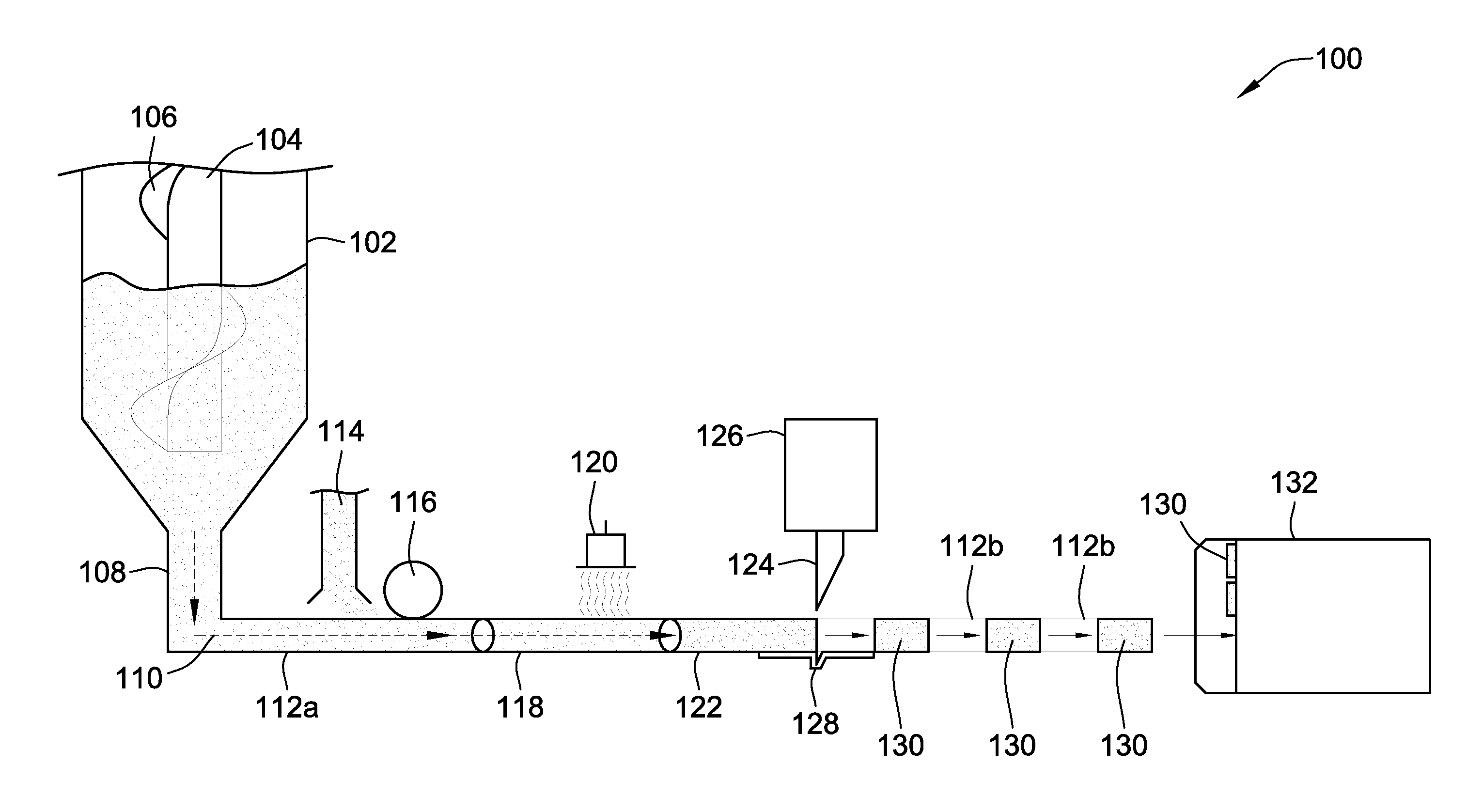

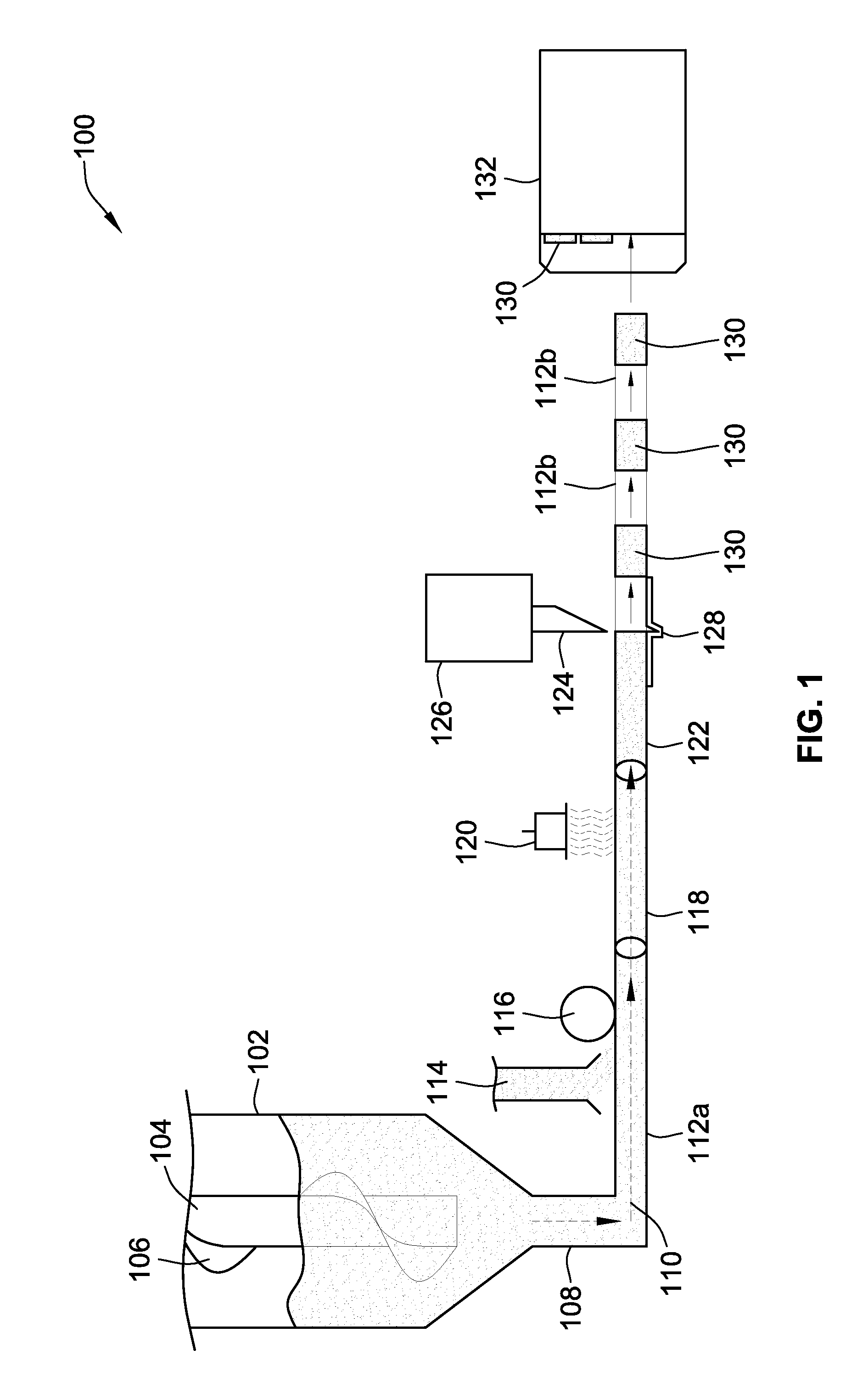

Smoking article having tobacco filter

InactiveUS20130104917A1Increase temperatureTobacco treatmentTobacco smoke filtersAdhesiveEngineering

A device for manufacturing cigar filters out of expanded Cut Rolled Stem tobacco and reconstituted tobacco is provided. The device includes a machine hopper wherein the expanded Cut Rolled Stem tobacco is added. A suction chamber the pulls the expanded Cut Rolled Stem tobacco out of the machine hopper and deposits onto a suction band to form a tobacco stream. Reconstituted tobacco is then added to the tobacco stream, which is then moved through a pencil paster that forms the tobacco stream into a cylinder and adds an adhesive. The adhesive binds the tobacco stream together into a cylindrical shape when heat is applied to activate the adhesive. A cutting section of the device cuts the cylindrical shaped tobacco stream into a desirable length for a cigar filter.

