Method for enhancing the aroma and flavor of tobacco products, tobacco raw material, cigarettes and cigars

A tobacco product, a useful technology, applied in the field of enhancing the aroma and taste of tobacco products, can solve the problems of effect changes, hindering the characteristics of extracts, and changes in content components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0029] The method for enhancing the aroma and flavor of tobacco products according to the first embodiment includes: preparing at least one selected from sugars derived from natural products, plant bodies, and liquid extracts extracted or concentrated from plant bodies. A step of growing raw materials for fragrance (first step); a step of storing the above-mentioned raw materials for fragrance in a pot at a volume ratio of 50 to 80% by volume relative to the volume of the pot (second step); The process of heating the raw materials for spices to 80-100°C at a heating rate of 1.0-2.0°C / min while stirring (the third step); cooling the contents treated in the above-mentioned pot at a rate of 0.40-0.85°C / min A step of cooling to a desired temperature (fourth step).

[0030] Here, the term "ingredient ingredient" refers to a component (or component group) that contributes to aroma and taste (flavor) when smoking or burning.

[0031] According to such a first embodiment, the above-m...

no. 2 approach >

[0046] The tobacco raw material of the second embodiment includes a flavoring raw material containing a flavor-enhancing ingredient enhanced by the method of the first embodiment.

[0047] Tobacco raw materials include, for example, tobacco flakes, shredded tobacco, reconstituted tobacco, puffed tobacco, tobacco stems, cut tobacco stems, cigarette filters, paste for wrapping paper, tobacco leaves for pipes, raw materials for cigars (fillers, binders, wrapping paper) tobacco leaves.

[0048] The content of the flavoring raw material in the tobacco raw material is appropriately selected according to the type of the tobacco raw material.

[0049] According to the second embodiment described above, it is possible to provide a tobacco raw material that does not change the original aroma and taste (flavor) of the raw material for flavoring during combustion during smoking, and can provide a flavor-intensive active ingredient in the raw material for flavoring. Fragrance and taste (f...

no. 3 approach >

[0051] A cigarette according to a third embodiment includes a tobacco raw material including a flavoring raw material containing a flavor-enhancing ingredient that is enhanced by the method of the first embodiment.

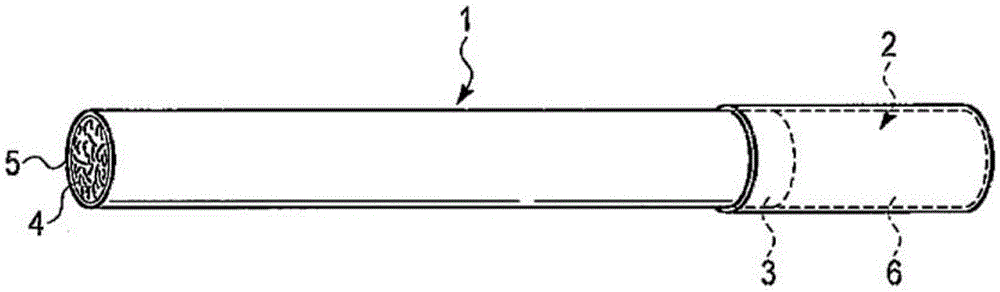

[0052] refer to figure 1 Specific cigarettes (for example, filter-tipped cigarettes) will be described in detail.

[0053] The filter-tipped cigarette includes a tobacco rod 1 and a filter 2 having a circumference equal to or thinner than that of the tobacco rod 1 . The ends of the tobacco rod 1 and filter 2 are aligned with each other, and fiber paper 3 is used to wrap the entire outer peripheral surface of the filter 2 and the aligned peripheral portion of the tobacco rod 1 nearby, thereby integrating the tobacco rod 1 and the filter 2 . The tobacco rod 1 is formed by wrapping shredded tobacco 4 in a cylindrical shape with paper 5 . The filter 2 is formed of a filter material (not shown) formed by bundling or folding a nonwoven fabric such as cellulose acetate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com