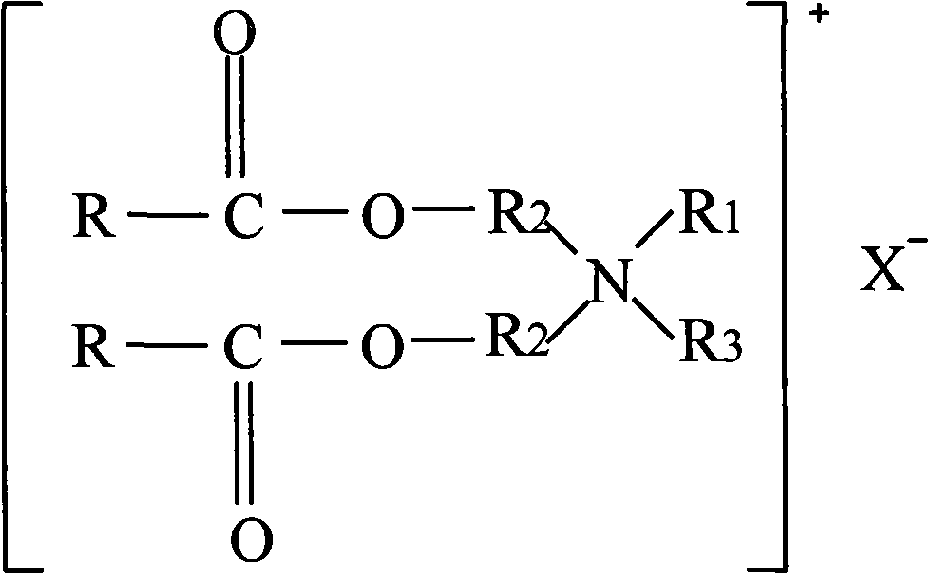

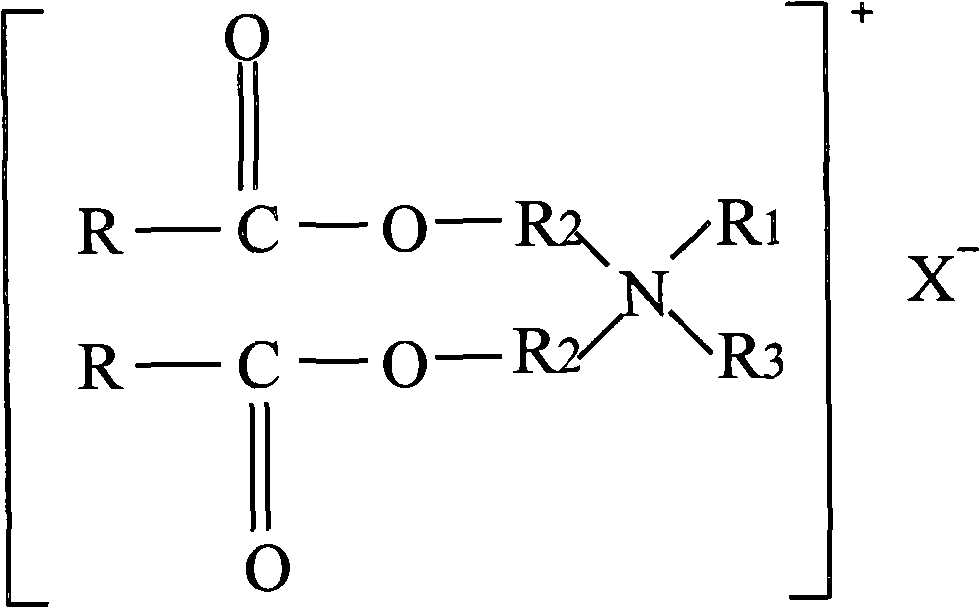

Method for synthesizing dual-long-chain ester based quaternary ammonium salt

A technology of ester quaternary ammonium salt and synthesis method, applied in the field of surfactants, can solve the problems of low content of di-long-chain ester amines, unreported methods, unsatisfactory methods, etc., and achieves low ecotoxicity, convenient use, and improved grades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