Owner:TWINKLE

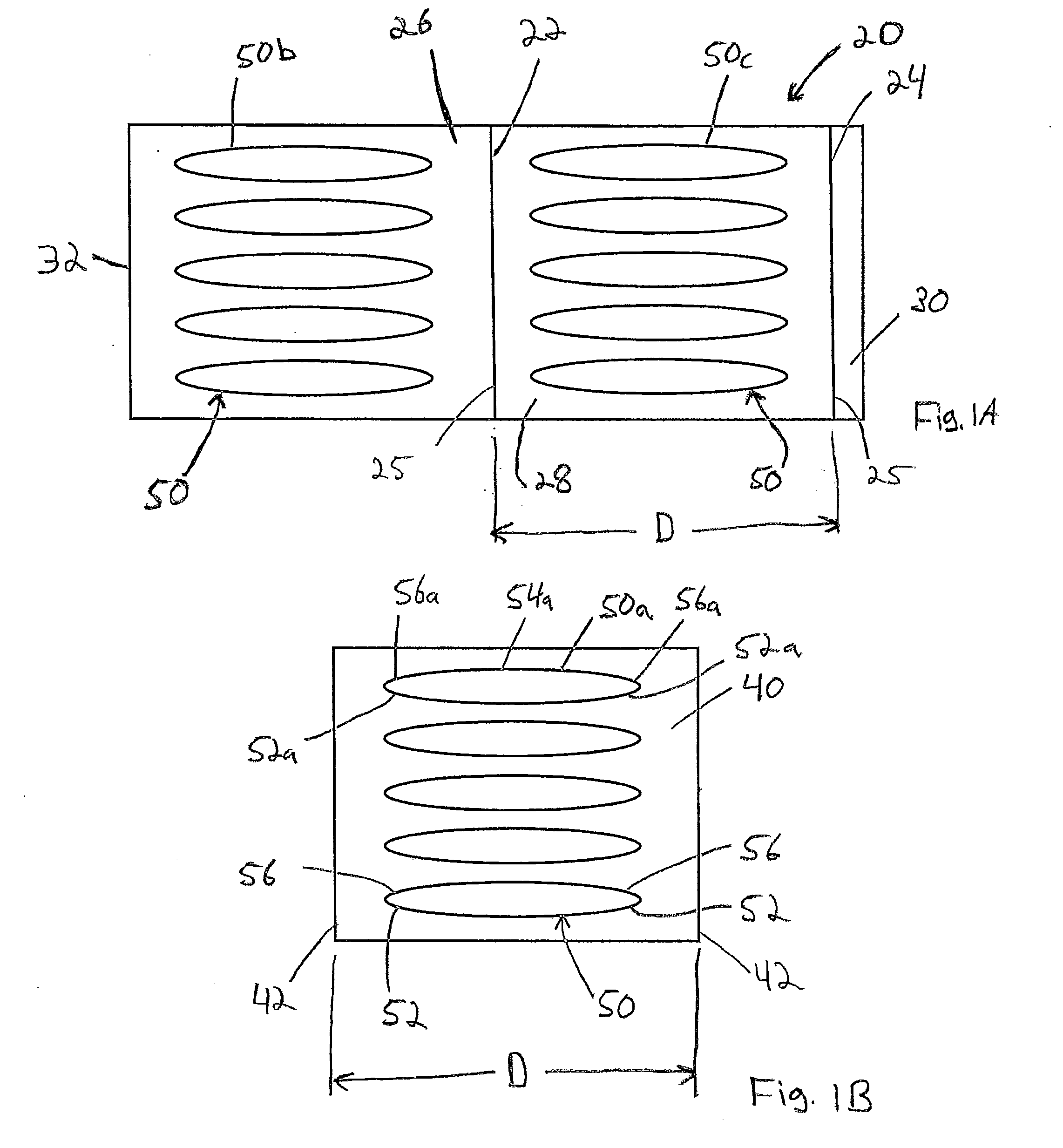

Cigar package

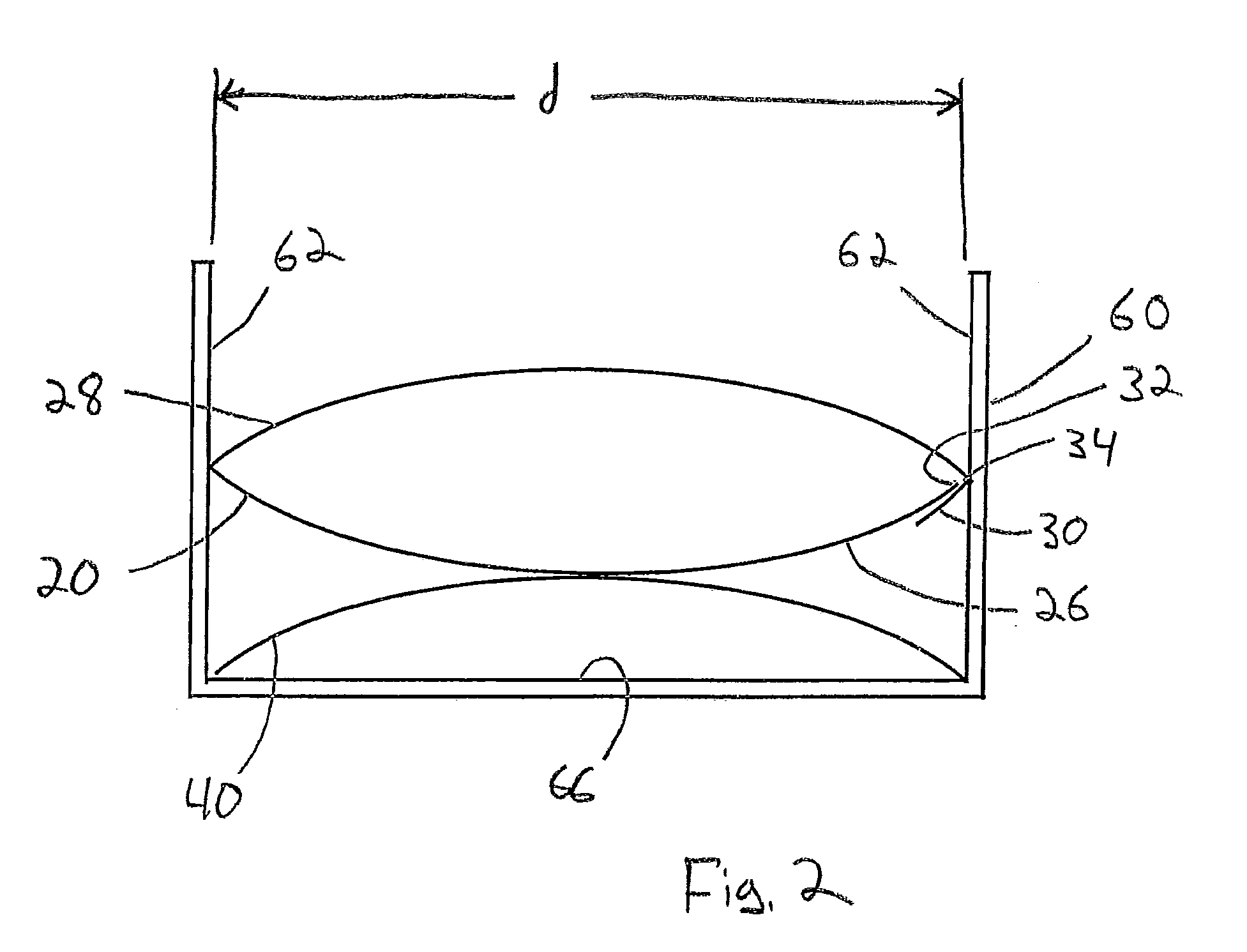

InactiveUS20120043233A1Containers for flexible articlesPackaging cigaretteMechanical engineeringCigarillo

A packing system for cigars including a cigar box and at least one support. The flat support is sized slightly larger than the distance between a pair of walls of the cigar box so that the support is compressed into an arch shape that is maintained by the walls when inserted into the cigar box. The support includes a plurality of elongate holes that define a plurality of collars. The cigars are seated by the collars and restrict the movement of the cigars. The support also provides a pleasing display for the cigars. In a more particular arrangement, one or more such supports include tabs that engage the cigars of a straight body type and restrict movement of the cigars.

