Preparation method of one-component polyaspartic ester finishing paint

A technology of aspartic acid ester and aspartic acid ester, applied in the direction of polyurea/polyurethane coating, coating, etc., can solve the problems of material waste, paint film performance defect, short, generally only 15-20min, etc. Convenience, the effect of ultra-high outdoor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

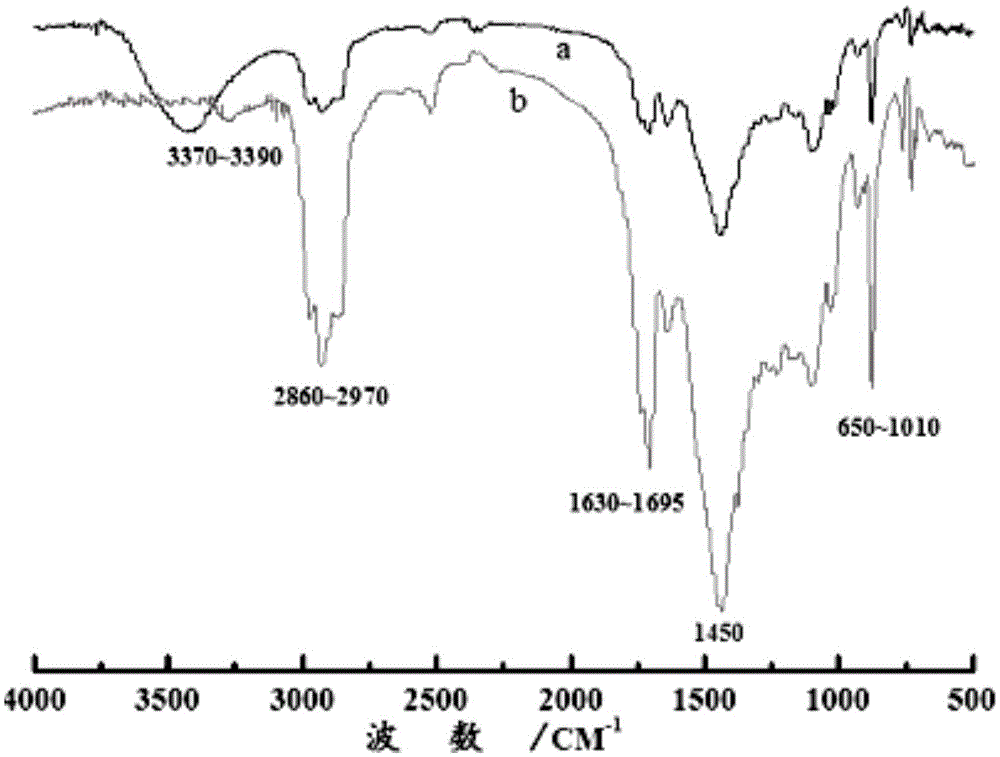

[0065] With 150g polyaspartic acid ester DesmophenNH1420, 40g butanone, 0.5g titanium tetrachloride, 45g toluene (the mol ratio of the secondary amino group in polyaspartic acid ester, ketones end-capping agent and the first catalyst is 2: 2:0.009) were added into the reaction vessel and mixed uniformly, and after reflux at 120°C for 6 hours, 9.5g of water was collected in the water separator and the secondary amine characteristic peak disappeared in the infrared spectrum (such as figure 1 As shown, the C=C stretching vibration peak at the 1630-1695cm-1 place is obvious, and the N-H stretching vibration peak at the 3370-3390cm-1 place in the original a disappears), and the unreacted butanone and toluene are distilled out under reduced pressure to obtain the capped After the polyaspartate NH1420;

[0066] (2) Add 250g of polyether polyol N220, 30g of polyether polyol N330, and 20g of polyester polyol F1190 into the reaction vessel, dehydrate at -0.08MPa, 120°C for 2 hours, cool...

Embodiment 2

[0071] (1) 200g polyaspartic acid ester DesmophenNH1520, 55g cyclohexanone, 30g butanone, 1g titanium tetrachloride, 70g toluene (secondary amino group in polyaspartic acid ester, ketone blocking agent and first The molar ratio of catalyst is 2:2.8:0.014) successively add in the reaction vessel and stir and mix evenly, after refluxing at 140 DEG C for 4 hours, 12g of water is collected in the water trap and the secondary amine peak disappears in the infrared spectrum (the infrared spectrum is slightly ), unreacted cyclohexanone, methyl ethyl ketone and toluene are distilled off under reduced pressure, obtain the polyaspartic acid ester NH1520 after end-capping;

[0072] (2) Add 100g of polyester polyol Desmophen670, 180g of polyether polyol N220, and 20g of polyether polyol N330 into the reaction vessel, dehydrate at -0.1MPa, 110°C for 3 hours, cool down to 70°C, and blow nitrogen Release the vacuum; add 101g IPDI, 157g IPDI trimer (70% solid content), 0.056g dibutyltin dilaur...

Embodiment 3

[0077] (1) 180g polyaspartic acid ester F524, 60g methyl isobutyl ketone, 2g titanium tetrachloride, 60g toluene (secondary amino group in polyaspartic acid ester, ketone end-capping agent and the first catalyzer) The molar ratio is 2:2.2:0.039) into the reaction vessel in turn, stir and mix evenly, and after reflux at 130°C for 5 hours, 10.2g of water is collected in the water separator and the secondary amine peak disappears in the infrared spectrum (infrared spectrum is omitted) , unreacted methyl isobutyl ketone and toluene are distilled off under reduced pressure to obtain end-capped polyaspartate F524;

[0078] (2) Add 210g of polyether polyol N220, 30g of polyether polyol N330, and 60g of polyether polyol N210 into the reaction vessel, dehydrate at -0.09MPa and 115°C for 3 hours, cool down to 75°C, and blow nitrogen Release the vacuum; sequentially add 119gH 12 MDI, 0.08g stannous octoate, react at a constant temperature of 85°C for 2 hours, after the reaction is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com