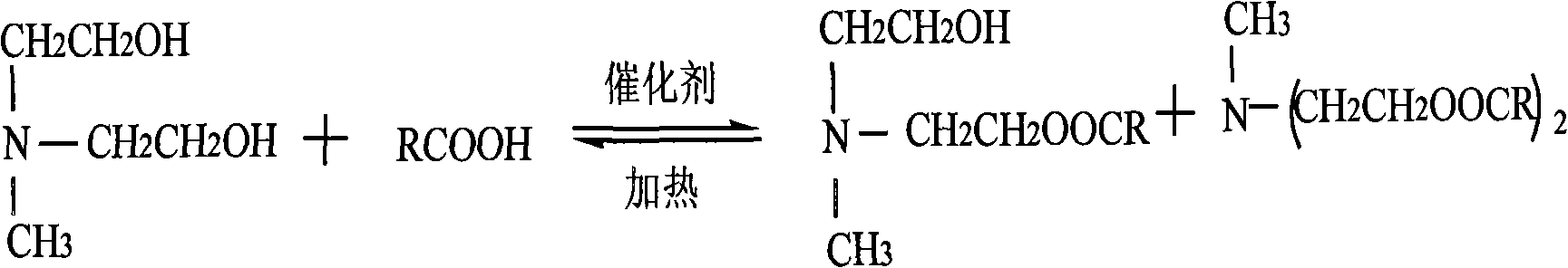

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Weigh 56.9g (0.2mol) of stearic acid, add it to a 250mL four-neck flask, stir and heat up to 70°C under a nitrogen atmosphere, and after it is completely melted, add 0.36g of hydrochloric acid, N- 7.9g (0.067mol) of methyldiethanolamine, stirred and heated to 160°C, after 3 hours of heat preservation reaction, added 7.9g (0.055mol) of triethanolamine, reacted at 160°C for 3h, the acid value of the product was measured to be 3.5mgKOH / g, and the reaction was terminated . Cool the reaction mixture to 60°C, stop heating, add 12.48 g of isopropanol as a solvent, and slowly add 13.23 g of dimethyl sulfate for quaternization, and do not heat during the dropwise addition. After the dropwise addition, heat to 85°C, reflux for 8 hours, and stop the reaction.

Embodiment 2

[0027] Example 2: Weigh 40.07g (0.2mol) of lauric acid, add it to a 250mL four-neck flask, stir and heat up to 70°C under a nitrogen atmosphere, and after it is completely melted, add 0.26g of hypophosphorous acid, N- 7.9g (0.067mol) of methyldiethanolamine, stirred and heated to 160°C, after 3 hours of heat preservation reaction, added 7.9g (0.055mol) of triethanolamine, reacted at 160°C for 3h, the acid value of the product was measured to be 3.5mgKOH / g, and the reaction was terminated . Cool the reaction mixture to 60°C, stop heating, add 9.4 g of isopropanol as a solvent, and slowly add 12.68 g of dimethyl sulfate for quaternization, without heating during the dropwise addition. After the dropwise addition, heat to 85°C, reflux for 8 hours, and stop the reaction.

Embodiment 3

[0028] Embodiment 3: Take by weighing 45.68g (0.2mol) tetradecanoic acid, join in the four-neck flask of 250mL, under the condition of nitrogen atmosphere, stir and heat up to 70 ℃, after it is all melted, add hypophosphorous acid 0.29g, N - 7.9g (0.067mol) of methyldiethanolamine, stirred and heated up to 160°C, after 3 hours of heat preservation reaction, added 7.9g (0.055mol) of triethanolamine, reacted at 160°C for 3h, the acid value of the product was measured to be 3.5mgKOH / g, and the reaction was terminated reaction. Cool the reaction mixture to 60°C, stop heating, add 10.13 g of isopropanol as a solvent, and slowly add 12.52 g of dimethyl sulfate for quaternization, without heating during the dropwise addition. After the dropwise addition, heat to 85°C, reflux for 8 hours, and stop the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com