Owner:MARAYNA

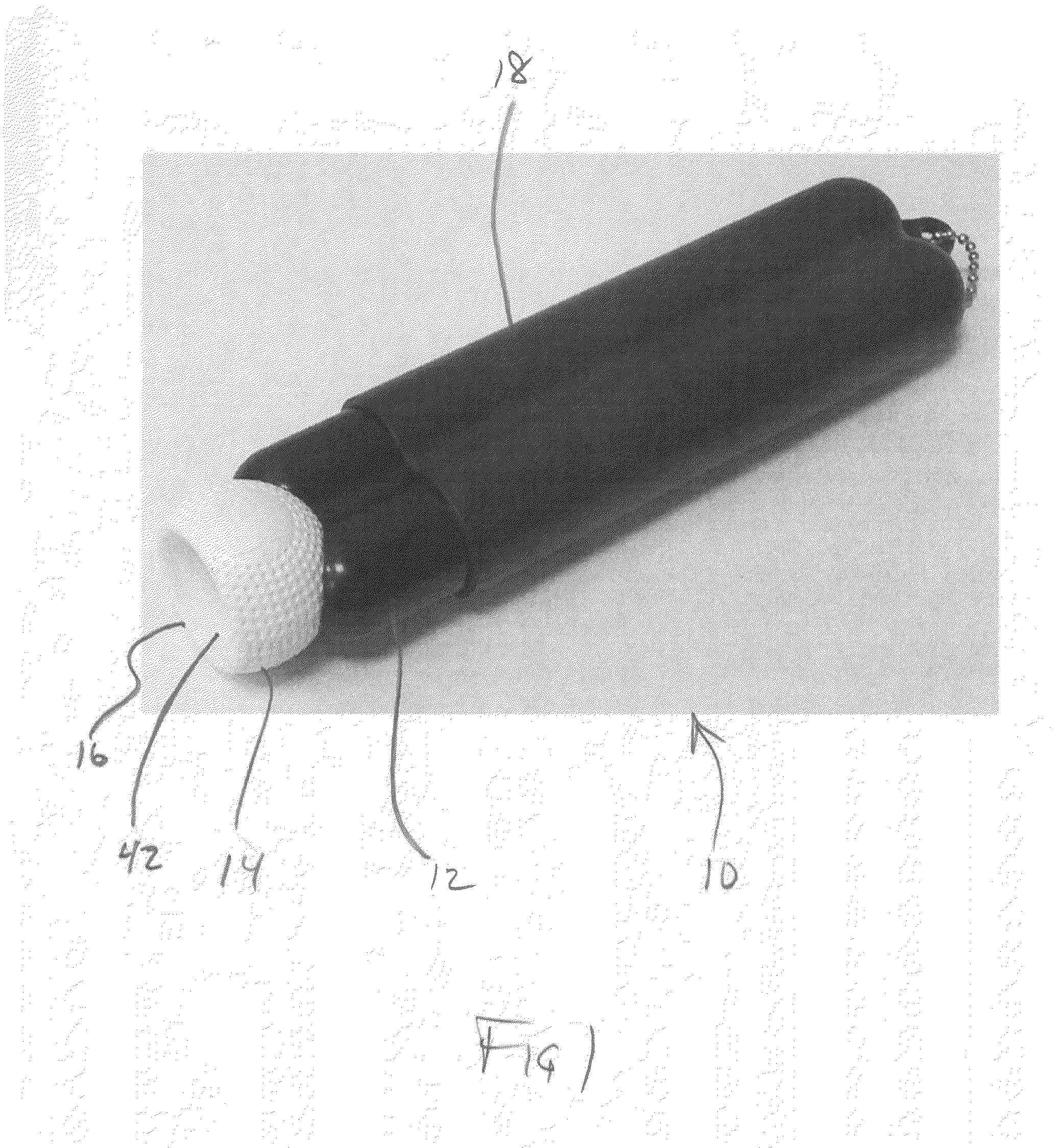

Smoking cessation device

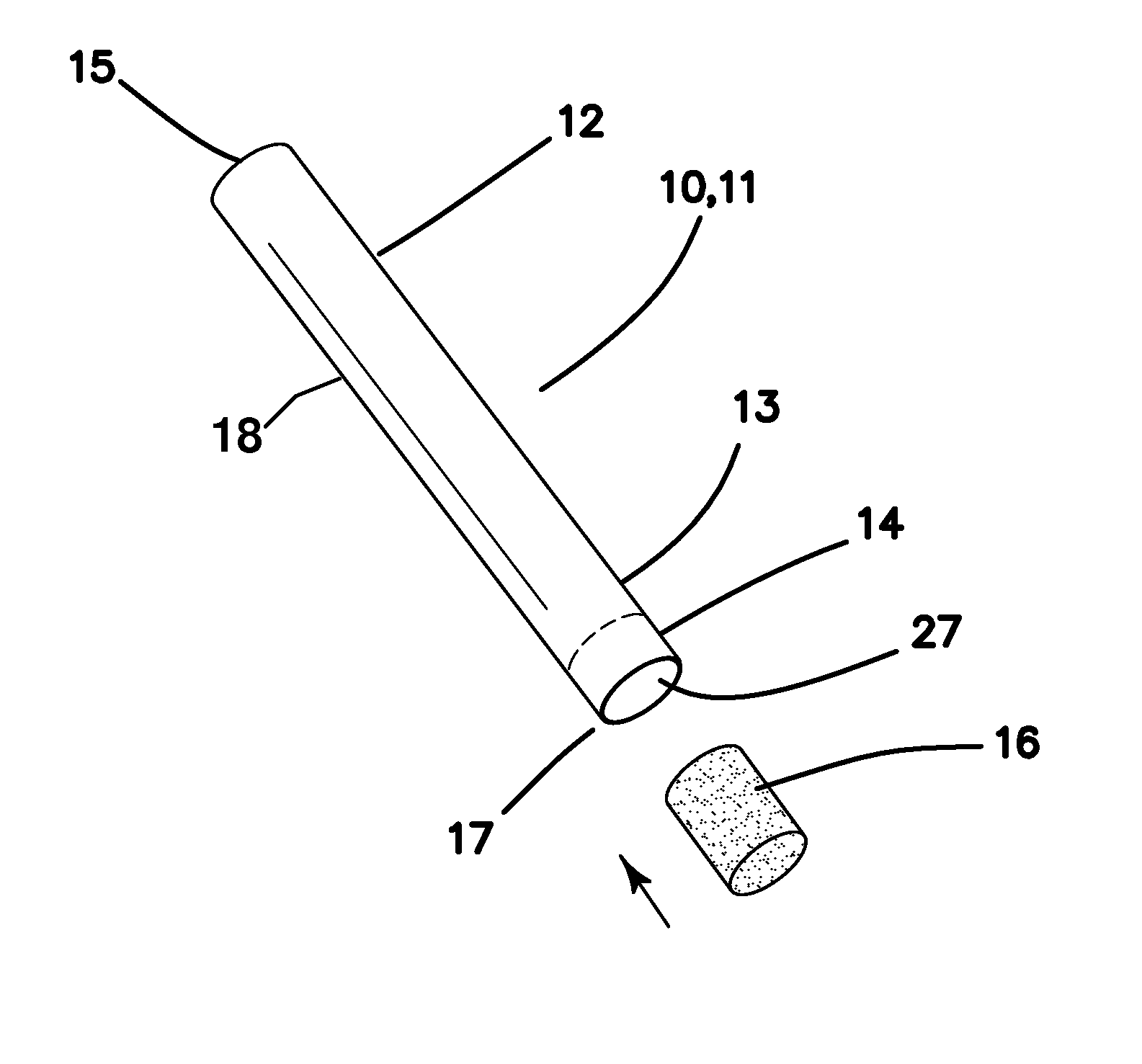

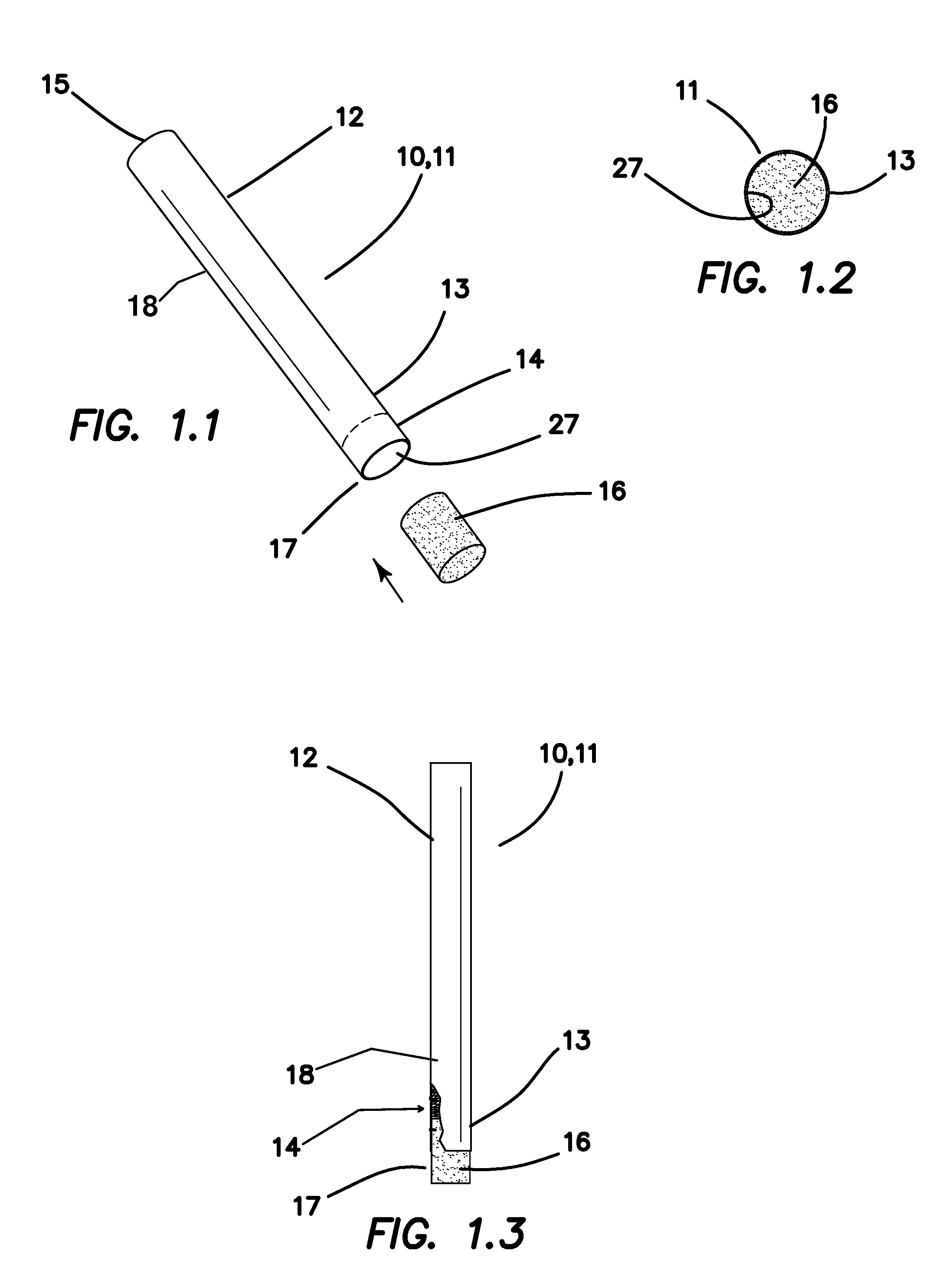

InactiveUS20150090276A1Increase ratingsImprove therapyOrganic active ingredientsPharmaceutical delivery mechanismNicotine replacementsTobacco pipe

A smoking cessation device for use in nicotine replacement therapy includes an imitation smoking implement with a body sized and shaped substantially identical to a conventional smoking implement chosen from the group consisting of a cigarette, a cigarillo, a cigar, and a pipe. The device also includes one or more nicotine replacement modules removably disposed at one end of the body, the one or more nicotine replacement modules removable from the imitation smoking implement by a user to ingest said nicotine replacement modules as part of a nicotine replacement therapy. Optionally, a plurality of said imitation smoking implements can be held in a package sized and shaped to resemble a conventional box of cigarettes, cigarillos or cigars. Said imitation smoking implement can be held by the user in their hands or lips while consuming the one or more nicotine replacement modules to simulate a conventional smoking ritual.

Owner:Q CIGARETTES

Cigar package

A packing system for cigars including a cigar box and at least one support. The flat support is sized slightly larger than the distance between a pair of walls of the cigar box so that the support is compressed into an arch shape that is maintained by the walls when inserted into the cigar box. The support includes a plurality of elongate holes that define a plurality of collars. The cigars are seated by the collars and restrict the movement of the cigars. The support also provides a pleasing display for the cigars. In a more particular arrangement, one or more such supports include tabs that engage the cigars of a straight body type and restrict movement of the cigars.

Owner:MARAYNA

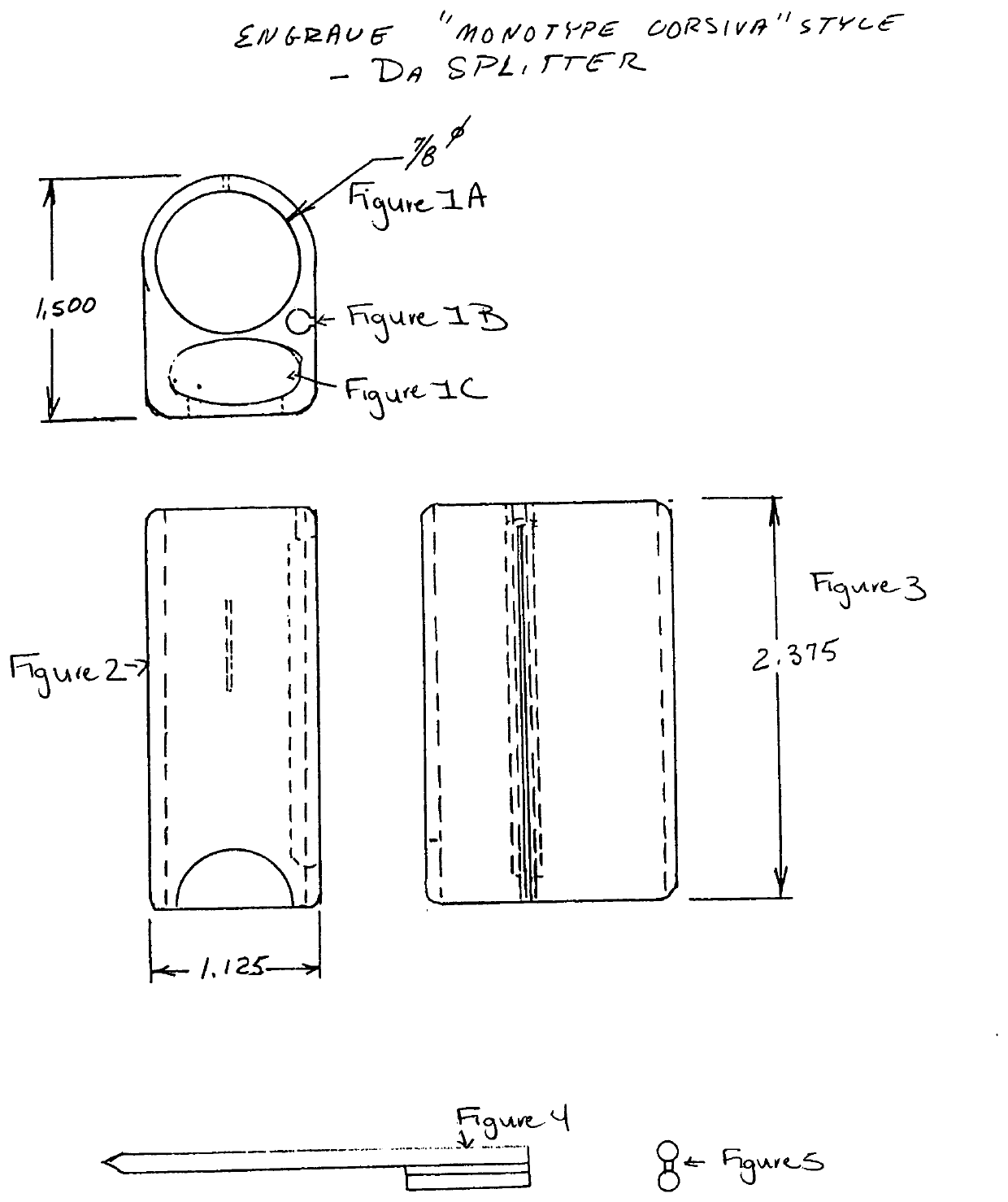

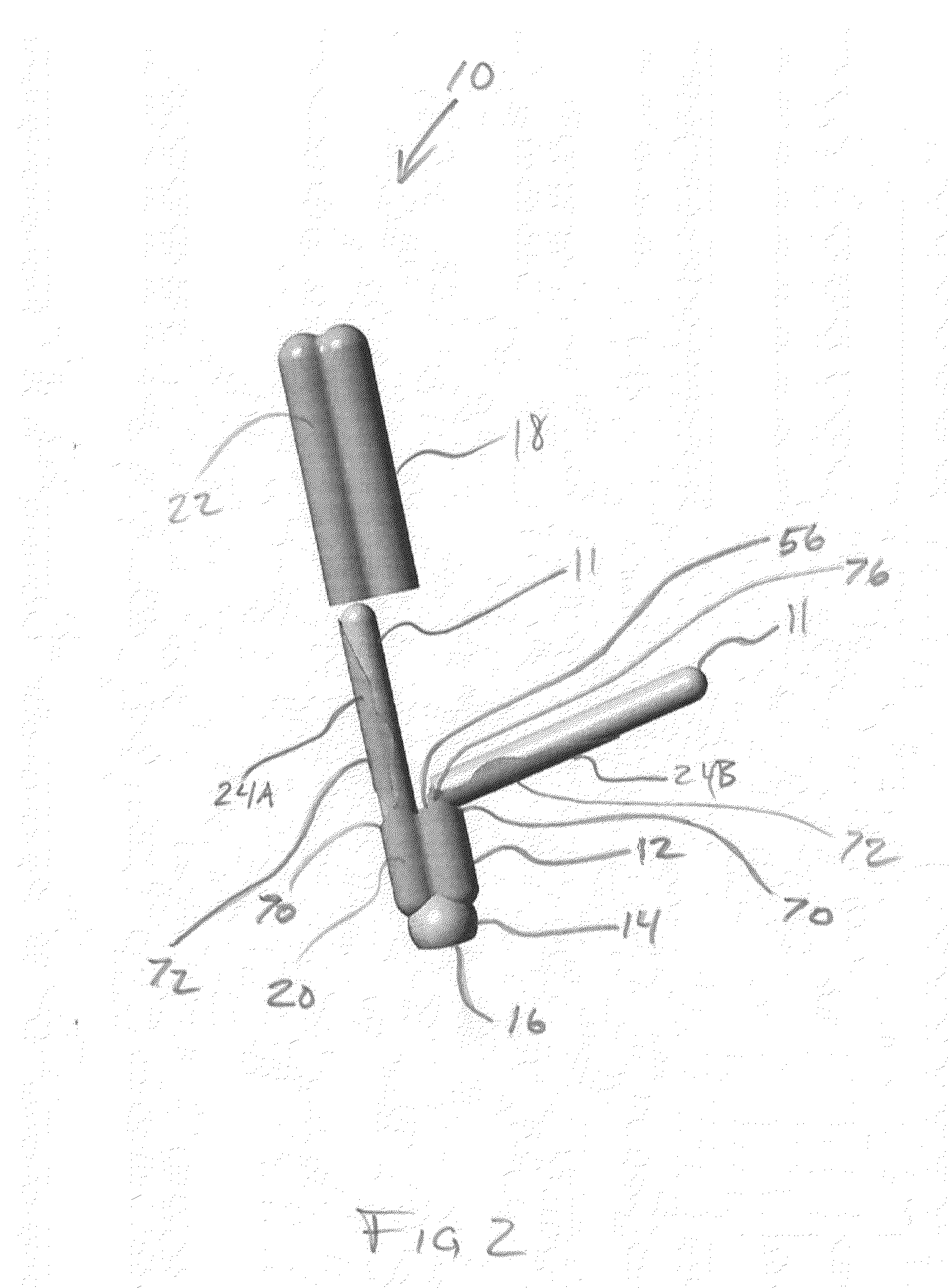

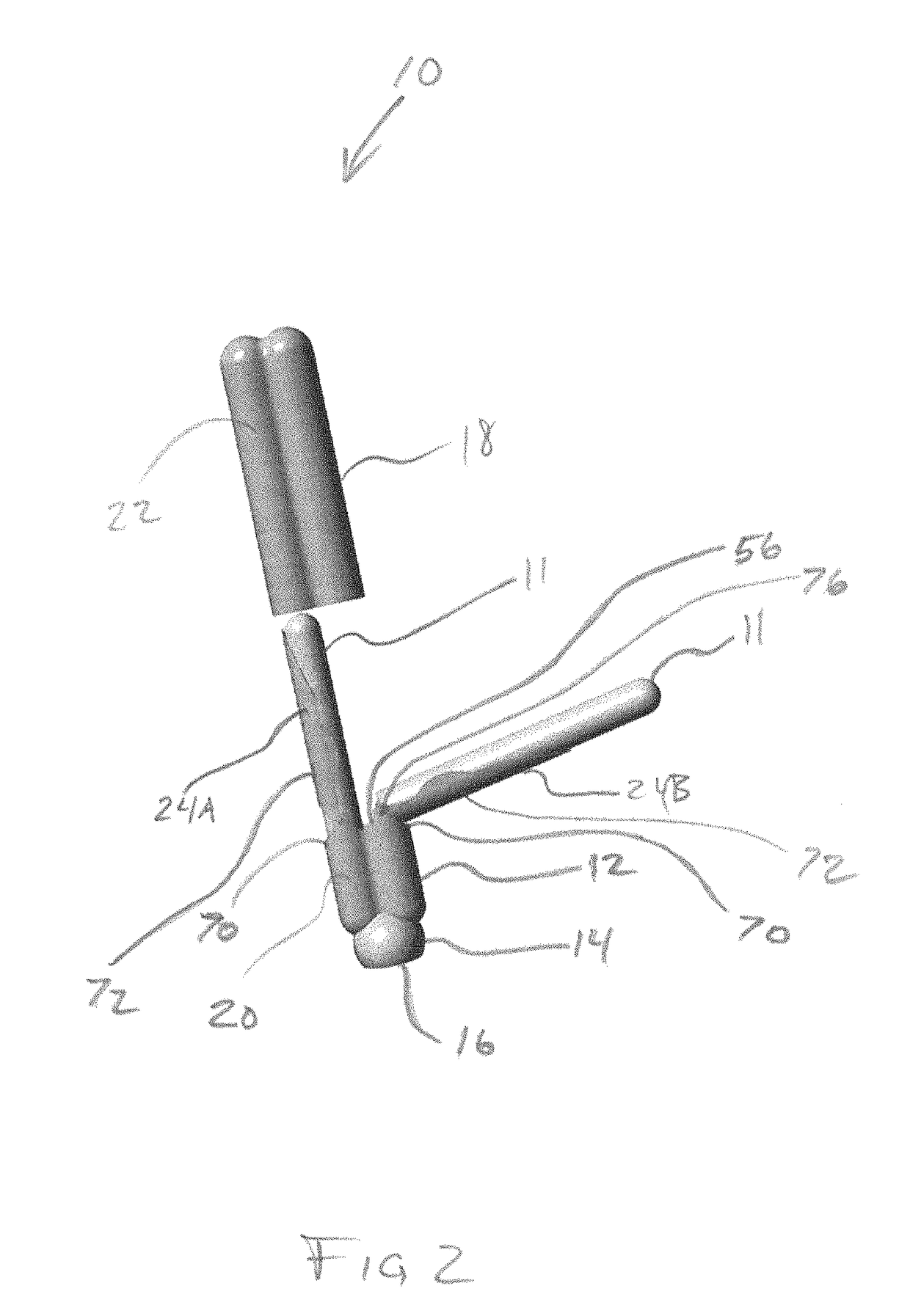

Apparatus for making cuts in cigars and method of use

Da Splitter″ is a tool made of plastic, created to make adequate cuts in cigars and cigarillos to provide for additional material to be inserted to enhance the use of the cigar, cigarillos and other objects. Da Splitter was designed to make changing the flavor of a cigar quick and easy. With the razor to cut open the previous cigar, the pick to stuff the new one and a lighter attached to smoke your new flavored cigar this tool provides the convenience of three separate instruments in one.

Owner:ALLS ANTONIO LEE

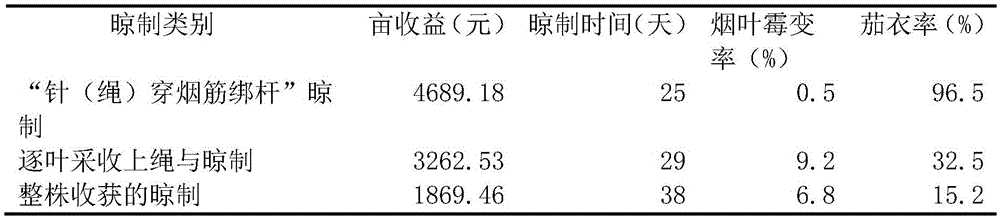

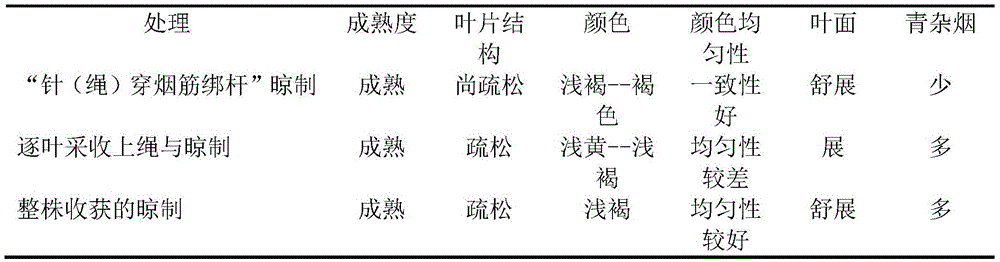

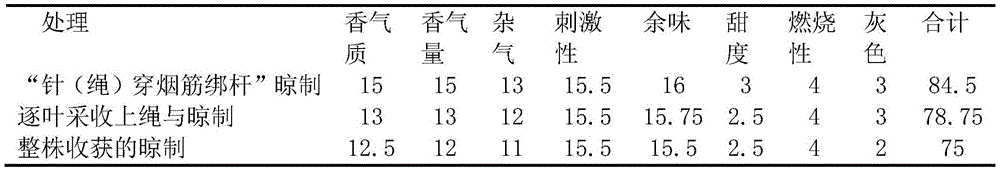

A method for drying cigar leaf wrappers by threading needle ropes through tobacco ribs and binding rods

InactiveCN104799425BEasy to store and take outImprove the drying levelTobacco preparationFlavorEngineering

The invention relates to a needle rope passing, tobacco stem binding and airing method of a cover of tobacco of cigar. The method comprises the steps of a, arranging in an airing room; b, picking tobacco; c, threading tobacco leaves; d, binding the tobacco stems; e, suspending; f. hanging to dry by the air; g, taking off. According to the method, the method of airing the cover of the tobacco of the cigar is changed; the method has a good airing effect; the surface and back of the aired tobacco are consistent in color; the produced cover is outstanding; the flavor is remarkable.

Owner:湖北省烟草公司恩施州公司

Glow in the dark cigar tools

Disclosed and claimed is a glow in the dark, size adaptable cigar splitting apparatus comprising an outer body and an inner size adapting sleeve adapted to be slidingly engaged therewith and further comprising a cutting blade for splitting the wrapper and, if present, packaging, of a cigar, cigarillo or other smoking device. In a preferred embodiment, the inner size adapting sleeve may be cylindrical in shape and is removable, allowing the invention to be adapted to various sizes of smoking devices. The improved size adaptable cigar splitter apparatus of the invention may further comprise a lanyard tang adapted to receive a necklace, lanyard, or similar structure to facilitate ease of carrying. Also claimed is a glow in the dark covering for cigar tools such as splitters, cutters and punches. Also claimed is a glow in the dark inlay for cigar tools such as splitters, cutters and punches.

Owner:SPURLING III GEORGE A

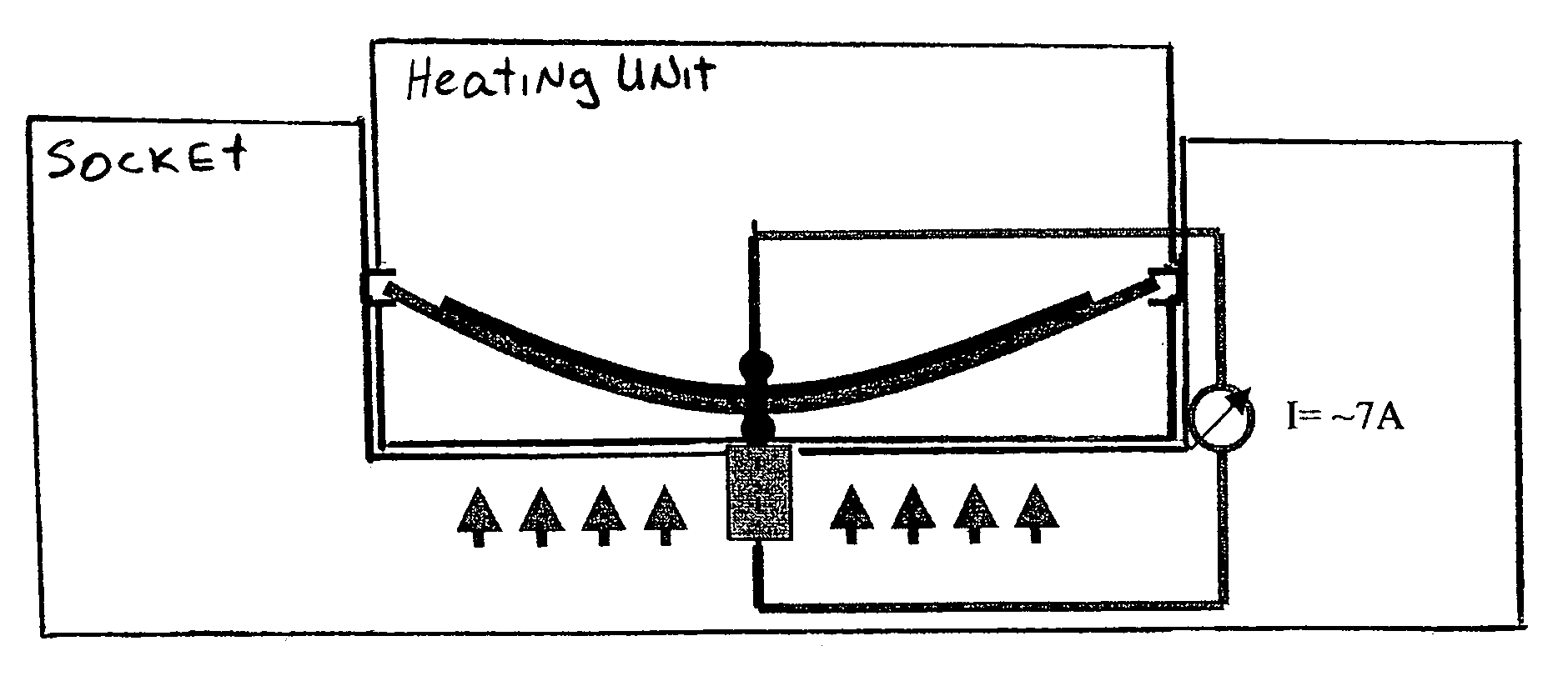

Fuelless Lifelong Cigarette Lighter

InactiveUS20120138591A1Creates heatReadily apparentIncandescent ignitionCapacitanceElectrical resistance and conductance

A fuel-less and battery-less cigarette lighter is a manually powered lighter that operates without the use of fuel. The lighter includes a super capacitor (low voltage, very high capacitance) that is discharged into a resistance. This resistance then becomes hot enough to light a cigarette or cigar upon contact. The super capacitor is charged by means of a mechanical system, such as the user winding or squeezing the lighter and a micro generator. After charging, a switch allows the capacitor to discharge into the resistance.

Owner:BARTHELEMY PIERRE ANDRE +1

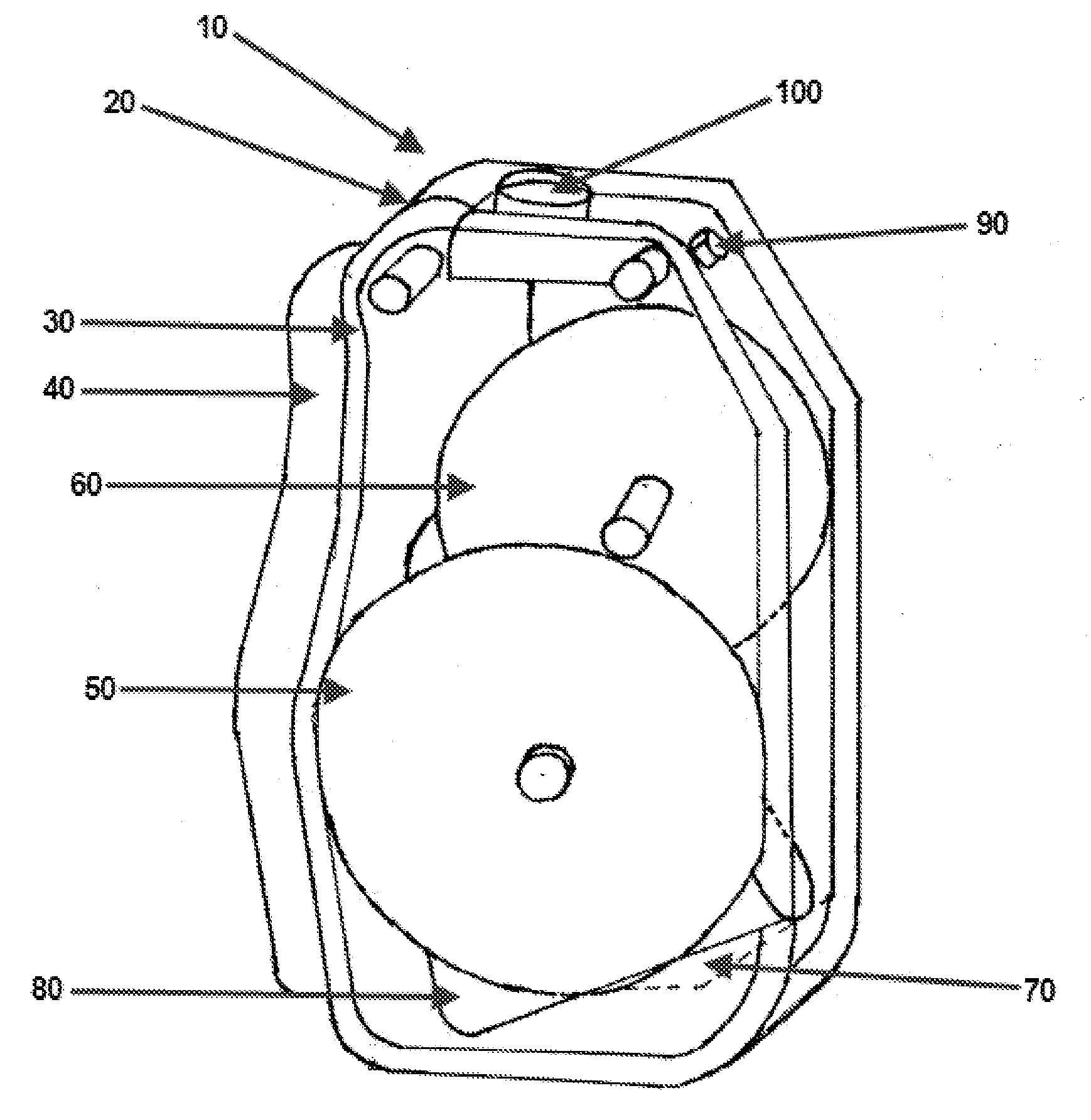

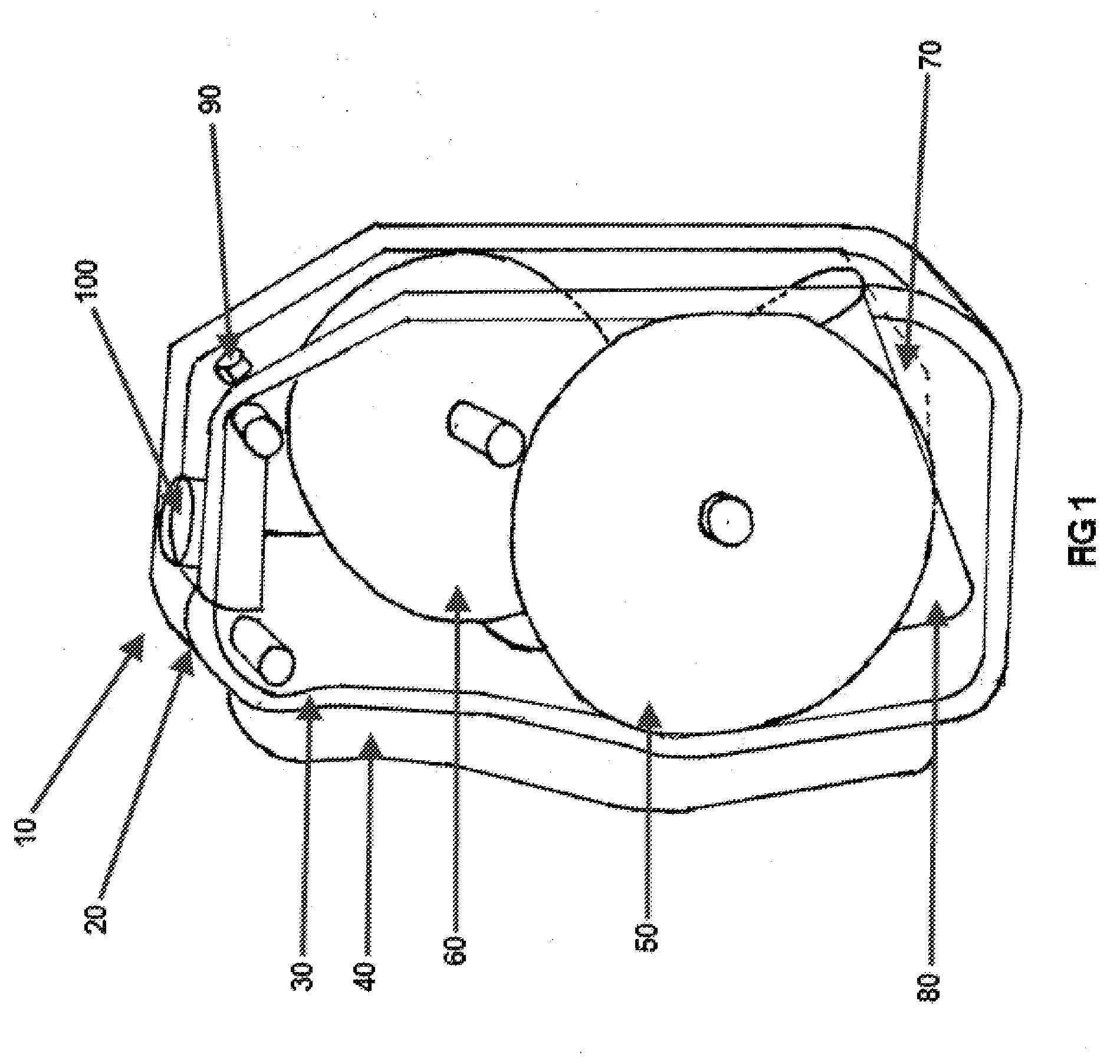

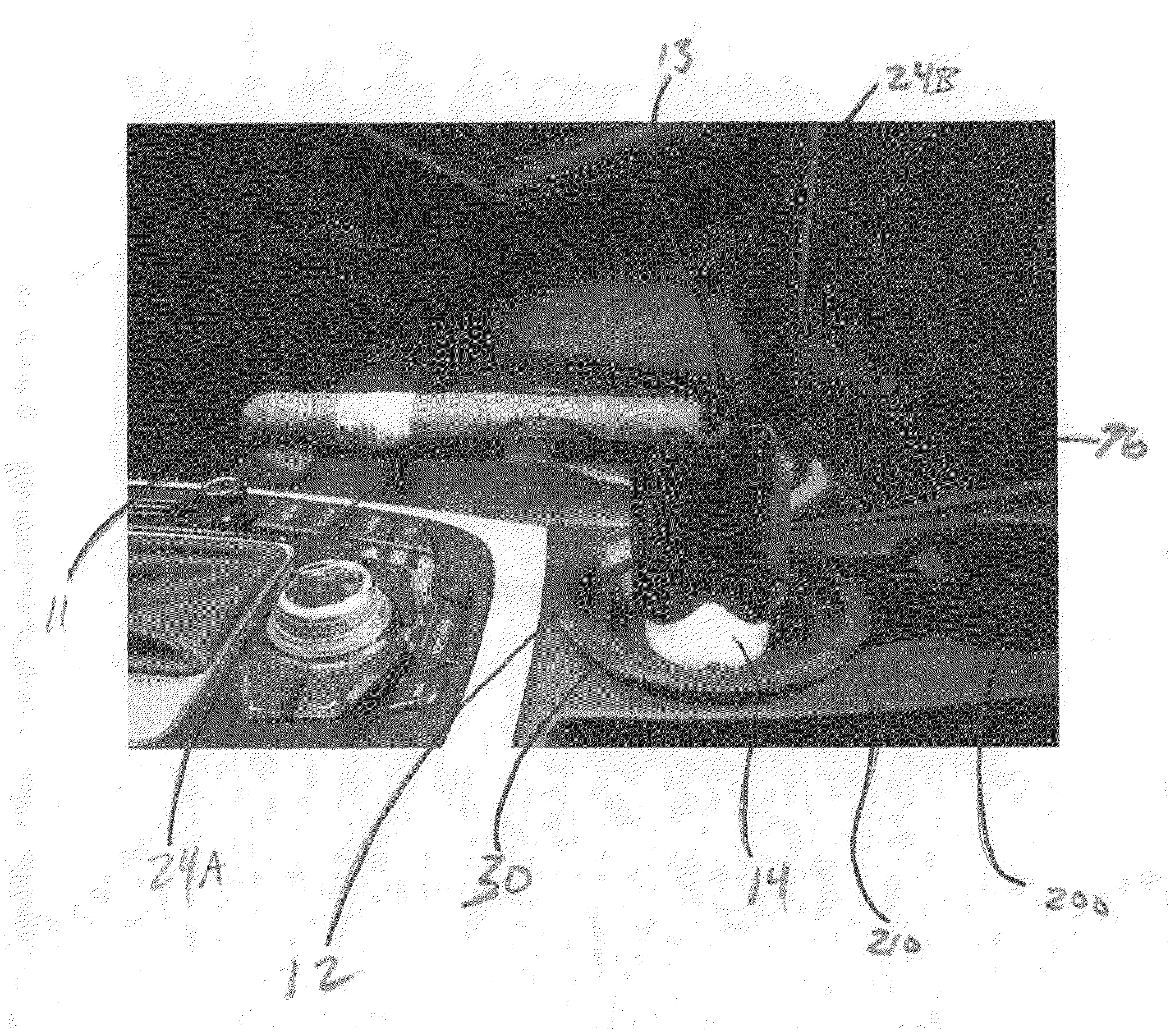

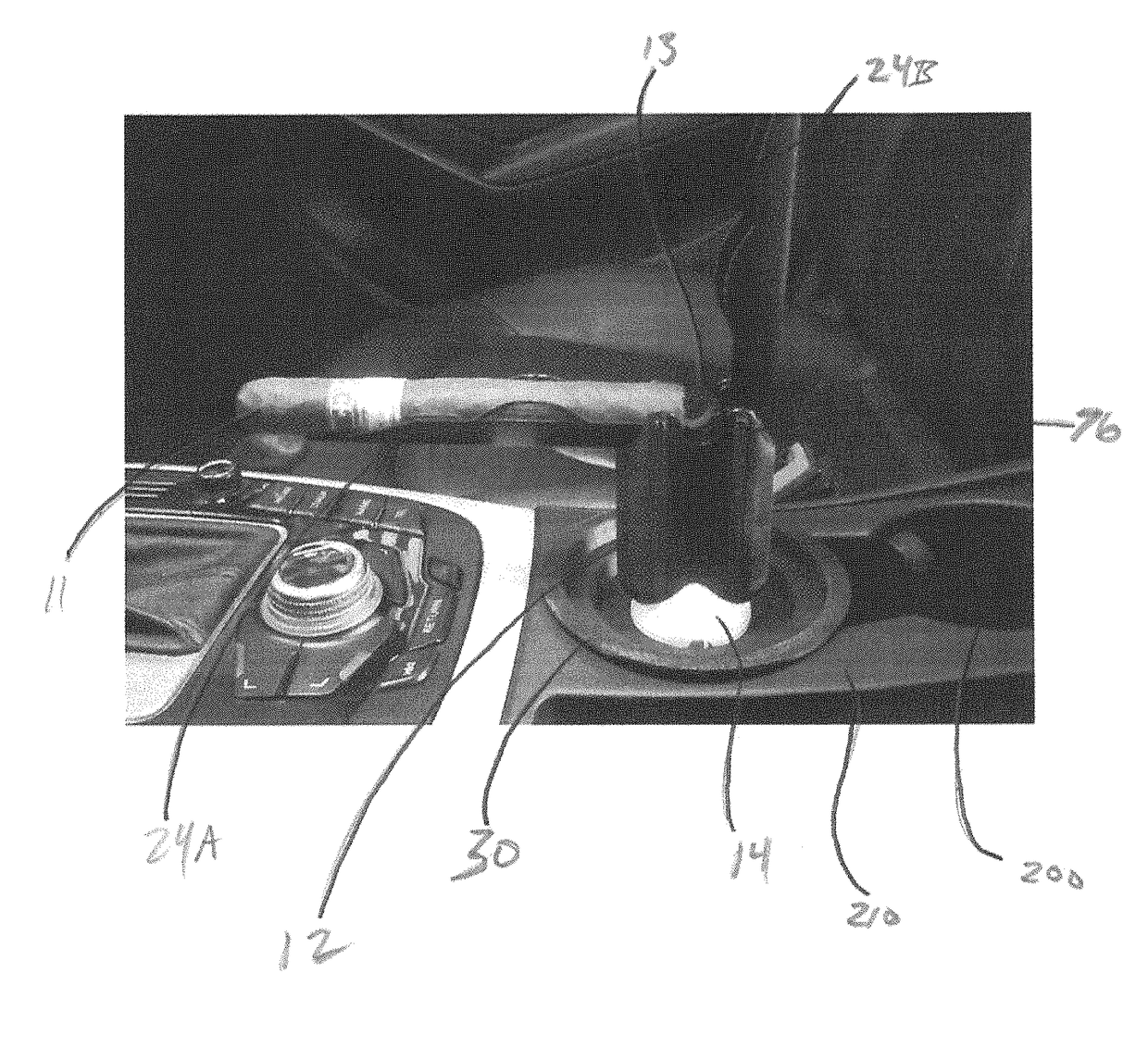

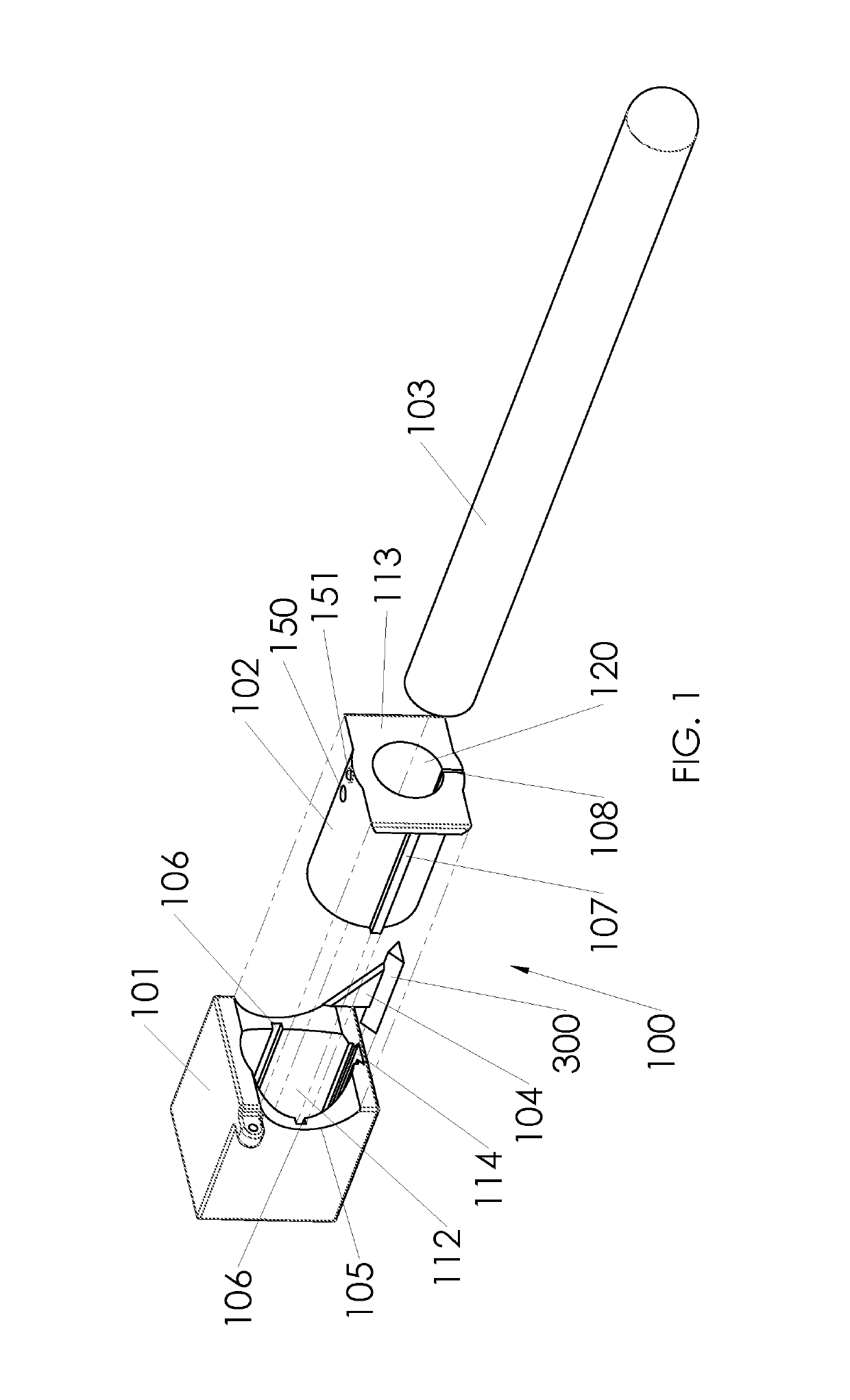

Holder for cigars, and the like

InactiveUS20160120217A1Easy to installSimple convenient caseContainers for flexible articlesCigar manufactureEngineeringGolf Ball

The present invention provide a new and novel holder for storing unlit articles to be smoked, such as cigar, and holding such articles when they are lit and not currently being smoked. When the holder is in a closed position, it acts as a carrying case for a number of articles to be smoked of any size (adjustable for lengths). When opened, the unit can be easily mounted to any frictional engagement device, such as a golf cart ball holder tray or easily with the cup-holder adapter. The device can also easily be applied to any cup holder typically found within golf carts, boats, and vehicles and any other structure that includes a cup holder.

Owner:FISHPAW JR RICHARD E +1

Holder for cigars, and the like

InactiveUS9861125B2Easy to installSimple convenient caseTobacco pipesTobacco devicesGolf BallCigarillo

The present invention provide a new and novel holder for storing unlit articles to be smoked, such as cigar, and holding such articles when they are lit and not currently being smoked. When the holder is in a closed position, it acts as a carrying case for a number of articles to be smoked of any size (adjustable for lengths). When opened, the unit can be easily mounted to any frictional engagement device, such as a golf cart ball holder tray or easily with the cup-holder adapter. The device can also easily be applied to any cup holder typically found within golf carts, boats, and vehicles and any other structure that includes a cup holder.

Owner:FISHPAW JR RICHARD E +1

Flavoring essence for cigar rolling paper

ActiveCN105112161BUniform colorAdd special scentTobacco treatmentEssential-oils/perfumesCooking & bakingFlavoring essences

The invention relates to application and development of flavoring essences or flavoring materials for tobacco and is especially applicable to the flavoring and casing of cigarette paper of cigars. The invention provides a casing flavor for the cigarette paper of the cigars, belongs to the field of application of tobacco flavors and relates to the flavoring and casing of the cigarette paper. The casing flavor is prepared through the following specific implementation steps of (1) selecting flavoring raw materials to form a flavoring essence formula according to a certain proportion; (2) carrying out cigarette paper casing: mixing the flavoring essence with coating liquid according to the ratio of 1: 1, and then, uniformly smearing the cigarette paper according to the casing quantity of 5%; (3) carrying out high-temperature hot-air seasoning: treating the cased cigarette paper in a baking oven with the constant temperature of 110 DEG C for 2 minutes; and (4) carrying out sensory quality evaluation: humidifying the cigarette paper to moisten the cigarette paper, then cutting tobacco leaves into shreds and making a cigar with the shredded tobacco leaves, and allowing professionals to make sensory evaluation on the cigar. The prepared casing flavor provided by the invention has an attractive scorched-bean fragrance and is added into the cigarette paper to cover relatively-heavy woody offensive odor, and the cigarette paper is endowed with the scorched-bean fragrance.

Owner:HUBEI CHINA TOBACCO IND +1

Cigar jar

InactiveCN103303592AVariable lengthObserve the actual situation at any timeContainers for flexible articlesCigar manufactureEngineeringCigarillo

The invention discloses a cigar jar, which comprises a body with a middle cavity and a transparent sleeve assembled at the head end of the body, wherein springs are embedded into the upper part of the middle cavity of the body; a tray is assembled at the upper ends of the springs, and slides along the inner wall surface of the middle cavity of the body; through holes are formed in the tray; a moisturizer box with a vent hole is embedded into the tail part of the middle cavity of the body, and is fixedly arranged at the tail end of the body through a cover; and an observation hole is formed in the bottom of the cover. The cigar jar has the advantages that the lengths of cigars between the tray and the transparent sleeve can be changed, and smoked cigars can be placed in the transparent box at any time for storage; the actual conditions of the cigars can be observed at any time; and the flavor of the cigars can be maintained, and the storage time of the cigars can be prolonged.

Owner:NINGBO GAS & FOGAGENT MAKING

A kind of cocoa essence formula and its process method for making cocoa-flavored cigars

The invention discloses a cacao flavor formula and a technique for producing a cocoa-flavor cigar. According to the cacao flavor formula, a cacao flavor obtained according to the formula comprises, by weight, 25 parts to 30 parts of cacao extract, 5 parts to 8 parts of ketone spice, 30 parts to 40 parts of extract of natural plants, 20 parts to 30 parts of a thinner, and 2 parts to 5 parts of lipid spice. The technique for producing the cocoa-flavor cigar comprises the steps of (a) selection of cigar raw materials, (b) sterilization, (c) recovery treatment, and (d) production of the finished cigar. According to the cacao flavor formula and the technique for producing the cocoa-flavor cigar, through the study on the special cacao concentration and extraction technique and the study on addition of a cigar formula, a new type of thin cigars with special flavor obtained through infusion of cacao flavor and the natural fragrance of cigars are obtained.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Method for enhancing the aroma and flavor of tobacco products, tobacco raw material, cigarettes and cigars

ActiveCN103813725BUseful ingredients to enhance aroma and tasteIncrease the fragranceTobacco preparationTobacco treatmentAdditive ingredientFood flavor

The present invention provides a method for enhancing the aroma and flavor of tobacco products with useful ingredients, which includes: preparing sugars derived from natural products, plant entities, and liquid extracts extracted or concentrated from plant entities. The process of at least one raw material for spices; the process of storing the raw material in the pot at a volume ratio of 50 to 80% by volume relative to the volume of the pot; stirring the raw material in the pot at a rate of 1.0 to 2.0 The process of heating to 80 to 100°C at a temperature rising rate of 0.0°C / min; and the step of cooling the contents processed in the pot to a desired temperature at a temperature decreasing rate of 0.40 to 0.85°C / min.

Owner:JAPAN TOBACCO INC

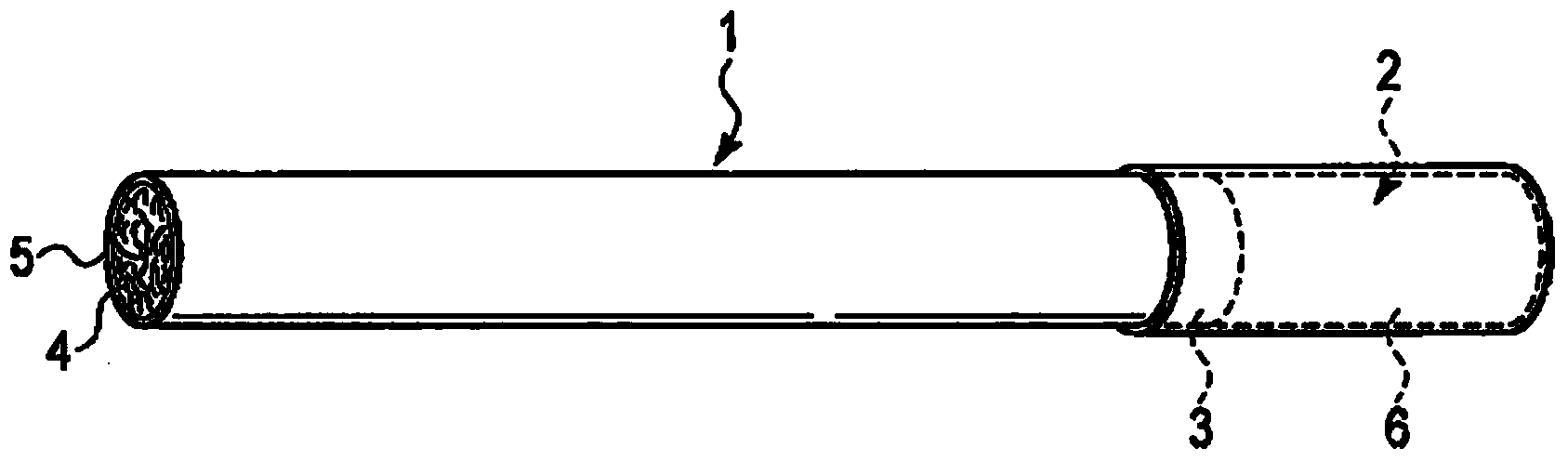

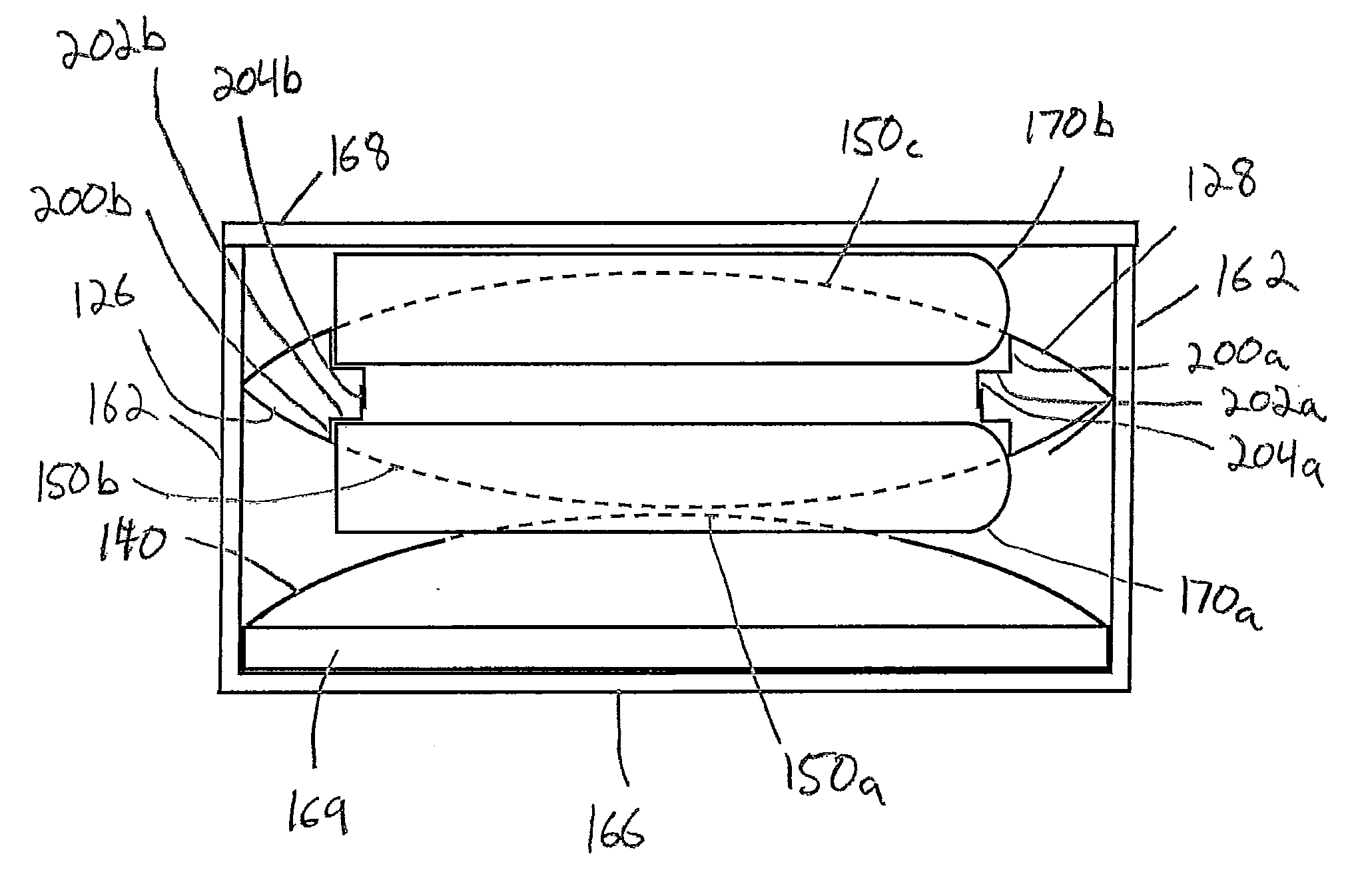

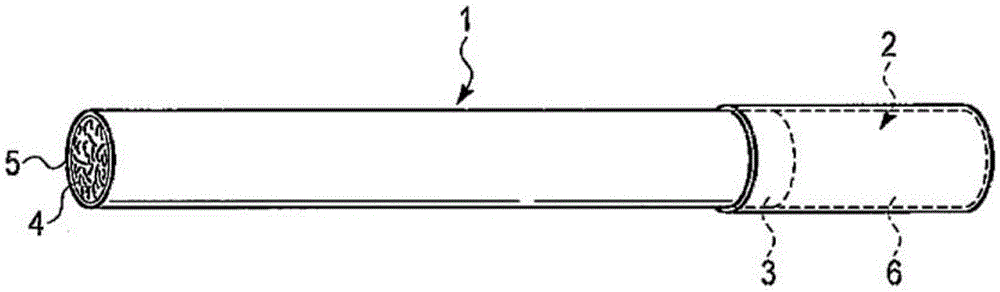

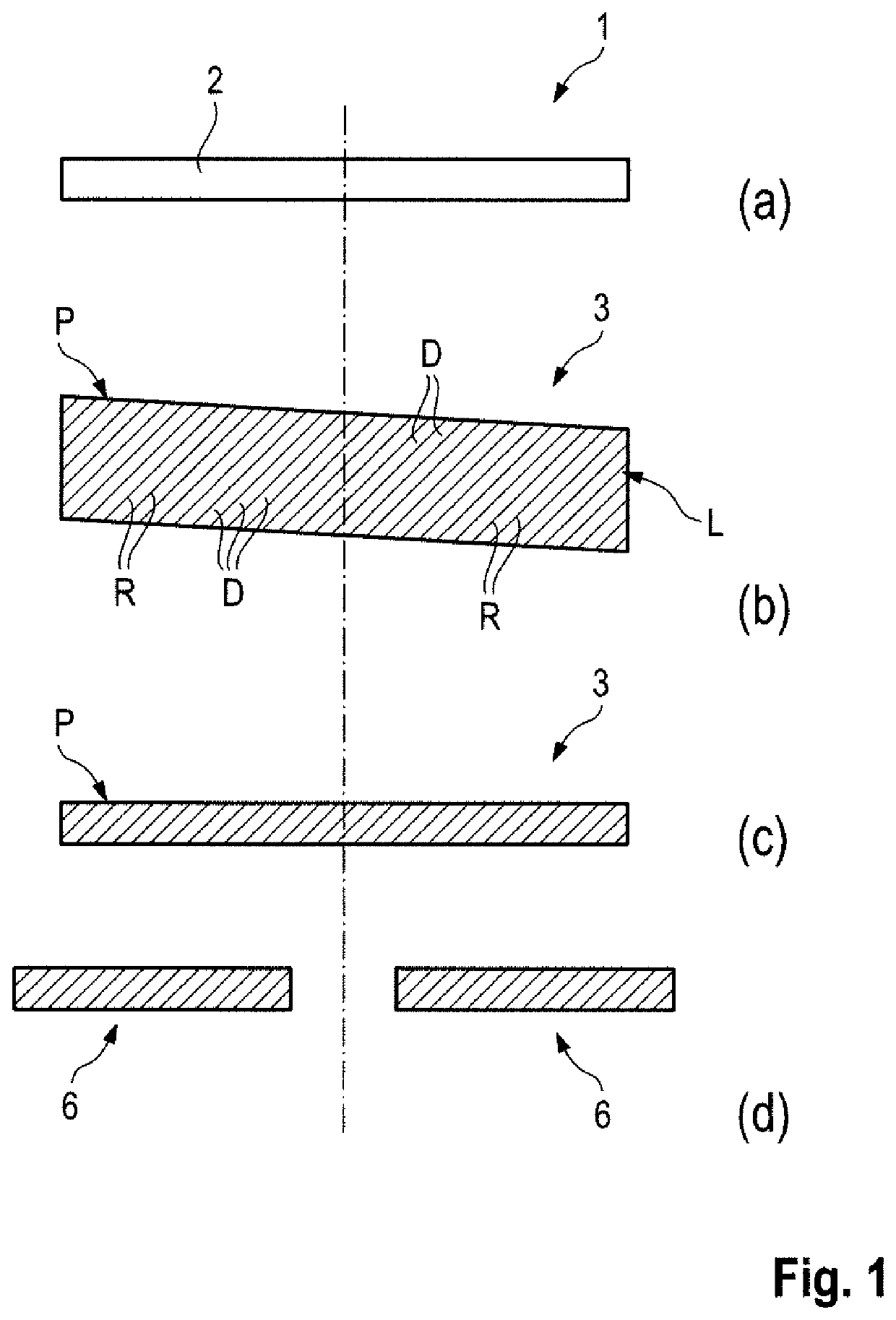

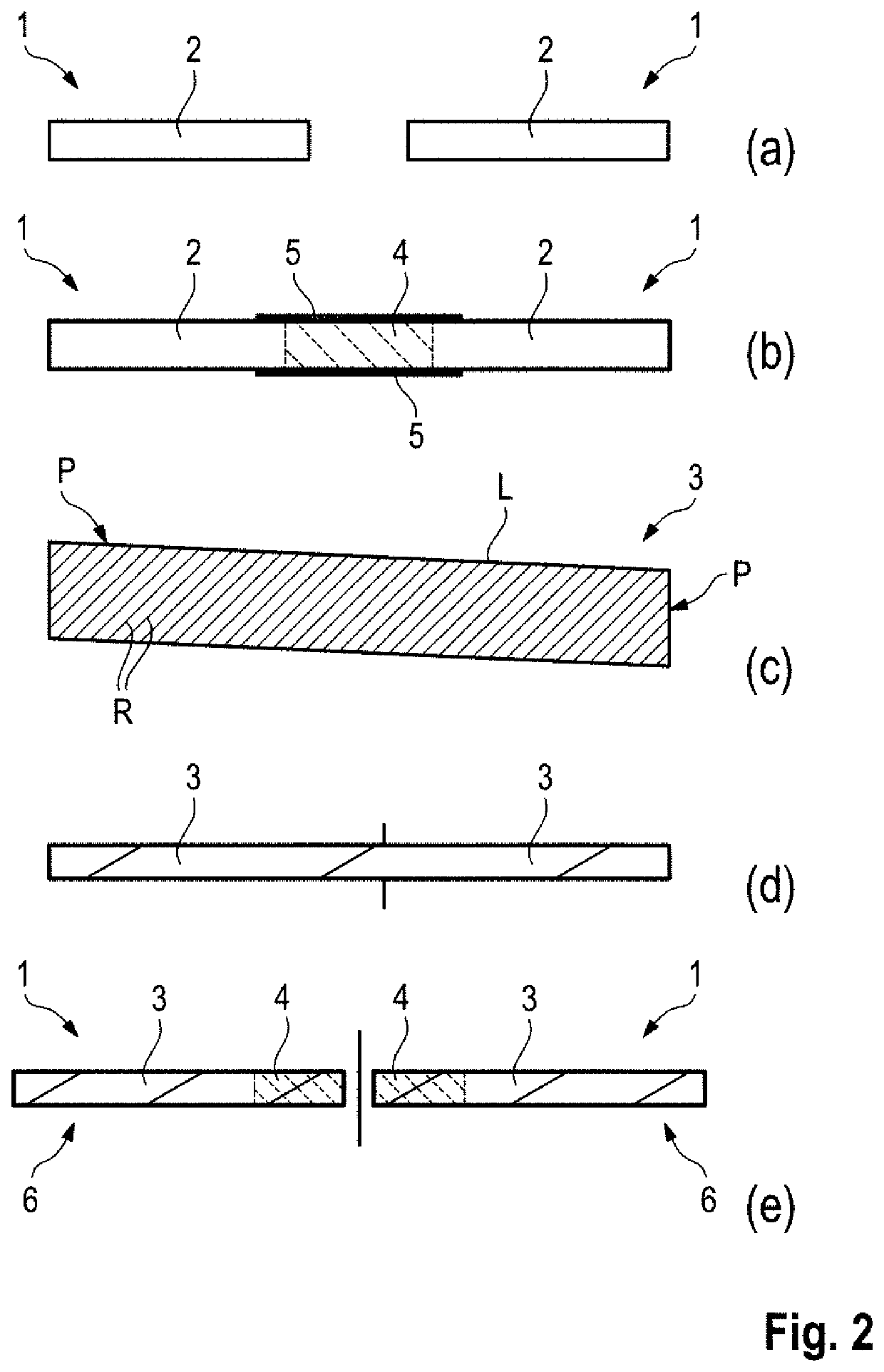

Cigarillo and method of manufacturing same

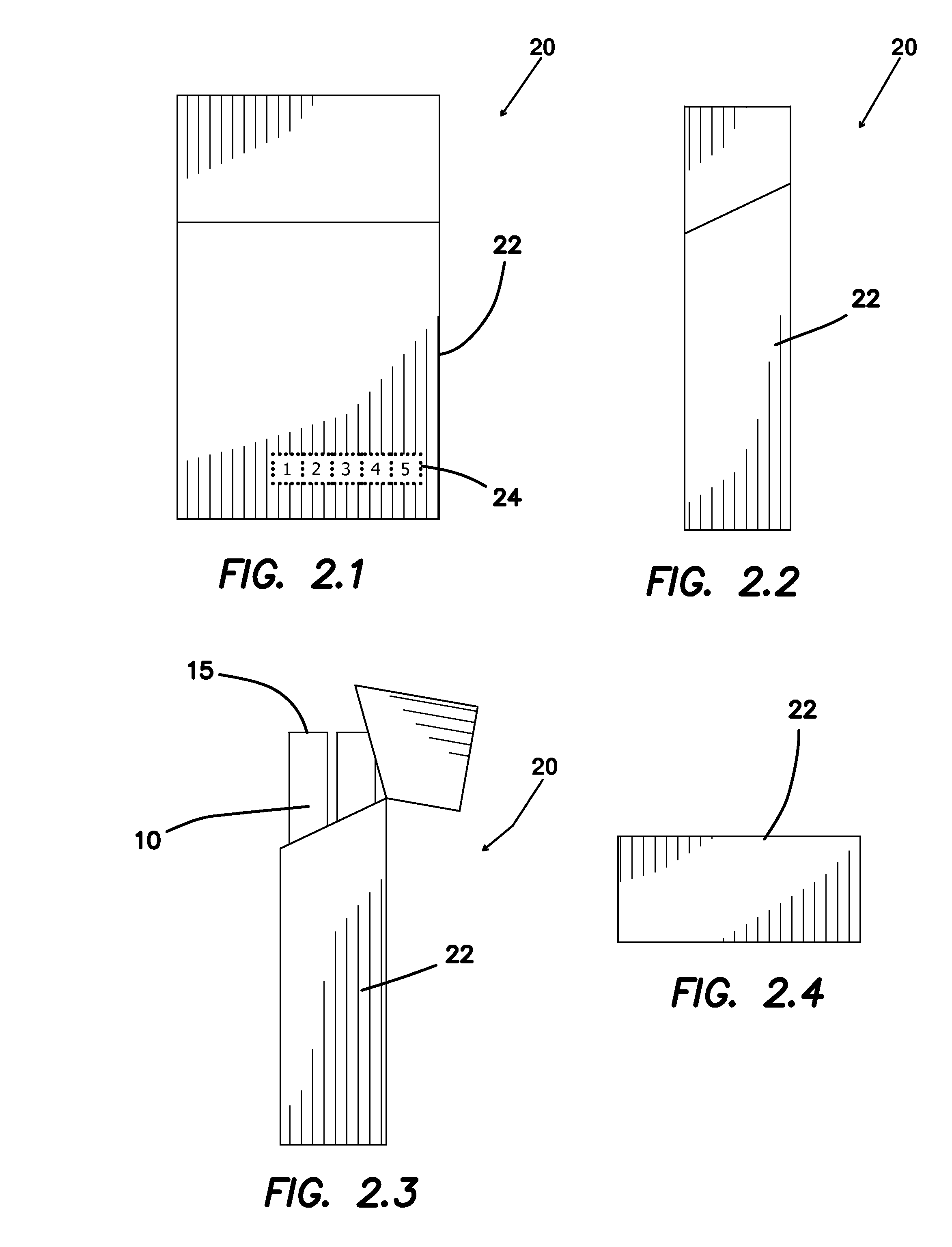

ActiveUS10986862B2Easy to operateHandled more easily and more reliablyTobacco preparationCigar manufactureNicotiana tabacumEngineering

A cigarillo includes a tobacco rod element having tobacco cut filler and a binder layer which binds or holds the tobacco cut filler within the rod element; and an outer wrapper of natural tobacco leaf which encompasses or covers the tobacco rod element, wherein the natural tobacco leaf of the outer wrapper comprises a pattern imprinted or impressed therein. A method of producing a cover layer of natural tobacco leaf for use in manufacturing a cigarillo includes providing a substantially continuous web of a support material having a surface profile, which typically includes surface profile elements such as projections; arranging a plurality of natural tobacco leaves extended flat over the web of support material; and layering the substantially continuous web with the plurality of natural tobacco leaves supported thereon, whereby the surface profile of the web impresses or imprints a pattern into the plurality of natural tobacco leaves.

Owner:JT INT SA

Glow in the dark cigar tools

ActiveUS10264818B2Save effortShorten the timeTobacco pipesLuminescent compositionsEngineeringCigarillo

Disclosed and claimed is a glow in the dark, size adaptable cigar splitting apparatus comprising an outer body and an inner size adapting sleeve adapted to be slidingly engaged therewith and further comprising a cutting blade for splitting the wrapper and, if present, packaging, of a cigar, cigarillo or other smoking device. In a preferred embodiment, the inner size adapting sleeve may be cylindrical in shape and is removable, allowing the invention to be adapted to various sizes of smoking devices. The improved size adaptable cigar splitter apparatus of the invention may further comprise a lanyard tang adapted to receive a necklace, lanyard, or similar structure to facilitate ease of carrying. Also claimed is a glow in the dark covering for cigar tools such as splitters, cutters and punches. Also claimed is a glow in the dark inlay for cigar tools such as splitters, cutters and punches.

Owner:SPURLING III GEORGE A

Cigarette and cigar lighter

InactiveUS20100003627A1Avoid overall overheatingFuel lightersGaseous fuel burnerAngular degreesEngineering

A lighting device for cigarettes and cigars having an upright elongate body, a lid openable approximately ninety angular degrees from the body, a nozzle for producing a flame and directing the flame from the body at an angled direction between the body and the lid. The proximity of the flame base to the lid protects the flame from being inadvertently extinguished, while the distance of the flame tip from the lid allows the lighting of large diameter cigars and avoids overheating of the lid.

Owner:MONT DOR OF AMERICA

Bidirectional cigar splitter

ActiveUS10278420B2Save effortShorten the timeFuel lightersTobacco pipesEngineeringInternal dimension

An improved size adaptable cigar splitting apparatus comprising and outer body and an inner size adapting sleeve adapted to be slidingly engaged therewith and further comprising a cutting blade for splitting the wrapper and, if present, packaging of a cigar, cigarillo or other smoking device. In a preferred embodiment, the inner size adapting sleeve may be cylindrical in shape and is removable, allowing the invention to be adapted to various sizes of smoking devices. The cigar splitter apparatus of the invention is adapted to receive smoking devices of various diameters which include all common diameters of smoking devices currently in use. The cutting blade is adapted to be removable and replaceable. The improved size adaptable cigar splitter apparatus of the invention may further comprise a lanyard tang adapted to receive a necklace, lanyard, or similar structure to facilitate ease of carrying.

Owner:SPURLING III GEORGE A

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com